Sorry missed a post from yesterday, I wont do all the stages as the repair was basically the same as the RH side lower Flitch.

Here's todays work:

As stated above the target today was to repair the LH front panel and outer wing. Well apart from cleaning up the welding on the wing I there about managed it. Would have completed it but had to go shopping

Here's what the lower front panel at the start after having removed the wing some time ago:

First of all I trimmed back the flange to just before the fold, that way I would be able to retain the profile.

Then I cleaned up the edges that would be welded to bare metal.

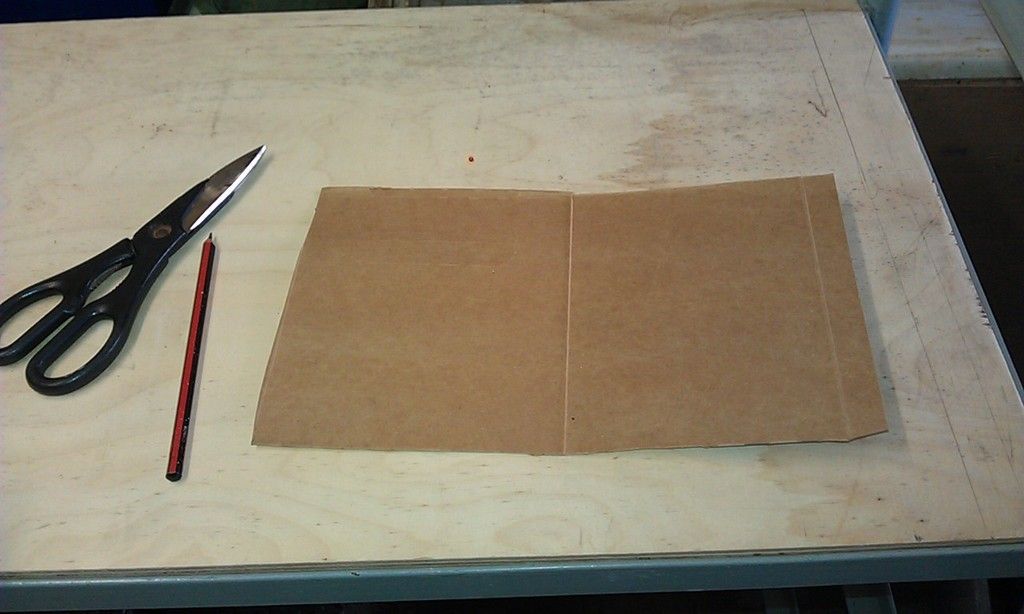

I decided to make several small patches which worked out quite well in the end, here's the first:

And welded in place:

Then after doing a little de-rusting with Deox Gell here's the next patch gently tacked in place:

Due to welding at the edges a piece of Non Ferrous metal was used as a heat sink:

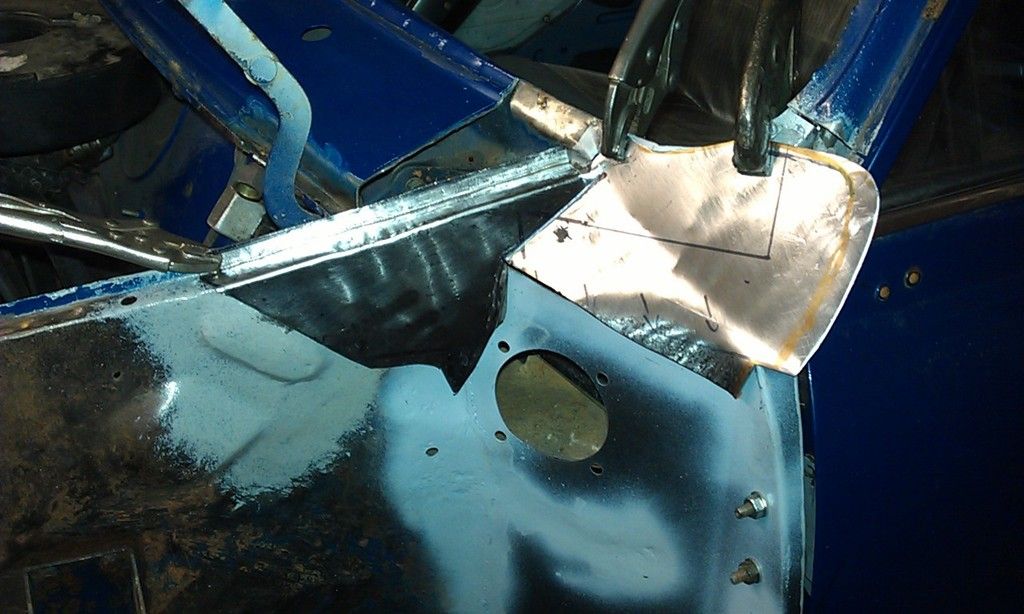

For the corner I made up a profiled patch:

Welding completed

And cleaned up with a flap disc:

Time was ticking on and at around 16:00 I started the wing:

Most of the metal was removed from the front panel so the wing only needed cleaning up and a few patches. The front inner corner was the worst:

First patch with a piece of flattened copper pipe as a heat sink:

Thought I had some more photos but cannot seem to find them, but end state was that I did managed to patch up the flange on the wing. All the welding was completed but at 20:00 it was too late to start grinding down the welds, didn't want to upset the neighbours

Just a quick extra note, on the RH side the flange on the Flitch that the A Panel bends around is touching the door and quite a gap at the top. The LH side is similiar.

I guess I can play about with the door by fitting washers but before folding over the A Panel what gap should I be aiming for?

Edited by JonnyAlpha, 29 March 2016 - 08:56 PM.