Well finally a day off with no other commitments and good weather coincided!! Its been a while so I thought if I am going to have any chance of meeting my June deadline I'd better get out into the garage.

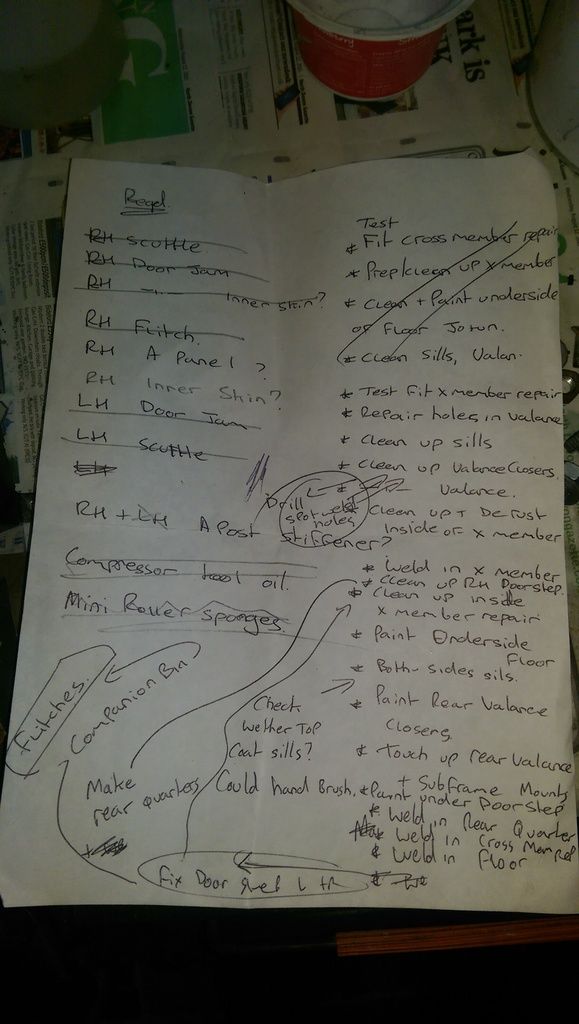

Target for today was to get the LF Flitch panel welded in.

First of all I needed to dress down the welds from the last piece of work I did welding in the A Post Stiffener.

Did that but it will need some filler before I paint it properly, so for now some Acid Etch.

Next job was to mark, drill and clean up all of the various plug weld locations and apply some weld through primer between all of the overlapping joints.

Then I was finally ready to tack it in place, all the testing and fettling took the best part of two hours, must be out of practice!!

After a tea break here it is tacked and part welded in place:

Then a late lunch and back to weld it all up, the welding went pretty quick to be honest, no real snags.

Apart from a couple of tacks I didn't do the bottom flange as time ran out and it needed some cutting and shaping.

All dressed down (well roughly).

And some etch primer to protect it for now and job done.

Then I flitted the door and it went on nice and snug.

Light was failing but time for a couple of motivation shots (came out a little out of focus sadly :-( )

And tucked up back in the garage!!

Hopefully the weather will improve and i'll get some more done this weekend?

Edited by JonnyAlpha, 29 December 2015 - 06:06 PM.