Had a long hard day in the garage, slow progress again but progress none the less.

I needed to make and weld in a repair piece for the bottom front corner of the RH door surround, the LH one will also need doing.

I knocked up a template using a Thatchers Cider Box that we had recently emptied ![]() and cut out and marked a piece of sheet steel.

and cut out and marked a piece of sheet steel.

The first bend was easy and luckily I was able to make the next tight bend using the edge of my home made bending vice:

The next bend was made by turning it upside down and using the bender:

Started bending it the wrong way at first, but then corrected myself ![]()

On test fitting (after a little correction, it was a pretty good fit:

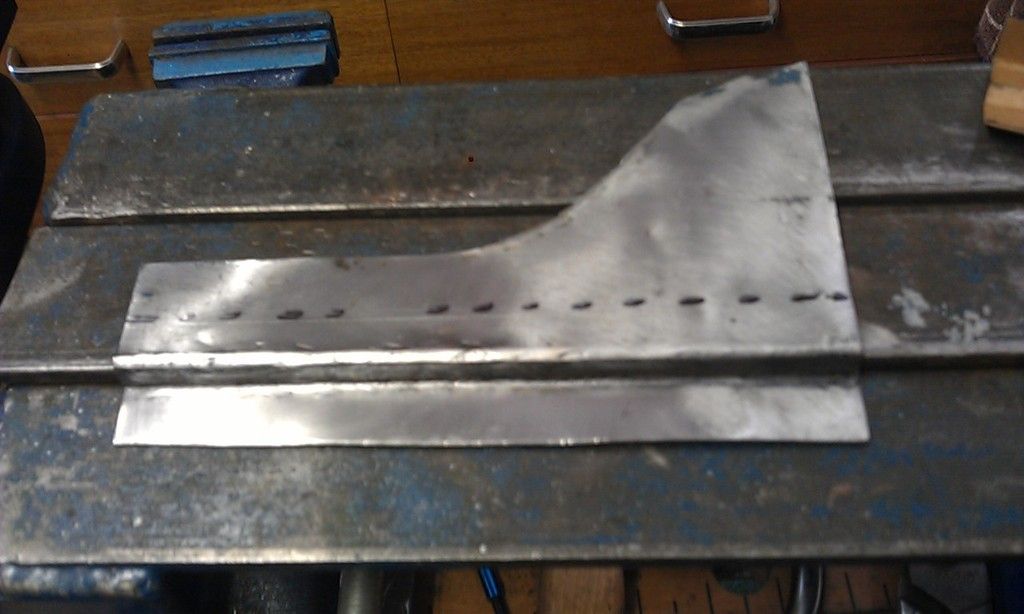

At this point I was still contemplating how to proceed as initially I was just going to plug weld the holes you can see in the inner edge:

First I cut them out with a 1mm cutting disc but then after spotting some pitted rust on the underside I decided to cut the whole lot out!!

Due to the complexity of this piece (it has a few reverse folds and curves) I decided to make it in two pieces. I trimmed up the outer edge piece and formed the curved edge.

To help with making the inner piece I welded the first piece in place. I had the welder set higher than I anticipated but it worked well so I left it.

I made the inner piece and made several cuts along the flange to make life easier, I then welded these up. Before welding them up I first made sure that the piece fitted exactly and only put a spot of weld on each cut before test fitting it again. This was to ensure that whilst welding the piece would still fit. Once I was happy I welded up the cuts in the flange.

Here it is held in place and fitting snug:

I also drilled three plug weld holes.

And here it is finished, took forever but very please with the result. I need to adjust the front profile a little as the Door Check was a little tight.

No time to Epoxy today so I flashed a bit of Etch Prime over it to preserve it for now.

I could clean up and repair the front wing but I really need to get the back wheels on so I am contemplating fitting both Sills, Rear Valance Closer and Rear Valance so the I can paint the rear underside and fit the Subframe?

Or I crack on with the Inner and Outer Wing and Flitch on the Left and then move to the right hand side?

Mmmm decisions, decisions ![]()