Made a little more progress over the last few evenings:

Took the windscreen out:

Need to remove the dash and the trim but haven't got a clue how to yet :-(

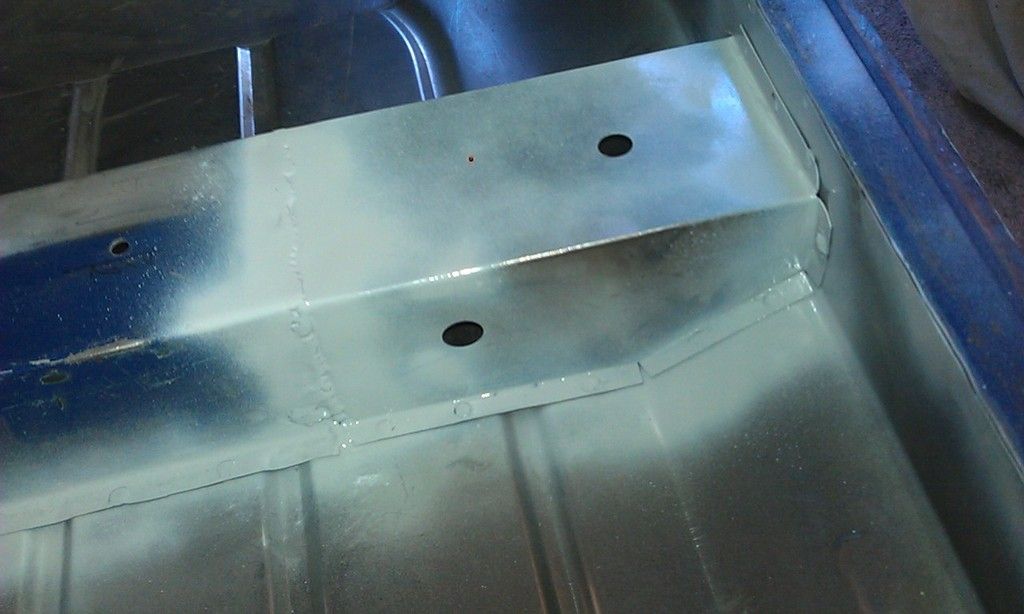

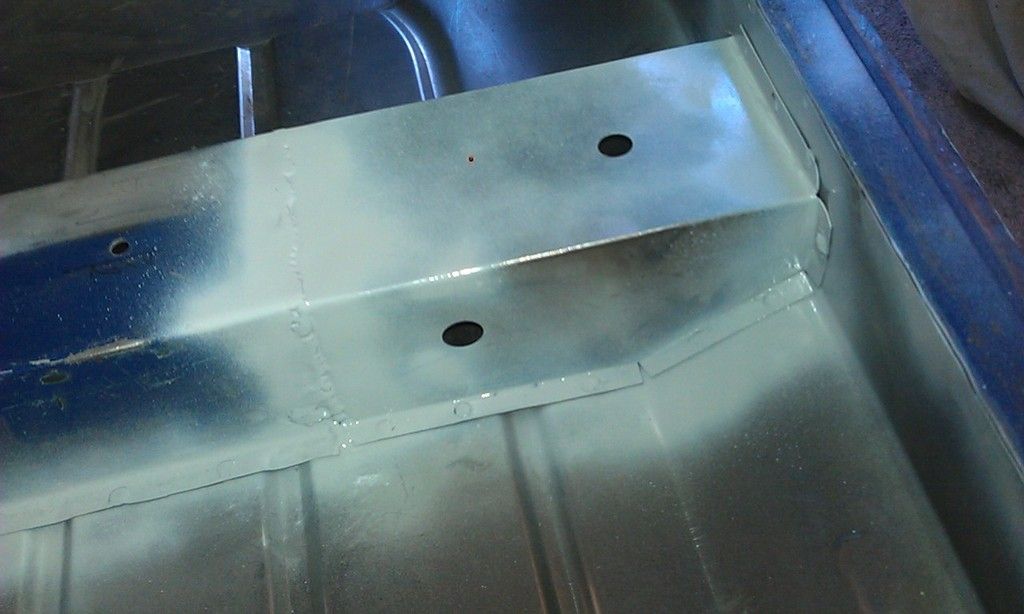

Sprayed some weld through primer on the flanges of the Cross Member repair, you'll remember from my previous post that the inside has been primed and top coated:

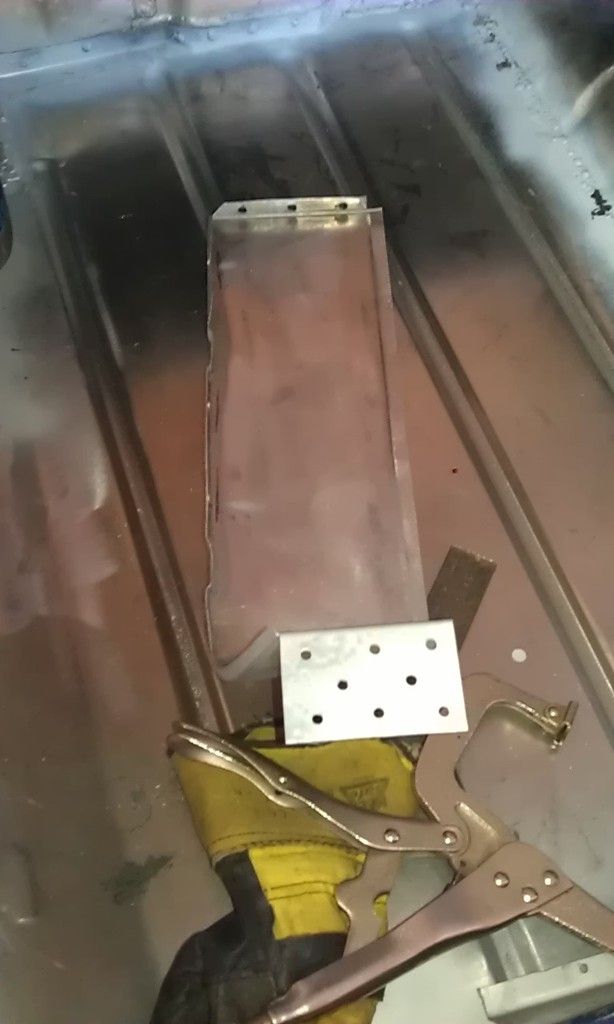

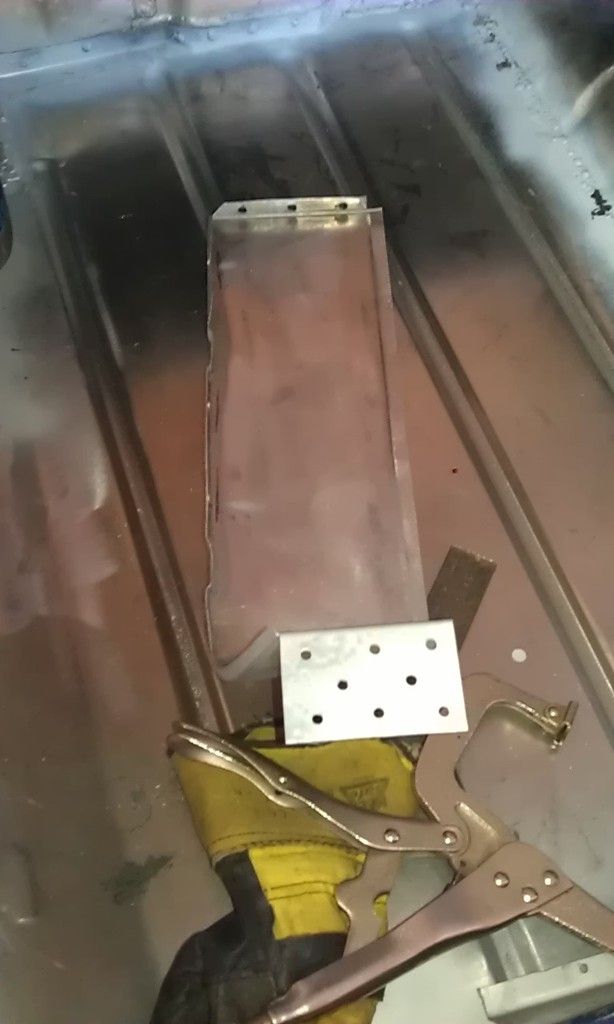

I also trimmed down, test fitted and drilled spot weld holes in the Companion Bin Repair Panel:

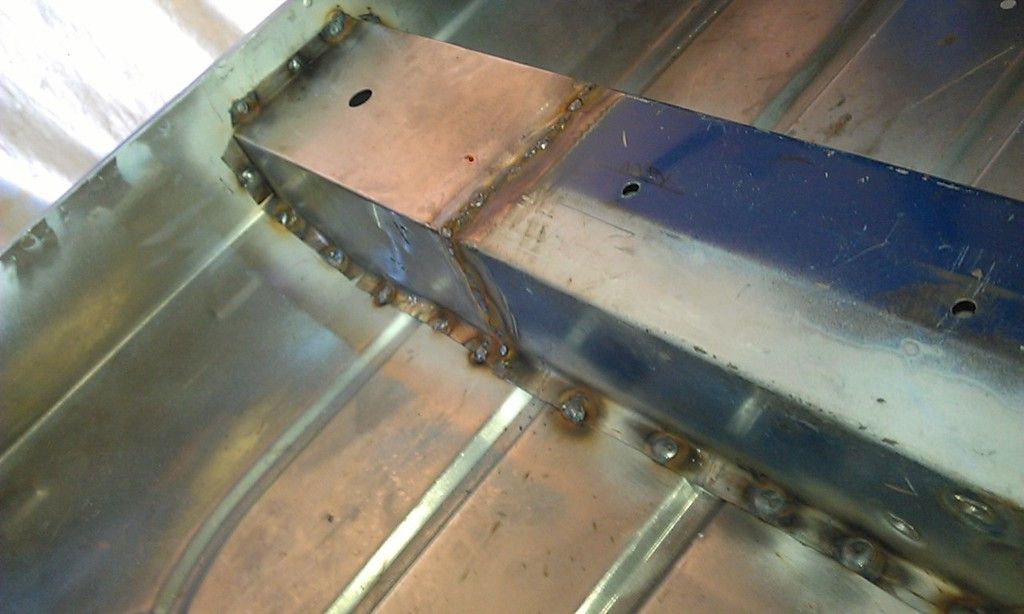

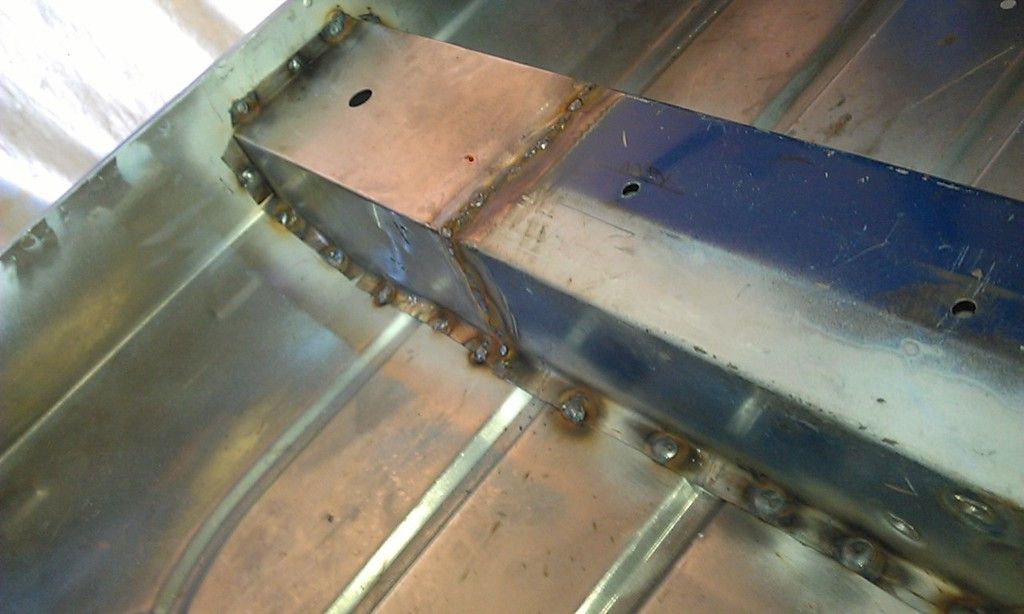

To help get the Cross Member lined up and welded to the floor I had to lift the floor with a jack and some blocks of wood, moving it as required:

I then welded it all in starting with a couple of strategically placed spot welds, a test of position and the started from the tunnel working towards the Inner Sill.

Managed to get it pretty much in line:

After partially dressing down the welds I dusted it with some Etch Prime to avoid rusting:

Trimmed and test fitted the Companion Bin Repair piece:

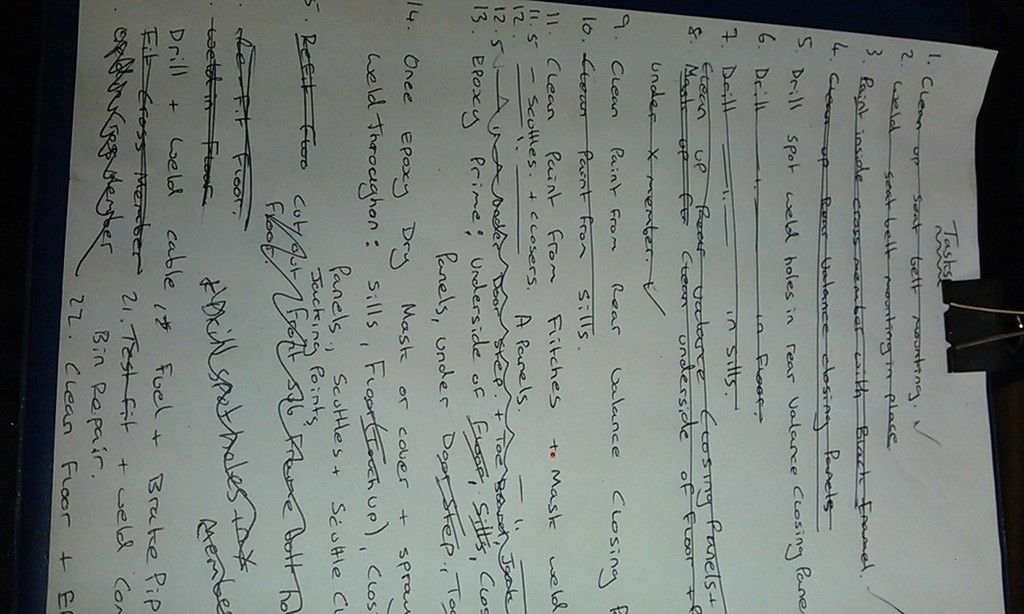

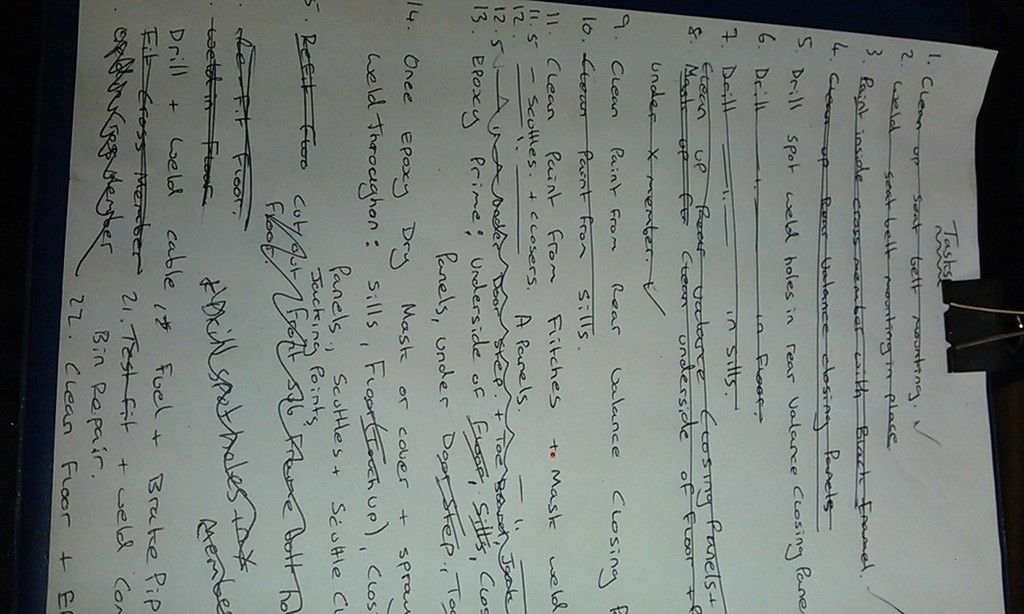

Gradually working through this phase 'TO DO' list:

Hopefully a little more tomorrow evening and Saturday, plan is to get the Companion Bin repair welded in and do the Jacking Points? Then either clean and paint the inside floor with some Epoxy or get the Scuttles and Flitches started.

The floor does need painting but I am a bit loathed to do it before the Flitches are done because of the mess. I also need to drill and weld in some bolts that will holed the Brake Pipe, Fuel Pipe and Battery Cable in place before the floor is painted inside and out.