I cut some more rot out of the Toe Board, the RH side appears to be worse than the LH side of the car :-(

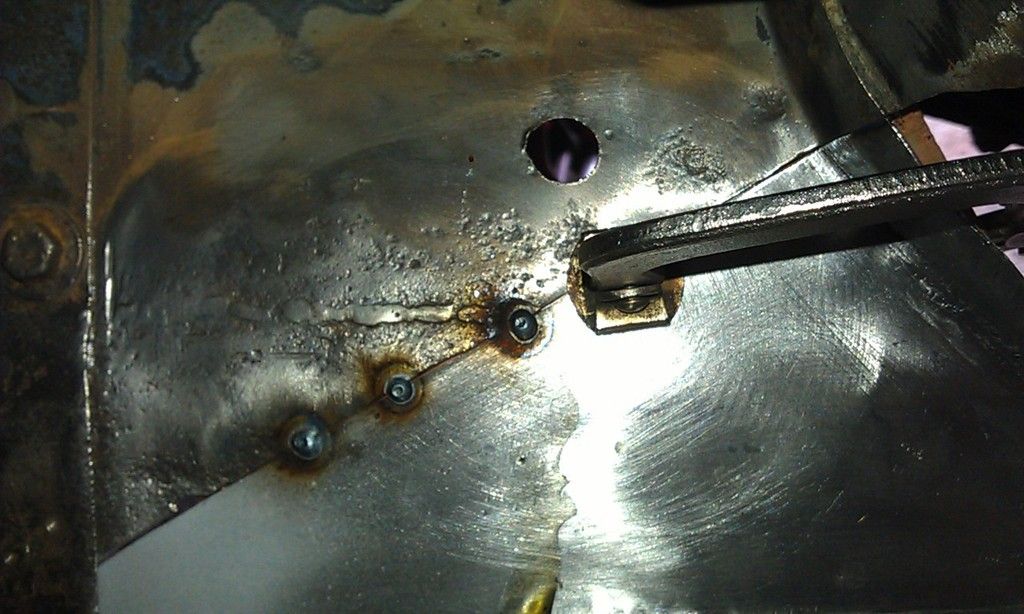

In the pic below I cut it in a downward sloping angle from just in front the small hole you can see in the Flitch to the top of the vertical cut next to the Subframe Re-inforcement plate. You can just about make out two layers of metal on the bottom end of the Toe Board below the Subframe Mounts, this is where a plate of metal has been welded under the original Toe Board. This will have to be remove.

I then started to make a repair piece, I started off making it larger than I needed but then got carried away and cut it to size but then realised that I had not cleaned up all of the Toe Board to confirm its condition and when I did another hole appeared!!!

The good news is that the metal that I had used was too thin anyway so it needed to be re-made (wasted time and effort)!!!

Here's the piece I made (which will now be ditched) :-(

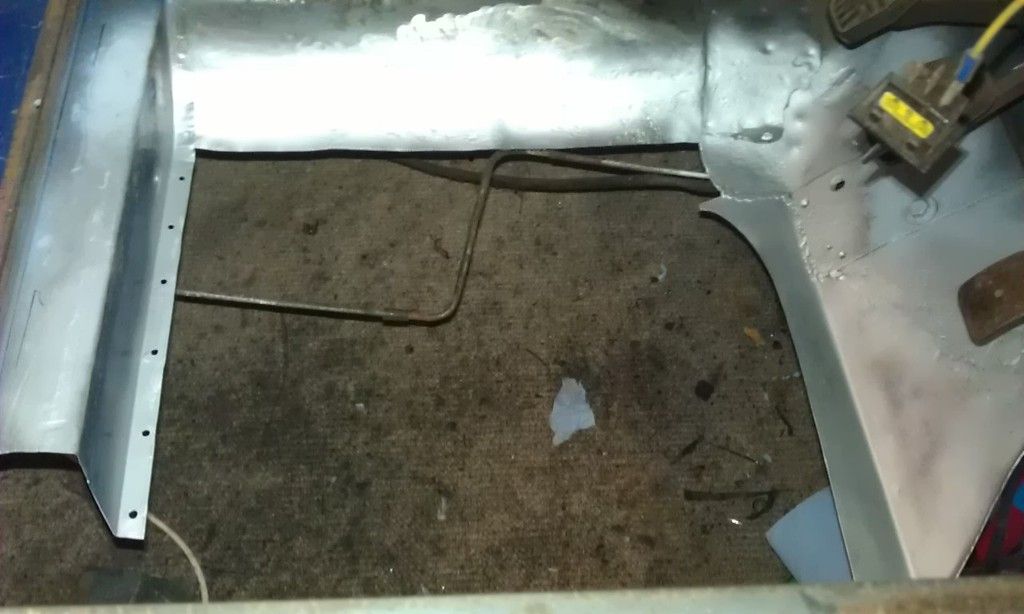

And here is a photo showing most of the rotten Toe Board removed:

I really need to repair the Toe Board before I fit the floor as doing it the other way around, whilst possible, is going to prove difficult, but a lot the repair piece that I will make will have to be welded rather close to the Subframe Mount. The bottom section of the Subframe Mount re-inforcement plate is also very pitted so as this is a mounting point I am tempted for this reason to remove and replace the plate as well but without removing the Subframe this may prove hard to do?

I know I keep saying it but I am desperate to get the Rear Wheels on but need to finish the floor and sills and paint the rear underside before I even think about putting the shiny rear subframe on and all this front end business is slowing down the progress.

I am happy to do the Flitches after the floor once the chassis is rolling again.

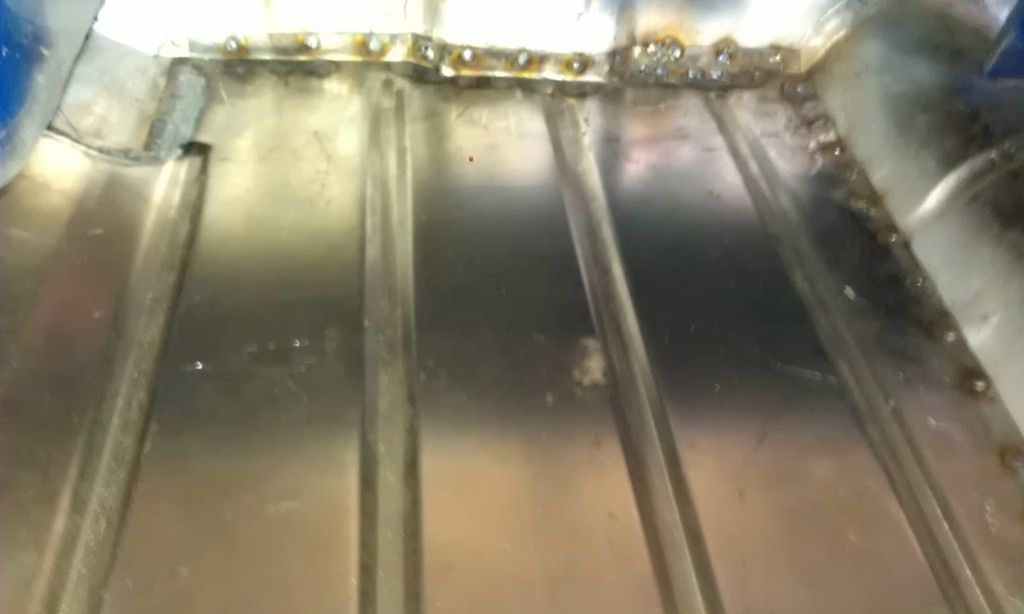

The front end of the door step needs repairing as well and again this could be done after the floor is fitted there is a lot of cleaning up and painting to do to the A Post. All that muck underneath is weld and welding wire where someone has attempted to repair it from the outside.

The other problem is the original Flitch repair, as mentioned earlier a Flitch repair panel was cut in half vertically and simply welded on top of the old Flitch. We also fitted an A Post Stiffener but the old A Post was not treated, some very silly mistakes :-(

I have considered cutting out the old Flitch from the inside but the further up you go the harder it is?

The last thing I want to do is make a bodge job paint the interior etc and then find that it fails an MOT and needs to be done anyway?? It will be a big shame to have to cut of and order a new A Panel and Flitch but I am not sure what else to do?

Anyway enough of the doom and gloom, this weekend my son and grandson came to stay, just before they left we got the original seats out and stripped off the covers as he is going to attempt to re-upholster them.

I was going to do I this is how we did it but after a few photos I stopped snapping :-(

Managed to get a couple though.

Here's the back seats:

And the front

As soon as we started to lift the materiel where the back joins the base, hey hey money, a grand total of £5.09, a receipt from B&Q Farnborough, many miles from here and another small receipt dated May 1983 when the car was 1 year old  and a load of straw?

and a load of straw?

Not quite a Saxon Hoard but it may pay for a new set of clips?

Removing the covers was simpler than I thought, getting the material off of where the seat catch fits looked like we might have to dismantle the entire mechanism but then my son suggested that the knob might be screwed on, it was

Mess up the plastic washer underneath, didn't study it enough, its turned out not to be a washer but a shroud with a retainer on the other end, it snapped coming off :-(

The part that looked tricky was where the materiel fits over the seat hinge but this turned out to be a simple rivet which was removed with a drill.

We managed to get the covers off of the front seats and the rear upright without damaging the sponge to much, the rear seat looked like a bit more of an issue so my son took that with him.

He is now going to carefully split the covers and make some new ones using the old ones as patterns, sadly he could not take the seats with him so it will be all done on a wing and a prayer. WIth any luck he'll have them back for Easter.

![]()