Project Paddy A Long And Slow Rebuild.

#661

Posted 10 January 2017 - 07:38 PM

Keep them coming.

#662

Posted 11 January 2017 - 01:24 PM

#663

Posted 12 January 2017 - 08:16 AM

Great work on the boot

Really like what & how you do things.

#664

Posted 13 January 2017 - 08:48 PM

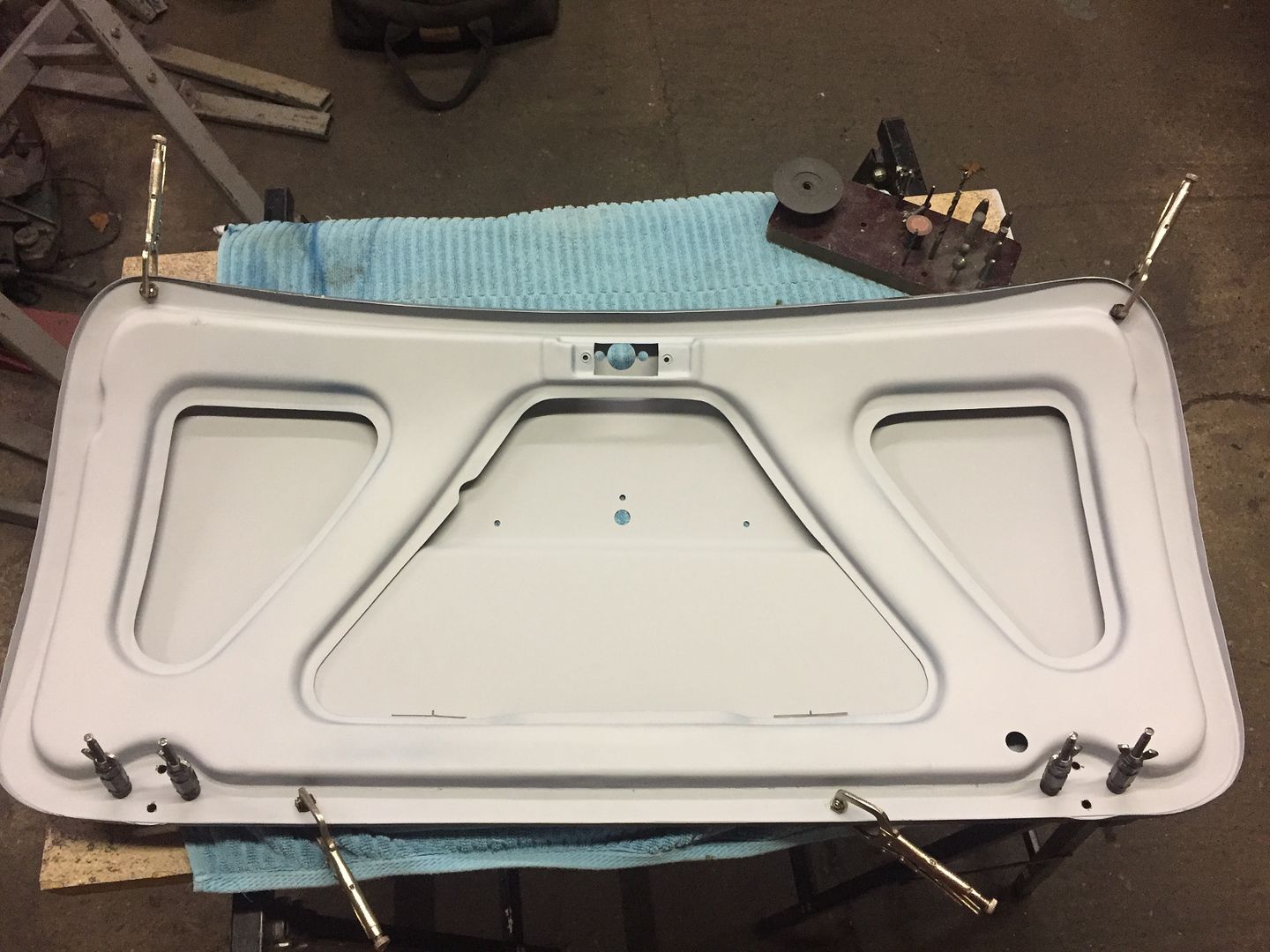

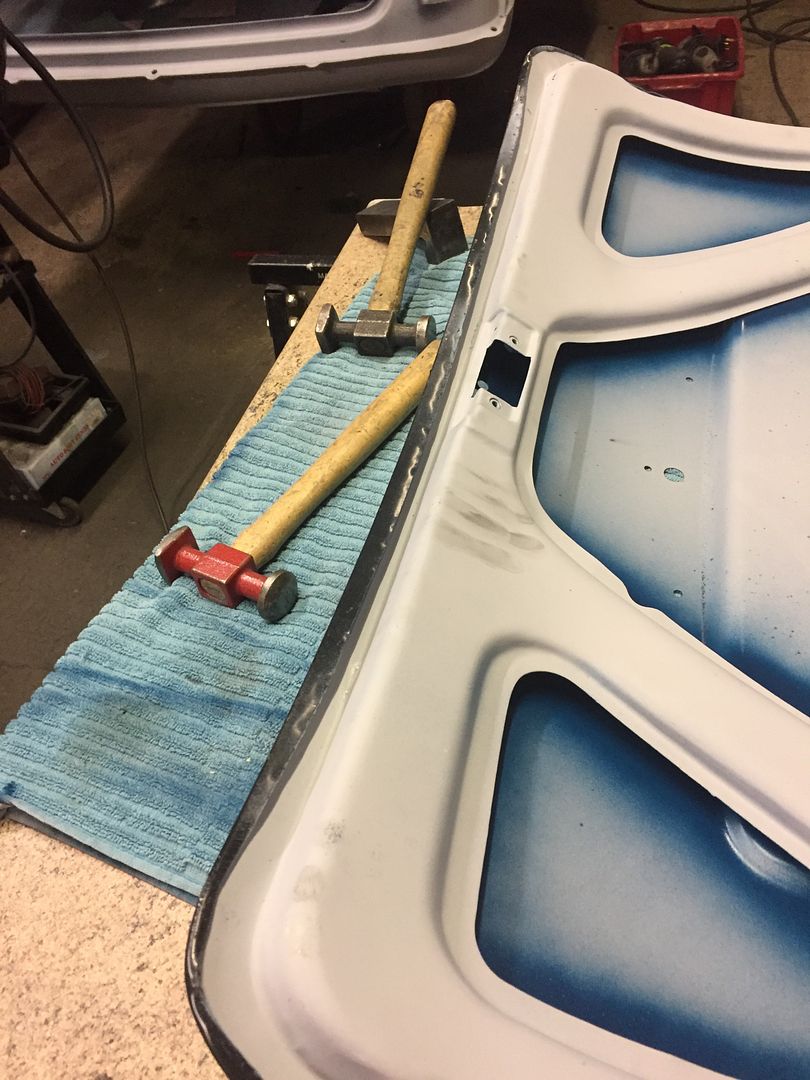

Skin is now on but there was quite a bit of prep work to do first so a few pulg weld holes and pins and top coat.

Then it was plug weld time

And all knocked back

Ready to fold over

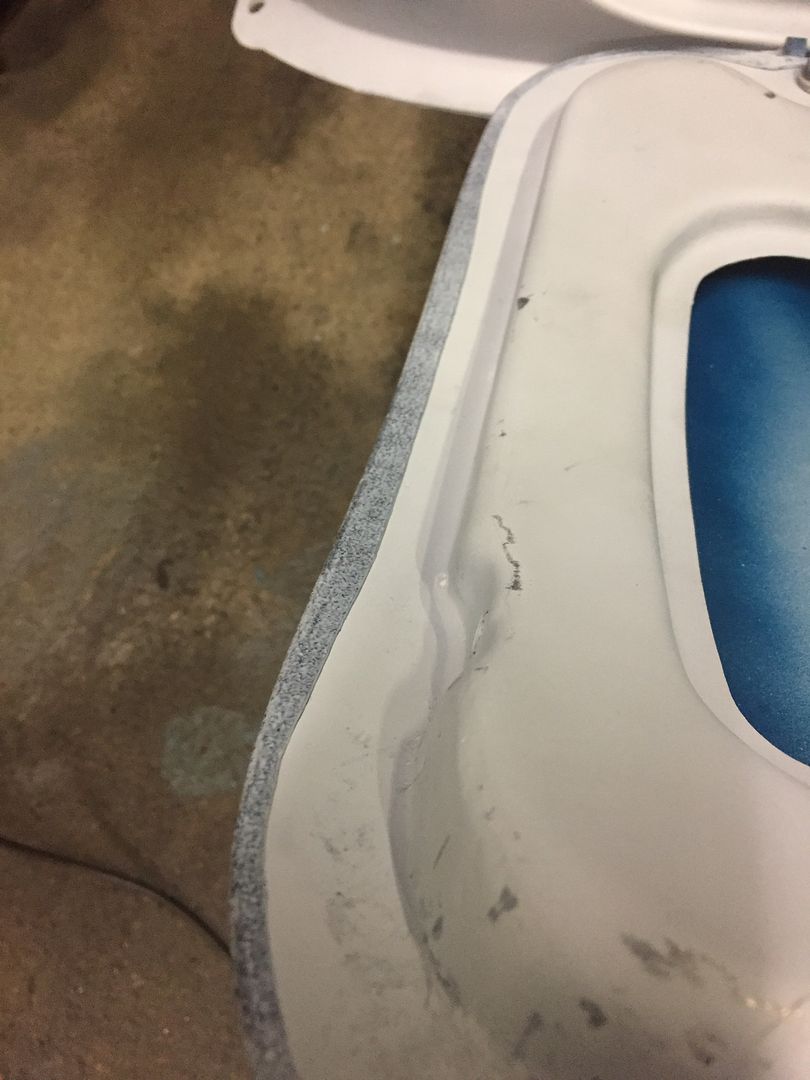

First pass

And the finished folds

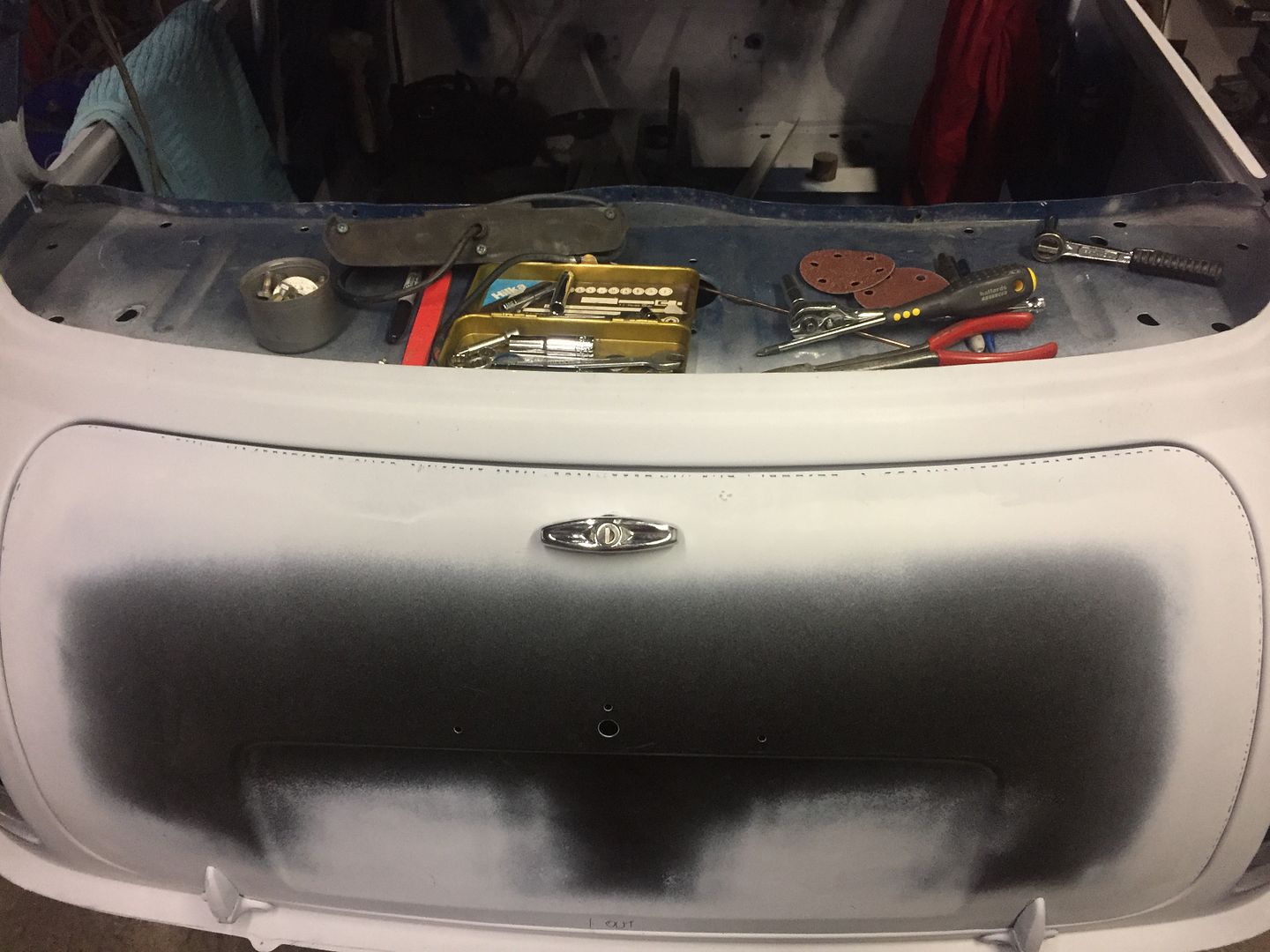

And the finished article although there is more tweaking and the all important gapping to do

#665

Posted 14 January 2017 - 08:46 AM

Pete

#666

Posted 14 January 2017 - 09:18 AM

How are you going to do the gapping Neil ? Mine is exactly the same as yours, weird gaps all around.

Pete

Pete I will be using welding rod, the same as I used on the doors.

#668

Posted 15 January 2017 - 09:16 PM

It's going to be a perfect mini when finished!!!!

#669

Posted 15 January 2017 - 10:36 PM

Damn that's good, are you the "saint of patience" don't think I have your skill, definitely not the patience!!

It's going to be a perfect mini when finished!!!!

Not sure about perfect as there are a few things I would do differently but that's life. The hard bit is coming up and that's paint prep and paint.

#670

Posted 16 January 2017 - 07:01 AM

Are you filling the little gaps between panel and welding rod? Or will it not pose a problem? Looking forward to doing this on mine too. Thx!

Ben

Edited by MacGyver, 16 January 2017 - 07:01 AM.

#671

Posted 16 January 2017 - 07:02 PM

#672

Posted 17 January 2017 - 08:04 AM

Is there any particular reason you used lots of plug welds to hold the skin on before folding the edges over..? At the factory they had a spot weld under where the hinges go, and two right in the middle near where the numberplate holes would go.

(I've got to do this to mine soon)

Q

#673

Posted 17 January 2017 - 09:01 AM

Is there any particular reason you used lots of plug welds to hold the skin on before folding the edges over..? At the factory they had a spot weld under where the hinges go, and two right in the middle near where the numberplate holes would go.

(I've got to do this to mine soon)

Q

It gives it all a bit more rigidity plus my skin had more spot welds than just the ones under the hinge and on the lower frame.

#674

Posted 17 January 2017 - 01:54 PM

#675

Posted 17 January 2017 - 04:32 PM

Are you painting the shell your self? Gaps are awesome!

Yes I will be doing all of it. Going to wait though for warmer weather although I will be spraying Gravitex next week after sealing.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users