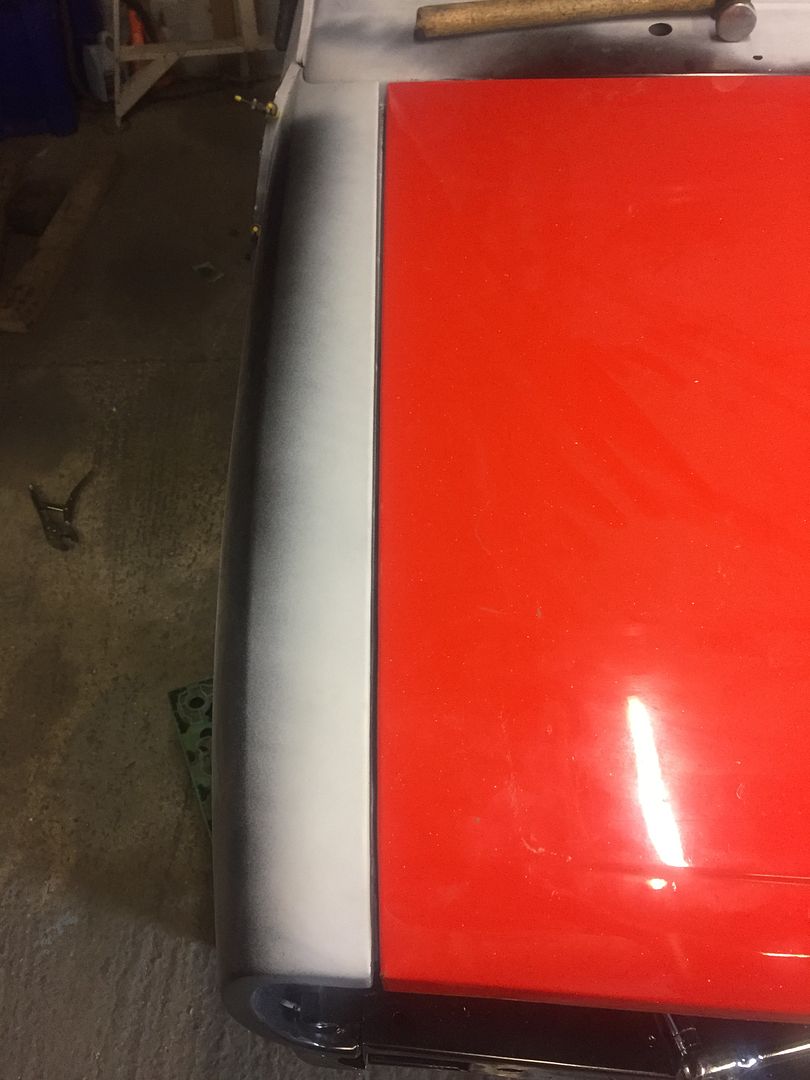

So more tweaking and finally i'm happy.

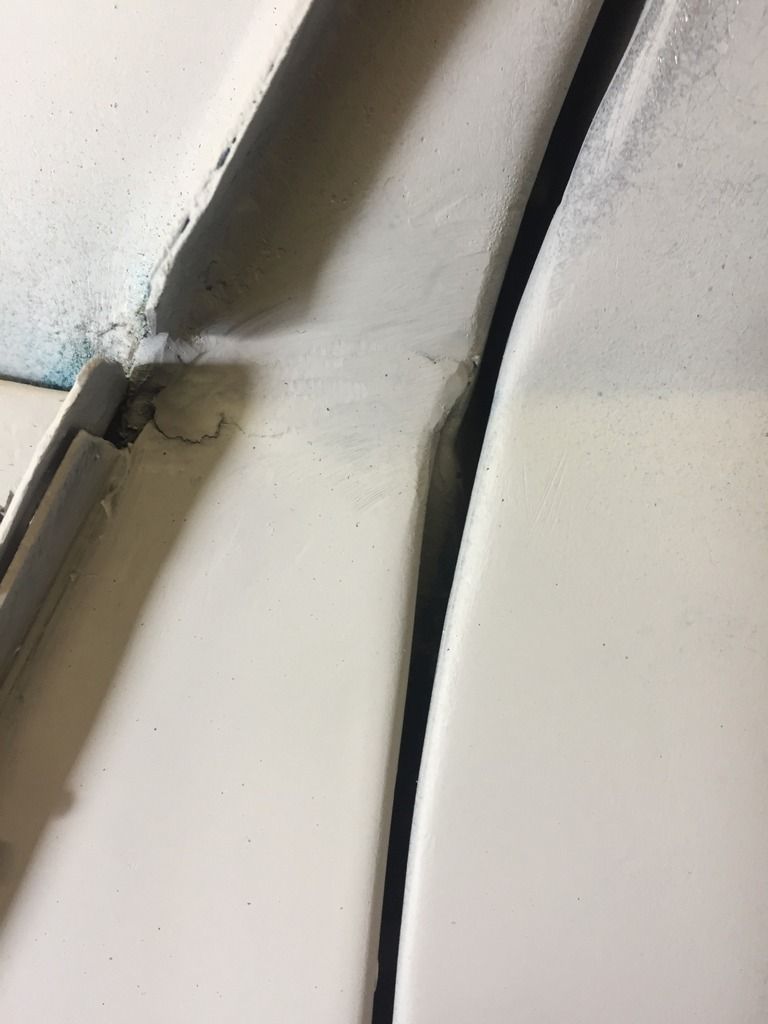

So replacement bonnet tried first just in case Paddy's original was knackered (which it is as its covered in filler) however the run out issue remained the same even with the new lid.

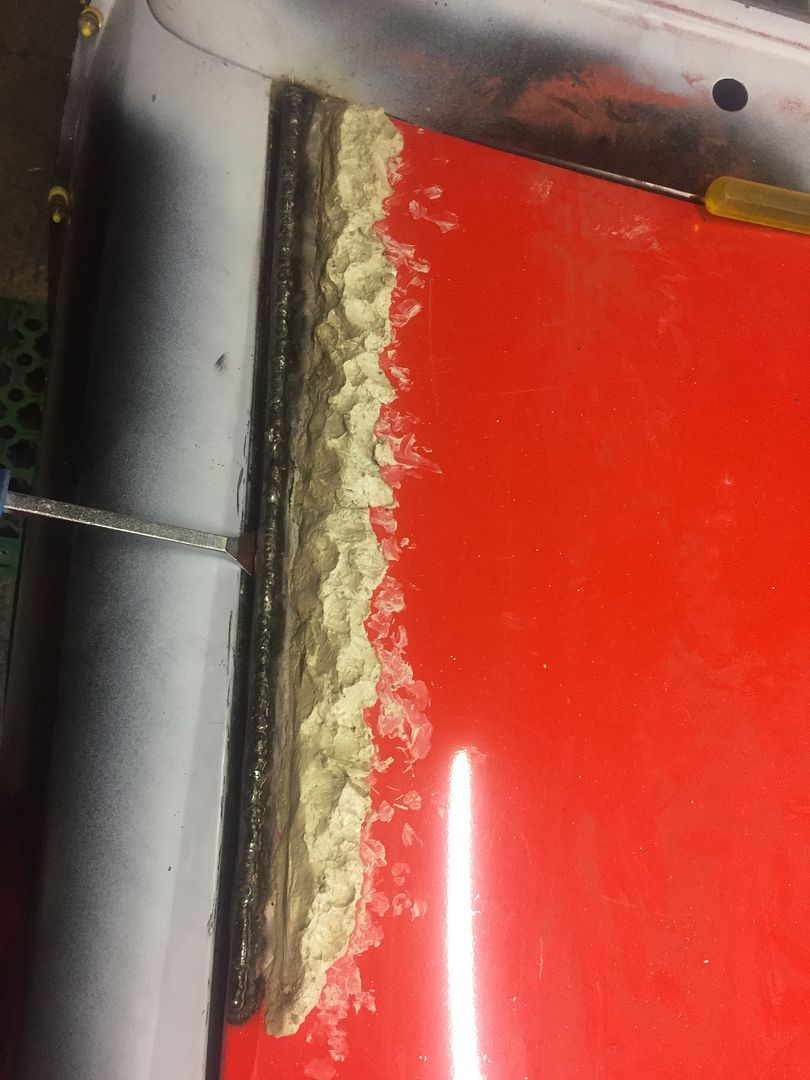

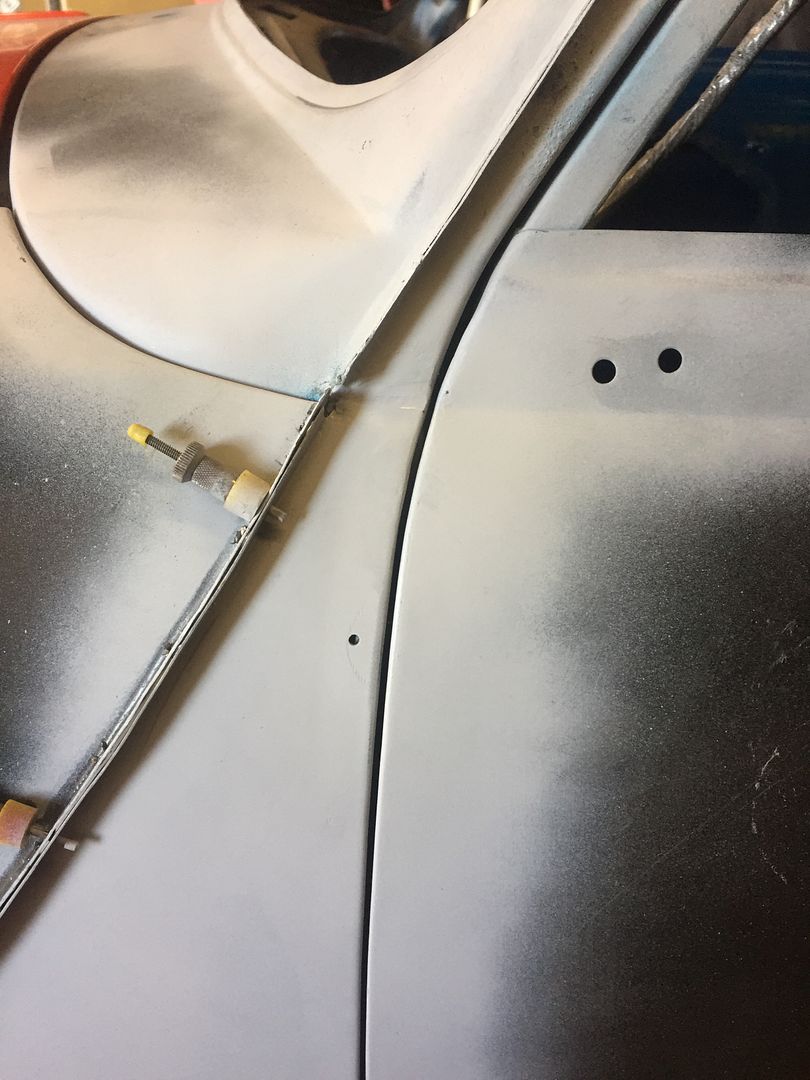

So after more cutting and tweaking, beating and cursing i had to resort to sectioning the bonnet

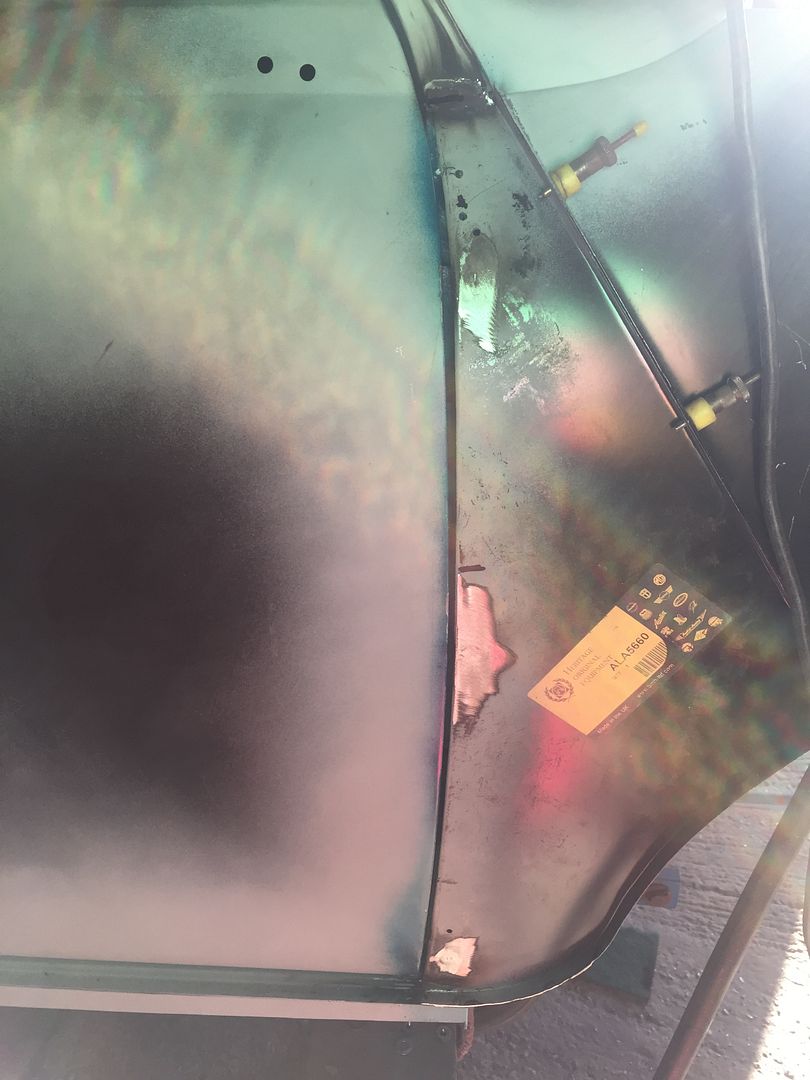

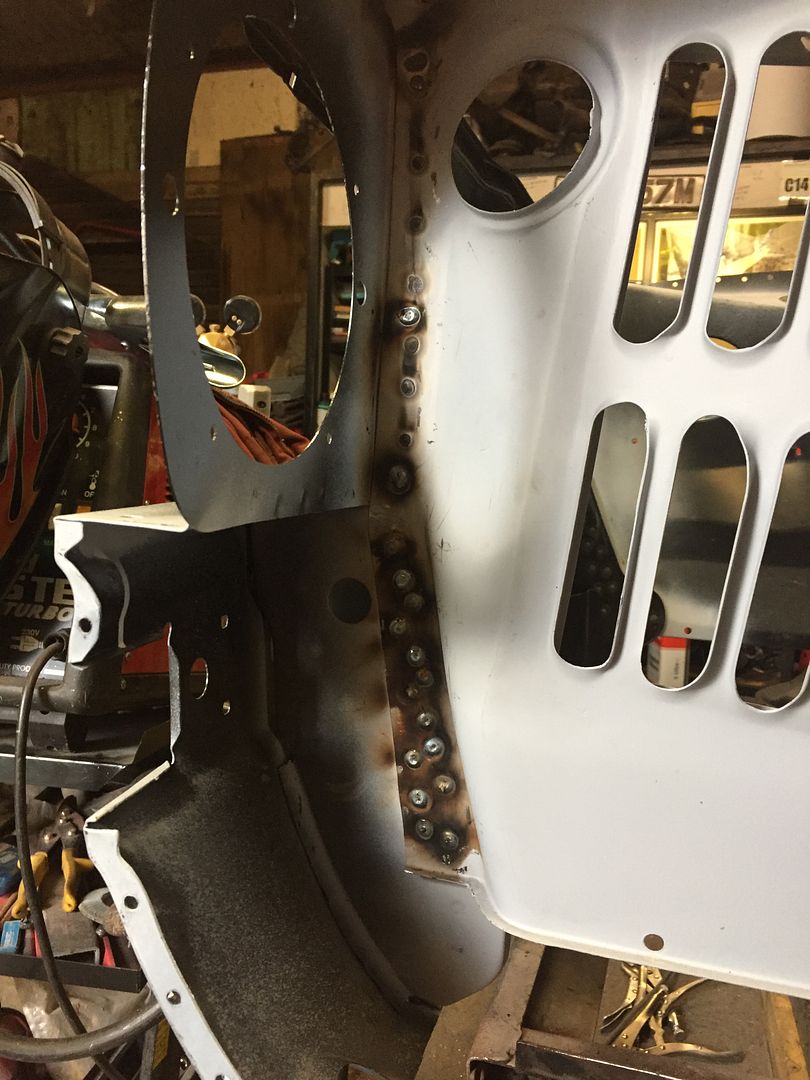

Then it was welding time

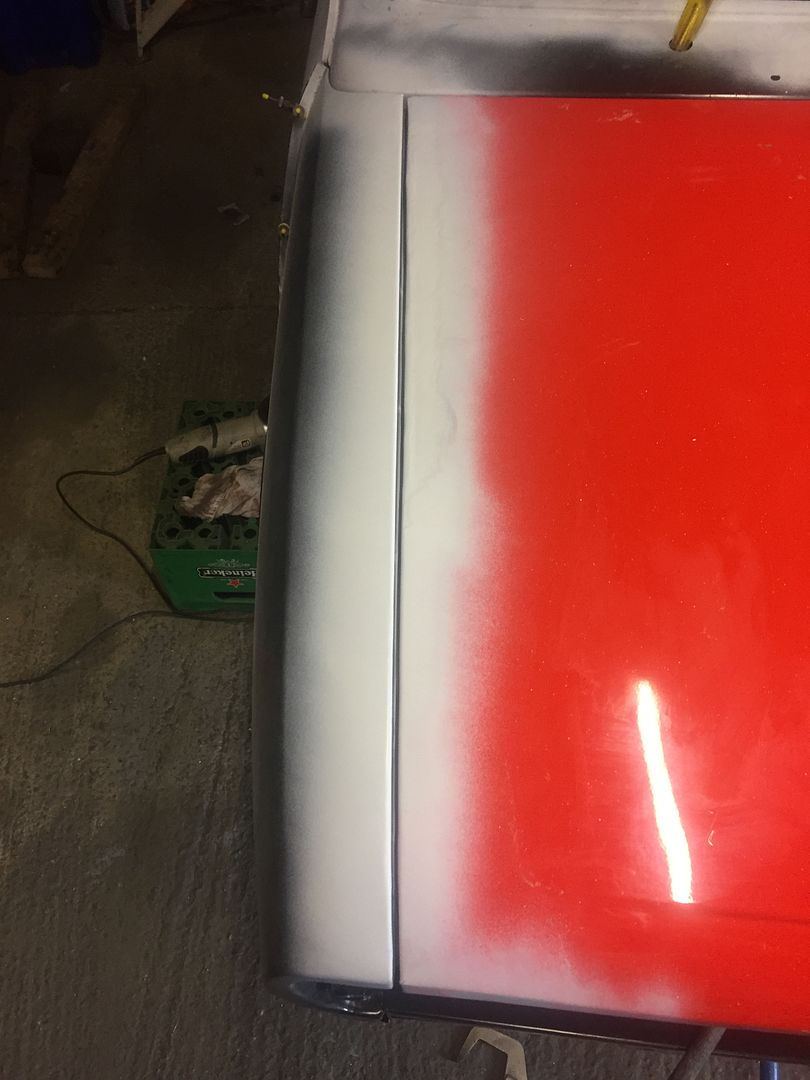

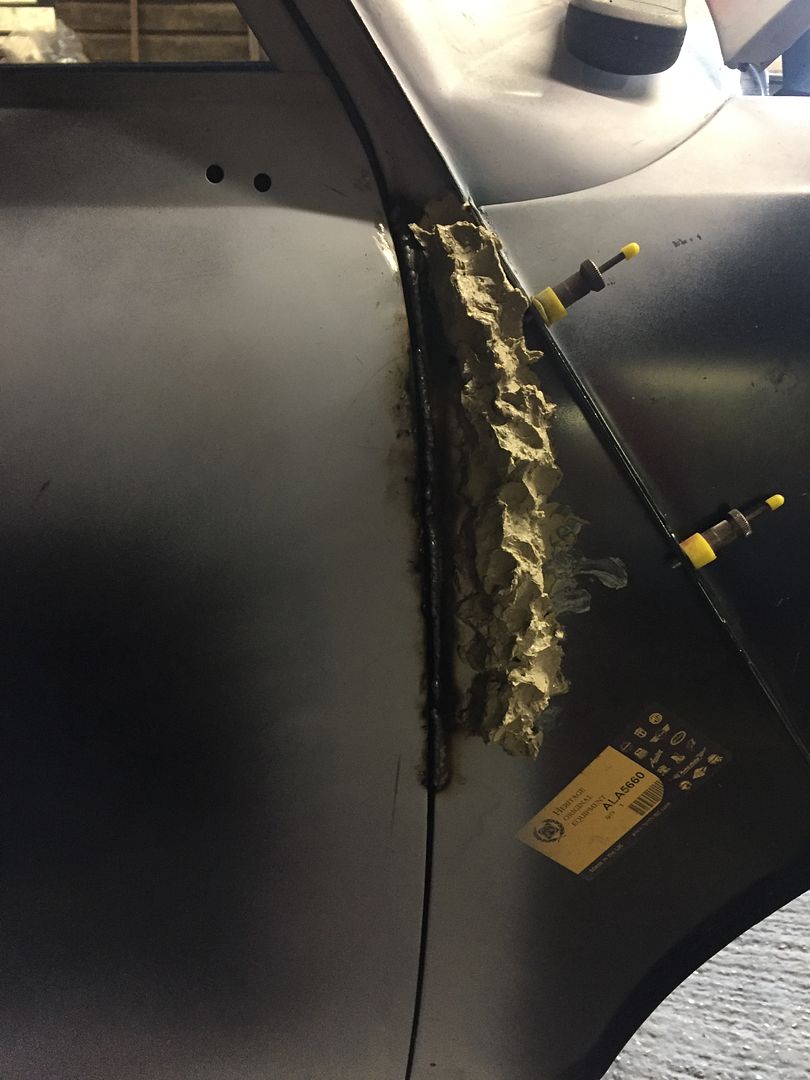

Dressed back

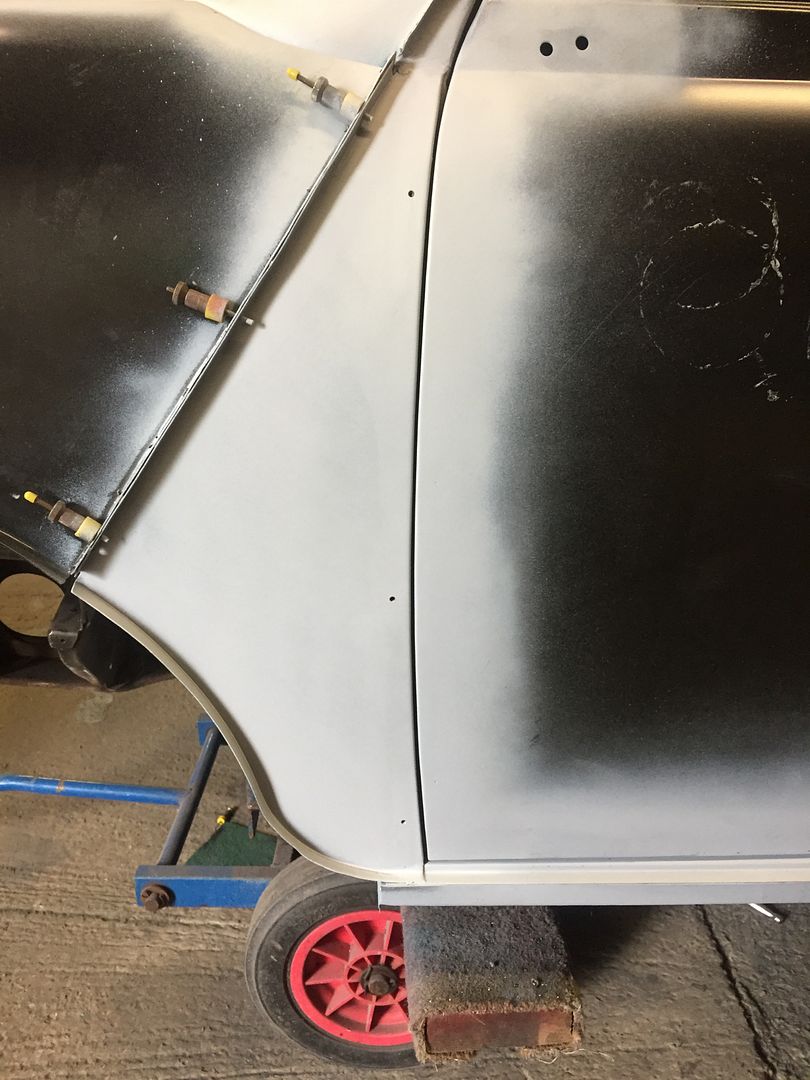

Just the inside to dress back and some final tweaking and it will be spot on