moving on now mate, cant wait to see it finished,

got the hinges by the way,

cheers

louis

Good good

So had a huge long day yesterday (Sunday) before going back to Uni later that evening. I did take a whole load of photos but they are all fairly repetitive. I am basically continuing the task of sorting the bodywork for paint and tidying up any rough edges. I found a few more rusty holes to either patch or fill, but nothing major!

I turned my attention to the rear as this is an area I hadn't touched bodywork wise.

Any rough edges like that have to go, can't justify skipping over them and even though they will be hidden under the bumper, it'd just bug me them being left there!

& this.

So that whole area was grinded, bare metaled, ku-rusted & etched.

Dropped the rear subframe which was a major PITA! Luckily I could rope in Dad to use a ratchet above board whilst I was underneath holding on for dear life with a pair of mole grips. It seems to be in good shape so I'll probably clean it up and sell it on as it's unneeded.

Few more holes discovered.. I hate that horrible factory fitted stuff, horrible and sticky when you attack it. That's down in the OS rear wheel arch pocket. When I've finished doing the bodywork on the top half the shell will be rolled onto a mattress and I'll bare metal and sort the underside out.

And these are near both the air vents, which will be easy to fill. BUT, if you look through the hole you'll see more rust.. which I can't reach at the moment, as above, when it's rolled on the mattress I should be able to reach up there, maybe..

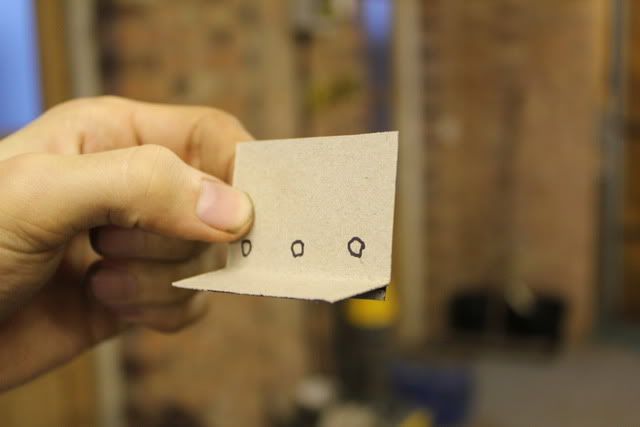

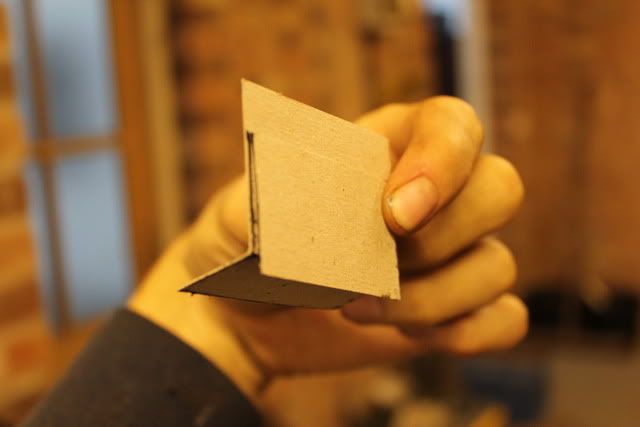

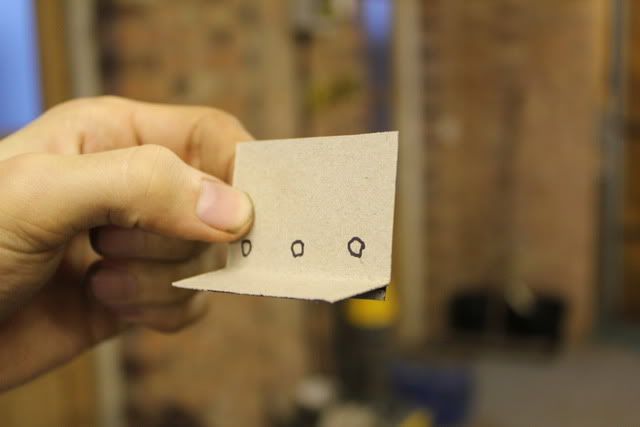

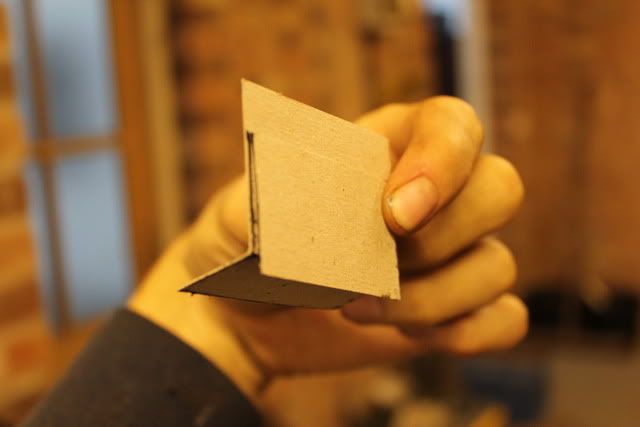

Patch that I started to make, I think I've gone the right way about this. I'll plug weld the right angled section to the flat section at the back and then position in place and then seam weld the edges. Obviously the top would be cut down afterwards, that was just to make handling the piece easier.

I also want to graft either one of these switch panels (prefer the one with the switches already in it I think) into where you can see the cut outs for the switches on the Autoplas dashboard.

& that's how I left her looking.

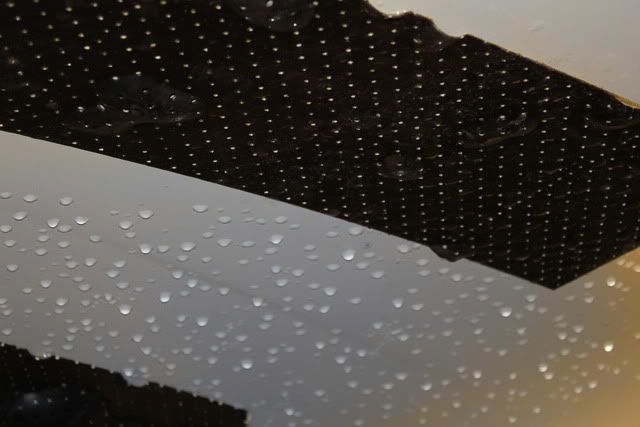

Did some more cleaning all over, tested my Under-seal as well on the lower half of the bulkhead. Just a test to see if it reacts with the etch and red oxide, hopefully it won't!

Edited by analogue_radio, 07 February 2011 - 02:19 PM.