I'll give it a bash next time I'm out and when I've got more gas!

Right.. who wants a HUGE picture filled update?

So I kicked off with testing out the underseal on an already red oxided and seam sealed area..

Looks good!

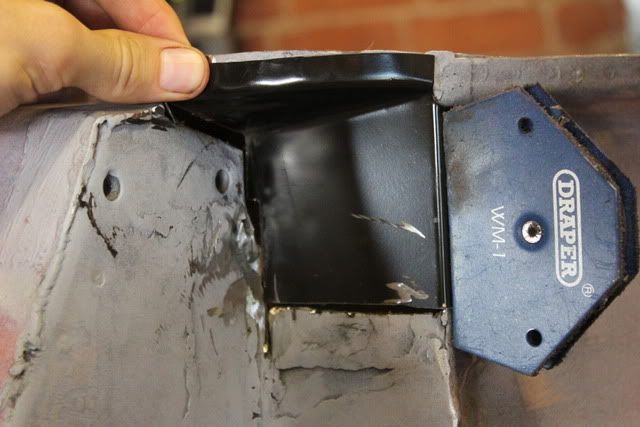

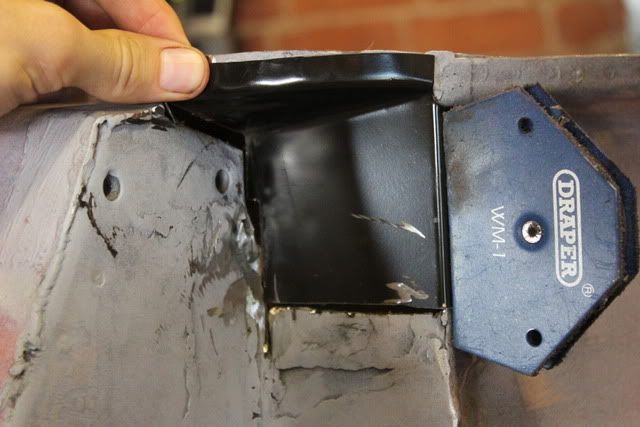

And then I had to sort the heelboard end out..

And then the welder did this

And then I fixed it and it did this..

So then I fixed that

and did this..

Pretty good for my first spot welds!

And dressed down

Then I rolled it down off the mattress onto a wooden horse covered by a dust sheet to protect the underside and the pallet under the front half.

Spent a while hoovering out the inside and engine bay, after it had been rolled so many times the dirt and metal shavings had gotten everywhere.. really did make the whole thing look tatty, much cleaner now!

Stripped the door cards down and removed all the fabric and sanded down any rough parts, they are now ready to be covered in the fabric I've got coming soon.

Another job was to sort the doors out.

A small rusty hole on the N/S and the previous owner of said door had kindly left me a screw with the head cut off!

I sorted that, popping to Grandads tomorrow to get the tap & die set so I can thread the hole again.

Wing mirror holes need welding up as well.. this is so I can mount my seats and get the correct positioning before drilling a hole for my own wing mirrors (they only need one hole)

And then ran out of gas

but I had other things to do so not a problem

Harness bar placed in, I need to check the positioning and make sure it's level before I drill holes and secure it.

*2nd part to follow*

This topic is locked

This topic is locked