Mini Scura Minus

#331

Posted 02 February 2013 - 10:50 PM

#332

Posted 02 February 2013 - 10:54 PM

Going to have a look up on getting some so just looking for a ball park figure.

how is it to work with & cut ?

#333

Posted 02 February 2013 - 11:08 PM

Regards Blue

#334

Posted 05 February 2013 - 10:42 PM

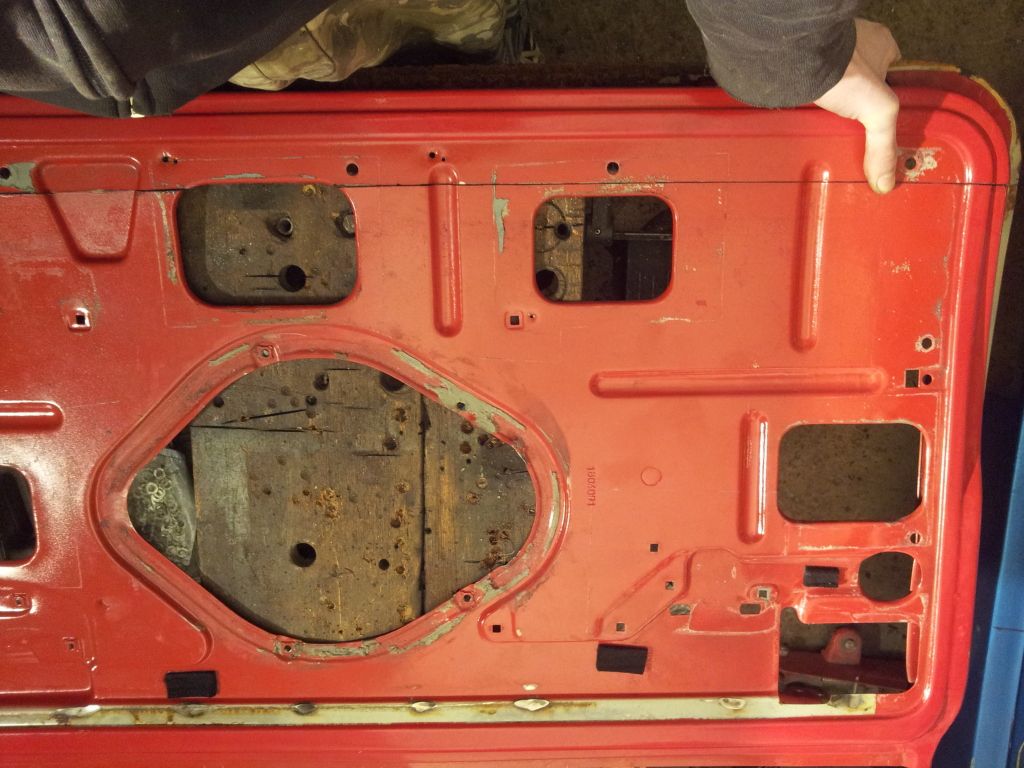

So after a few measurements and some marking out I cut the bottoms off

Now this is where my previous doors didn't work so well as I threw the old bottoms away and used repro door repair panels which are absolutely shocking. They do not match up at all, the recessed part for the door cards is large and they twisted / straight as bananas!!! So I will be refurbishing the bottoms to reuse, like I said before the door weren't in all that bad condition so the bottoms are useable with a bit of work done here and there.

Carrying on I went to hang a door but forgot that the one lower corner is round so I had to cut a square section out the corner. Re tried it to remeber that the raised part to keep the door card in place presses against the door frame when closed (these parts on original minus' were either bashed in with a hammer/club or just cut out both pretty ugly) so I cut a small section out for when I re work the door bottom on retaining the raised curved part (if that makes any sense).

Here is the door hung:

and even with no shims the panel gap looks like it will be quite good (as long as the skins go on with out a hitch)

Thats all for now folks.

Regards Blue

#335

Posted 14 February 2013 - 12:18 AM

I also took another better quality video of it working. As you can see the bonnet still sags on one side but I do put it down to having a chunk out of it. The other issue is the pin doesn't always click into place so I may have to widen the hole a fraction. The squeak is from the nylon bushes but a but of WD40 sorted that out. Finally the last few moments of the video are of the panel gap on the back of the bonnet which is exactly what I want it to be :)

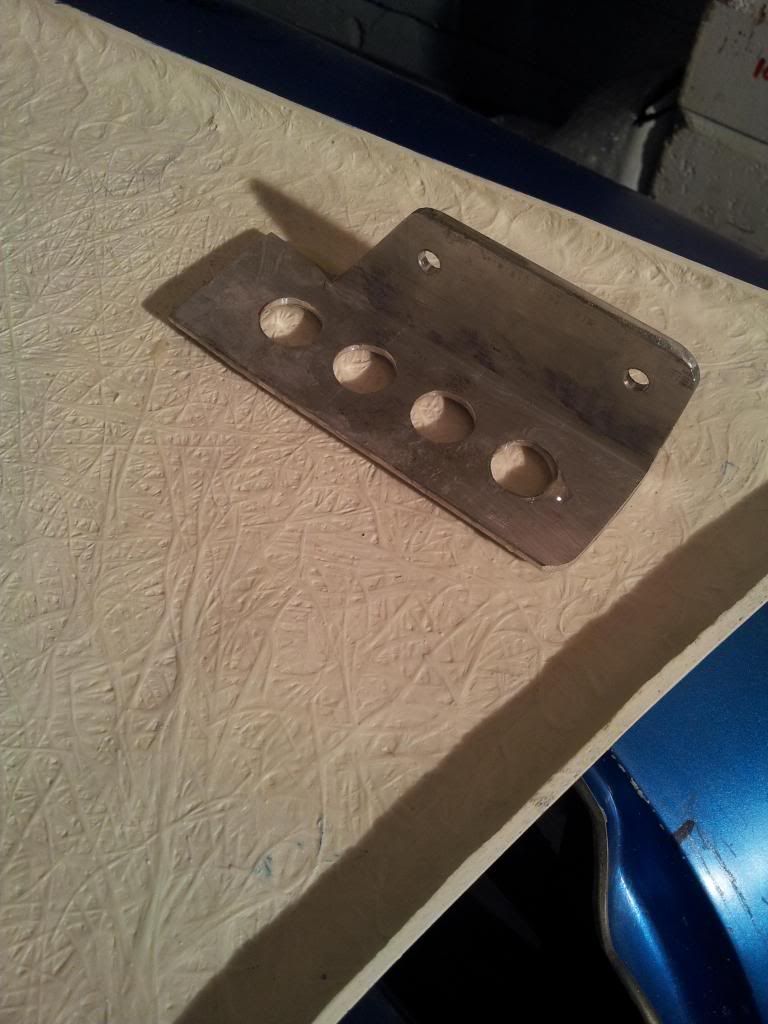

Finally I got round to marking, drilling and fitting one of the new Titanium bulkhead subframe spreader plates:

(old stainless steel piece on the left)

The titanium was surprisingly easy to drill (easier than stainless I thought). Like I put last time the new one is a bit bigger so can spread the load more efficiently.

In situ:

Thats all your getting for now folks.

Blue

Edited by blue blood, 14 February 2013 - 08:11 PM.

#336

Posted 16 February 2013 - 09:02 PM

#337

Posted 16 February 2013 - 09:17 PM

i guess those hex bolts will be replaced with allen head bolts?

#338

Posted 16 February 2013 - 10:06 PM

Regards Blue

#339

Posted 23 February 2013 - 06:53 PM

Keep up the good work and I look forward to further updates.

#340

Posted 23 February 2013 - 07:02 PM

The minivation hinges seem pretty smart too.

#341

Posted 23 February 2013 - 08:59 PM

Regards Blue

#342

Posted 02 March 2013 - 11:21 AM

#343

Posted 02 March 2013 - 06:04 PM

Regards Blue

#344

Posted 19 March 2013 - 05:58 PM

So what I do have to show:

I started by drilling out the holes bigger on my bonnets brackets so when I come to fibreglass them into place there is more area to grip to on the bonnet and it should hopefully hold better.

Then from there with everything in place i.e the hinges, bonnet and coverage for no drips.

I used good old fashion araldite epoxy to stick the hinges in place:

It has a bit of spacing between some part of the hinge and the bonnet but thats o.k as it will be filled up with glass strand matt and resin.

So with that all done and me having to get under the bonnet and hold everything in place while it dries enough (5minutes dry time my anus) I carried on with the doors a bit. I managed to chop down a section on the passenger side (no pictures) and then got side tracked and started to cut out the edge for the door seal on the drivers side. I did it by hand with a hacksaw and hand files as I didn't want to balls it up like I did on the other side and had to fix. Anyhow with that partially done I decided to add the door latch and locking mechanism to give it all a whirl:

"Just like a Golf"

Anyhow, upon closing the door I noticed at the bottom it tapers out a good 5/6mm outwards without a skin on so I will be cutting a slither out and welding it back together a bit thinner so the bottom of the door doesn't stick out loads.

Anyhow thats all for now folks. Next time I will be finishing off fibreglassing the bonnet hinge brackets and also finishing off the boot hinge brackets that just need the ends finishing off.

Regards Blue

#345

Posted 19 March 2013 - 07:50 PM

Want to make me a set of doors? Mine are horrible.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users