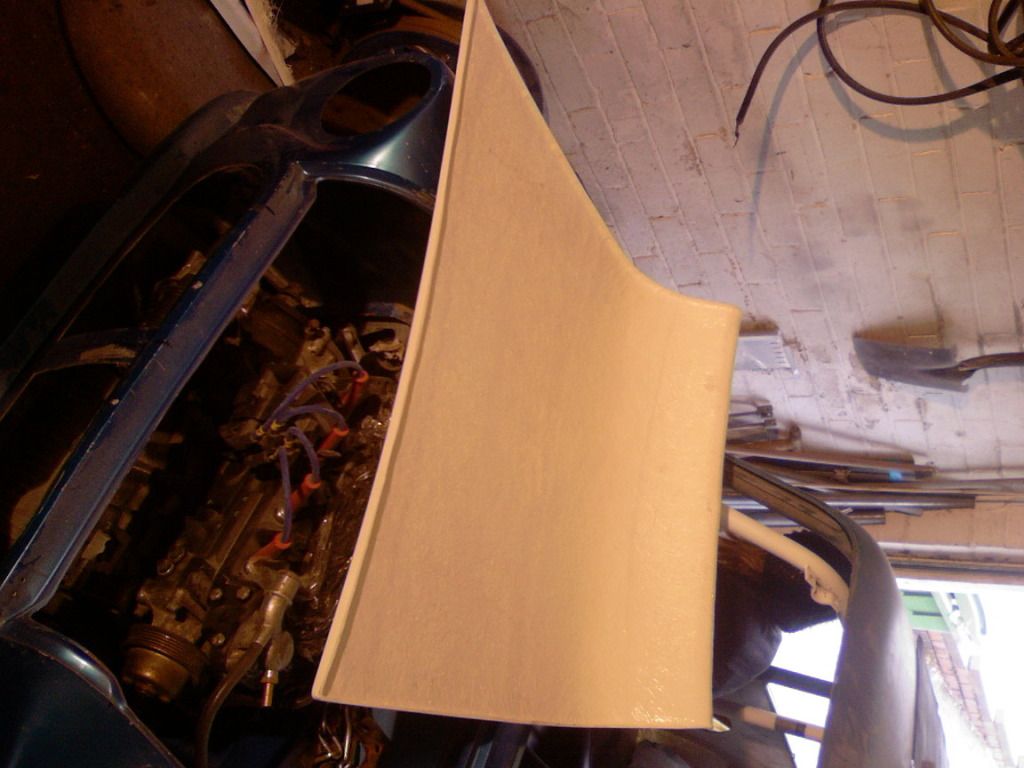

I also got round to fitting the quick release poly engine mounts and without the top engine steady they allow the engine to move around loads!!

That is it for today again.

Regards Blue

Posted 14 June 2012 - 06:18 PM

Posted 17 June 2012 - 01:02 PM

I also got round to fitting the quick release poly engine mounts and without the top engine steady they allow the engine to move around loads!!

Posted 13 July 2012 - 07:24 PM

Posted 14 July 2012 - 03:01 PM

Posted 14 July 2012 - 03:49 PM

Posted 14 July 2012 - 05:11 PM

Fantastic work! I love this!

Posted 14 July 2012 - 07:23 PM

Posted 14 July 2012 - 07:39 PM

Wow, looking good blue ;) It's asif this has had a female touch!!!!!!!!

I can't wait to see the end product.

Ha

Posted 14 July 2012 - 07:56 PM

Wow, looking good blue ;) It's asif this has had a female touch!!!!!!!!

I can't wait to see the end product.

Ha

Thank-you babe. I'm not sure what you mean by female touch though as you well know I am male!! ;)

Posted 15 July 2012 - 07:18 AM

Posted 16 July 2012 - 03:58 PM

Posted 19 July 2012 - 09:01 PM

Posted 19 July 2012 - 09:09 PM

Blue, your build is very impressive....your passion for detail is even more so. I haven't been on the forum for ages and to come across this story is truly awesome. The materials that you are using are very very nice indeed and remind me of the time and effort I have spent on my build which sits at about 80% complete after 5 years. I haven't posted mine on here as I wanted to keep as a surprise but there are definitely similarities in the way we work, mate.

See you at Santapod perhaps ;)

Posted 19 July 2012 - 09:33 PM

Posted 26 July 2012 - 05:58 PM

0 members, 1 guests, 0 anonymous users