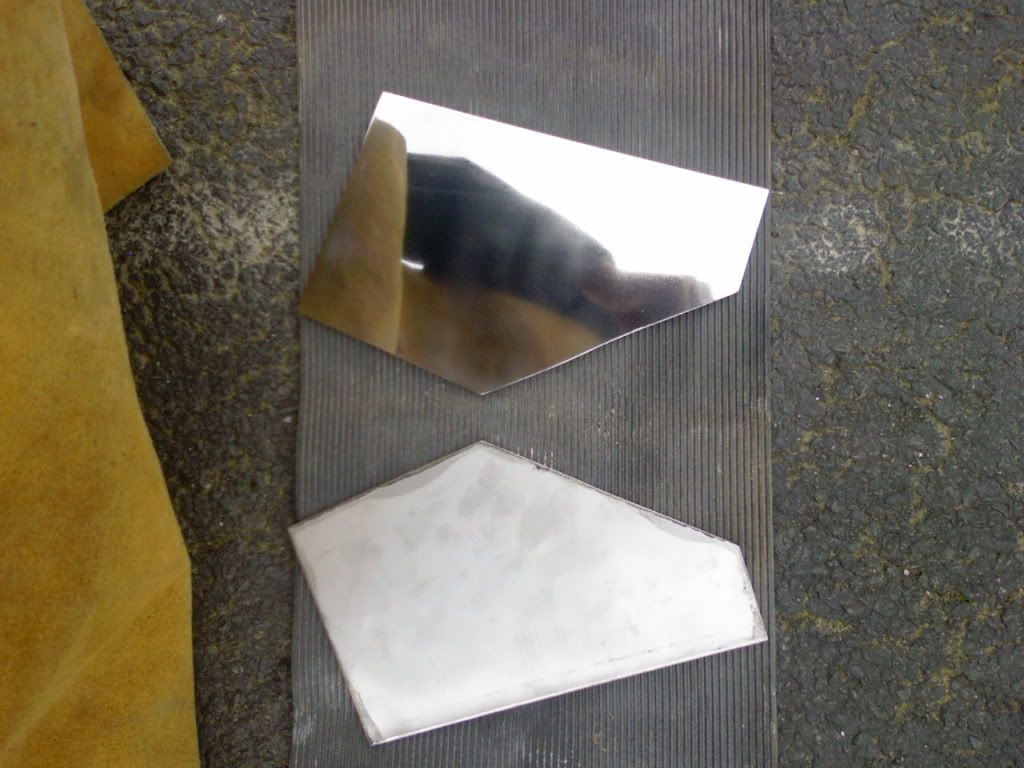

Then I slung a wheel arch on just to have a look:

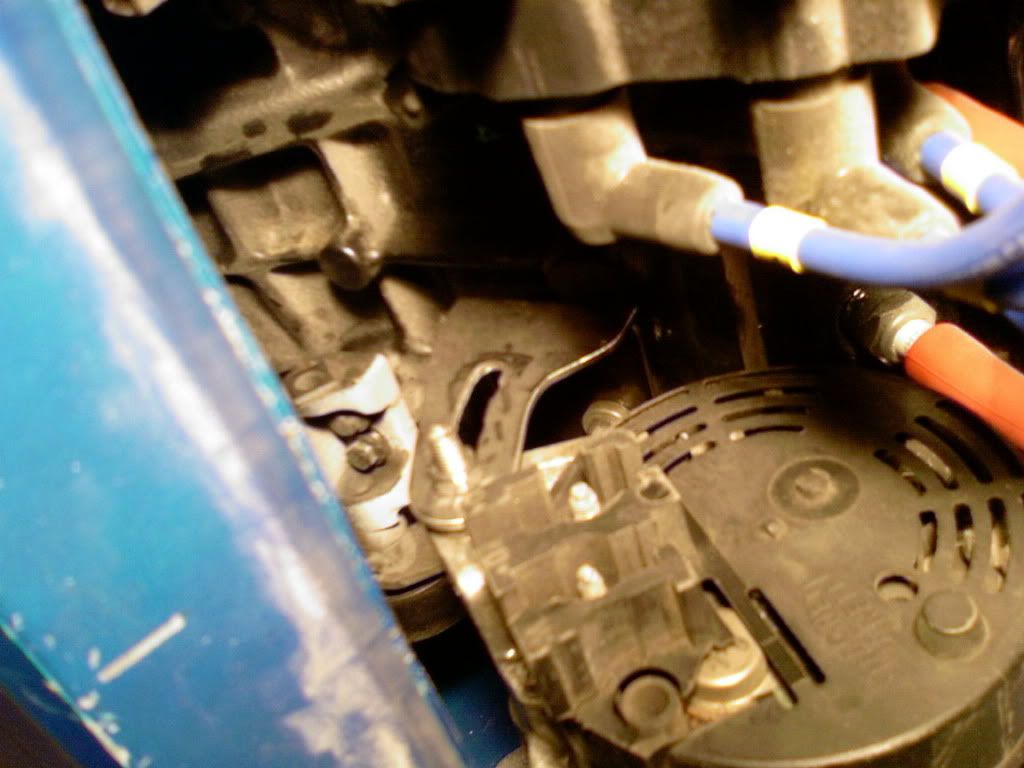

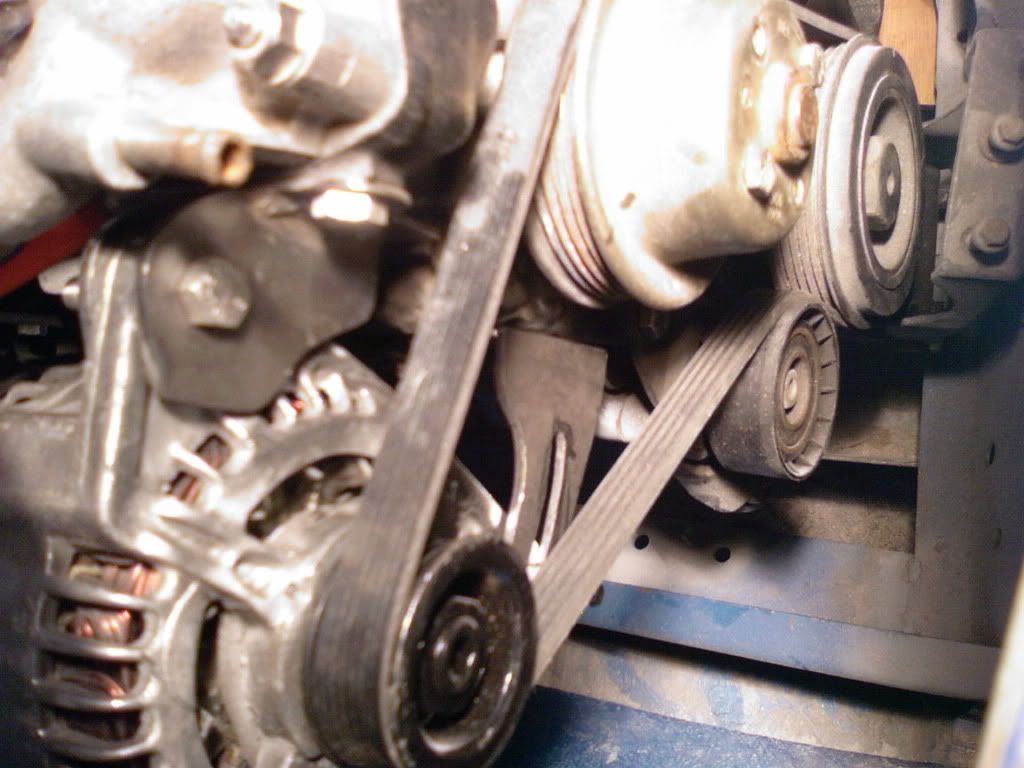

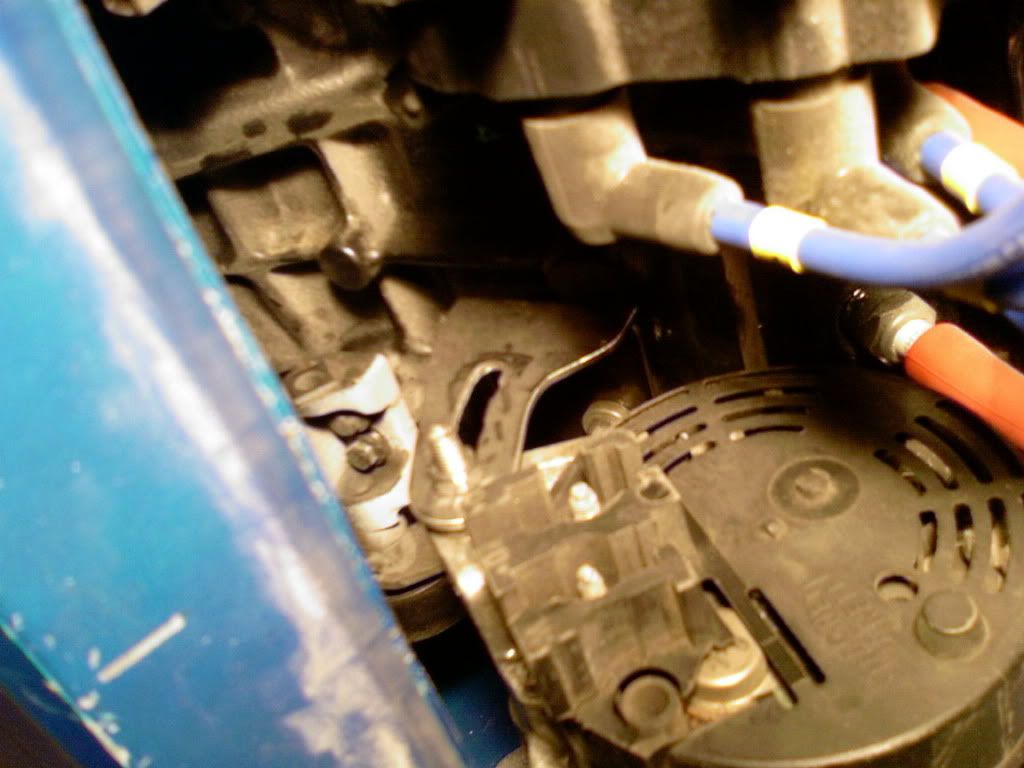

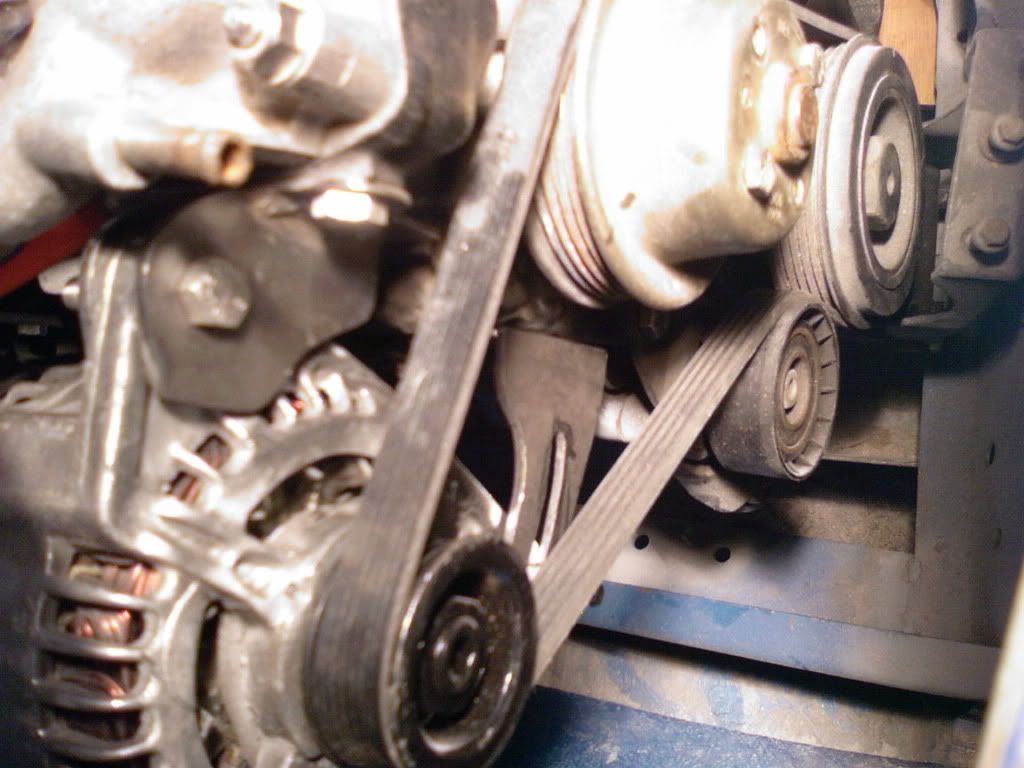

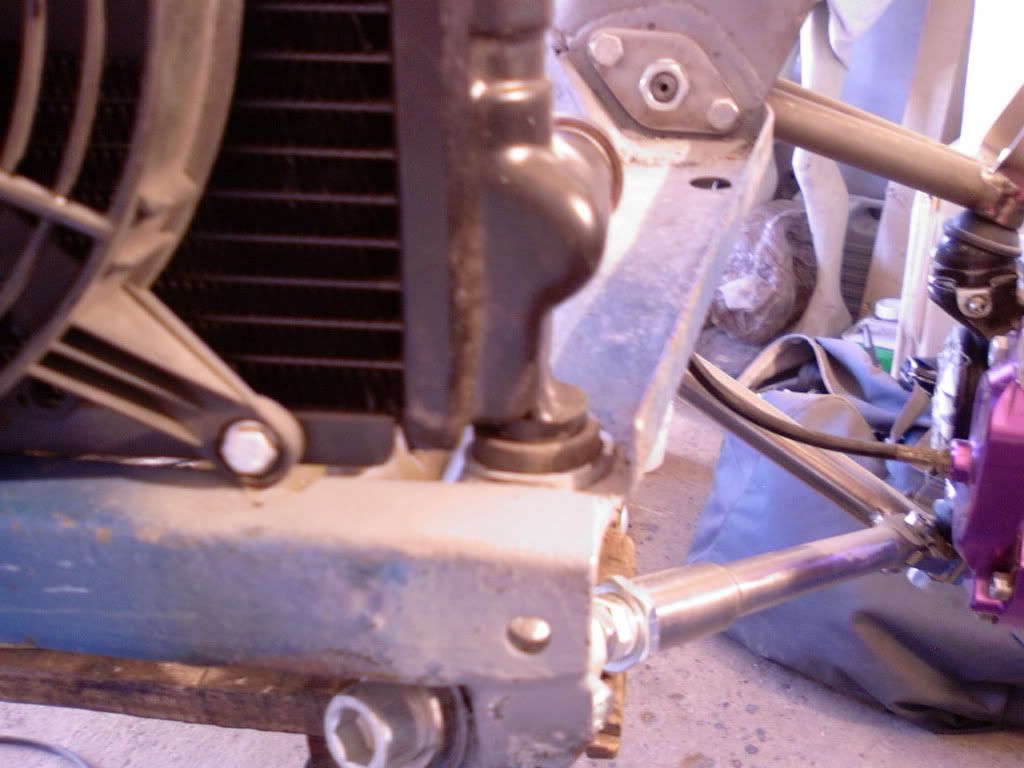

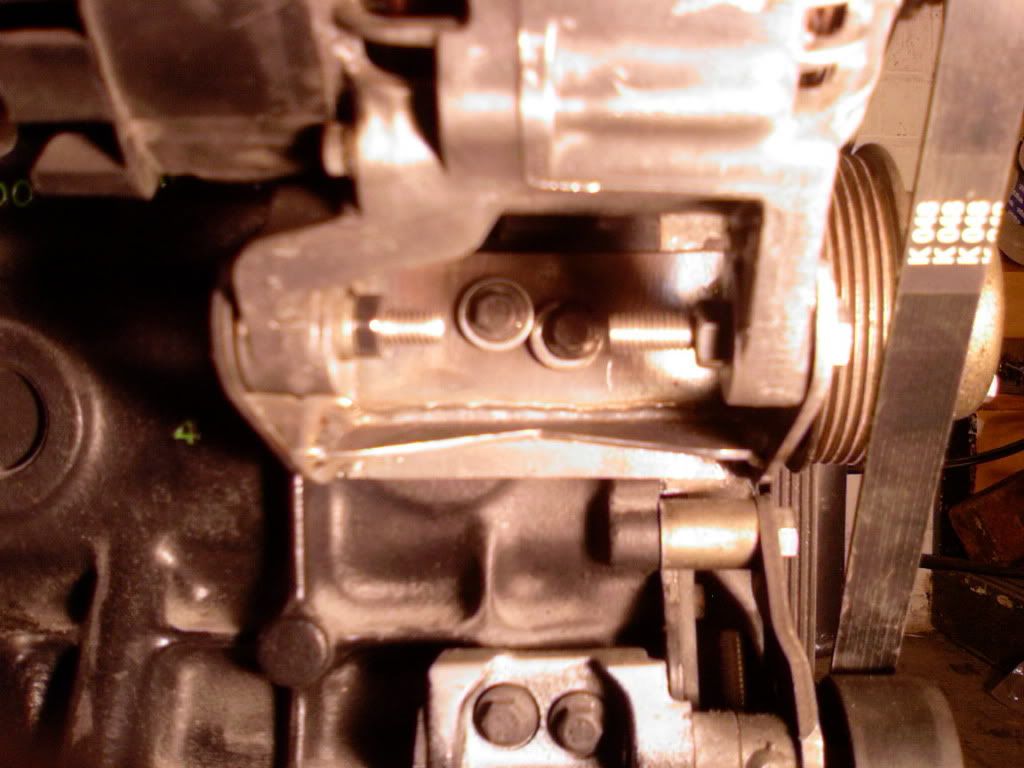

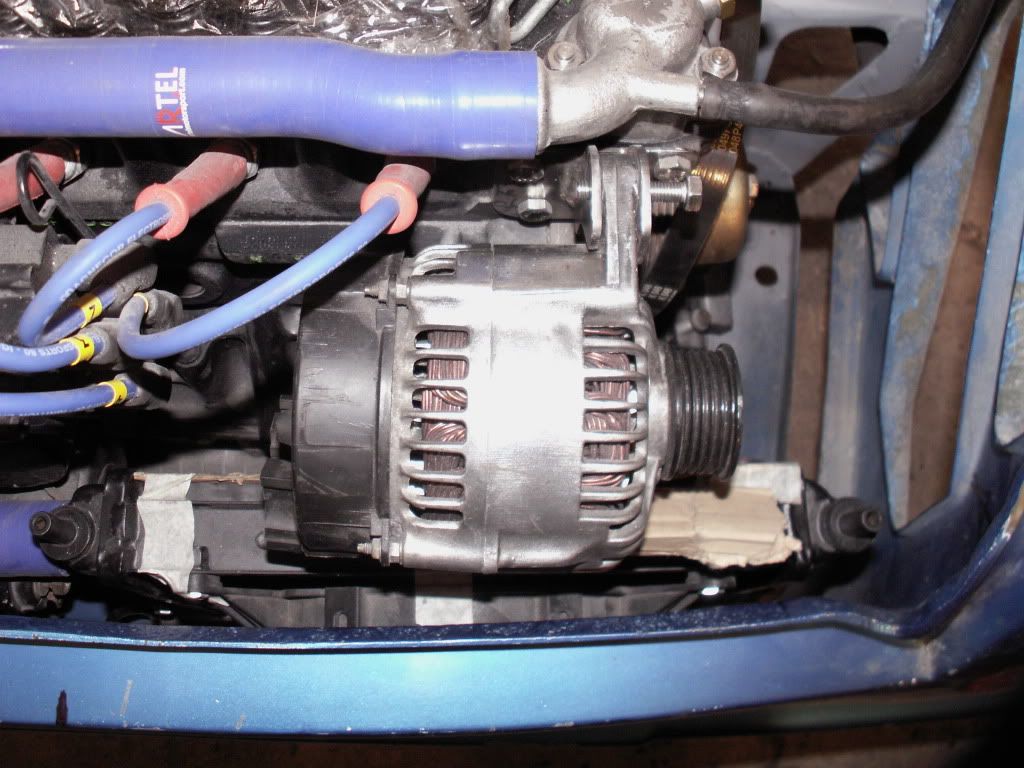

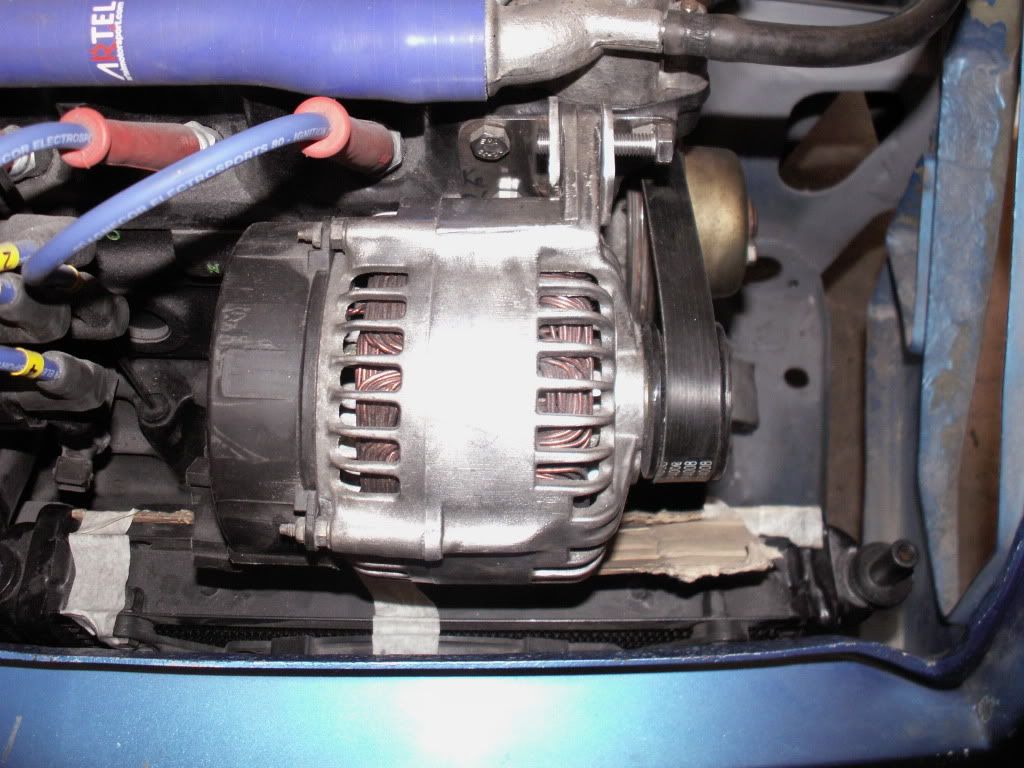

I also got a start on with my lower alternator bracket/tensioner :

Thats all for now.

Regards Blue

Posted 23 March 2012 - 07:42 PM

Posted 25 March 2012 - 08:05 PM

Posted 26 March 2012 - 05:19 PM

Posted 28 March 2012 - 07:39 PM

Posted 28 March 2012 - 08:44 PM

Posted 28 March 2012 - 10:21 PM

Posted 29 March 2012 - 08:08 AM

Posted 29 March 2012 - 09:42 PM

Posted 02 April 2012 - 10:09 PM

Posted 03 April 2012 - 11:10 AM

Edited by blue blood, 03 April 2012 - 11:12 AM.

Posted 19 April 2012 - 06:26 PM

Posted 19 April 2012 - 10:54 PM

Posted 19 April 2012 - 10:57 PM

Posted 19 April 2012 - 10:59 PM

Posted 19 April 2012 - 11:10 PM

0 members, 1 guests, 0 anonymous users