O.k so recently i have been trying to get things finished off and things started in order to get other things finished.

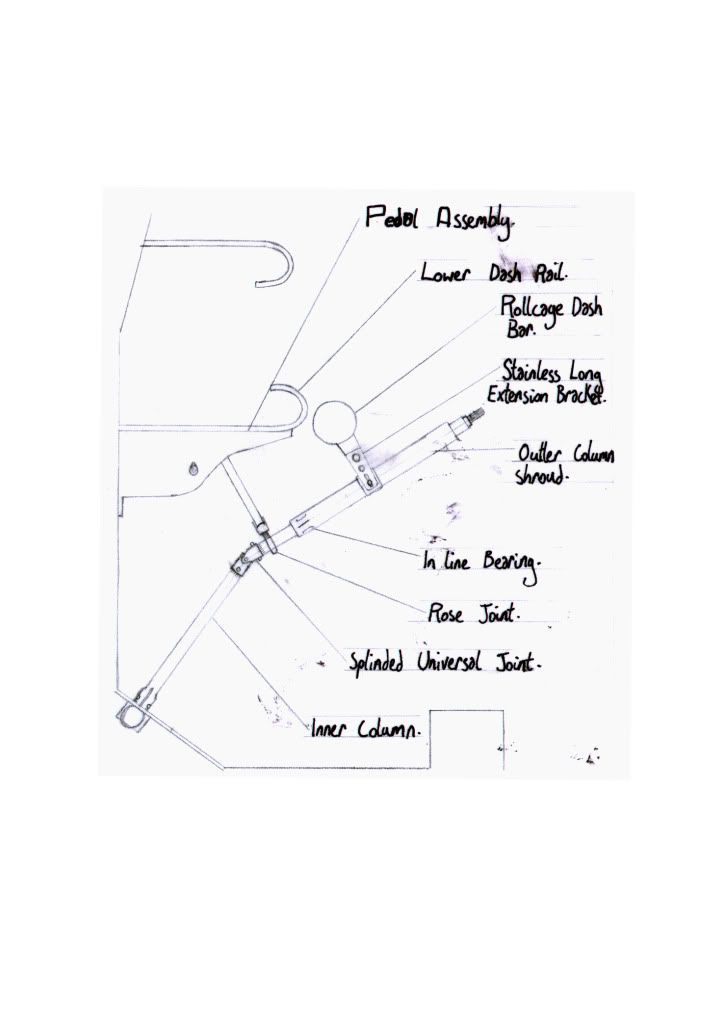

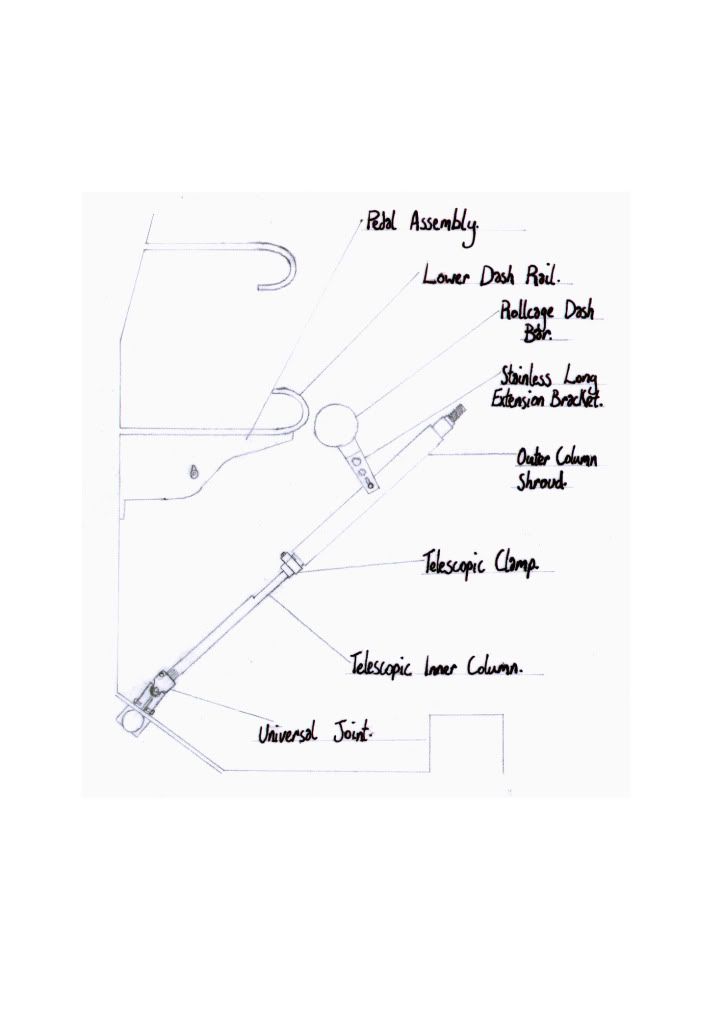

So i started off by working out a few things to do with my steering column. I checked for the fitment of the boss adaptor on my new column, on the MPI column i would of had to have a sleeve made and hardened to weld between the column and adaptor (which is a bit unsettling with so much heat being passed through the column and a lot more parts that were involved) Thankfully though the adaptor fits perfectly to my new column:

Obviously i will have to cut off the splined part before welding and boss fitment but its just to illustrate fitment. However i will not be fitting my boss before an SVA test because SVA stipulates that snap off boss' are not allowed.

Also on my column from taking off the old collar i had taken a few nicks out so i have had them filled in with weld and will have them lathed down to be uniform with the rest of the column.

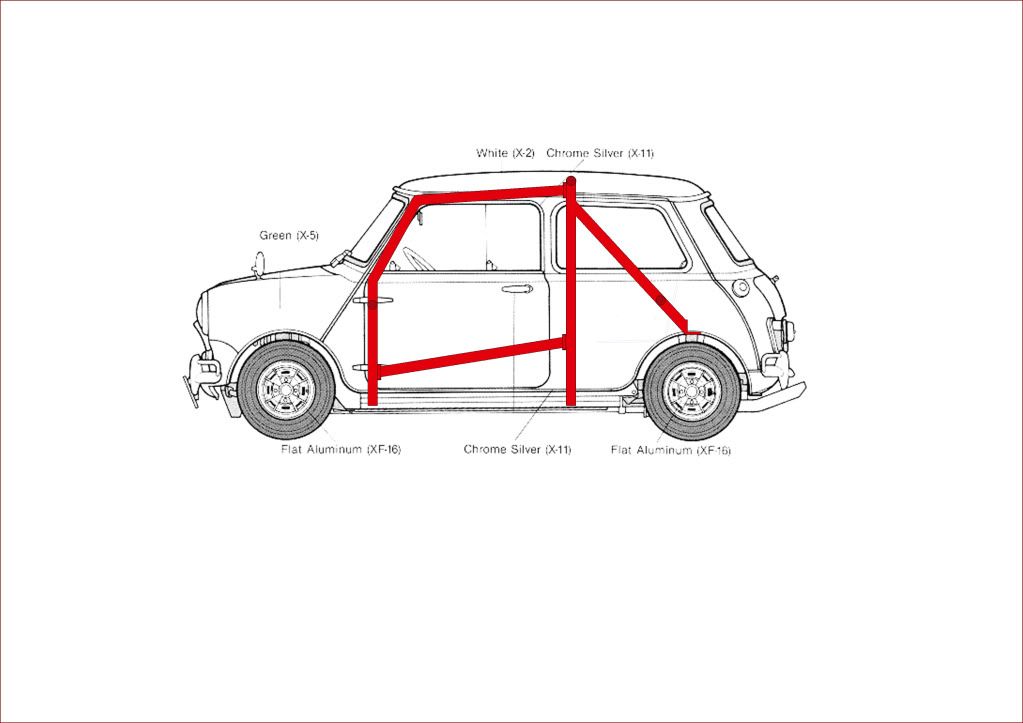

I have also started to dismantle my safety devices roll cage:

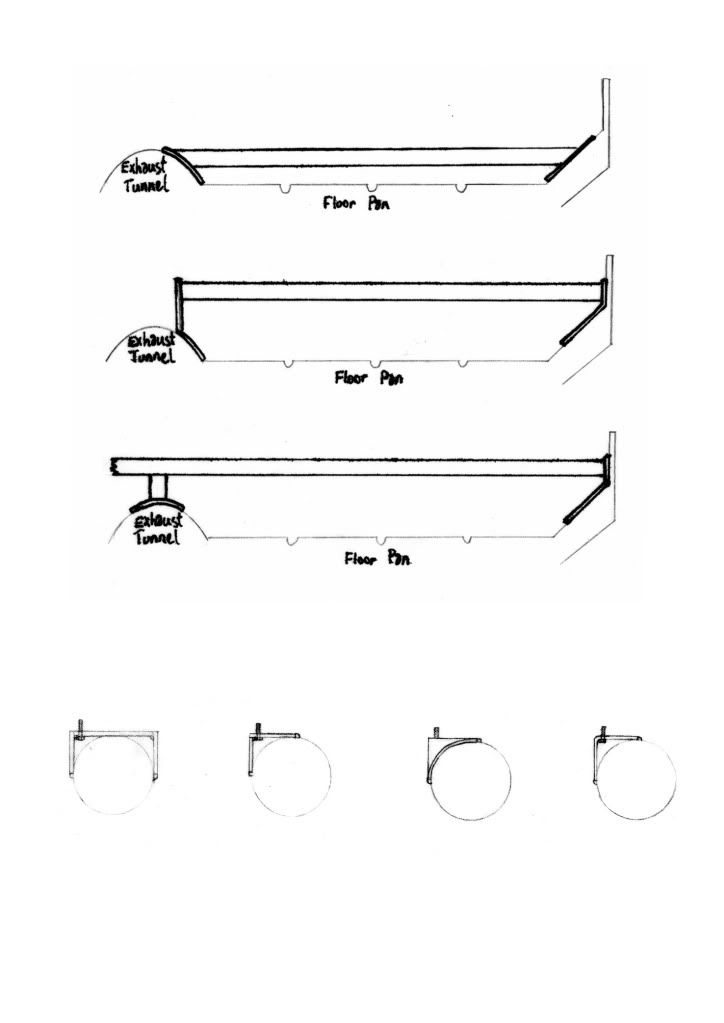

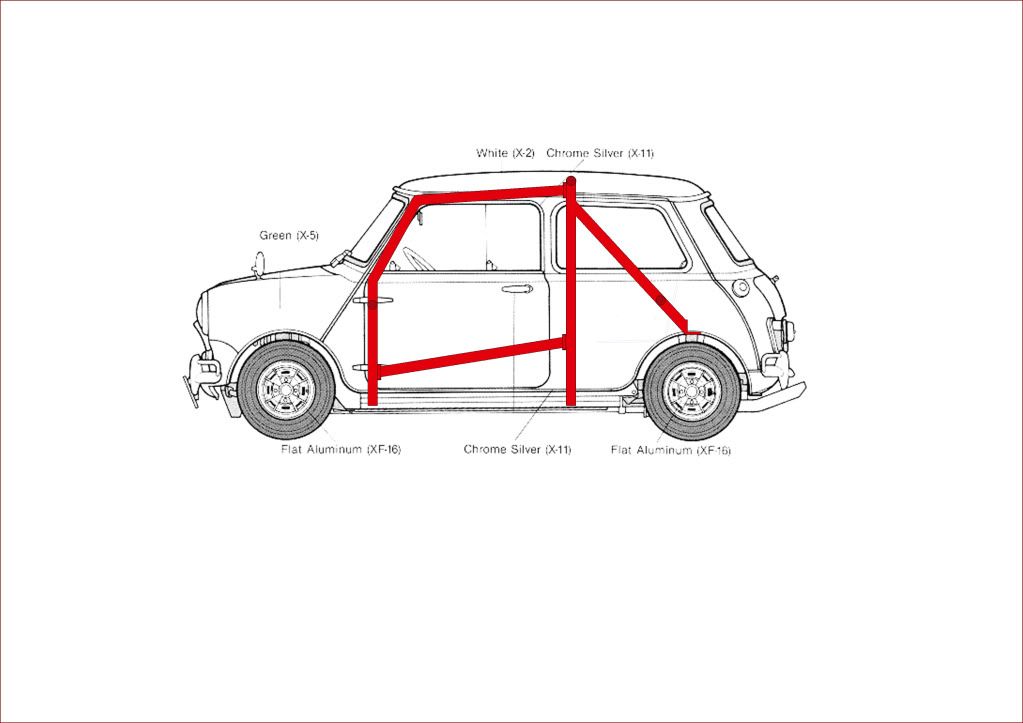

It will have to be smaller due to the minus being shorter in the body and i am going to add in some of my own needs. I am going to be having the rear arms going to the suspension turrets to make things more rigid, coupled with a cross on them for more weight at the back. I am also going to be having a harness bar before the arms go through the rear seats back board. This is a quick diagram to illustrate what i mean:

So another thing i have started is my front subframe. I have seam welded it all up for more strength.

To begin i used nitromors on it to help lift and strip the paint on the areas that needed welding then used a wire brush tool in my drill to get the metal clean:

So here are the two towers welded up:

There was quite a surprising amount of rust on this subframe but it is still useable. I started to dress all the welds up but as i said i did not finish all of the dressing due to some holes that need working in to:

In the end i gave some areas a lick of primer to stop rust forming but i will be sending the frame off once its been test fitted and gone through a dry run setup to be sandblasted and powder coated.

As you can see more weld and work needed on this one

With some spare time i decided to check the fitment of the titanium arms i have and they do seem to be alright as i had a lot of issues with the rear radius arms i purchased.

Well thats all for now folks

Regards Blue