1978 Austin Mini (Cg13 Build)

#31

Posted 21 February 2015 - 09:53 PM

#32

Posted 22 February 2015 - 02:49 AM

#33

Posted 01 March 2015 - 04:09 PM

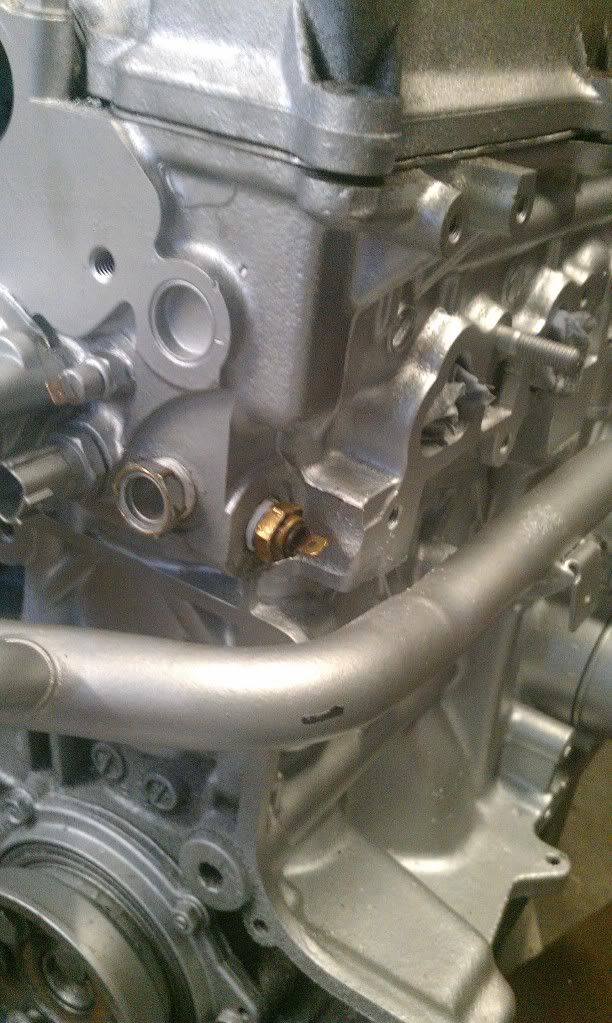

Bit of an update:

Managed to get the frame in and engine. Today was more to look on how it all is going to fit together.

I must admit I was pretty impressed with the fit.

It is a little heavy but considering the rest of the car I am not overly fussed.

I have all the sections for the exhaust so it will be getting the exhaust and inlet manifold done next then I can set the final position as the mounts allow quite a lot of choice on final position.

I am eventually going to go for the wildwood slave pull cylinder as I can then retain the original clutch cylinder.

As for the alternator I am still unsure I may have shot myself in the foot by cutting the crank pulley down.

Edited by smudger068, 02 March 2015 - 07:32 AM.

#35

Posted 06 December 2015 - 09:44 AM

I bought an inlet manifold from Matty and the build quality is immense so definitely worth a buy.

Then I started the exhaust, I must admit I was doing well then I hashed up the cut so luckily I had two sets of flanges laser cut so I had to space the outer two to make it look like it was somewhat suppose to look like it does

Then there was the fuel tank. Because I only had on line to the front I removed the original pipe and changed it all for rubber hose so it matched. I did try to go for anodised unions but it was eye watering expensive so it will do for now. I also needed a low pressure and high pressure pump and whilst we were at it might as well fit a swirl pot not much space left now.

I do need to weld some sort of legs of feet onto the tank because I don't like the straps it currently uses because the tank can still move around.

I got a bargain on this double fibreglass boot so snapped that up.

I seem to building my mini when it is dark so I will try for some better pics in some better light in the future.

Also my other toy I purchased was good to get back into this I used to race a lot when I was younger

Also my boss asked if I wanted to drive this well of course I suttely said yes of course

Me and my dad:

Yes a Ford GT40

Thank you all

#36

Posted 02 February 2016 - 08:04 PM

Evening All,

Small Update slowly getting there.

Finally finished all the fab work before getting the engine and the frame back out for some paint and some powder.

Then got the frame back and put the manifold on before installation.

Also gave the engine a service. CHANGE THE O RING ON THE STEEL WATER PIPE!!

I learnt the hard way as it leaked later.

I also gave the bulkhead a freshen up as cleaned the master cylinder.

Finished plugging all in. Cranked for some oil pressure then it started first time and runs great.

To Note:

The Micra Temperature sensor for the gauge resistances are way out

Micra: 470-570 Ohms @ 90 Deg and 1.2 - 1.4k Ohms @ 65 Deg and 2.1K Ohms @ 52 Deg.

Mini: 800 Ohms @ 20 Deg and 50 Ohms @ 90 Deg.

Which explained why my temperature never worked with the micra sensor.

Luckily I am not using the water to dash heater hoses so blanked them off and welding a 5/8 UNF nut to take the sensor.

(I would have gone with L-Jonez idea but I wasn't getting the engine out again for that)

I also changed as many nuts and bolts as I could for either new or Allen bolts.

Get your orders from Suffolk Fasteners in Ipswich, they do the best price super cheap and fast delivery.

I am using modified original castor arms just waiting for the boss to get an acetolyene kit so I can put a slight bed in both of them.

I cannot get my Elliot rev counter to work. I have powered it I used the blue and black!? signal wire but no luck so I need to investigate this.

I then mounted the and wired the fuel pumps.

Also got my tank welded and made some shims up so the tank sits nice and level and also drilled for the fuel return.

I will hopefully be able to upload more pics and more updates now I have Wifi in my place.

Also it has a maniflow 2" centre box exhaust with a midbox in and is still bloody loud and pops well too haha

Enjoy.

Edited by smudger068, 02 February 2016 - 08:11 PM.

#37

Posted 07 February 2016 - 01:18 PM

Afternoon all,

Hopefully I have finally sussed out the alternator. Opinions on strength and rigidity are more than welcome as I don't overly like the concept but it seems to be the best solution to fitting in such a tight space.

Firstly I turned down the tensioner pulley so it would fit as seen, it does rub slightly so will just shim that out.

Anyway Pics

I then made a bracket to hang the alternator. The alternator is a Diahatsu Sirion 2008. it isn't actually that much smaller than the micra so I wouldn't recommend one but is just enough for what I need.

I also had to machine a shim down so I could fit an M10 bolt through the bearing on the idler.

Hopefully some sharper images.

Only other issue was fouling the indicator so I need to shift the engine over to clear luckily enough I have it quite a way over to the right.

#39

Posted 28 March 2016 - 08:18 PM

Evening all, hope we are all well....

Right I found the alternator was rubbing against the indicator so swapped it up the other way and fitted a lot better...

I do however seem to have a squeak from the water pump so need to check that out.

The exhaust is on and sealed and the car sounds so crisp! For the induction I have a cold feed duct run to the front hopefully this will aid flow.

As we all know bolting some K&N filter on the end of the throttle body isn't going to anything any favours. As for an air filter I have a course mesh in the front of the duct and I have left the fine mesh in the throttle body so that should be good enough.

I have dusted it off, Paper work off to the DVLA. Fuel Tank Leaked so that went back with the drive shafts to be finished....

Also, had some spare time this afternoon and cracked on with the fiberglass bootlid, real happy with the fit. Off to the Mini Centre tomorrow for a T Handle and boot light. I also removed the lock from the old boot lid so hopefully that will fit the new handle so the keys all remain the same.

Off to the body shop for the lid for some paint...

Anyway Pics....

So to finish:

Fresh lick of paint on the inside were feet rub.

Finish wiring as the micra feed causes the car to keep running after i have killed it, plus a few other bits.

Finish building boot lid

Install Shafts

Set up the geometry and suspension

MOT TAX And Insure.

Thanks All.

Edited by smudger068, 28 March 2016 - 08:25 PM.

#40

Posted 08 April 2016 - 07:24 PM

Just waiting to get the fuel tank back. Fitted the driveshafts and it moved for the first time in two years.

Just a little but of picky fetiling left to do. I also have abit of a squeal from the water pump at idle and it does seem abit tight so may need to investigate. Also managed to get rev counter to work but still can't get my Elliot counter to work think it's naffed

Edited by smudger068, 08 April 2016 - 07:33 PM.

#41

Posted 02 May 2016 - 08:02 PM

Bit of a finalised update:

Just waiting to get the fuel tank back

Got to glue lettering to the rear boot lid, so recommendations are welcome, i am not going to drill the fibreglass.

Need to borrow a welder from work when one is available to finish gear linkage

Changed the water pump runs a lot better certainly quieter.

Happy with how the clutch and cable system is working goes into gear well. Doesn't seem to slip under brake tests.

Got the G3 and Tech 2 and polished it up ready.

As and when: I need to finish loom and tidy and freshen up the inside.

Enjoy

Edited by smudger068, 02 May 2016 - 08:13 PM.

#42

Posted 17 May 2016 - 09:43 PM

Finally,

It is on the road ![]()

it does still need a setup but is square set at the moment so its 'okay'

Love the power, I feel it is powerful enough for what id like as my aim is not to have 200hp and go mad with it.

1st isn't really in existence as it manages it from 2nd just fine. Higher gears are taller enough so really a mix 'n' match of gears maybe have to be revised at a later date but will see.

Drinks Fuel but need to see what I am going to do about induction as I think this maybe the cause.

I was rather impressed with the headlights i was expecting to not be able to see but works great

![]()

Edited by smudger068, 17 May 2016 - 09:46 PM.

#43

Posted 21 August 2016 - 11:01 AM

Hope all are well...

Went for another drive and a short sharp snap after a halfords run for some CV grease...

I found the threaded bar on the alternator isn't the best so need to make a more robust fix for that.

Still trying to find the time to get it setup.

Other than that great power delivery enjoying it...

#44

Posted 23 August 2016 - 10:10 PM

#45

Posted 24 August 2016 - 08:38 AM

Looking good! Very jealous!

Did you ever get your induction/fuel problem sorted? I see from your photobucket that your inlet manifold cracked.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users

This topic is locked

This topic is locked