Been a while since I last updated anything, but there's been a new addition to the family and a house move. That said, a fair bit of progress has been made.

Chris and Steve at North West Mini Centre have done a great job with prep and paint and refurbed a set of 100+ minilites for me

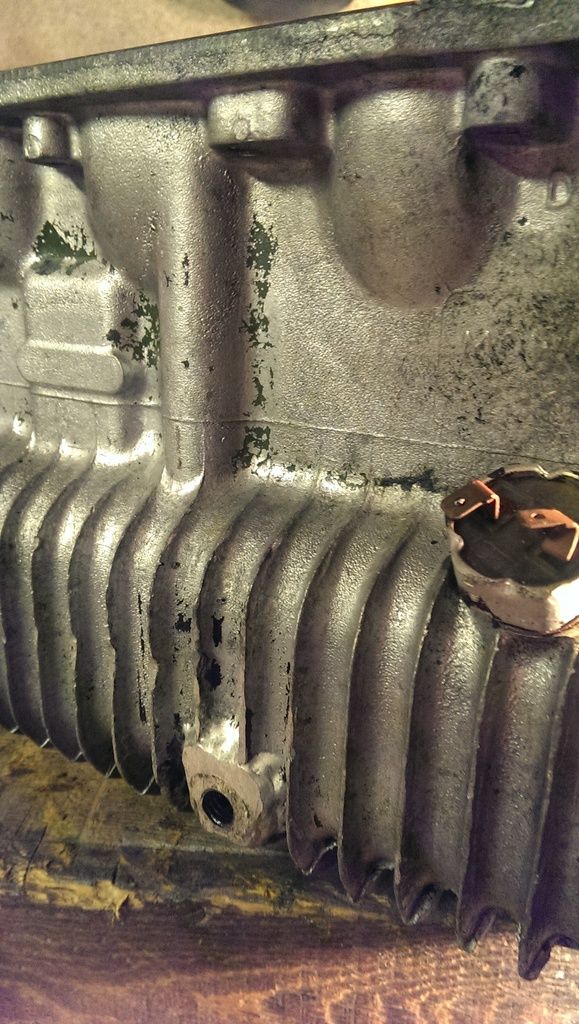

I am now trying to put an engine and box together. I have a 12g1128 4 synchro remote box with immaculate gears I bought off ebay but it's been left standing and the layshaft and laygear are all mashed up unfortunately.

#

#

The interior bearing surface of the laygear is ruined at the flywheel end unfortunately and the laygear itself has no markings apart from 'M E' stamped along the body.

BOTH those rollers came from the flywheel end. Is this normal? There are indications that the box has been built for a performance engine: Central oil pickup and magnetic traps in the sump plug, front plug AND the pickup pipe union, can post pics tomorrow.

Can anybody advise as to what part numbers I need (Laygear, layshaft and needle rollers)? I'm guessing the bearing surface cannot be machined and re-sleeved?

Cheers. And a Happy New Year :)