Now I noticed a while ago that on the back, the passenger side wheel was poking out of the arch more than the driver side one did so I did some brief measurements in reference to the body:

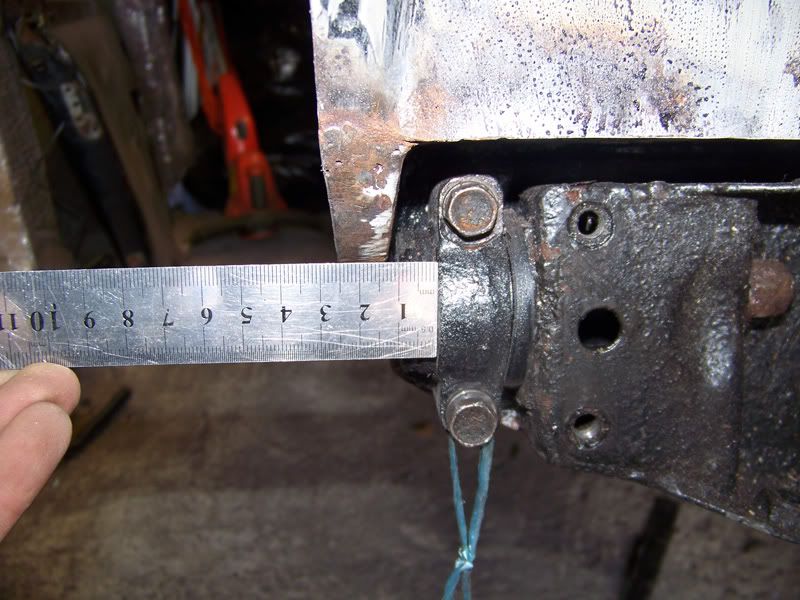

Passenger side, mount to lip edge.

Driver side, mount to lop edge.

Passenger side, rear mount to valance edge.

Driver side, rear mount to valance edge.

All these pictures suggest that the rear frame is further over to the passenger side. I made some DIY drop weights with some string and some wheel nuts and hung them from the rear mounts on the front subframe and the front mounts on the rear frame.

You can see the weights dropping down.

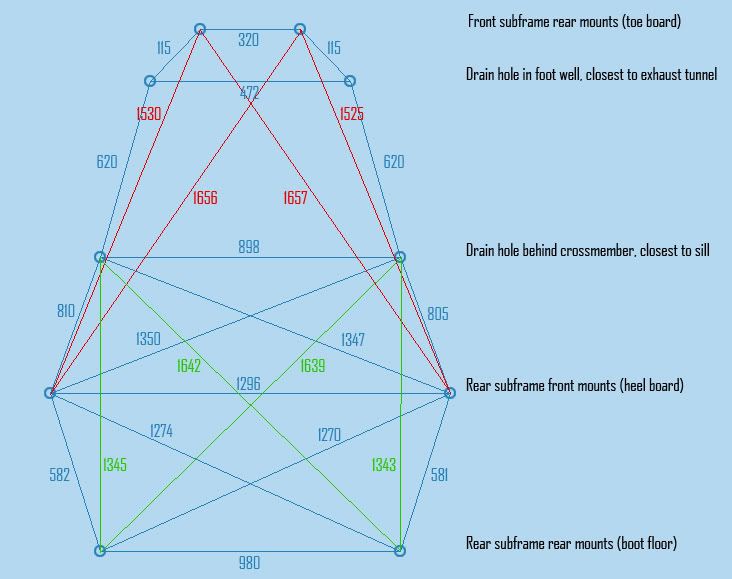

Key:

P - Passenger Side, D - Driver side, F - Front, R - Rear.

Results:

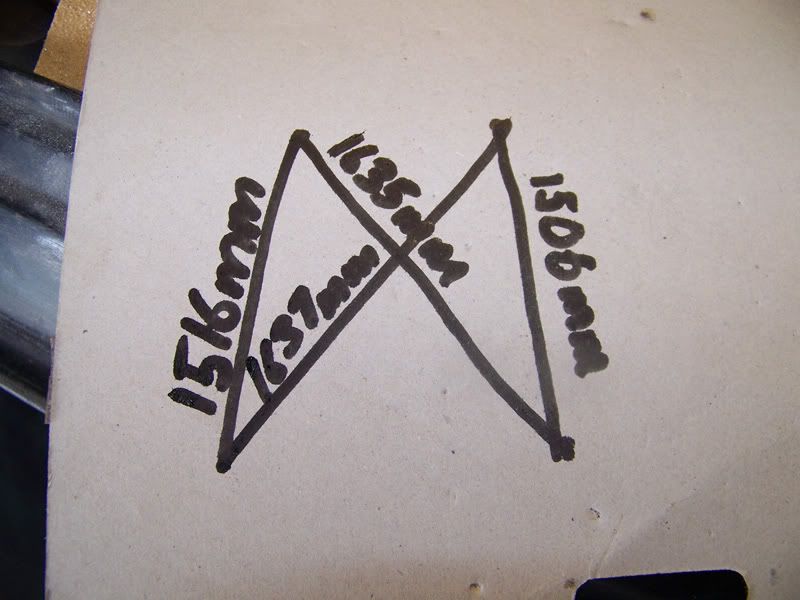

PR to PF = 1516mm

DR to DF = 1506mm

PR to DF = 1637mm

DR to PF = 1635mm

Picture to make it a little clearer:

What do you guys think of this? I was thinking since I need to replace the heelboard ends anyway, maybe I should be thinking about moving the heelboard mounting holes over to the driver side by a few mm to try and correct this?

All advice is welcome as I'm really a bit puzzled about what to do here!

Thanks,

Adam