1960 Morris 850 And Friends

#76

Posted 14 August 2011 - 11:55 PM

As for the 850, I's likely going to be hoisted up into the rafters filled with my early bits when our shop is built so as to get it out of the way for now.

Chris

#77

Posted 16 August 2011 - 08:58 AM

It was simply 3 pieces of inch square I drilled and fitted around the one mount I had so I could fabricate up a jig.

I don't have any suitable steel around to make a subframe mount from so I just rough cut a couple pieces and drilled them to test out the jig.

It seems to fit well, though I need to bevel the wide edges. At least I can use this for mocking up the subframe on the van now. I will probably make up a pattern for the two pieces of the solid mount for the next ones I make, and probably put some larger wire in my mig for some better penetration.

Need to do some repair work to the subframe before I can mount it... I am not going to post any pictures of it untill it's repaired... you bunch will call me nuts!

Chris

#78

Posted 18 August 2011 - 09:42 PM

#79

Posted 19 August 2011 - 04:58 AM

Fitting out, The van is going to get late rover interior If I can manage it with a pressed grill and the yellow that it is, the pup will be a mk1 cooper replica in almond green and oew roof. And the 60 if it hasnt moved on will be restored back to oew with a repro fleck interior hopefully a 1100 if not it will be a 998 with magic wand.

And parts, not hard to get, just somewhat expensive for the skint. Most of the time it is cheaper to buy there and have shipped here if you have a sizeable order... Bed sides and whatnot will likely come that way.

Chris

#80

Posted 27 August 2011 - 03:52 AM

Into

And angles and measurements are measuring up and square so far so I think it will be useable when I am done.

It's a late jap spec auto front subframe, the condition of the bearings and cones were in great shape, the subby however was in a shape more befitting a pretzle. First thing I did after getting it home... Actually I think I should make this statement.

I Got this for free when I bought a mk1 solid mount front subframe that has a rusty rubber cone locator ring in one tower. It was ment to be the donor for the spring mount to go into the mk1 subframe. I however had the rubber frame that was chopped up that I can get the spring mount out of so there was no harm trying to straighten this. I will be using this subframe to mount a subaru/geo g10 3 cyl 5speed 1.0 engine so much of the damaged area on the right side will be cut out and reformed with new steel to make room for the front pully of the g10 power unit... Now where were we? Oh yeah.

First thing I did to it after getting it home was to pull out the grinder with a 1mm cutting disk and cut right through the center of the big folds in the metal so I was only needing to straighten one section at a time and would not be fighting the folds. Once I had done that I used a long bar and some eye bolts to pull the front bar back to where it should be (and a little too far, had to do some unbending) Aslo bent some of the engine mount area back and then the shop became a priority so It got set off to the side.

A week later I started working on the mangled rear mount some, I make up a template from the left side to set the slice to where it should be and welded it up and set the frame aside, this is when I went and made that silid mount earlier.

During my free time after that I used the mk1 subby to make up a frame jig locating the suspension arm mounts to the front mounts out of inch square tuping and angle iron to which I forced the bent subby onto and bolted it to the van. Using a series of long poles and strategic bracing IO worked on the tweaked areas to get it in as close to original shape as I could and to the point it is in the pictures.

At this point I need to pick up some steel plate in a compareable thickness to this subframe and make a couple patches, but at this point it measures out as square.

Some more pictures at

http://s1202.photobucket.com/albums/bb374/clm1977/mini%20van/subframe/

Chris

#81

Posted 27 August 2011 - 02:53 PM

I love reading this thread.

Keep that jig. If you add to it so you can bolt a sub frame in it with all the mounting bolts,you can use it to check and straighten sub frames, and mod them to fit other engines and transmissions.

You said "subaru/geo g10 3 cyl 5speed 1.0 engine".

Do you mean Suzuki/geo g10 3 cyl 5speed 1.0 engine.

Or Subaru/Justy 3 cyl 5speed 1.x engine?

I have the Suzuki parts, and a sub frame I'm making fit.

I cut up the sub frame more than needed because it was bent. I don't know why I didn't think of straightening it.

The only issue I saw so far is the diff of the trans hits the the rack where the pinion goes in it.

Some judicious grinding on the trans and rack should sort that out.

But with my too many projects, I haven't got back to it.

Keep up the good work. and keep posting.

I'm still trying to make time to come down to see you, but I have to get my place cleaned up, or my wife will be unhappy

john

#82

Posted 27 August 2011 - 08:33 PM

I was planning on adding other mounting points, but for this it sort of needed to be a bolt on the bottom type so I could use it with the subframe bolted to the van.

Should post some pics of your projects John

Chris

#83

Posted 28 August 2011 - 05:32 AM

Chris

#84

Posted 17 September 2011 - 12:49 AM

Yes,I should post some pics of your projects, but I don't know if it goes in Mini based, or other.Oops yeah Suzuki/geo like the post above it says heh.

I was planning on adding other mounting points, but for this it sort of needed to be a bolt on the bottom type so I could use it with the subframe bolted to the van.

Should post some pics of your projects John

Chris

john

#85

Posted 17 September 2011 - 03:00 AM

Well the engine part may not, but it is still a complete mini rebuild I imagineYes,I should post some pics of your projects, but I don't know if it goes in Mini based, or other.

Oops yeah Suzuki/geo like the post above it says heh.

I was planning on adding other mounting points, but for this it sort of needed to be a bolt on the bottom type so I could use it with the subframe bolted to the van.

Should post some pics of your projects John

Chris

john

Chris

#86

Posted 17 September 2011 - 04:44 AM

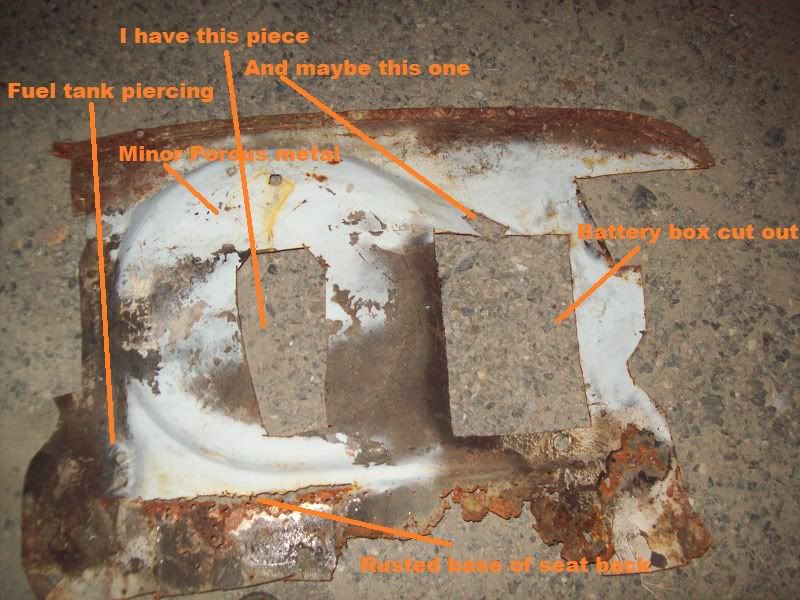

The shape of the spare well is there and intact, I believe that was what you were needing. It's slightly porous towards the bumper side of the spare well, but most of it is solid.

Chris

#87

Posted 20 September 2011 - 08:23 PM

Oh Boy Oh Boy Oh Boy.Hey john,

The shape of the spare well is there and intact, I believe that was what you were needing. It's slightly porous towards the bumper side of the spare well, but most of it is solid.

Chris

That will work.

I can rebuild it.

Got to go.

john

#88

Posted 21 September 2011 - 09:45 AM

Chris

#89

Posted 23 September 2011 - 08:58 PM

Gives me time to get the 1100 short block off the transmission. I found it way in the back of the garage.

john

#90

Posted 01 October 2011 - 08:29 AM

After the other inner wing was off I took the toeboard loose from the firewall, that turned out to be the easiest job so far, a few spot welds and it fell off.

After it was off I stripped it down taking off all the items I had neglected to take off to this point and worked at determining how to remove the parcel shelf which proved a bit tricky.

I finally decided how best to get it off would entail damaging it slightly, I drilled out the 6 spotwelds that are above the line of the front crossmember and gently folded it down so I could get to the spot welds from the dash side as they are different from the crossmember spot welds and then had the dash off in short order.

It is in somewhat rough shape, but it's far better then the dash in the van that has the whole center chopped out. I would rather a more correct dash in the van, but this is what I have heh.

That left me with the bulkhead and the crossmember, I marked out the areas I am going to need to cut for the van to get your thoughts on it John.

I should cut it right to the bottom of it for the van, but that will leave the remaining pieces somewhat flimsy. If I cut them off before removing the crossmember however I should be able to put some sheet back in there if you would like. I'm not sure, so havent cut anything yet.

Oh, and here's that b-pillar.

Chris

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users