Aside from the holes in the floor along the crossmember it could sit back on subframes at this point, however I decided I needed to put it on the back burner for a bit and work on the van some, put it in the little garage and opened a can of (tin) worms when I started digging into it.

in that one picture along I will need inner wings, scuttle panel, inner and outer a panels, door step panel lower rear quarter panel.. etc etc etc.

Previous owners musta had bodging in the blood... they had large unshapely plates randomly welded in over top of the rust in this van, It will be at least shaped correctly and devoid of rust when I am done

Bondosicles anyone?

droops of bondo under the scuttle end does not bode well.

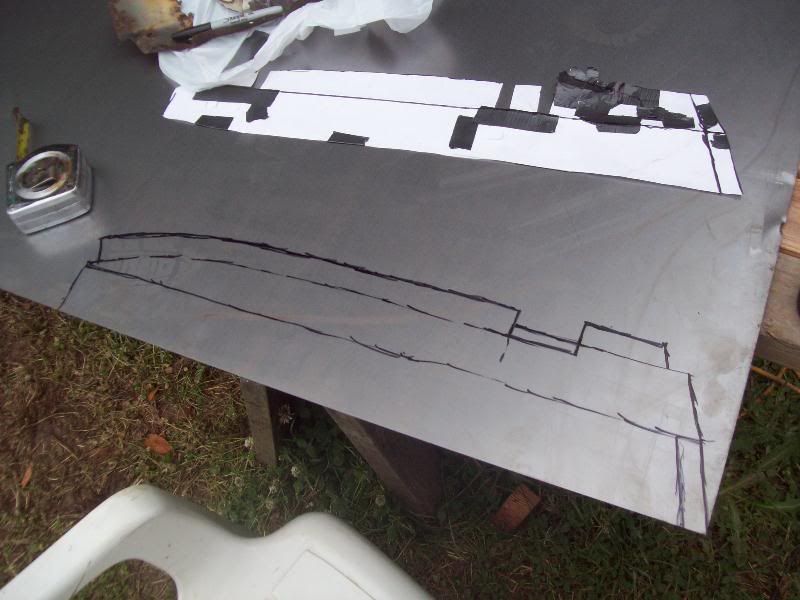

I decided to try my hand at making some panels so started with trying to make a pattern.

Using that pattern I trimmed a 2x6 chunk into the shape and hammered out a panel... of almost 2mm steel.. that was thick... too thick...

and... well there was not enough curve and the steel was so thick it was resisting me trying to increase the curve enough to make it a satisfactory fit.

So I decided to try again, As I have the 850 which has immaculate inner wings, i used it to make up a pattern along with using a piece of copper tubing to copy the existing curve in the doorframe and reshaped my 2x6. I did have a hard time bending the long straight section.. untill it dawned on me to use 2x4's as a makeshift sheet metal brake.

This fit Much better!

including the little joggle at the bottom.

continued...