1960 Morris 850 And Friends

#301

Posted 20 September 2012 - 07:16 AM

#302

Posted 20 September 2012 - 07:19 AM

Chris

#303

Posted 21 September 2012 - 06:12 PM

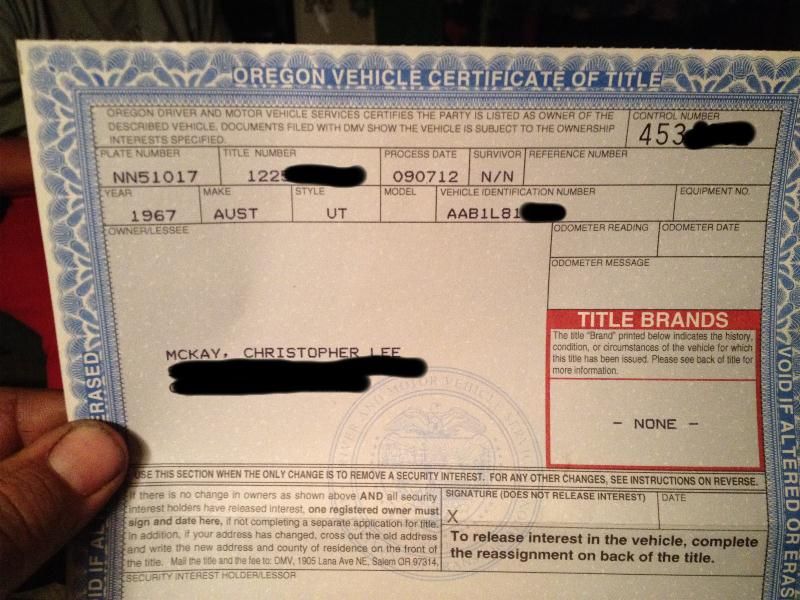

14 days processing with somewhat dubious paperwork must be a record!

Ahem.. Back to the job, a title on a big 4 wheeled rust flake is nothing to celebrate about.

Yesterday It was badly overcast and threatening rain, but I had to work anyways, I need to get my bottom jig done outside of the shop so rush rush rush. Well rush if I wasn't making it all up as I go along. But anyways, I managed to borrow a decent bubble level to help me twist the car back into a semblance of straight. Following the leveling procedure I built up the first part of the rear jig, I am using the badly rusted subframe as part of the jig for this project because the subframe mounts in the body are rather.. erm.. suspect of being not up to the job.

I also leveled and welded a spreader bar to my front subframe jig so it will mount to the jig frame rails, and with the frame rails set into place it looks like it should function nicely.

10 foot long .120 wall 2x4 tube is heavy stuff by the way... in case you didn't know!

Also I discovered more ambiguous construction on my Moke, the pannier outer sills I received appear to have a bend at the end where they lap over the end bulkheads in the pannier. Well only 3 of the 4 connections still exist in this Moke, the battery having eaten the fourth one. And they seem to be assembled somewhat haphazardly one way or the other.

left rear lapped over the bulkhead

left front lapped under the bulkhead

right front lapped over the bulkhead

We don' need no steenkin' Quality Control!

Chris

#304

Posted 22 September 2012 - 03:08 AM

Chris

#305

Posted 22 September 2012 - 07:09 PM

#306

Posted 22 September 2012 - 09:55 PM

Nice to see you around these parts again Hugh :)

Chris the Insane

#307

Posted 24 September 2012 - 12:14 PM

#308

Posted 24 September 2012 - 11:56 PM

Well I have finished the bottom of the frame jig more or less. I don't have the legs on it, but I'm not quite sure what height I want it at so that will come later. I managed to tie in all the points I wanted except for the "front of front subframe" mounts as I questioned their condition. There was a bit of distortion at those points. At this point I just need to flip it over and trailer it into the garage... once I get my 1960 saloon shell out.

Questions comments critiques?

Chris

#309

Posted 25 September 2012 - 08:39 AM

#310

Posted 26 September 2012 - 01:18 AM

Chris

#311

Posted 26 September 2012 - 10:08 PM

That leaves a largish open area to clean out for working on the moke :)

Along with that I got the moke rolled upright which oddly was not all that hard, me and a neighbor just rolled it on over it was not really overly heavy. I am about to drag it up on the trailer so I can move it into the shop (after taking it to the club meeting... tommorow

Chris

#312

Posted 28 September 2012 - 10:22 PM

It appears to have been done from the factory as it has the cable guard that doesnt appear to fit on LHD fittment!?

Chris

#313

Posted 03 October 2012 - 09:07 AM

The one annoyance I see however is that to retain the body number I am going to either have to transfer it to this new panel or split this down the length and weld the two halves together, minor issue.

Once I had the Moke off of the trailer I finished stripping all of the lights off of the back and went to pull the last of the interior bits out. Who was it that chose these huge number 4 philips head screws for the Moke? I could just... just... have strong words in their general direction! I have one in the right hand drive pedal box mount location that absolutely refuses to budge.

Also it seems a previous owner replaced the brake master cylinder some time back and used a bolt with two nuts in place of the clevis pin, that was a pain to unbolt.

Apparently there was some issues with the engine steady...

Well, I was worried it would be difficult to remove the engine steady... it wasn't... but... Houston, We have a problem!

Chris

#314

Posted 08 October 2012 - 05:48 AM

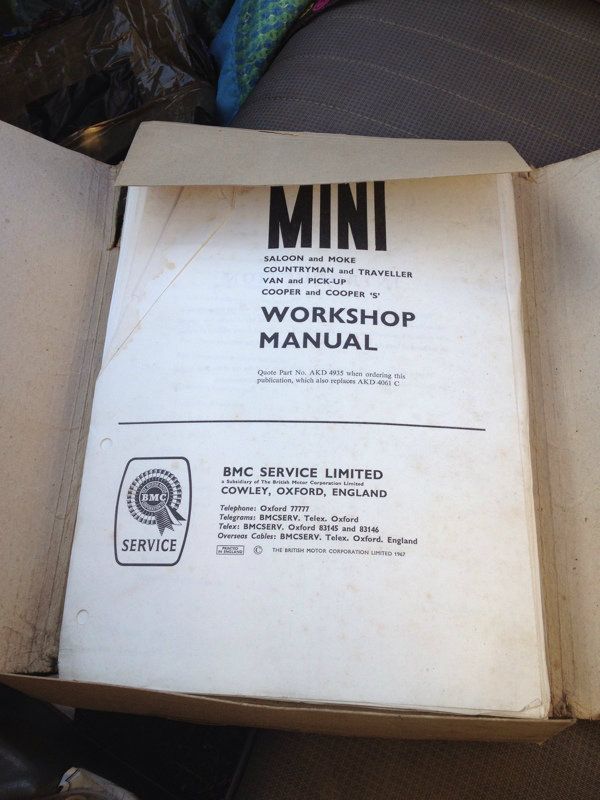

I also got this last week, but photobucket was having issues so couldn't show it. I purchased a NOS workshop manual in original box to replace my water damaged original pages for £4.99 plus not much shipping. I am afraid to take it out of the box now!

Once I got the shelf up and a bunch of stuff moved onto it I was able to drag the Moke off of the trailer and set to work on it, I had to pull the last of the loom out and the pedal box out. I swear whoever decided to fill this thing with #4 philips head screws..... But I won in the end, vice grips trump shoddy striptastic screws!

As it is I have been working for the past several days to get the inner jig built, it is probably 3/4 or 2/3 done at this point, but it is looking ok :)

There are more pics in my photobucket I just didnt want to flood you all with pics. I am hoping to be done with this inner jig shortly so I can actually pull the shell off and start fitting panels together, I can't wait!

I am however on the fence about picking up the new welder I have my eye on, the prospect of being able to "not have to grind down thousands of plug welds" is very appealing. That and I have several projects to use it on. I have some good first hand reviews on it from family friends. What do you think? I plan to not use it to make two welds at once, but to reach around funky shaped structures making one weld at a time.

http://lencoautomotive.com/index.php?q=product&p=l-4000

Chris

#315

Posted 10 October 2012 - 06:00 AM

Chris

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users