Well, I slept till noon today and then did some cleaning on the sailboat my father wants to sell. I need to do some more tomorrow, and I am not a fan of the selling of it we shall see.

A funny story about the sailboat happened today. It has been sitting in the same place for maybe 3 years with the mast up on a stand on top of it, I climbed up in the sailboat to clean out the interior and call my dad to talk to him, as soon as I hang up there is an ungodly crash. When I go outside to investigate, the mast is no longer laying on the deck of the boat... It had fallen to the ground... right over my car! Luckily the forward end of it was tied to the pulpit so it didnt end up laying on my car... But still, many years it sat there happily, we live 250 miles from it, the day I go in to clean it up and call to talk to dad... it falls off right as I hang up. Nice coincidence! Scary though!

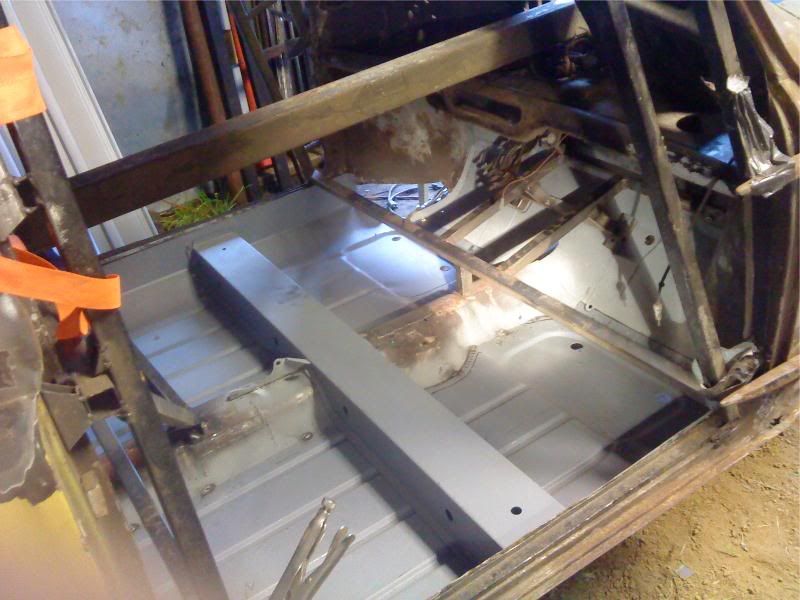

I have some more pics of the doner shell I took today, it's really not all that bad considering what they had it listed as. The boot floor, what remains, virtually has no rust in it.

The a panels are gone but that's not too bad, it would need scuttle ends as well.

The inner wings are for the most part intact, even the face level vents have no rust around them..

the inner wing appears to have been crumpled before and straightened quite well actually as the front end (aside from the rust) Looks quite good.

I do think I am just going to repair the rust on the front end and use it intact on the van, repairing it should be a sight easier then building that rear door I did

It is a shame really, it's really not that bad. It would be fairly straight forward to repair everything but the holes in the roof, and I dont think that would be too bad to do either. It is in far better shape then the van... but the van is still rarer then a mk4 saloon shell... which you still can get from BMH new.

Oh, and look what I got in my Festivapickupdeliveryvancar!

Mmm 1100 goodness(hopefully ;) ) I need to split it from the transmission and return the transmission to John, but that's not a problem (knock on wood)

Chris