More welding practice this weekend. Behold my gallery of little bits of metal!

For the sake of comparison, this was about the standard I was at last week (ie. crap):

This weekend's mission was to work out how to do a decent butt weld. This was my process... (Experts, please feel free to critique. I'm all ears!)

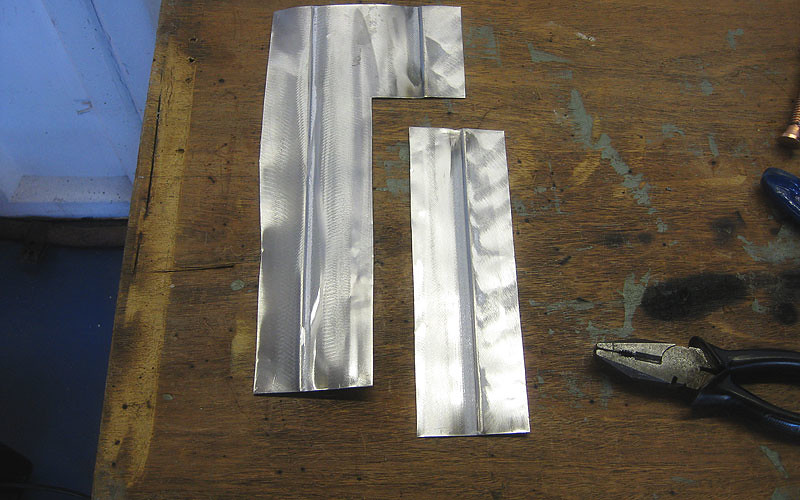

I was trying to join these two pieces of 0.9mm steel...

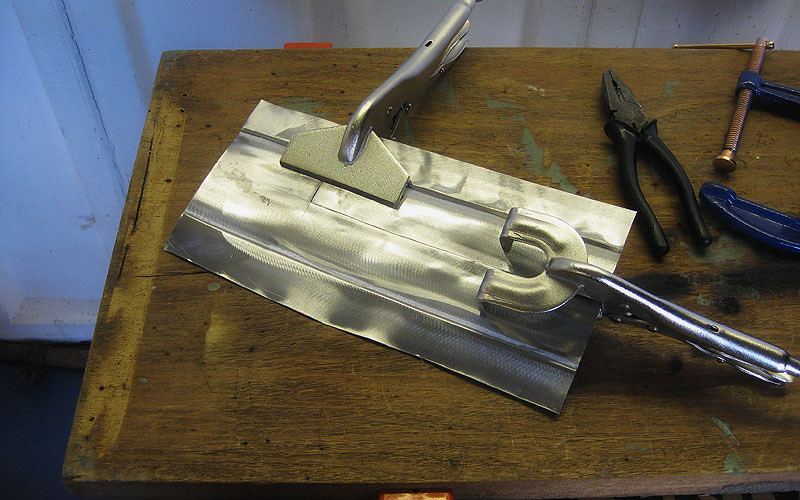

Clamped up as closely as possible.

Tack welds in place.

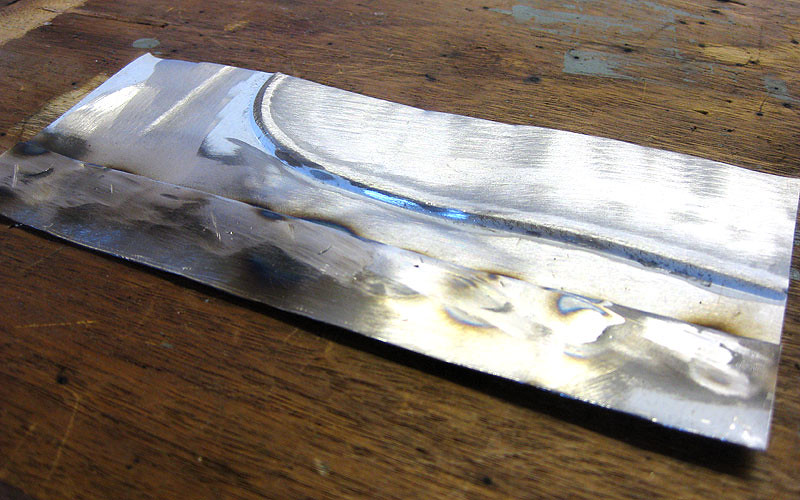

Stitch welded, jumping from one area to another to avoid heat build up. Still blew a few holes, and the metal got really distorted in the process.

Ground down the welds on the reverse around the holes and taped on copper coins, so that I could fill the holes

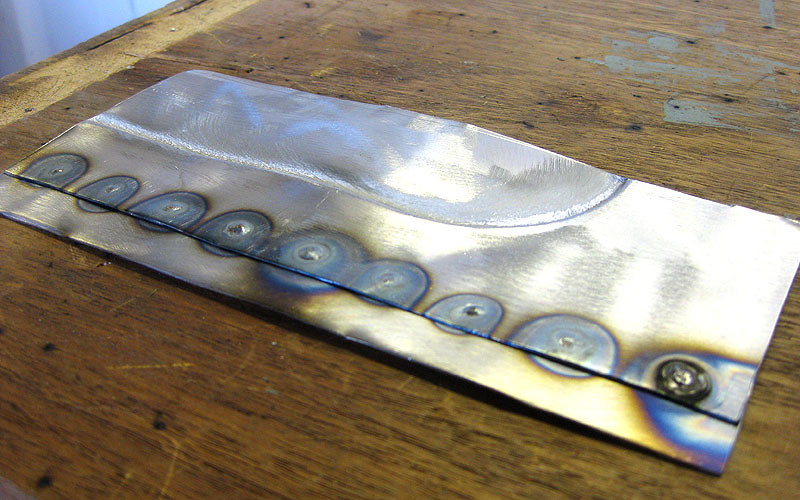

All welded up and dressed down.

So am I doing this right? I still don't understand how using intergrips are supposed to be used. Whenever there is the slightest gap between the join, I immediately blow holes. Can anyone shed any light?

I'm finding plug welding much more straight forward...

(front)

(back)

So now I should really start ordering a few panels! There's a newark autojumble next weekend, so I might see what I can find there.I really regret not buying a pair of really cheap rust-free doors I saw last time!

Hi.

Got the same welder as you. Just in the process of going through the practicing welding stage myself now

Would you be able to let me know what settings you had the welder on and wire speeds for the different welds you have there? I'm only using the bottle of Co2 they supply with the welder at the moment, but may look at getting a BOC subscription when I know it will be worth my while because I will be able to produce a decent weld.

Many thanks

Howard