minimuk: I'm trying my best!

madboy: believe it or not, the rabbit lives in the house and lives a life of luxury, so there is no chance of any arc eye :)

grahama: Cheers - yeah its already been invaluable!

minifcd: thanks for the tip. In the end I just went for it and cut a hole as neatly as possible. :)

hughJ: Cheers!

Finished building the spit and got the car off the ground. Whoop! Surprisingly, the shell isn't that heavy and I managed to lift it into place by myself.

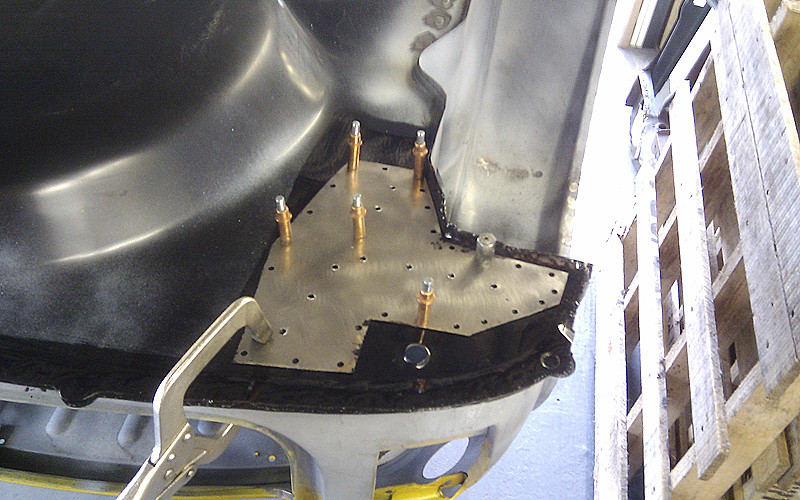

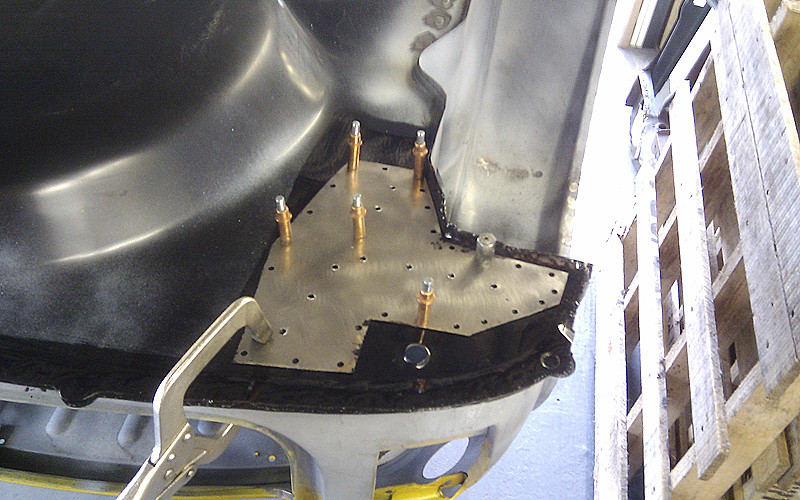

With the car upside down, I finished all the little jobs on the boot floor that I couldn't reach before. Lots of little holes were welded shut, and old welds from the inside were tidied up. As I went for the budget option boot floor skin panel, (as opposed to boot floor complete) my boot floor is missing the reinforcing plates where the subframe is bolted in. Oh dear.

I looked at a few other projects on the mini forum to find out roughly what shape they should be. This area on my car had entirely disintegrated so I had no idea what they should look like. Then I made some card templates and cut the bits out of steel. While I was at it, I knocked up a rear valance closing panel, copying the one pattern panel I already had.

Welding my home made floor reinforcements in place...

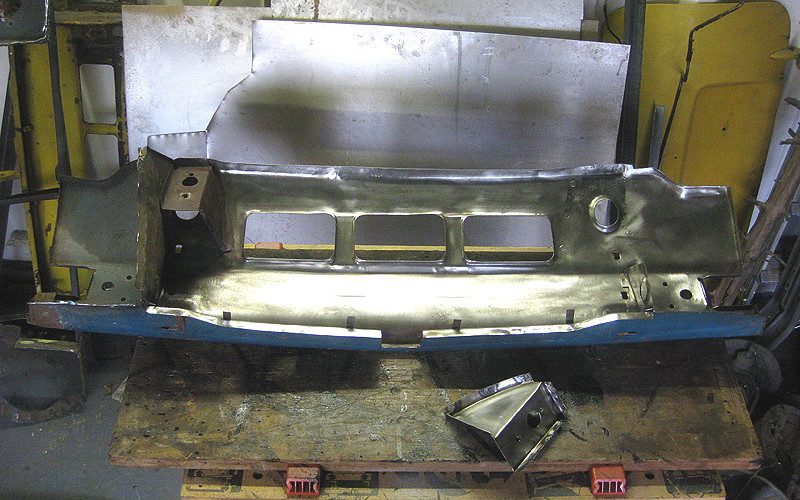

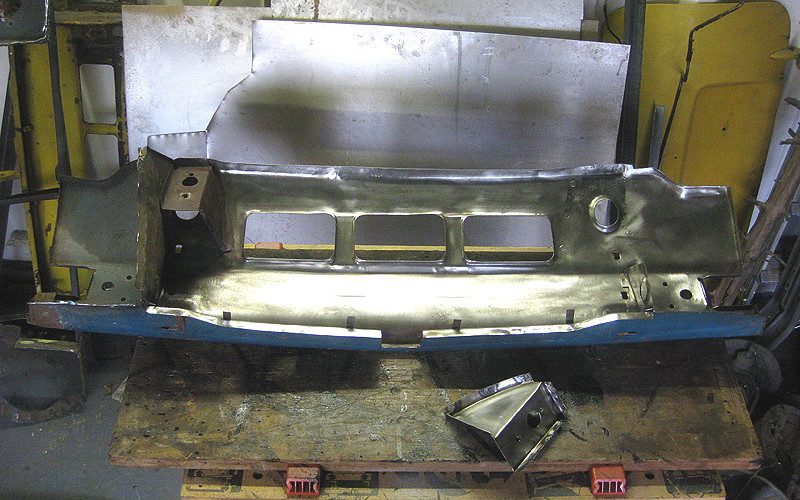

I decided it would be easier to build up the rear valance while it was off the car, and then fit the whole thing in one go. As usual, all boxed in bits received liberal POR 15. Do people usually leave drainage holes in the valance corners, or weld the whole thing up so no water can get in at all?

I dug the rear subframe out of storage to check the fitting against the floor reinforcements and the new valance. Everything looks SWEEEET!

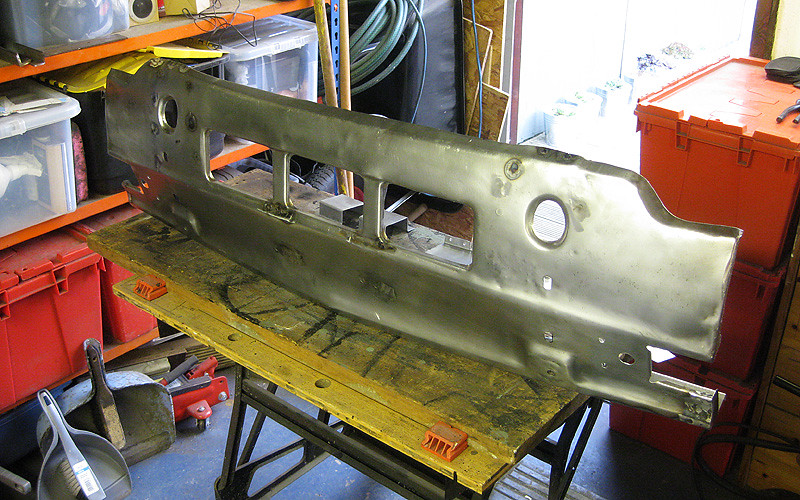

In the meantime, I had scooped this bargain from the TMF classifieds...

Its not exactly in ideal nick, but its a massive improvement on the panel I removed from my car, and its a massive saving over buying a new clubman front panel complete.

I started by separating the lower panel and the slam as these are the only bits worth keeping, and new light surrounds are cheap as chips. Then I set about stripping back to bare metal. It will take some work, but I think (hope) I can restore it to a decent standard.