1979 Rust Heap Clubman Rebuild

#181

Posted 07 January 2012 - 06:20 PM

danny

#182

Posted 07 January 2012 - 08:37 PM

#183

Posted 07 January 2012 - 08:41 PM

#184

Posted 07 January 2012 - 09:48 PM

#185

Posted 05 February 2012 - 08:26 PM

Can't believe I didn't do it earlier, but I finally realised there were discounts to be had with a TMF+ membership. Instantly got my money back in minispares discount on these two bad boys.

Genuine quarter panel and not-so-genuine door step. I added the door step to the shopping list after staring at the B post for a while trying to work out the best plan of attack. It finally dawned on me that I would need to sort the doorstep before even thinking about putting a new quarter panel on. Also, the doorsteps I had sourced previously weren't going to cut it because the rust extends into the curved bits. DOH.

Prior to surgery:

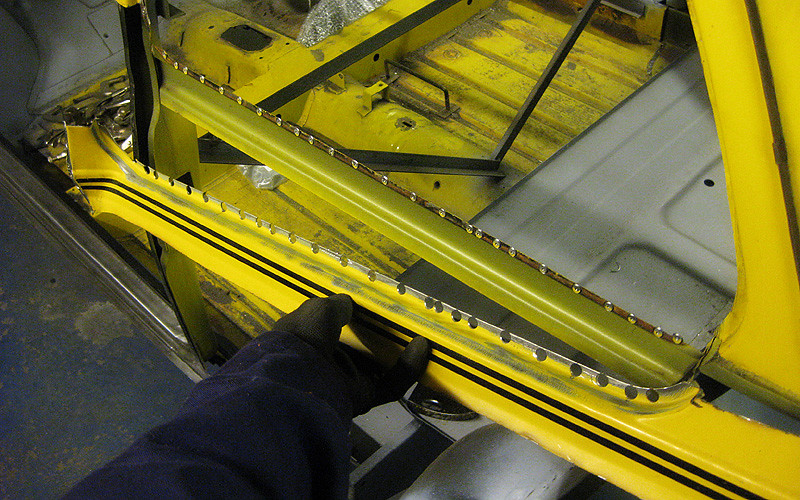

Since the inner sill is mostly rot, I welded in a quick brace to hold it straight while I removed the old door step. The brace will be removed when I replace the inner sill, but the door frame will be much more rigid by then. One hopes, anyway.

Old door step gets chop. Yuk.

Stripped the e-coat off the new door step and trimmed it to size. It took a lot of fettling to get the correct curvature in the corners. Looks messy at this stage, but everything is in the right place.

I did a quick test fit of the door to make sure everything was OK, and when I was happy, I seam welded the joints.

Annoyingly, the curvature into the A post turned out to be a bit thin from rust on the inside. Ho hum. Better to find out now rather than later I guess. I started to cut out the affected area, but it was getting well cold by this point so I called it a day. Hate leaving bits like this unfinished, so hopefully I'll be able to get it sorted during the week.

#186

Posted 06 February 2012 - 07:44 AM

You're braver than me in this weather.. mine has been locked in its garage, untouched since November!

#187

Posted 06 February 2012 - 09:25 PM

#188

Posted 06 February 2012 - 09:47 PM

Hugh

#189

Posted 07 February 2012 - 11:45 AM

#190

Posted 07 February 2012 - 01:21 PM

Paul.

#191

Posted 12 February 2012 - 09:33 PM

#192

Posted 12 February 2012 - 10:36 PM

#193

Posted 25 February 2012 - 06:23 PM

After much delicate grinding, I got those welds from the previous update cleaned up a bit. Not exactly concors smooth yet, but the best I can do with the tools I've got at the moment. There are a lot of welds on the car I'd like to revisit with an air grinder at some point. Anyway, a pass with filler might be enough to sort this area out.

On with the quarter panel fitting! I drilled out the spot welds on the remains of the old panel. The inside of the waist rail turned out to be in OK nick.

Wasn't too happy with the state of the seam lip on the lower rear panel so decided the chop was in order.

New metal in:

Before putting the new quarter panel on, I did the usual routine of stripping and double coating all enclosed surfaces with POR15. I've also got the little filler panel clamped in place here. I'm planning to fit the companion bins at a later stage because I've got to replace the inner sills first, so I am leaving a little gap between this panel and the edge of the rear squab. Hopefully I can slot the companion bin into place when the time comes.

I'm not sure if there should be a jacking point in here somewhere that I am missing... I'll have to do some research. Unfortunately the old metal that I cut out of this area was so rotten it was impossible to tell exactly what was in there originally.

Also prepared the enclosed parts of the quarter panel with POR15.

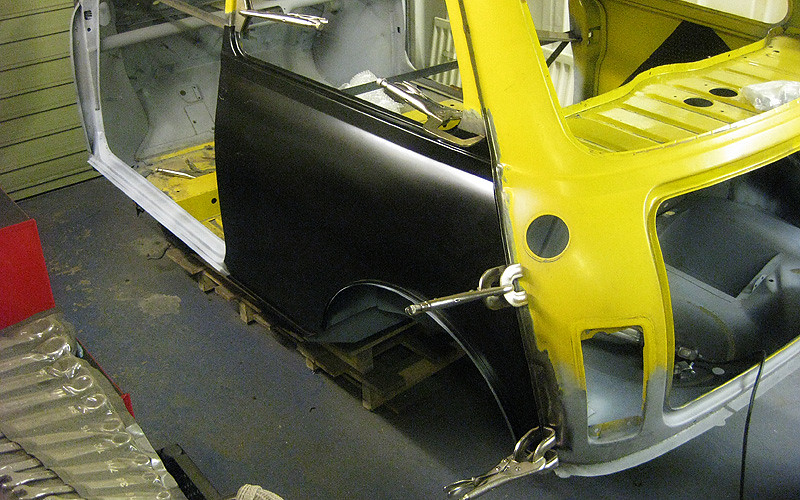

Test fitting - not bad! Hopefully I'll get this properly welded on this weekend or next (depending on what I do about that jacking point).

As I haven't posted a photo of the whole car for a while, this is how things are looking at the moment. Rock and indeed Roll. :)

#194

Posted 25 February 2012 - 08:20 PM

Have a look at minifcd's build thread as he has just done one.

#195

Posted 25 February 2012 - 10:23 PM

Hugh

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users