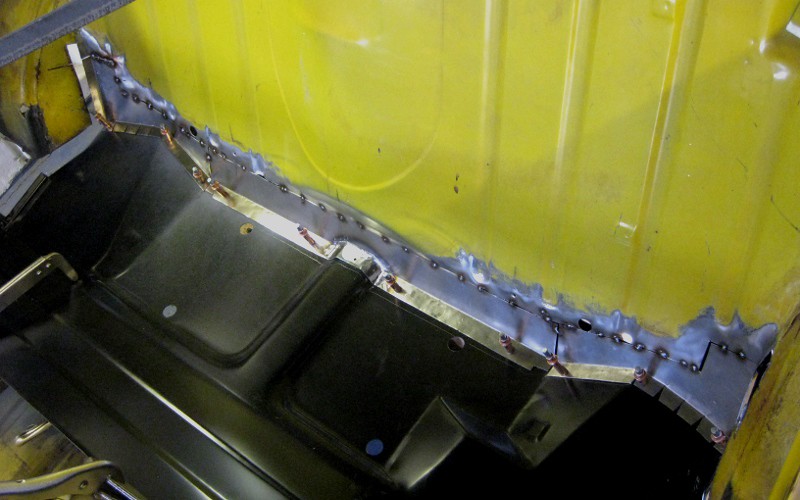

Just a quick update as I spent ages this weekend on the tedious and awkward job of welding in the heel board. After many hours of faff, I'm confident that its on and solid. A bigger C clamp would have made the job 10 times easier. Note to self: invest in correct tools for the job next time, moron.

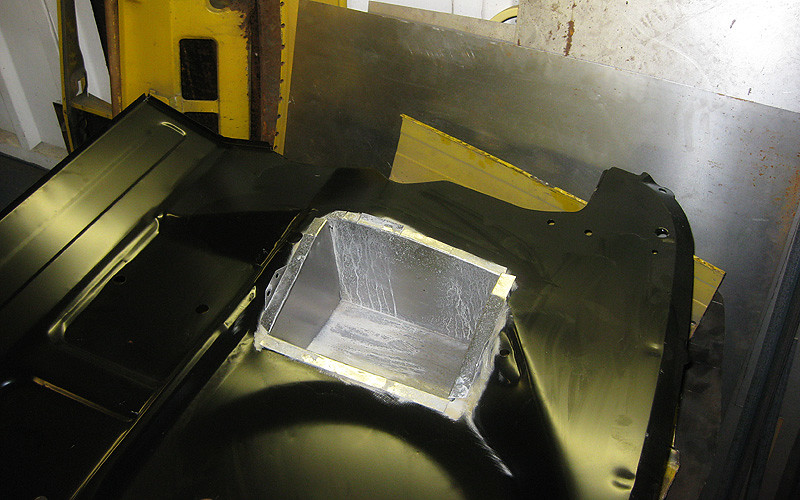

I also put a bit more work into my home-made battery box. Its coming together quite well, but will still need a bit of fiddling to fit into the annoyingly curvy boot floor panel. The white stuff is POR15 metal ready as I'm going to paint the flaps before welding it all together (just to be super thorough).

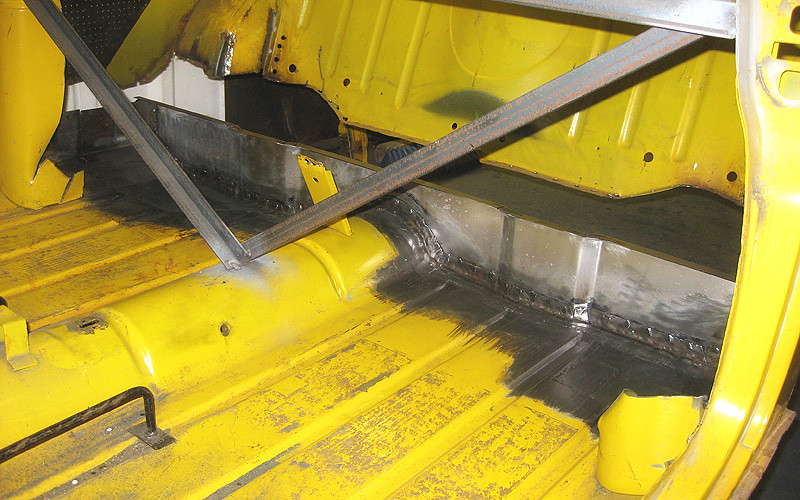

I tried a quick test fitting of the boot floor and it looks good. Did an excited little dance in the garage to celebrate. Its almost starting to look like this car might return to

being in one piece eventually!