Wide Ratio Gearbox And 1380 Engine Build

#391

Posted 21 May 2012 - 01:48 PM

#392

Posted 11 June 2012 - 08:36 AM

#393

Posted 01 August 2012 - 09:49 PM

And I fitted a set of Hallogen headlights that have been lying around the cave for six months..I wired them through 2 relays for lights and High beam..using the existing loom connections as switch wires to the relay coils..main feed taken from the battery feed through a 30amp in line fuse.

Cant make my mind up about the grills though...what do you think? should I keep them or bin them?

#394

Posted 01 August 2012 - 10:08 PM

Bob

#395

Posted 18 September 2012 - 04:56 PM

Im changing the final drive to 3.76 next month after the Final club run of the year. So thought it would be wise to slip in a cross pin diff at the same time!!

#396

Posted 20 September 2012 - 08:51 PM

I have built up the final drive on my new diff..First I needed to strip an old diff in order to get the output shaft out. The diff bearings come apart easy enough, and then I used the pullers to get the inner race off..

next was to undo the six crown wheel bolts. then a smalll tap with a rubber mallet and its apart..

This is the bit I was after..

So all the bits go in the parts washer for a good clean.

And here is the new crown wheel waiting to go on..

64 divided by 17 = a final drive ratio of 3.76

New fiber washer on the ouput shaft, has been soaked in oil for a while.

And then all bolted to the cross pin diff...Job done!!

And if anyone fancys a 3.1 final drive...PM me!!

#397

Posted 16 February 2013 - 03:32 PM

Its ok boy!! it wont hurt...Open wide!!!

All out!! Was easy..all the bolts had been copper greased when they were fitted, so they flew out!!

The subby was pretty clean...not bad after a year or so in the car, oil leakage and brake fluid leak didnt help, But here it is ready to go the the shot blasters!!

Tonight I took the rear wheels and radius arms off haggis, its still pretty clean under here..

Not going to remove the rear subframe, just give everything a good claean and bolt stuff back on..

These are the shiny bits that arrived this week...Hope to be back on the road by next weekend!!

#398

Posted 16 February 2013 - 03:52 PM

#399

Posted 16 February 2013 - 04:02 PM

#400

Posted 16 February 2013 - 10:04 PM

Thankyou..I love coming to your bit of the world ..Who knew ther were 2 Inverness's...yours is a bit warmer then ours though!! which part of the sunshine state are you in?Great posts and pictures as always, Andy!

#401

Posted 17 February 2013 - 12:10 AM

Thankyou..I love coming to your bit of the world ..Who knew ther were 2 Inverness's...yours is a bit warmer then ours though!! which part of the sunshine state are you in?

Great posts and pictures as always, Andy!

I am located on the eastern side in Merritt Island by the Space Center. Never been to either of the Inverness's.....

#402

Posted 17 February 2013 - 02:21 PM

#403

Posted 18 February 2013 - 02:00 PM

#404

Posted 05 March 2013 - 09:39 AM

Got a bit more done last week. Front hubs all painted and regreased the bearings.

Rear radius arms fitted..

The front subfram came back from Powder coating so got that fitted with solid mounts.

Calipers were blue and now they are red!!

I think Im going to have to raise the ride height a smidge though!! lol.

And the reason I did bugger all on the car this weekend!!

#405

Posted 05 March 2013 - 07:06 PM

Calipers on!!

So that all the runing gear sorted and the front subby all completed with either brand new parts or refurbished bits.

I then fitted some stuff made from Green..

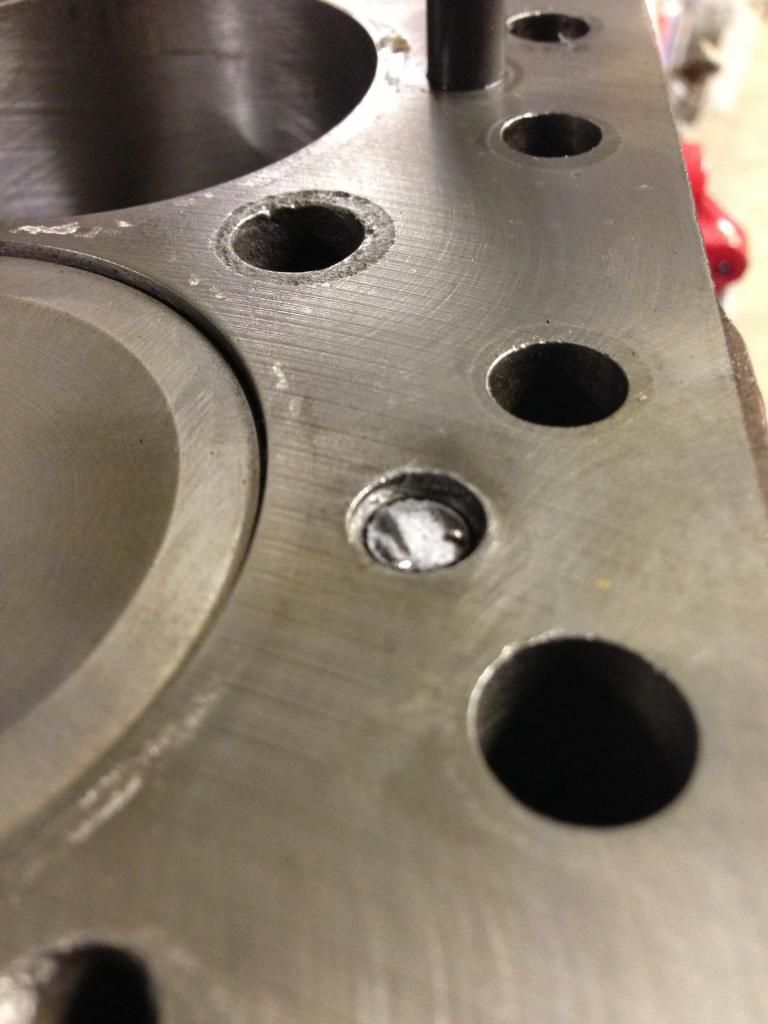

And decided it would be best to get the cylinder head fitted onto the engine...so first was to give it a quick wipe!!

Checked all the valves wrer seated correctly and nothing was damaged..

A final clean of the bores and it was on with the new bk450 and the head..

But then disaster struck in a big way..

I snapped this stud clean off as I was torquing everything down to 68nm, Oh feck!! So once I had stopped swearing and belting stuff with a hammer...I drilled the stud to a depth of 3mm..screwed in a selt tapper and welded it on.

Slowly I unscrewed it..the weld was holding!!

At last it was out!! what a horrible job!!

So after that episode I quickly fitted a new stud and got the head fitted..

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users