Thank you for all your kind words and constructive comments.

The state of play now is there is some mods needed now the engines back in the car, but nothing I can't sort out.

I'm going to run th engine in the state of tune it was before I took the engine out. Run it in for 500 miles, then fit the Megajolt system, run this for 100ish miles, then fit the new head and charger etc, drive it around the block, then onto a trailer to Slark Engineering for them to do the final adjustments - better be safe than sorry...

Very nice work Graham,

I have just posted a thread up asking if anyone has done it all themselves and appears you have done the lot. Do you work in food industry as I recognise those dairy elbowsThat's given me a some great ideas. I don't have an AC tig set but may end up getting one now looking at that alloy work.

Was the supercharger an Eaton M45?

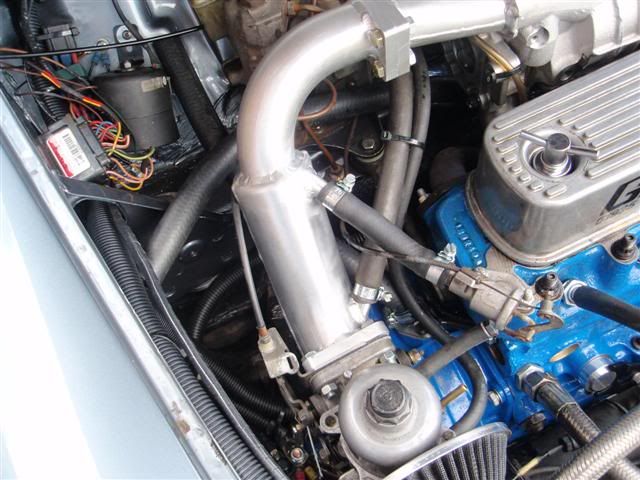

Good eye sight, yes they are elbows from the food industry, I bought a few, thinking I may makes some inlet manifold's at some point if the demand was there. All welds are purged. Everything you see is made in my garage.

I work for an aerospace company in the life support division.

Yes the supercharger is an Easton M45 with black rotors

Thanks for the reply. That may be the route i go then and will also purge the welds to give a nice smooth interior. I like the idea of roughing the inside walls also as a polished surface leads to allsorts of turbulance and inefficiency.