Recommended Welding Clamps For Body Repairs

#1

Posted 04 February 2010 - 11:09 PM

-Floor pans

-Outer sills (possible inners aswell)

-Heel board (where rear subframe mounts to)

-Each corner of the scuttle

- Whole front end including flitch panels,

-Rear valance

-Door steps

-Arches

Using that info, what clamps would be suitable for tackling each job? Thanks in advance Ian.

#2

Posted 05 February 2010 - 08:27 PM

Hi guys, in need of advice and guidance on what welding clamps you would recommend for welding various panels, first off I guess knowing what panels need welding would help you out, so the list as follows...

-Floor pans

-Outer sills (possible inners aswell)

-Heel board (where rear subframe mounts to)

-Each corner of the scuttle

- Whole front end including flitch panels,

-Rear valance

-Door steps

-Arches

Using that info, what clamps would be suitable for tackling each job? Thanks in advance Ian.

Try these for door steps - http://cgi.ebay.co.u...c#ht_786wt_1165

Try these for arches - http://cgi.ebay.co.u...1#ht_874wt_1165

Try these for floor pans flitch panels, scuttle - http://www.frost.co....o...(pack of 5)

The vice grips come in various sizes from tiny upto very large, i use the on valance panels, inner outer sills, door steps.

The skin pins i use on most things as they are very versatile (cleco pins are all metal and as such do not melt but you will need the special pliers that go with them)

The intergrips are ideal for flitch panels, floor panels as they only need a small gap to be used.

I f you have a look under complete mini rebuilds for Project Erm you will see where i have used most of the above tools/clamps.

There are other products out there but these are what i have to hand and fill all my requirements.

Hope this helps

#3

Posted 05 February 2010 - 08:53 PM

#4

Posted 05 February 2010 - 09:56 PM

Top man! Appreciate your reply, I'll definitely have a wee goose at your project, those intergrips look very handy. Would I be correct in saying the rivet pins are just like removable rivets, so after the welding is complete you simply weld over the small holes created by the rivet pins?

Yes just weld them up though they are not rivet pins as such just temporary clamps. If you are thinking about purchasing some then i would recommend yellow 1/8th and blue 5/32 but as i mentioned the nylon pads will melt so it may pay you to use the Clecos in the same sizes just remember to buy the pliers as well. These will not melt.

The other thing to remember about the skin pins is that as well as coming in different sizes that come in different grip ranges. If i remember tomorrow i'll take a photo to show you what i mean. It basically means the thickness of metal they will grip.

#5

Posted 06 February 2010 - 08:55 AM

For my seams on rear arches and boot floor, ive used small G-clamps and vicegrips.Thinking of purchasing some cleeco clips when i get frount to the front end.

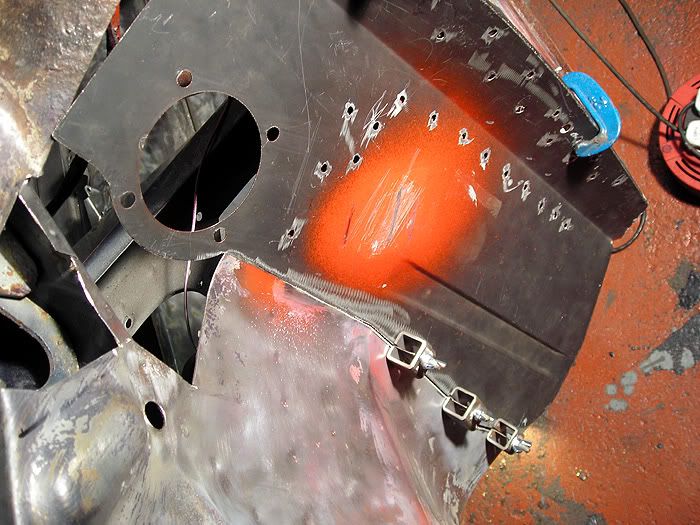

a couple of photos showing the intergrips in use

#6

Posted 06 February 2010 - 11:42 AM

If you look at the right yellow skin pin you can see where i have melted the nylon base, not the end of the world as it is still useable.

Pins in use.

I use the longer grip range ones through thicker skins or multiples of skins.

Neil

#7

Posted 11 February 2010 - 04:35 PM

Should give you an idea of the size of 'C' clamps that i use.

Neil

#8

Posted 11 February 2010 - 05:29 PM

#9

Posted 11 February 2010 - 07:35 PM

Out of interested how do those intergrips work? i mean once you have welded the panel in place how do you remove them?

Basically they are a flat thin piece of steel with a round pin through it, the flat plate goes between the items to weld, the round pin is installed and by doing up the butterfly nut the round pin is pulled up and clamps the material in place using the pin on one side and the frame of the intergrip on the other.

To release undo the butterfly nut and remove the pin and its as simple as that. I should add that you do need to get access to the pin so you cannot use the intergrips in an enclosed area.

Hope that explains it for you.

Neil

Edited by sonikk4, 11 February 2010 - 07:38 PM.

#10

Posted 11 February 2010 - 07:37 PM

The pins you need a special tool to remove them but they can be used into box sections and the like as you don't have to get behind to remove them.

JR

#11

Posted 14 February 2010 - 05:00 PM

#12

Posted 16 February 2010 - 11:52 PM

#14

Posted 17 February 2010 - 06:57 AM

There seems to be quite a few available brands of clamps to choose from, anyone have any preferences, I was thinking on getting a couple of the Clarke sets. anybody have experience using them? Thanks for all your replies been interesting reading.

mine are called "vice grip" made in the us and are great quality i would highly recommend them as i have mine for over 10 years and they are still as good as the day i bought them and i use them professionally

here are the ones i use

i would suggest you get the type in the link or similar with the release handle not lying on the bottom arm as most f the cheaper ones do as they can be easily released when you are using them, whereas the ones i have don't come undone whilst you are using them only when you press the release lever making them much better for your knuckles

michael

Edited by kez_19, 17 February 2010 - 07:02 AM.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users