welded on the strenghtener panel

lots of penetration inside

tacked on the other half of the valance

there was an awfull fit in the middle so i had to section it a few time to try and cut down on the filler that will be used, still will be quite alot tho

decided to fill this hole

panel made and welded in

ground down and primed that section of the valance

thats all for today as lots of things happend after this, first i discoverved i have ran out of cutting and grinding disks, then my grinder bearing broke when i fitted my wire wheel, then my welding helmet didnt auto tint so now have a headache and to top it all the wire on the welder was getting stuck at the tip and i have no idea where the spares are!

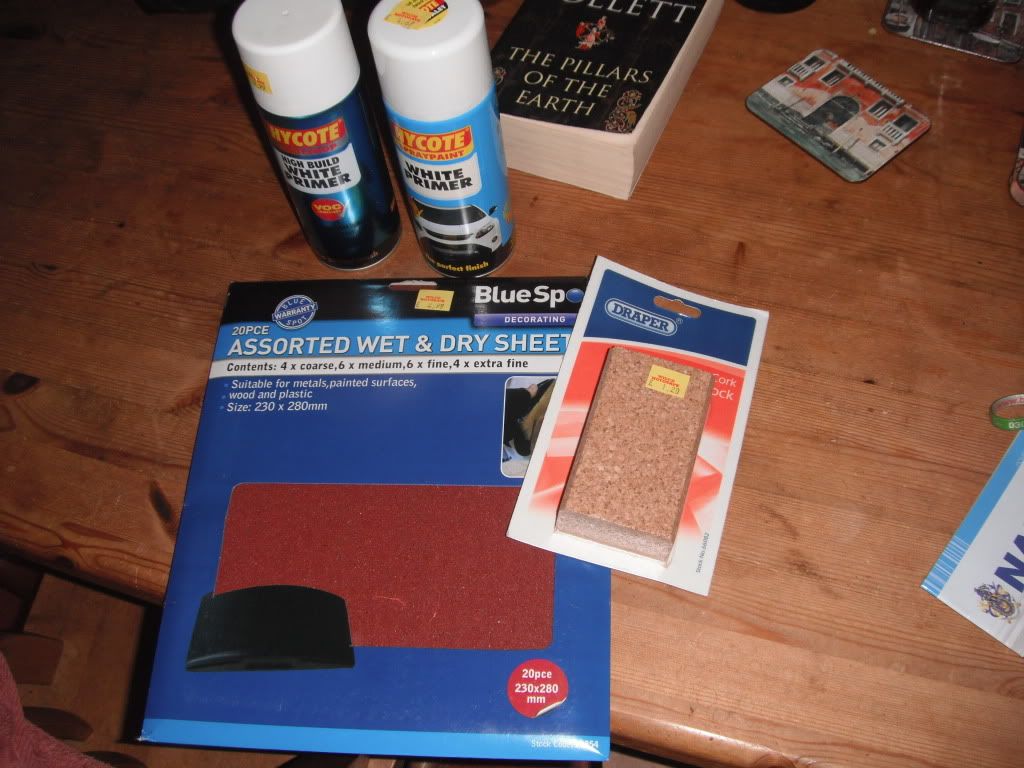

so possibly no more updates till friday (pay day) unless i find my welding tips

hope you like todays though

Lawrence