Ken -The 1275 High Compression Engine Micra Mini (Running Project)

#76

Posted 13 October 2011 - 09:40 PM

#77

Posted 15 October 2011 - 06:01 PM

so then, havent written up my update from the other day yet so here it is

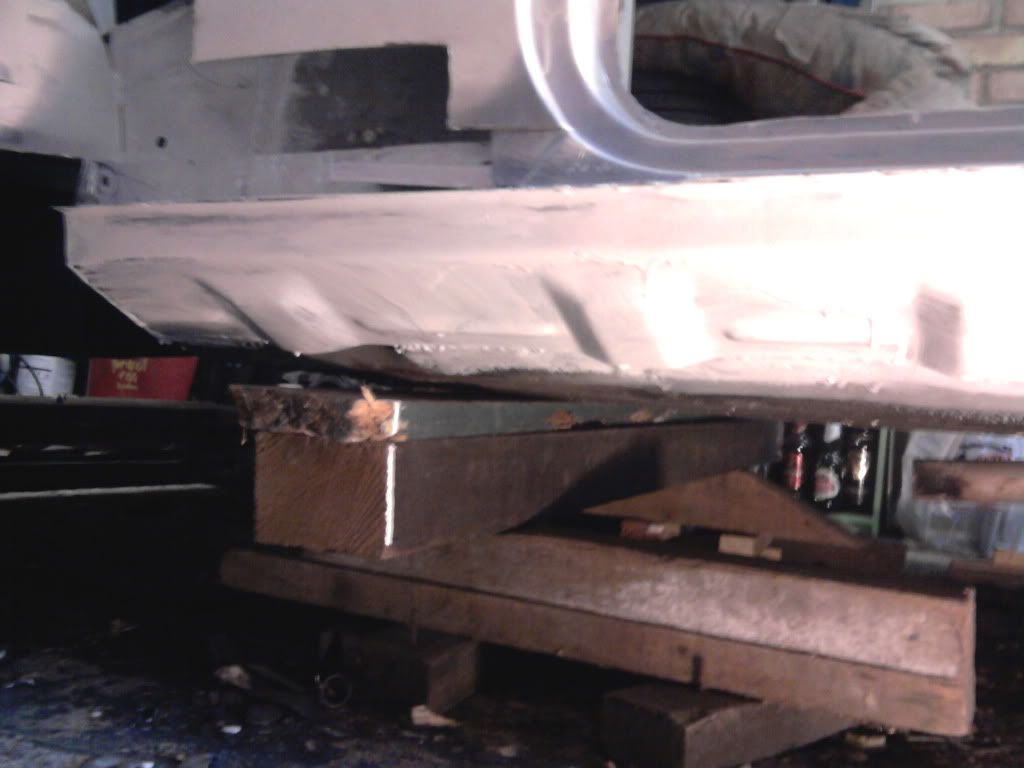

clamped the sill on

plug welded along the doorstep and im glat that i did the work for the lip as this sill was so much easier to do than the other side

seam welds at either end

and seam welded at the floor

made a slight mistake of forgetting this!

so welded it on the inside with alot of strength

ground down the welds and wire brushed off the burnt paint areas

and finnaly prepped and resprayed the doorstep

needs a little touch up on the floor but that side is just about done otherwise

im now moving on to start the boot and rear valance

hope the update is liked

Lawrence

#78

Posted 16 October 2011 - 11:07 AM

first update from today is paint

floor done

sills done

rear bin done,

so all nice and solid here!

moving onto the boot now!

#79

Posted 16 October 2011 - 01:08 PM

made a start on the rear subframe mount strengthener panels

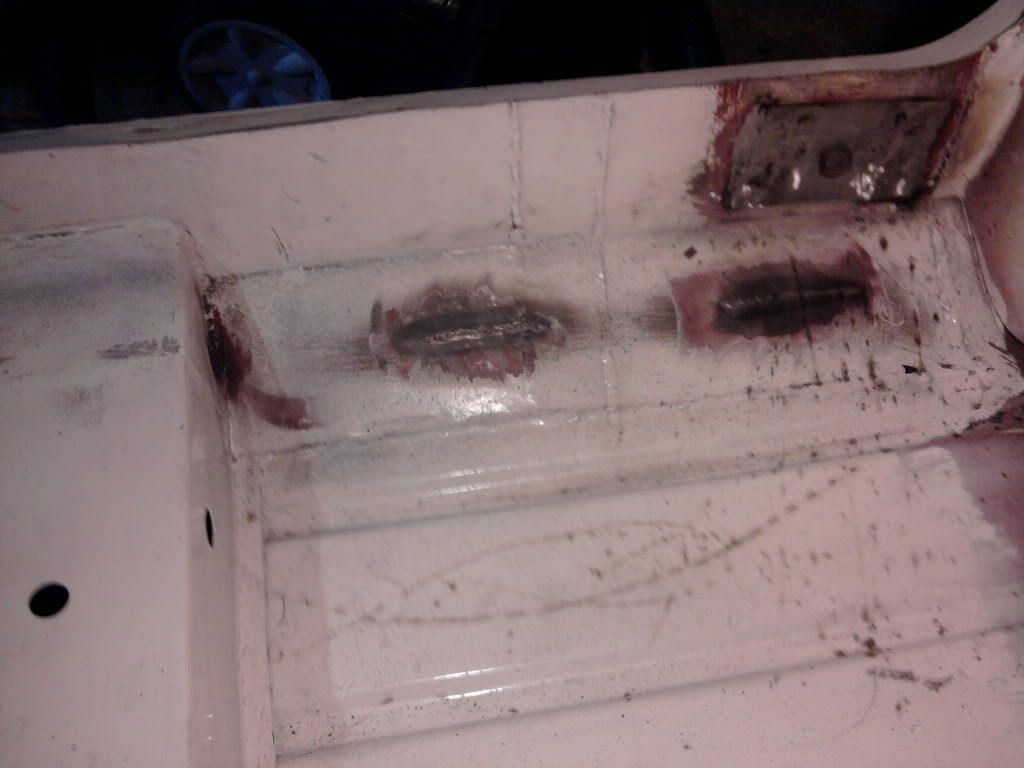

drivers side started out like this

now i thought that i had trimmed back to the end of the rust but i was wrong

so i had to remove the rest of the metal which took me ages

the other side is alot better so shouldt take long

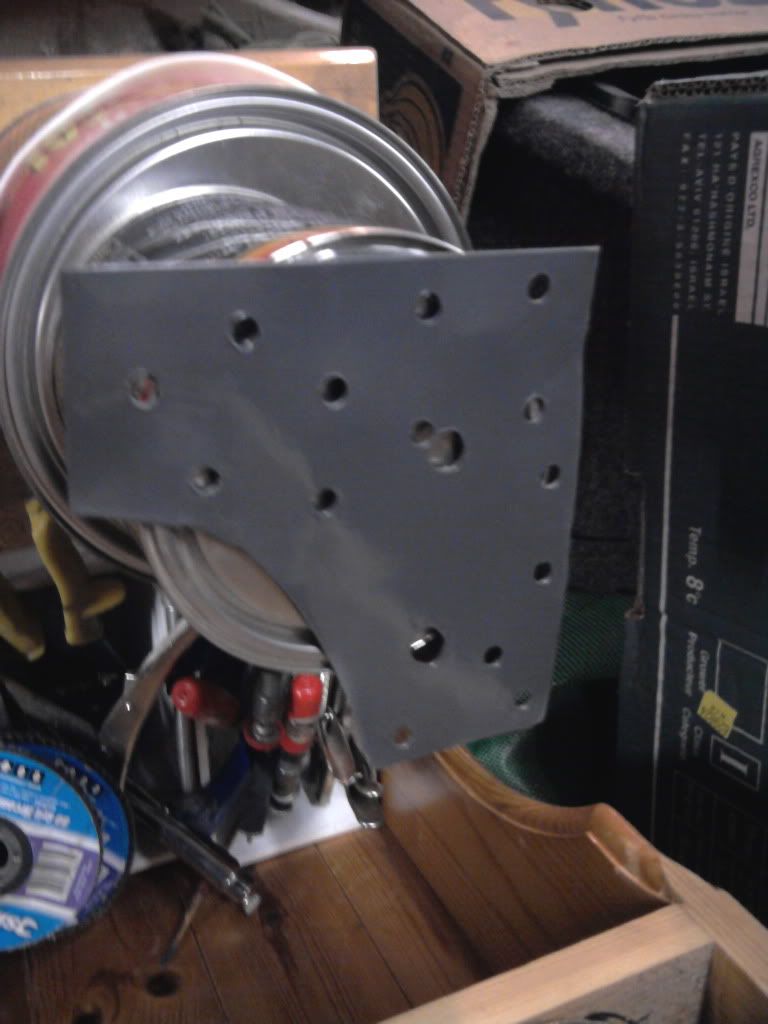

strengthener plates made

bacon break now and then another update later

Lawrence

#80

Posted 18 October 2011 - 02:14 PM

so then, my internets was playing up yeaterday so this is two days of updates

zinc primered the strengthener plate

zinc primered where it goes

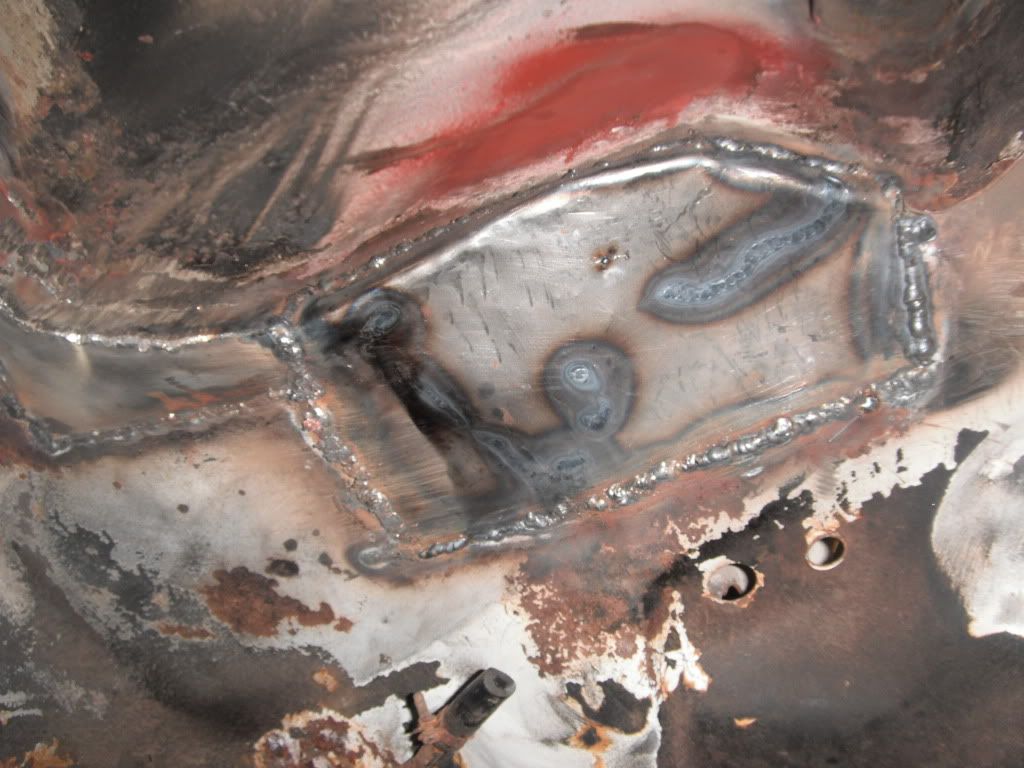

plug welded on and seam welded round the edges for strength, my welding updside down is getting better

lots of nice penertration inside

now moving onto the back panel

there was a crack in the light mount and i went to weld it up but it was lovely and crusty and kept blowing thourugh. this area was covered in filler so i assume before i got the car she had had a shunt

crusty area cut out

tricky panel made

welded in

ground down, doesnt look to bad and but is alot stronger than before

moving onto the corner bit

crusty section cut out

panel made and partly welded in

and ground down and primed

next piece made, the bottom of the light was a bit crusty so i decided to add a few patches to make a stronger job

held in

tacked in

and ground down with the next patch held in

next patch welded in, it is also ground down but no pics im afraid

inside corner of boot is now all painted too

due to my rear valance being a pattern part ive had to cut it in half to get a good fit

so my plan of action is to make a closing panel for the drivers side and fit the drivers half of the valance

then ill be turning the old girl round to do the other side easier!

hope you like, comments are always nice!

Lawrence

Edited by lawrence, 18 October 2011 - 02:15 PM.

#81

Posted 19 October 2011 - 02:54 PM

zinc primered the strengthener plate

zinc primered where it goes

plug welded on and seam welded round the edges for strength, my welding updside down is getting better

lots of nice penetration inside

now moving onto the back panel

there was a crack in the light mount and i went to weld it up but it was lovely and crusty and kept blowing thourugh. this area was covered in filler so i assume before i got the car she had had a shunt

crusty area cut out

tricky panel made

welded in

ground down, doesnt look to bad and but is alot stronger than before

moving onto the corner bit

crusty section cut out

panel made and partly welded in

and ground down and primed

next piece made, the bottom of the light was a bit crusty so i decided to add a few patches to make a stronger job

held in

tacked in

and ground down with the next patch held in

next patch welded in, it is also ground down but no other pics im afraid

inside corner of boot is now all painted too

due to my rear valance being a pattern part ive had to cut it in half to get a good fit

so my plan of action is to make a closing panel for the drivers side and fit the drivers half of the valance

then ill be turning the old girl round to do the other side easier!

hope you like, comments are always nice!

Lawrence

#82

Posted 19 October 2011 - 07:27 PM

went shoppinh for gas and got a heater too! and a light

this is how it ended yesterday

valance been trimmed and getting tacked in place

small problem with the fit!

welded some more

and problem solved

Fully welded on

starting to make my closing panel

tacked in

partly welded

full welded

painted

hope you like this update

more tommorow

lawrence

#83

Posted 20 October 2011 - 06:50 PM

crispy plate that i had removed a few weeks ago

very little work to do in this corner compared with the other side

hole at the back that needs patching

hole at the back of the boot extends to the rear seat base

Area cleaned up and trimmed ready for panels

all the holes on the rear seat clened up ready for welding up

welded up

panel made up for hole and held in

tacked in

fully welded

ground down

second part of the hole prepped for patch making tommorow

hope you all like this update, feel free to comment

Lawrence

#84

Posted 20 October 2011 - 06:52 PM

#85

Posted 20 October 2011 - 08:02 PM

#86

Posted 20 October 2011 - 08:21 PM

#87

Posted 21 October 2011 - 06:34 PM

anyhow update from today

found my fuel tank bracket after a while of looking, was all prepped to be welding which is a nice surprise

sited it

welded, ground down and primed

started making the panel for one of the last holes

finished making it, took absolutely ages. no wonder garages slap patches over stuff! its so much quicker!

tacked in and partly welded

fully welded

found a new hole while giving the boot floor a wire brush

cut out

welded a little patch

then cleaned up where the subfame strengthener plate goes and zinc primed it

and zinc primed the panel ready for welding

hope you like todays update. its nice to have a solid floor again!

next update probably this sunday as im a bit busy tommorow

Lawrence

Edited by lawrence, 21 October 2011 - 06:36 PM.

#88

Posted 21 October 2011 - 07:20 PM

Hugh

#89

Posted 22 October 2011 - 05:27 PM

Graham

#90

Posted 23 October 2011 - 10:05 AM

if i go out i will

>prime and paint the patch and area i did the other day

>clean up the passengers side heelboard and as its still not completely welded and then prime and paint.

>paint the majority of the boot floor including both arches ready for undersealing once the paints dry

>prep the bumper lip ready for the second half of the valance to be put on

>possibly weld on the valance and closer if i have time before work at 4

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users