Edited by minimuk, 16 August 2011 - 06:20 PM.

Ken -The 1275 High Compression Engine Micra Mini (Running Project)

#61

Posted 16 August 2011 - 06:19 PM

#62

Posted 16 August 2011 - 08:34 PM

#63

Posted 17 August 2011 - 06:28 PM

I decided that i wasnt going to fit the front end untill i had finished off the heelboard end and sill, however i did fettle it somewhat to try and improve the fit, ill post pictues when i get around to fitting it.

So i started out with clearing rust and making some patches for the heelboard instead

this is how it ended up one the rust was cut out

i then made a cardboard template

however i was finding it difficult to make the shape in metal fit so i halved it

first half welded in and red oxided

Second half welded in and red oxided

whilst waiting for the paint to dry i moved on to filling the holes in the wheel arches

holes welded, ground down and primed, looks so much better now

i then got bored with the heelboard repair so started on the door

rust bubbles all along the bottom and a bad filler repair done by me

cut back part of the skin to see what the door panel is like under the skin and its not good

so on that anlagy i decided to remove the entire skin

on cleaning it up it only need a slight repair on the bottom

Thats all for today. Small chance of an update tommorow morning but highly unlikely

Lawrence

#64

Posted 04 September 2011 - 09:33 AM

#65

Posted 06 October 2011 - 09:40 PM

1st i finished off by the bonnet pin location so it look the same as the otherside, also ground down slight rust by the scuttle

2nd i cracked on with the wiring as it had yet to be finished from last time

i bought a fusebox from the internet and have attached most systems to it

i have also finally finished my new steering wheel stalk wiring, which went extremely well. i have now got the option to fit an intermittent wiper and a rear wiper as well as not needing to reach to the centre console to turn on the lights

3rdly i removed the servo and clutch to clean up the bulkhead,ground back the rust and gave it a good coat of hammerite, picture doesnt show much but its loads better than before

4th i bought a panel beating set to help me fit the front end and it has been very usefull so far

5th fitted the sump guard on brackets welded to the subframe for easy removal

6th improved the fit of the flitch panel. the panel had to be sectioned to improve the door panel gaps

7th After alot of fettling of my pattern panels i have finally made them fit in a reasonable way, so prepped the a panel

and welded it on

8th prepped the wing for welding on

gaps for the wing which i think are pretty good

and finally welded

so there we are, now up to date

hope you like this very late update

next few tasks are

1>section part of the front panel by the headlight to make it fit better

2>prime and seam seal wing

3>undercoat wing and a panel

then i need to order some rustoleum and move on to driver side sill

1>finish drivers side heelboard end

2>paint sill with rustoloeum

3>fit drivers side sill

Lawrence

#66

Posted 06 October 2011 - 10:18 PM

#67

Posted 10 October 2011 - 06:08 PM

my origonal to do list was

1>section part of the front panel by the headlight to make it fit better

before

during

after (a much better fit)

2>prime and seam seal wing

partly done, just under the wing left to do

3>undercoat wing and a panel

seam sealing will be finished tommorow and then ill paint it all in rustoluem

4>finish drivers side heelboard end

still to start

5>paint sill with rustoloeum

inner is now done as well as the floor, enclosed area still to be done (rustoluem is a great paint!!)

6>fit drivers side sill

doorstep prepped to be ready to welded in, including the drilling for plug welds

more work happening tommorow as i have most of the day off

hope you like

Lawrence

#68

Posted 10 October 2011 - 06:54 PM

How have you put the rustoleum on and how has it settled, shiny or matish??

Graham

#69

Posted 11 October 2011 - 09:13 AM

the rustoleum i put on just like it said on the tin, rub down with a wire brush, below it is a mix of red oxide and zinc primer and it seems to cover red oxide very well, i used a soft paintbrush to try and keep it smooth and its dried shiny. hope this helps

today will be a rolling update day as ive brought my laptop to the garage

tasks are

1> cut and weld doorstep panel

2>prep rest of doorstep lip for plug welding

3>rub down and paint sill inner box section and sill

4>finish sealing and painting drivers side wing and a panel

Lawrence

#70

Posted 11 October 2011 - 10:44 AM

grotty doorstep removed ready for shiny new one

partly welded in

fully welded in

and ground down

now onto the front wing

#71

Posted 11 October 2011 - 12:19 PM

added a run of welds to the scuttle join to try and prevent paint cracking later on in the seam

finished welding the front panel to the wing

just got a small dent to fill on the scuttle then i will seam seal and prime it

seam sealed the font wing

time for a monster bacon sandwich to get my strength back

hope you like

Lawrence

#72

Posted 11 October 2011 - 02:33 PM

wing all painted in my new best friend rustoleum, seems a shame to slap a load of underseal over this shinnyness now! ive sealed round the headlight ring to try and prevent rust

inner sill also painted up so looking proper mint

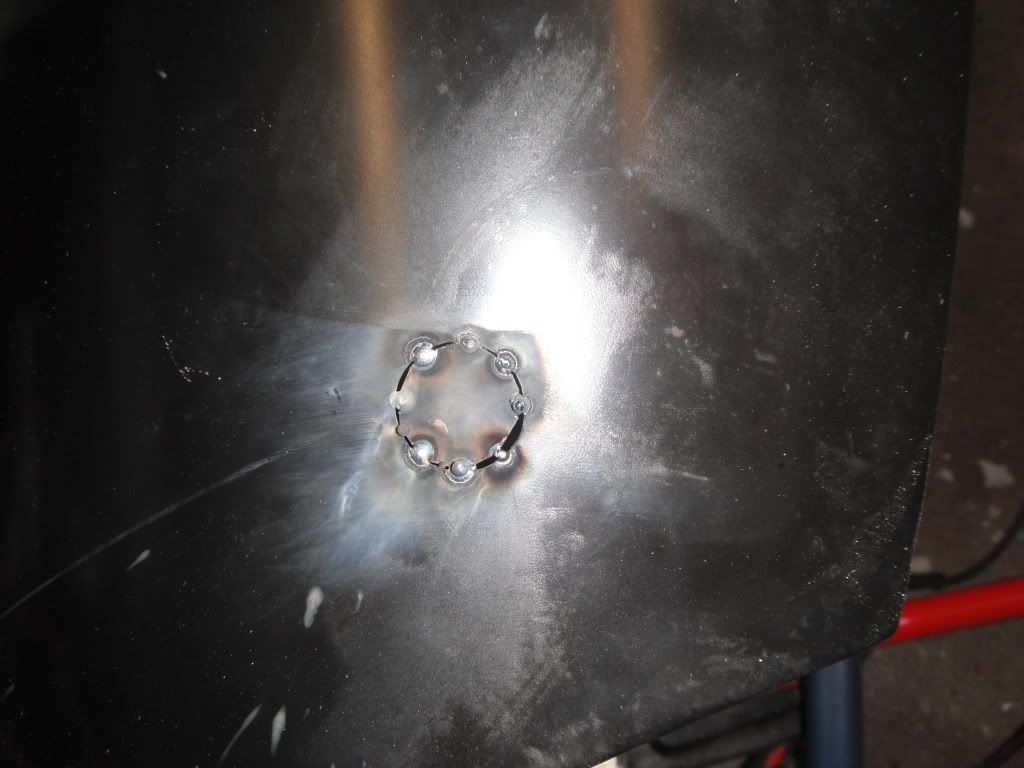

hole being filled for arial

metal disk made

tacked

ground down,will need a slight skim of filler but not alot

lastly outer sill painted

tommorows work will be

1>finish prepping the doorstep for the new sill

2>fit the rear subframe so i can line up the last subframe mount

3>weld in rear subframe mount

4>fit drivers side sill

thats all for today folks

hope you like

Lawrence

#73

Posted 11 October 2011 - 04:42 PM

#74

Posted 11 October 2011 - 09:01 PM

more updates tommorow

#75

Posted 12 October 2011 - 02:14 PM

my tasks today were

1>finish prepping the doorstep for the new sill, this is now finished , i decided i would cut part of the rear quater panel off as it was a bit crusty

2>fit the rear subframe so i can line up and weld in the last subframe mount

i zinc primed the subrame mount panel and trimmed it to fit

fitted the rear subframe and lined up where to weld the panel in

welded it in

made the sill strenghtener panel and will weld this in once the sill is on

4>fit drivers side sill

i havent completed this all yet, howver may finish it after work at 8. what i have done is

clamped it on to check the fit which is good

i have also then removed it and zinc primed where i am plug welding through

next few tasks will be:

1>clean up underside of the boot floor

2>weld reinforcement patches the rear subframe mounts that are on the boot

3>cut out and weld 2 small patches on the passengers side of the boot floor

4>paint whole of boot floor with grey rustoleum

5>make 2 closing panels for the rear valance but in this style http://www.somerford...roducts_id=1217 this is to try and prevent a rust trap

5>Weld on rear valance

6>fill the debumpered rear seam and then prime

hope you like todays update, sorry about the poor photo quality but my cameras being borrowed

Lawrence

3 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users

-

Bing (2)