Cheers Lawson, she might work one day!

So then, update time

Last time the engine was running and the issues were

>Oil leak + no alternator charging

Ive skipped the alternator problem for now mainly because I can get her mot’d and up and running and then deal with that. Everything on my car is LED bar the indicators and my overall running battery draw is low.

But there's a starting problem. On the bench my starter is fine. On the engine, my starter is fine off jump leads and a spare battery.

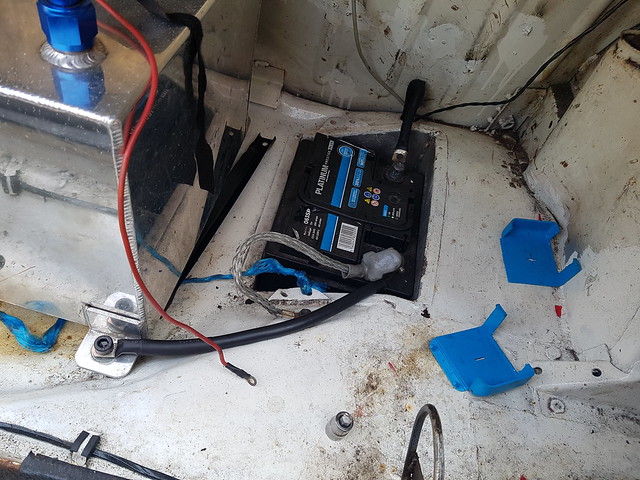

But the current power cable just isn’t man enough. I did voltage drop test and its not dropping voltage it just doesn’t have the capacity to crank the new high compression engine fast enough to start. I also cant cleanly solder a connection on to it due to being very thin copper coated steel wire. Car starts fine off the current battery using jump leads in series to act as the main battery cable.

So ive purchased some 170amp battery cable that’s purely copper so I can solder some connections on it at the starter.

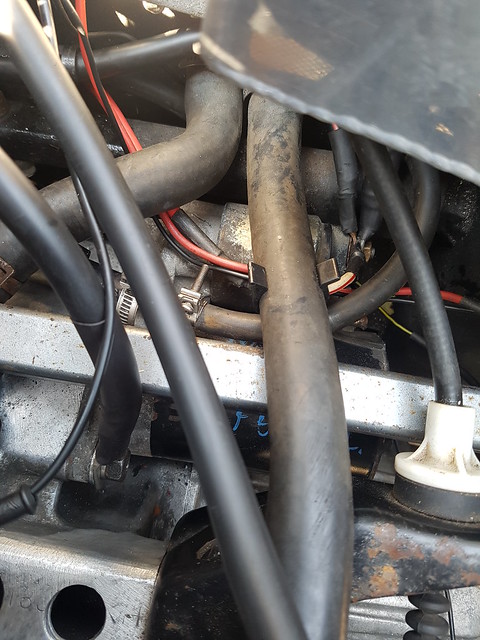

Photo showing rubbish quality and corrosion

20180714_143132 by Lawrence Balls, on Flickr

20180714_143132 by Lawrence Balls, on Flickr

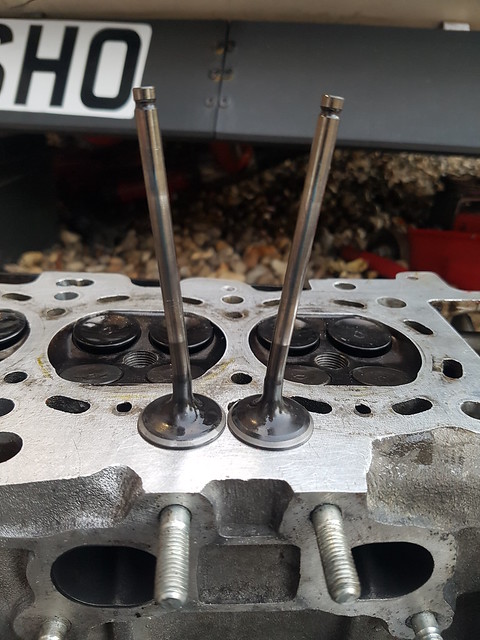

>Then I had an engine problem

The ceramic on the spark plug cracked. Heard a weird popping noise when she was running for her to then drop to running on 3

20180714_154322 by Lawrence Balls, on Flickr

20180714_154322 by Lawrence Balls, on Flickr

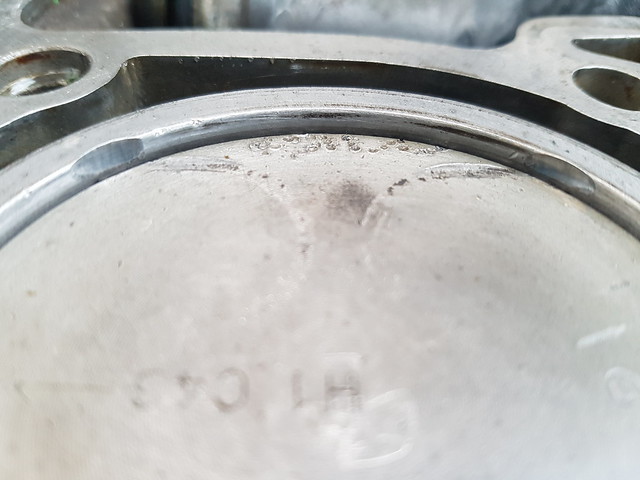

The bit of ceramic then bounced about until it closed the electrode off on the plug. I used my endoscope and spotted it in the cylinder.

So I put a spare plug in hoping the bit of ceramic would bounce out the exhaust. Well the flipping thing didn’t, it smushed another plug. Tried one more time and heard a lovely tinkling noise as it left the cylinder and made its way down the exhaust. When I took the exhaust off. I found it, went to take a photo, kicked the mat I put it on and it flew away into the gravel. Shame.

But least it was out.

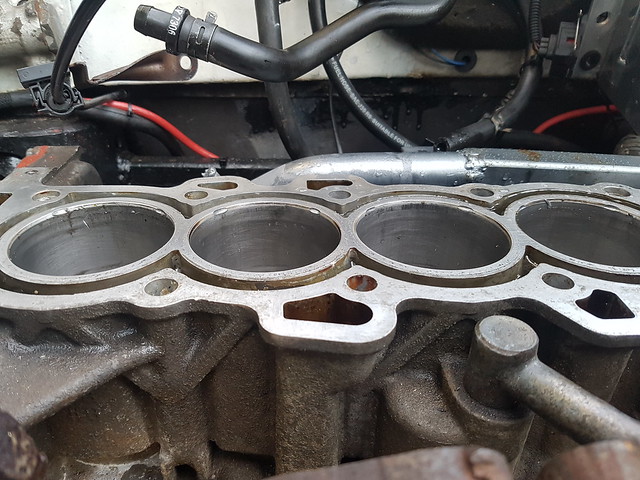

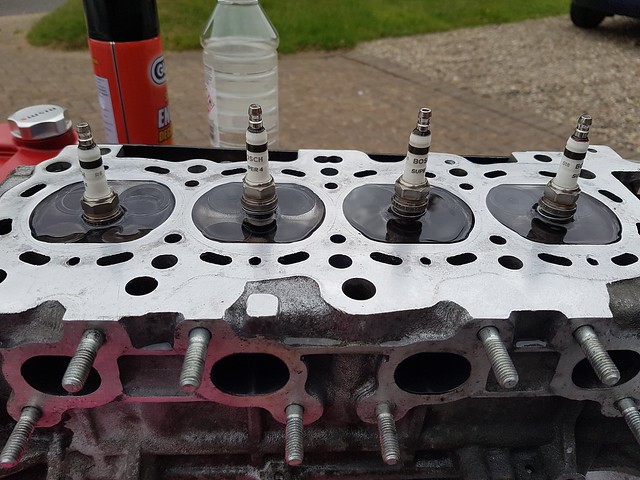

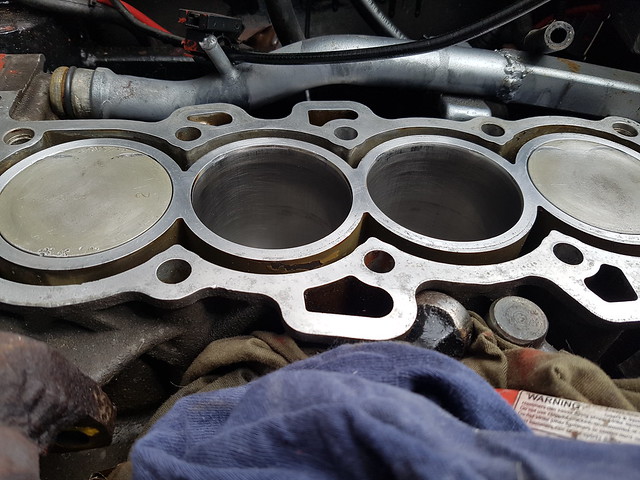

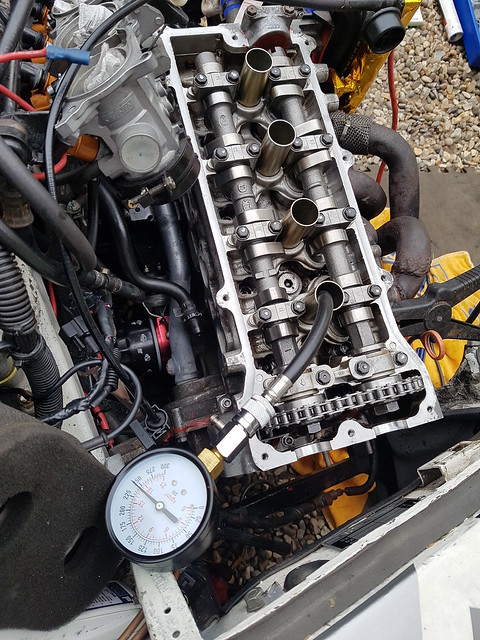

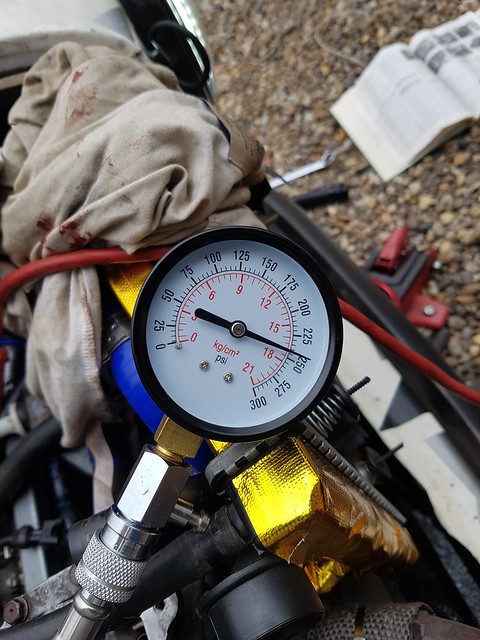

Pressure checked cylinder

No change. They are all about 225ish.

20180714_154640 by Lawrence Balls, on Flickr

20180714_154640 by Lawrence Balls, on Flickr

put down the scope and bar a few marks on the piston crown it looks ok. No scratched bores etc.

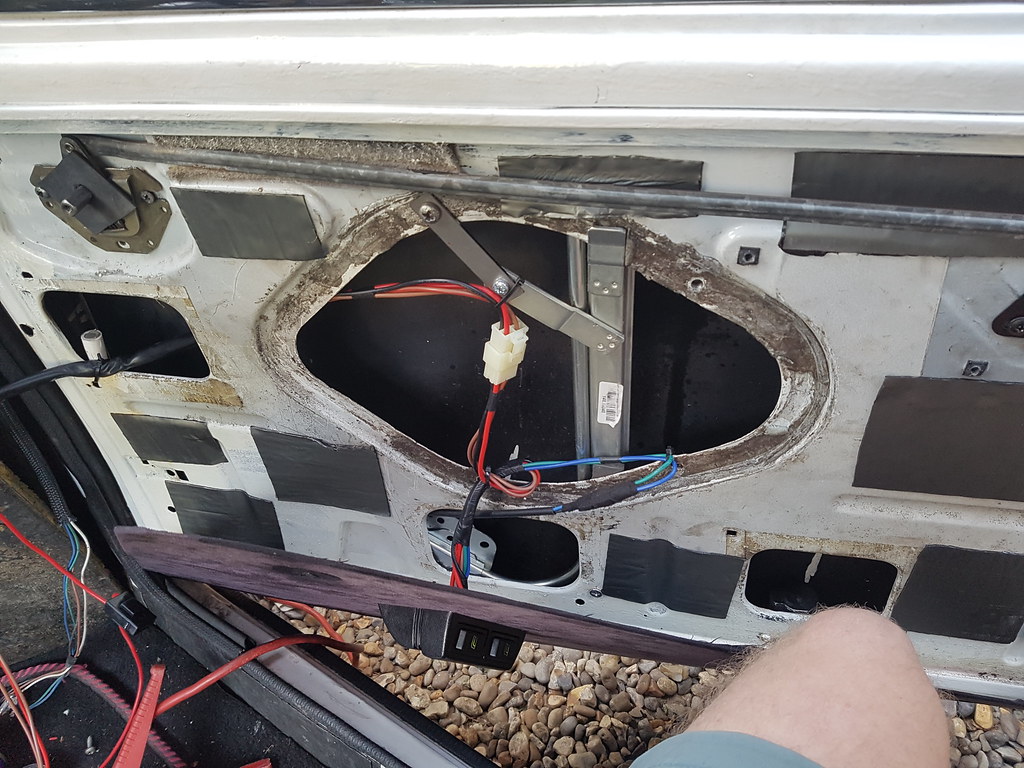

did a bit of wiring- fan was running the wrong way. Also wired it to a switch in the cabin for now.

20180717_163723 by Lawrence Balls, on Flickr

20180717_163723 by Lawrence Balls, on Flickr

Squirt has an output for the fan but my coolent numbers etc are all wrong.

So today

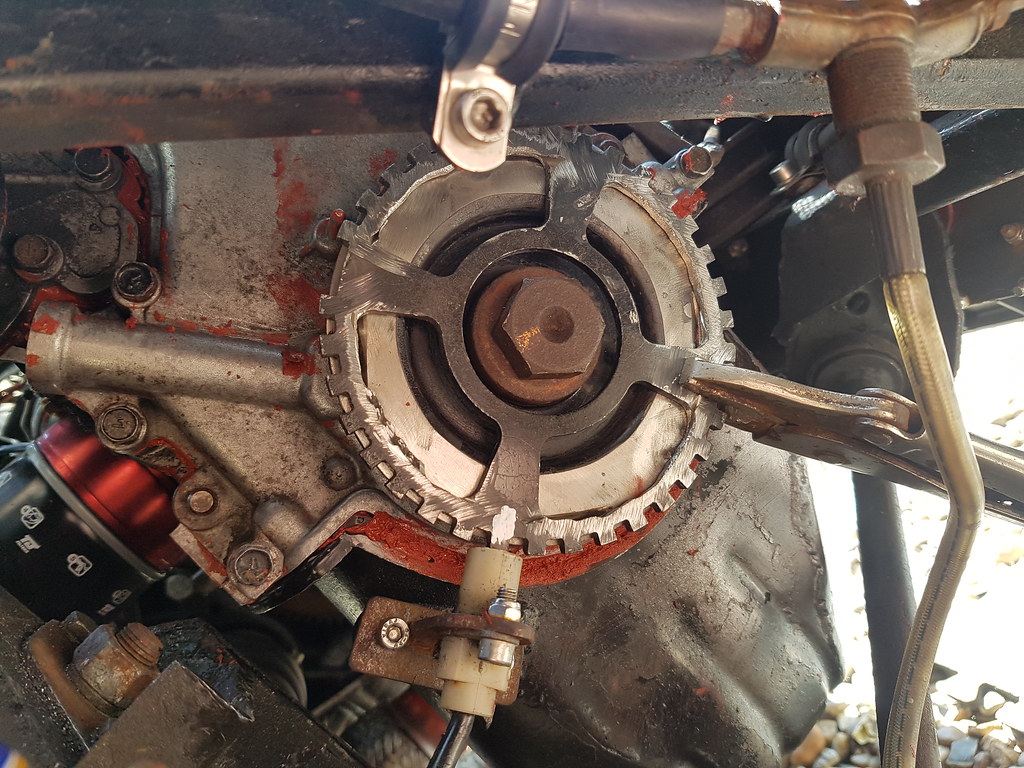

Ø Sort oil leak

Problem found

20180718_124639 by Lawrence Balls, on Flickr

20180718_124639 by Lawrence Balls, on Flickr

nice and tidy work area – bit of shade too from the trees

20180718_155746 by Lawrence Balls, on Flickr

20180718_155746 by Lawrence Balls, on Flickr

and all back together

20180718_155811 by Lawrence Balls, on Flickr

20180718_155811 by Lawrence Balls, on Flickr

seal no longer touching the flywheel.

So that’s all for now. Next update will be next week.

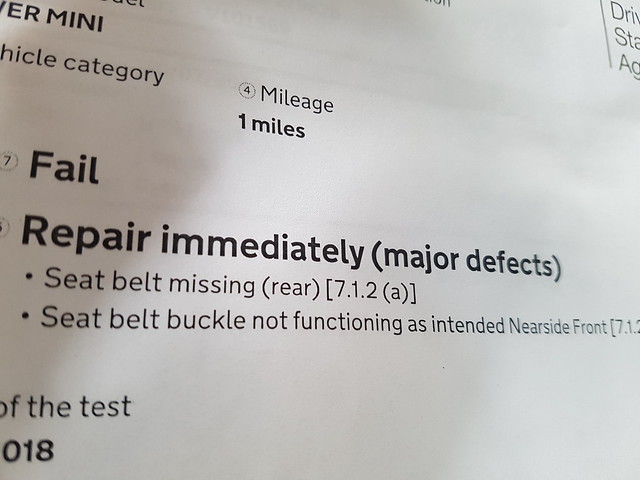

To do list for mot

Ø Run new battery power cable. – ordered. Map gas bought to solder connector on also.

Ø General checkup and put dash back in.

Deadline for the MOT is before the 3rdAugust as that’s when I move to my first house!!!

I expect her to fail the Mot, probably on emissions – will take laptop so can tune her to pass ;)

Lawrence

20180702_095834 by Lawrence Balls, on Flickr

20180702_095834 by Lawrence Balls, on Flickr 20180702_110229 by Lawrence Balls, on Flickr

20180702_110229 by Lawrence Balls, on Flickr 20180704_164718 by Lawrence Balls, on Flickr

20180704_164718 by Lawrence Balls, on Flickr 20180704_165514 by Lawrence Balls, on Flickr

20180704_165514 by Lawrence Balls, on Flickr