Good morning People,

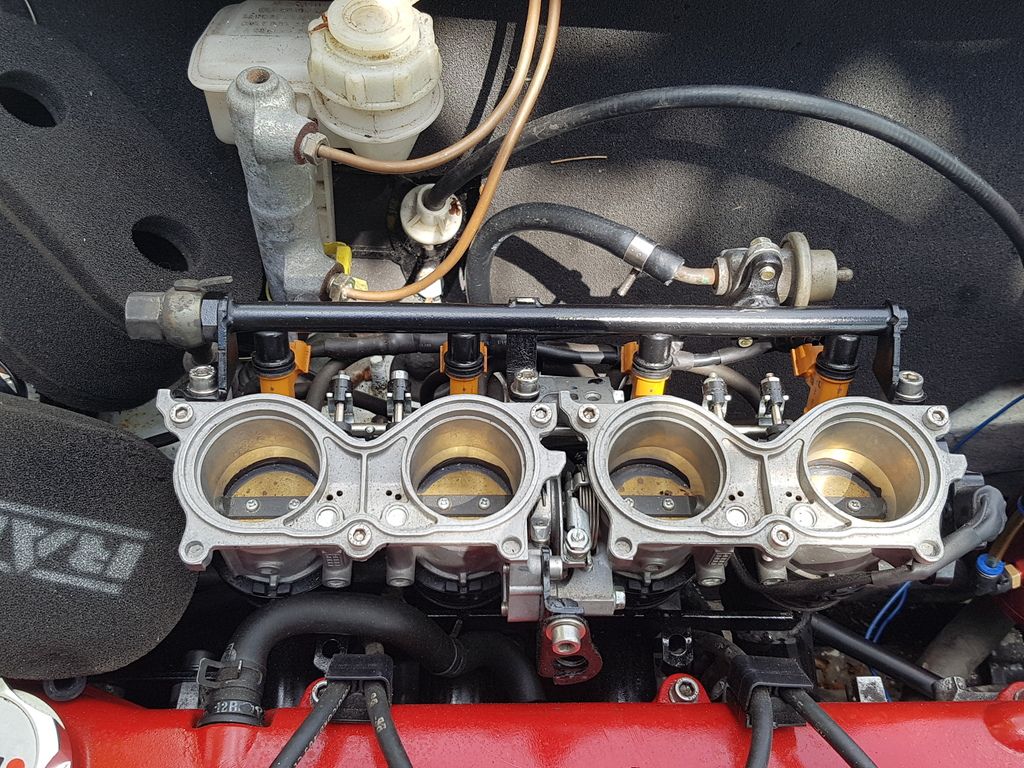

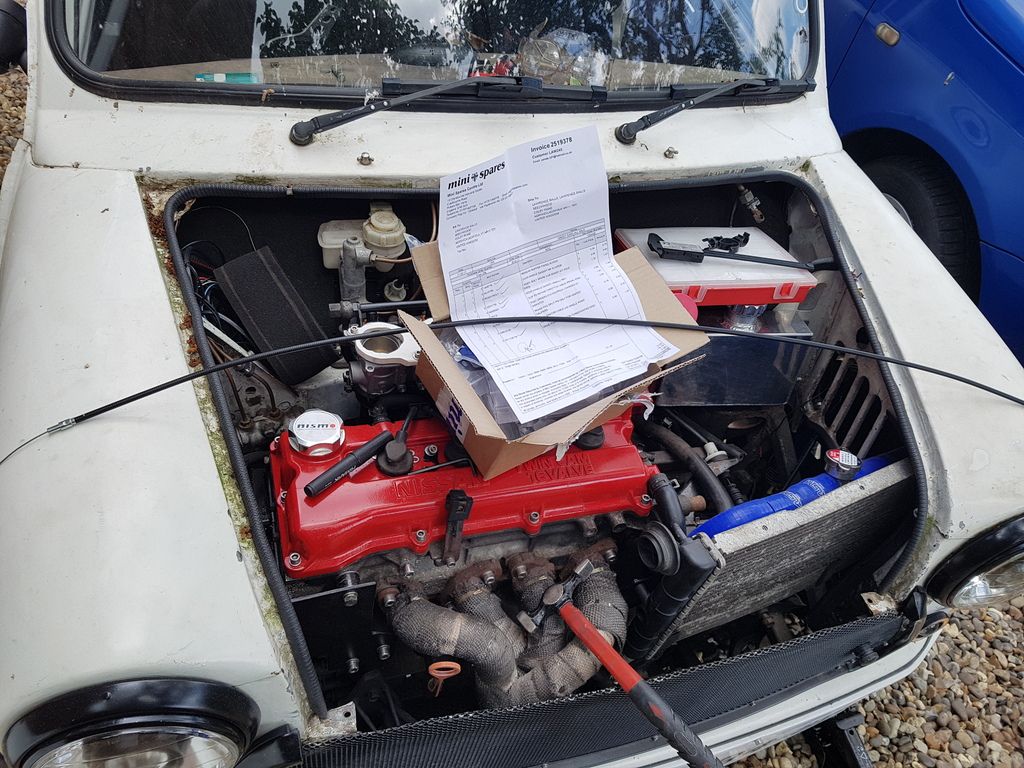

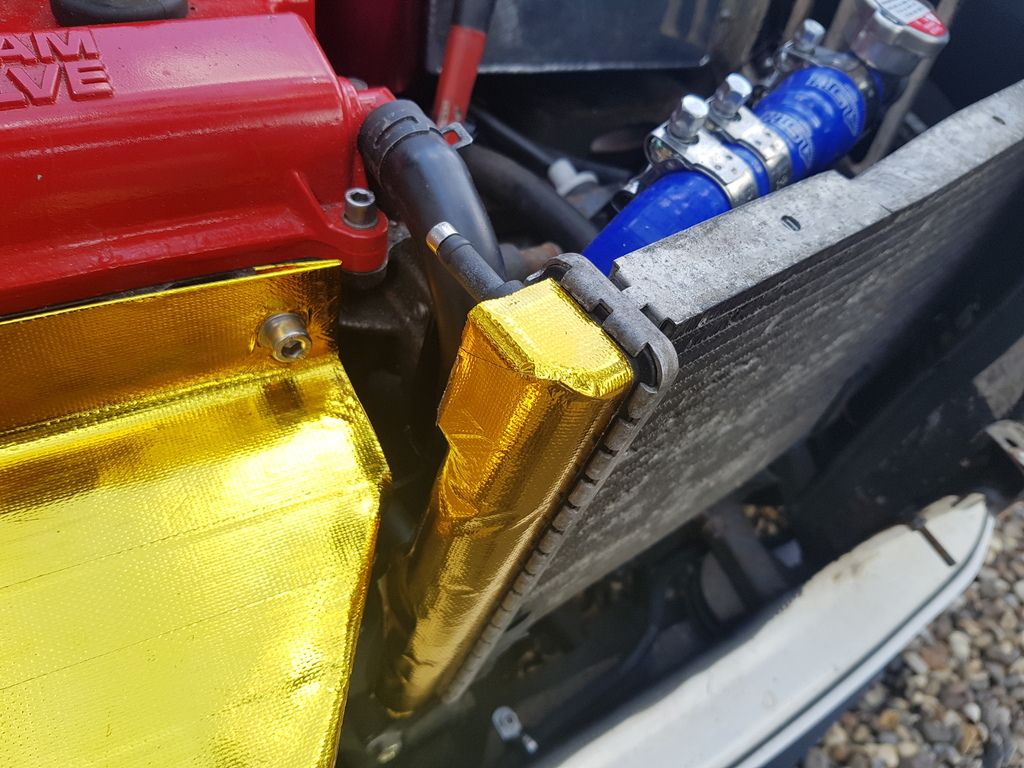

Time for an update, like I said previously I need to finish off the cooling pipework etc

So lets get cracking

Pipes and joiners all arrived

fitted the majority

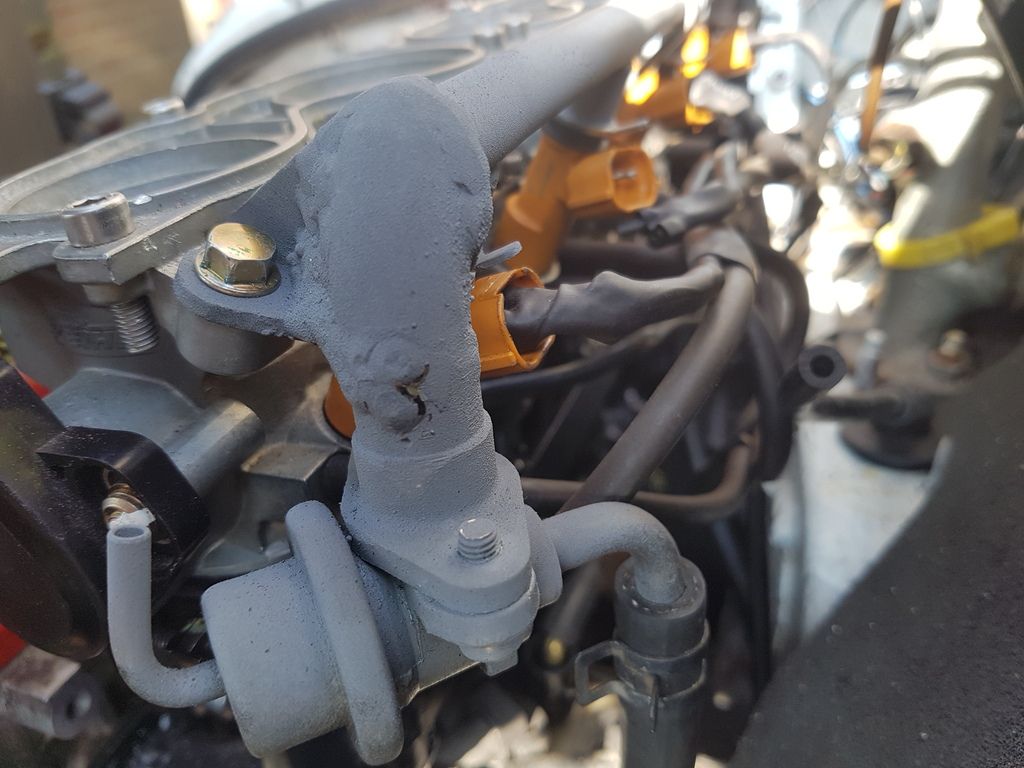

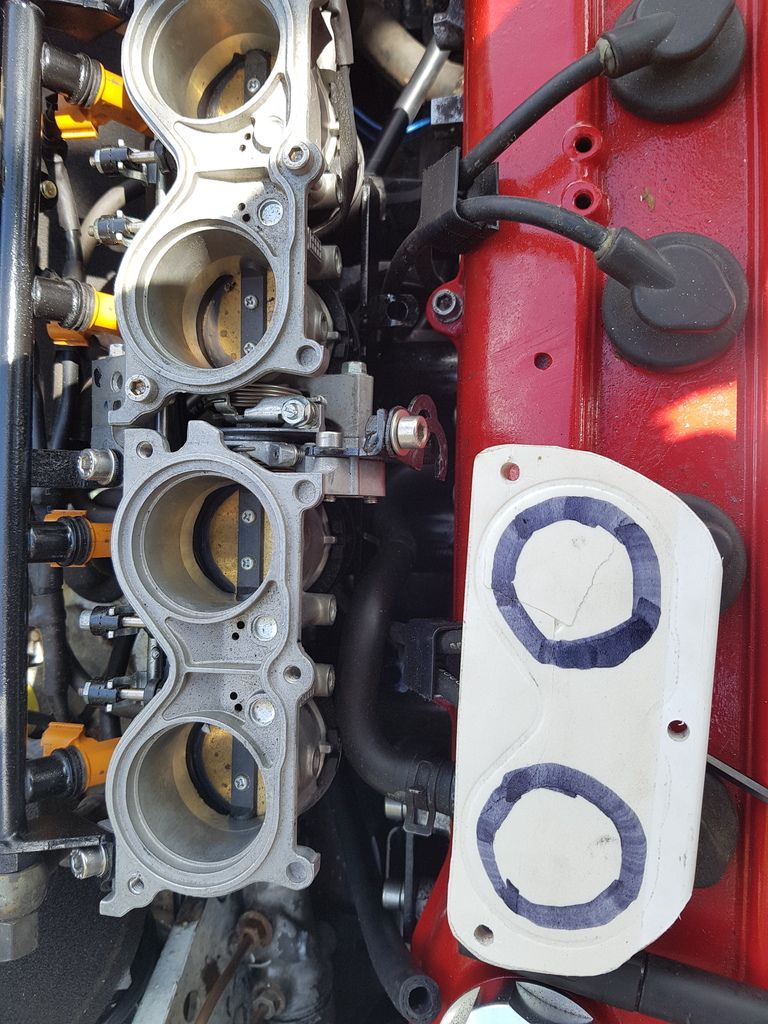

now to do the solid hose part

Tacked to trial fit

weldy weldy

primed

painted

and all the engine side of the plumbing is now completed J

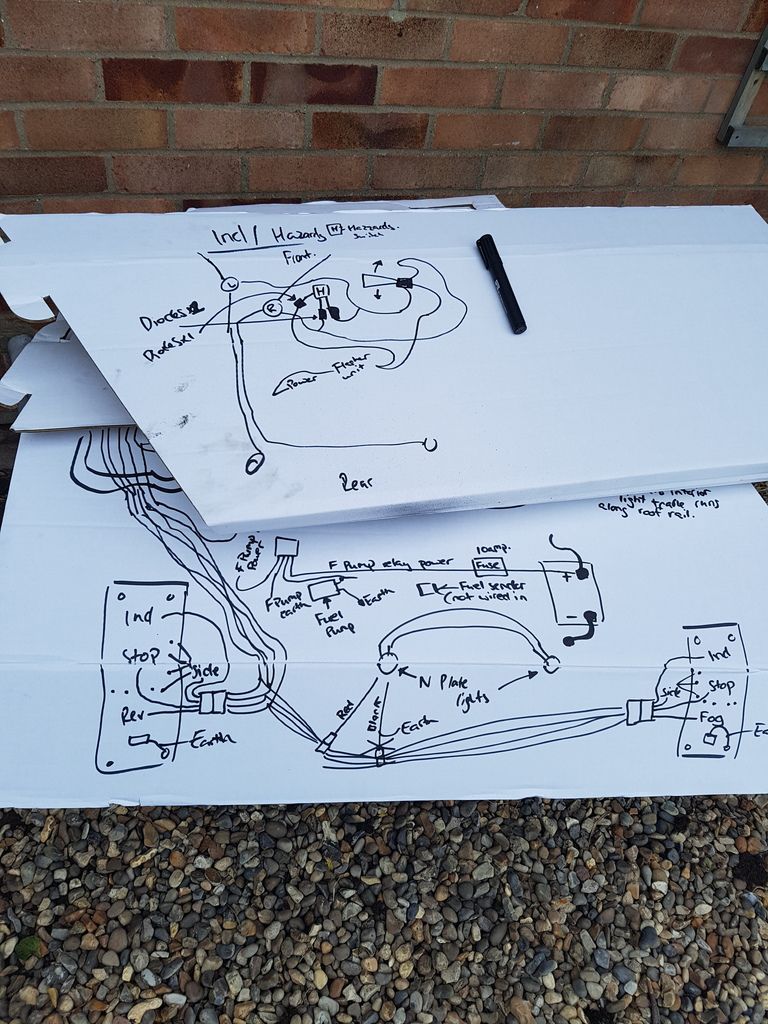

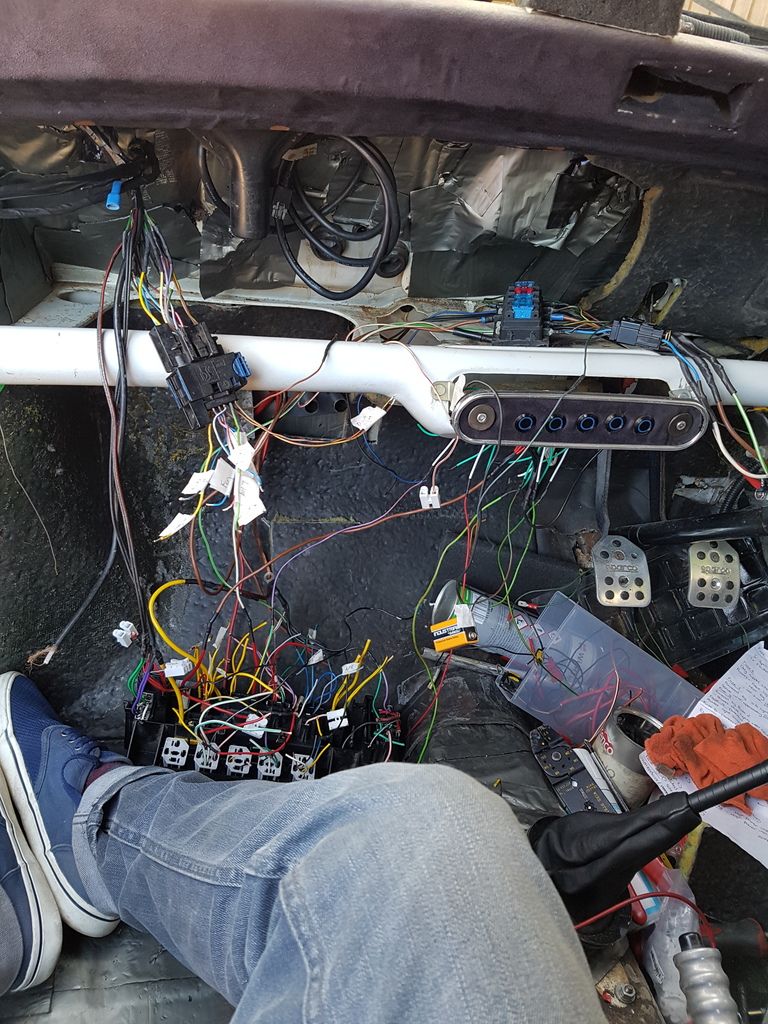

So onto wiring, this is a big chunk of my to do list and will take me a lot of time!

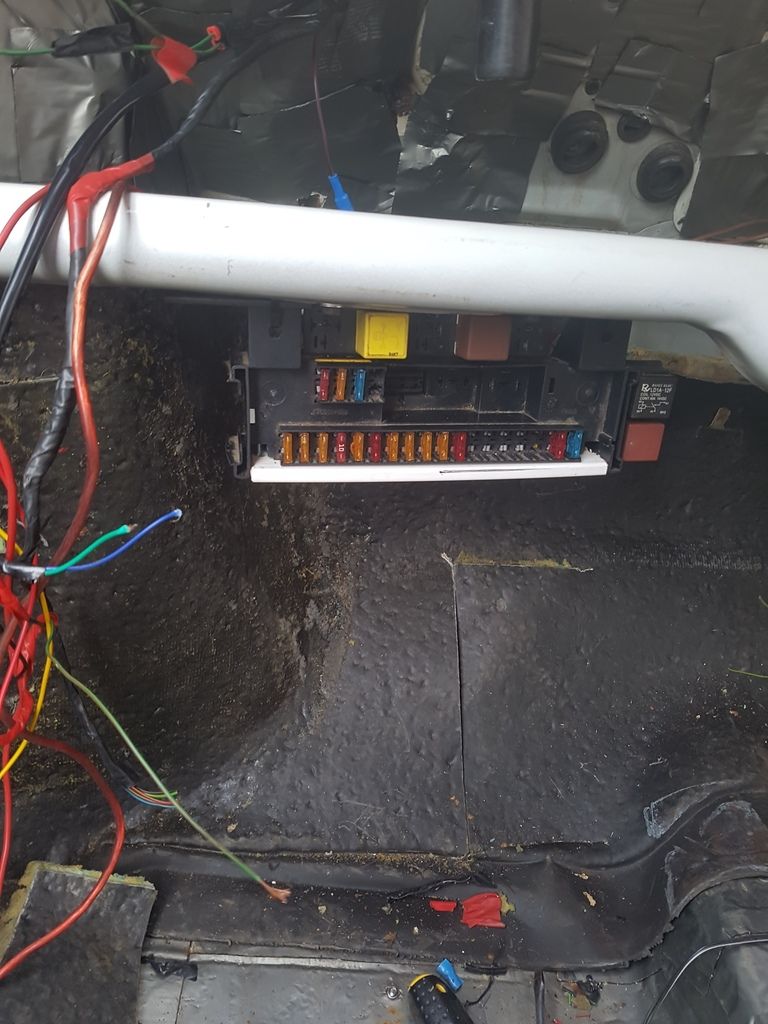

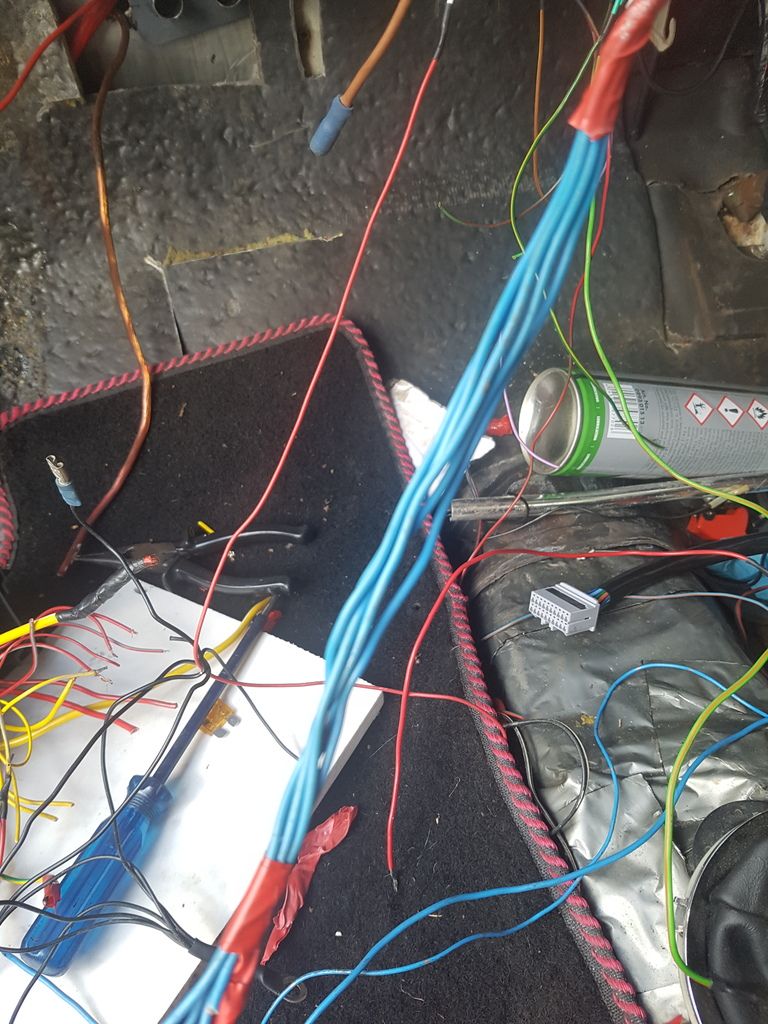

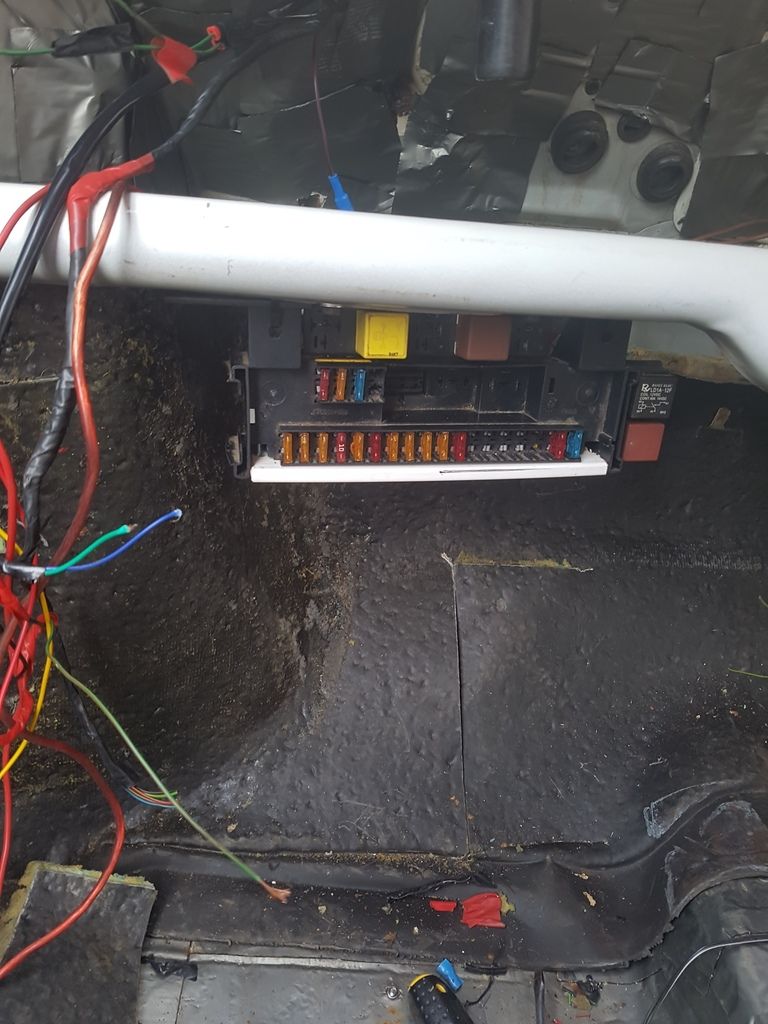

Firstly I properly inspected the wiring that I had completed a long time ago back in October 2011, this is what it looked like then

Although fundamentally it’s not the worst wiring in the world, there are many issues

Firstly it was originally designed to run a standard mini

Then it was modified with my different switches etc for lights

Then I added megajolt

Then I got rid of the mini wiring and changed the dash buttons

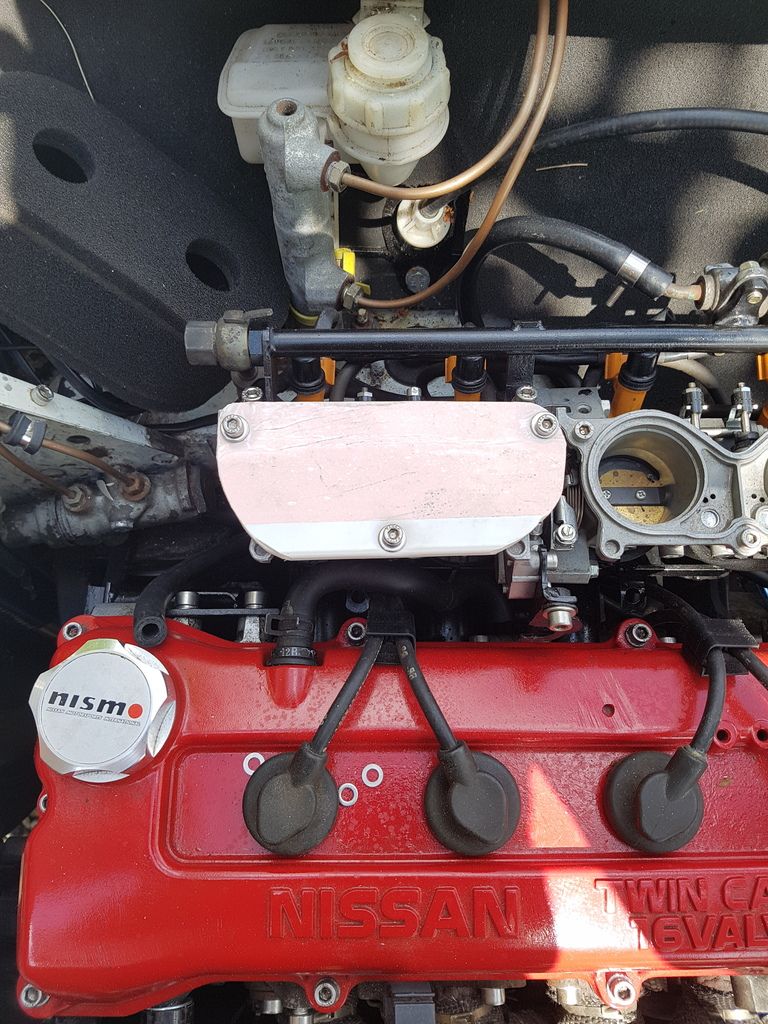

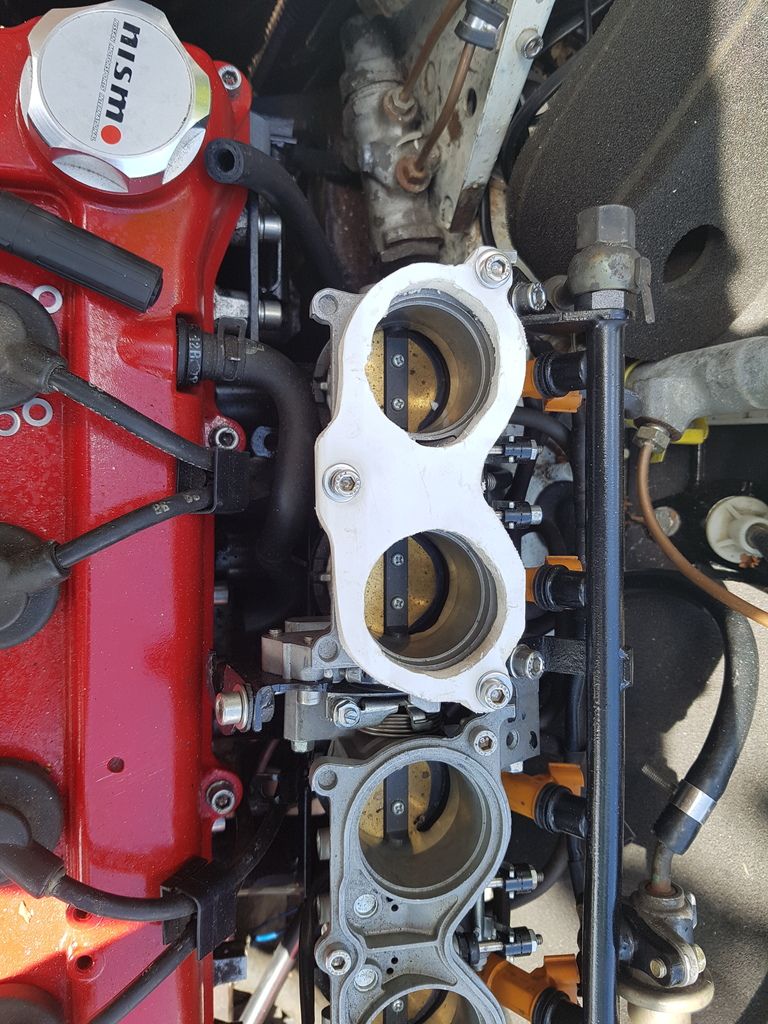

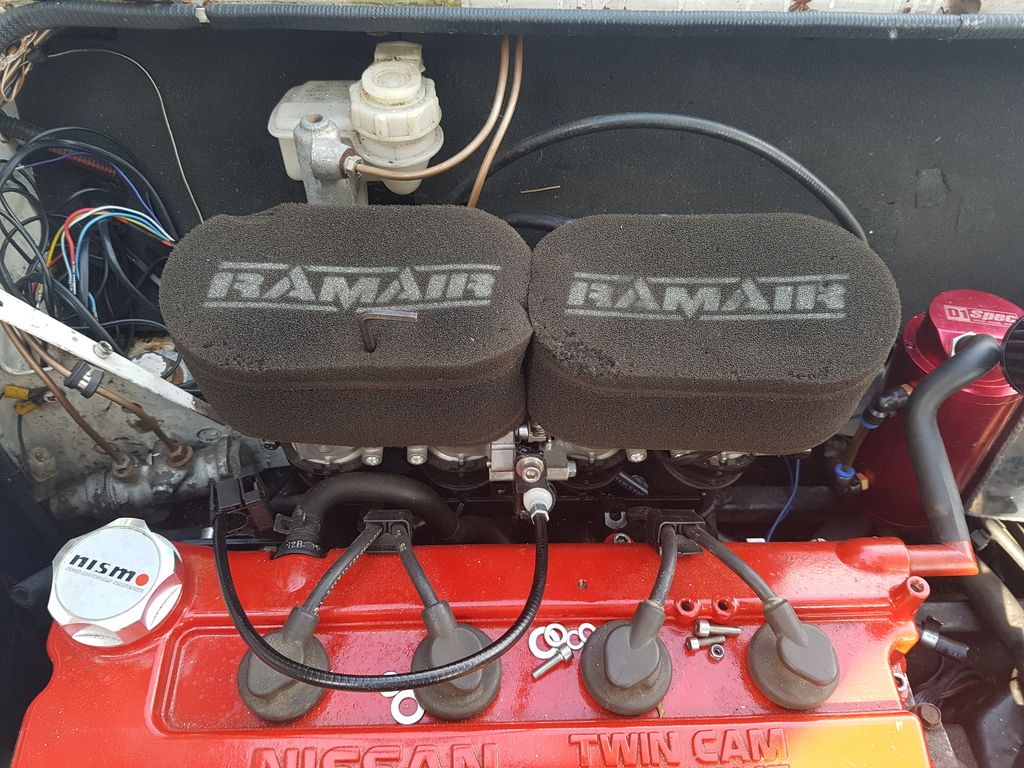

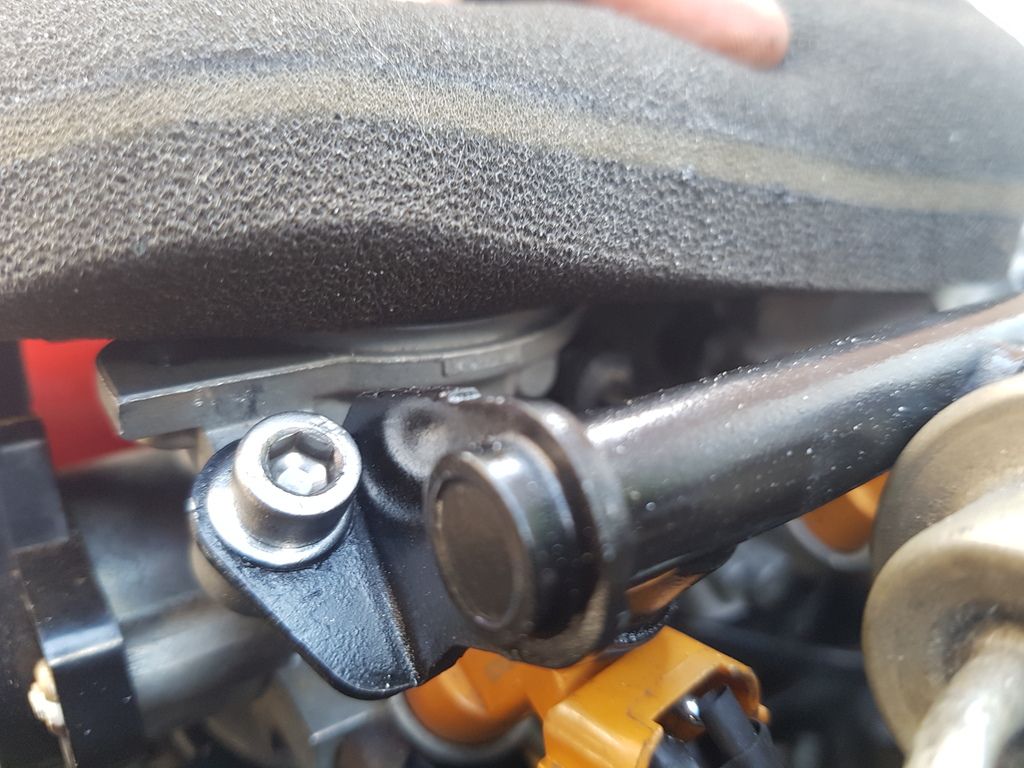

And now im adding fuel injection!

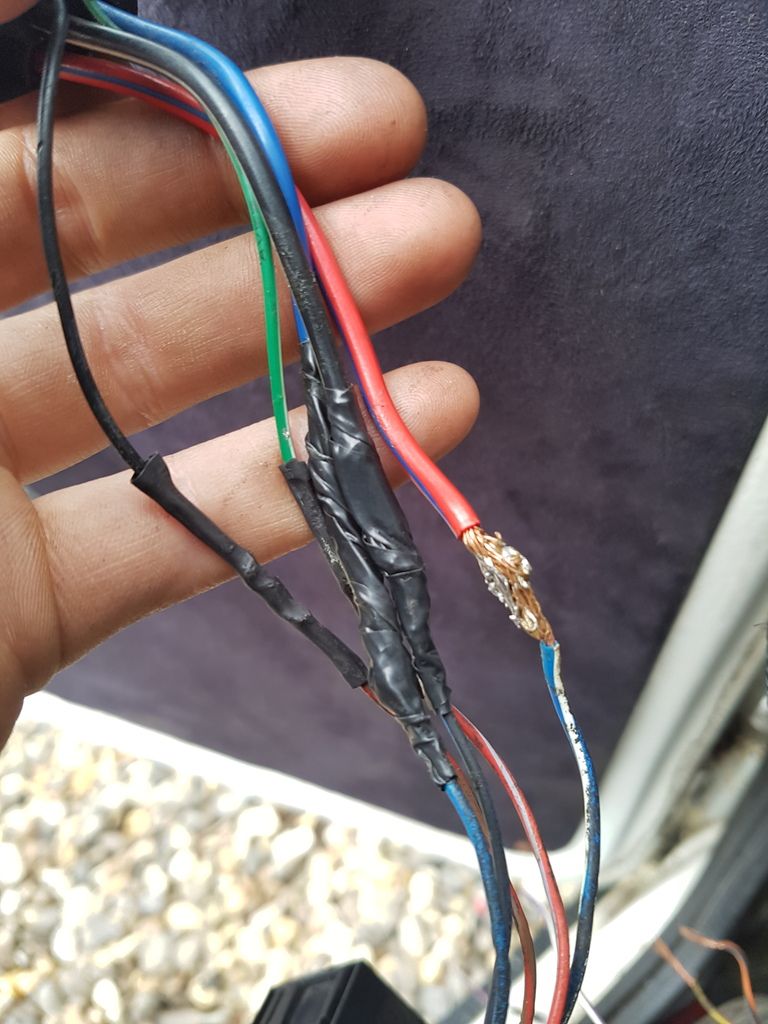

Its been cut and chopped so many times that in some places I had wires that had been cut at least 3 times and each time soldered and heatshrunk!

Also if you look closely in that photo above there is red electrical tape wrapped around many connections and those connections I have simply twisted the wire around itself and smothered it in solder.

So its now 2017 and ive got 6 years improvement in my soldering skills.

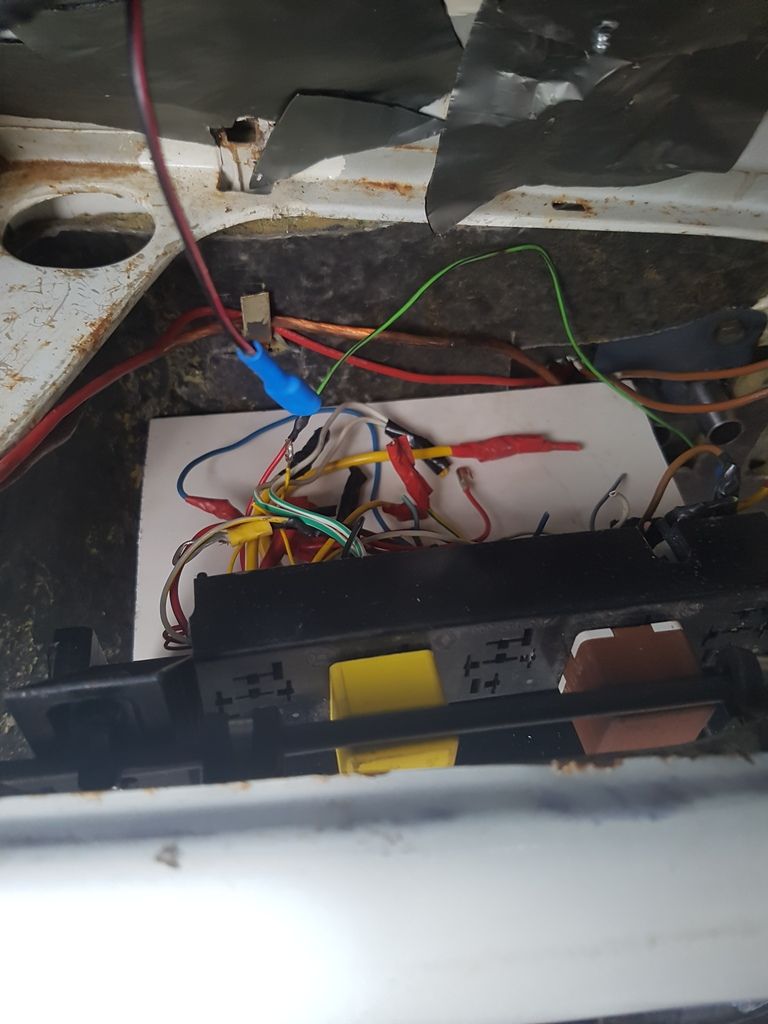

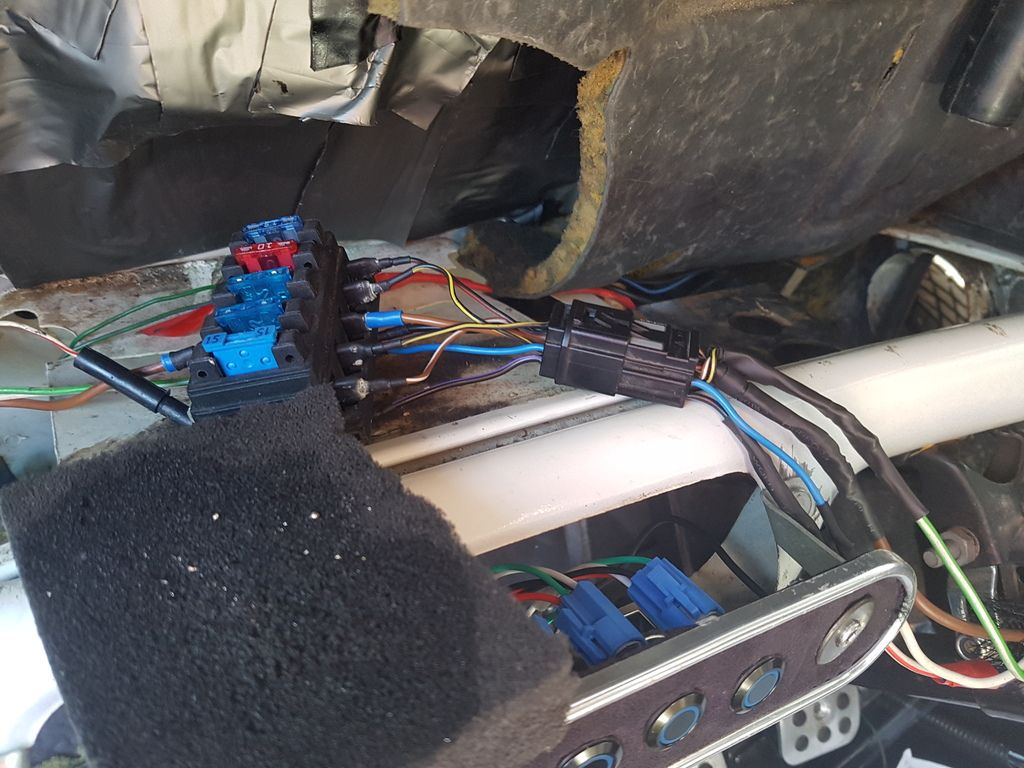

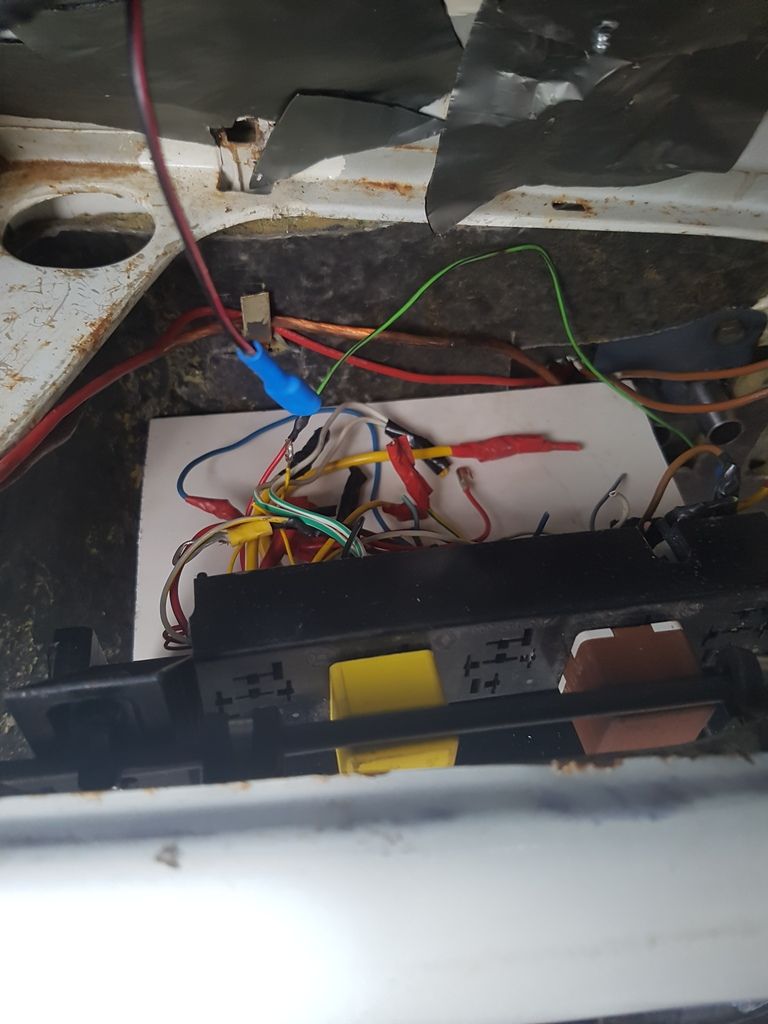

So the fusebox has been removed

modified

and ive started to make a covering/handle for it also so it doesn’t flop open all the time!

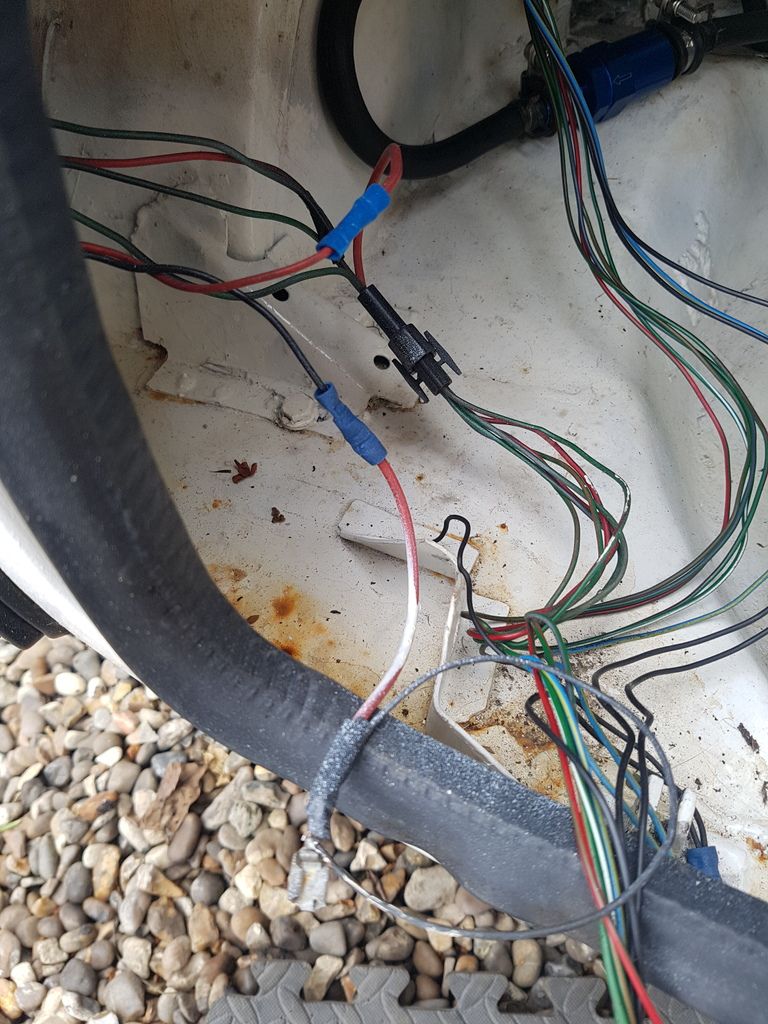

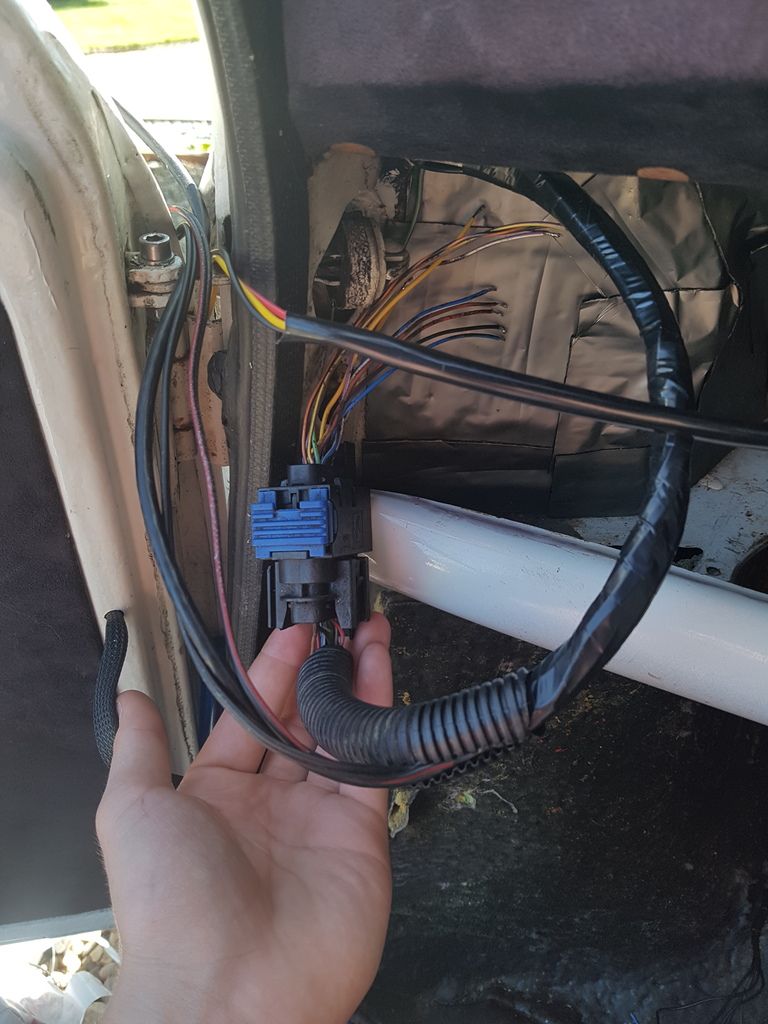

Plan is to start from the rear of the car forward. I will label everything so I know what wire is which. The rear wires are the ones hanging over the left door handle.

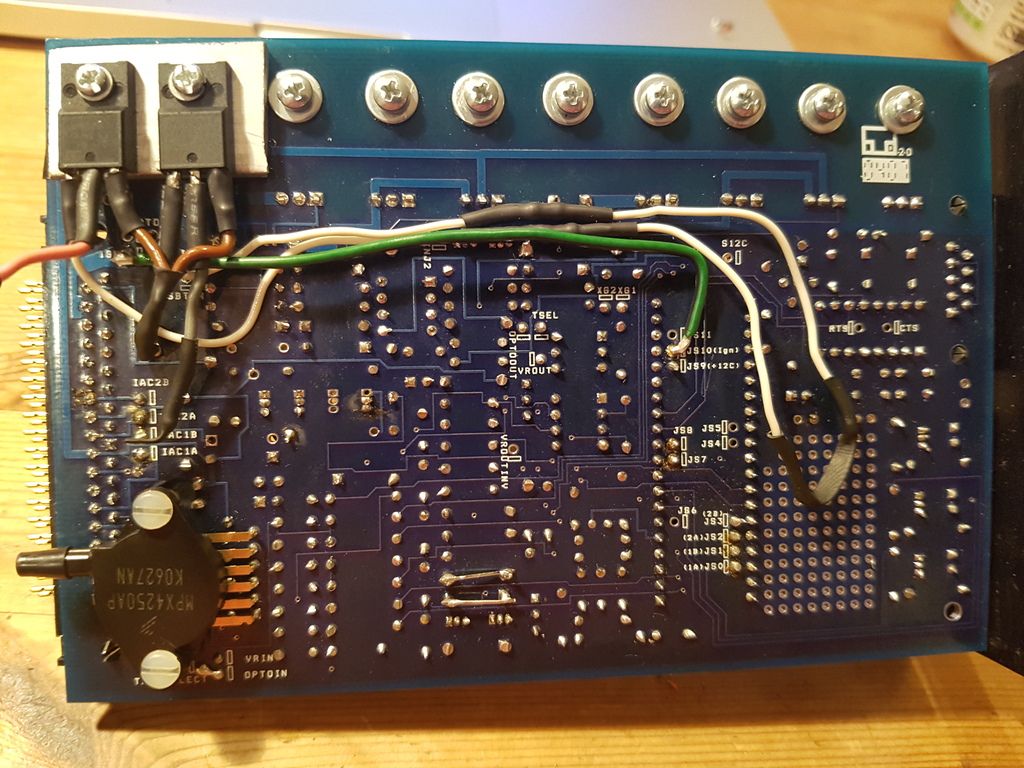

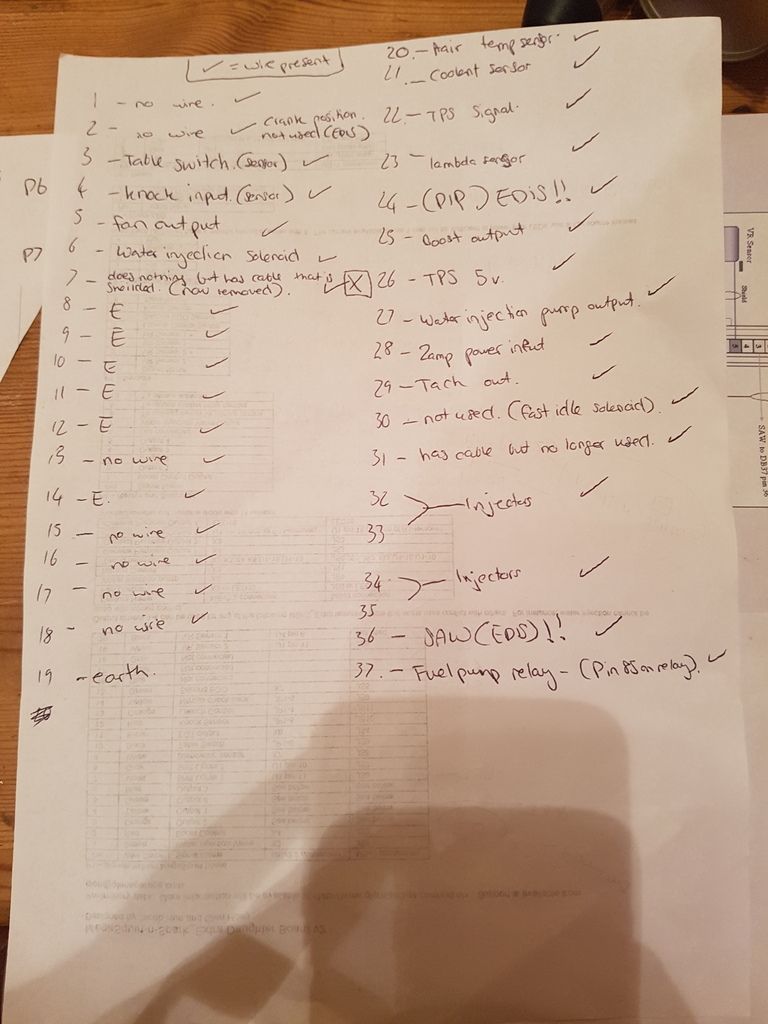

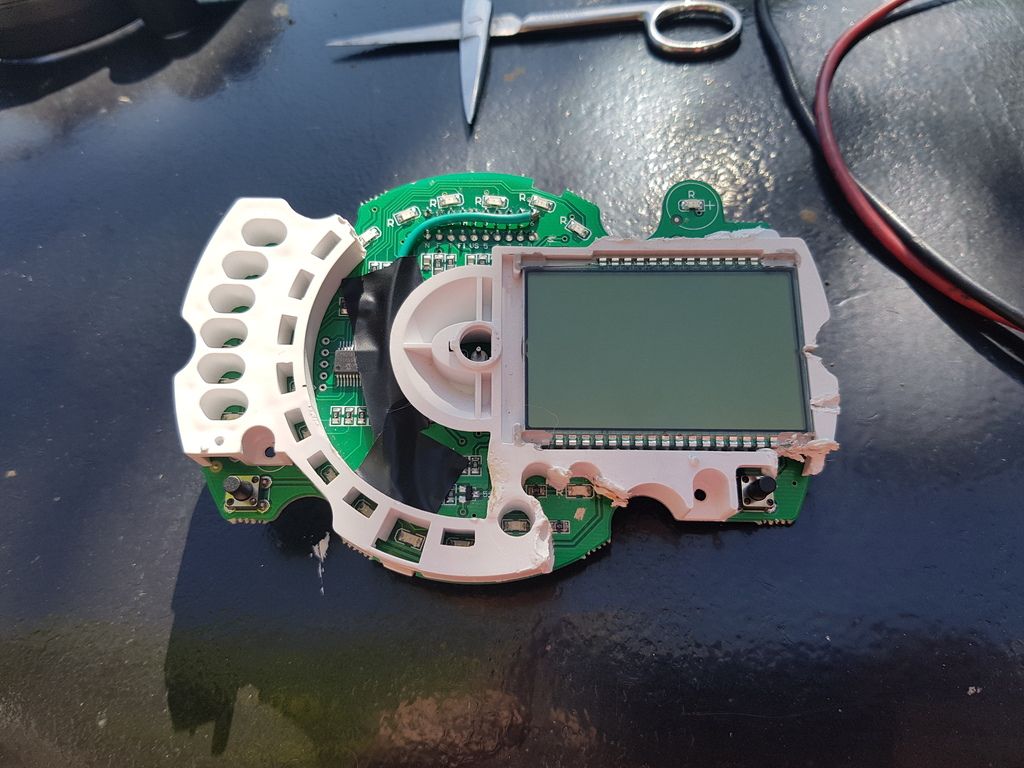

Lastly ive repaired the megasquirt and I think I know enough now of it to make it work with EDIS

So my plans today are wires wires wires! Im stocked up with soldering gas, new tips, plenty of solder, head shrink electrical tape the works.

Wish me luck

Lawrence