Good afternoon.

So ive finished faffing around with the coolent system (for now at least)

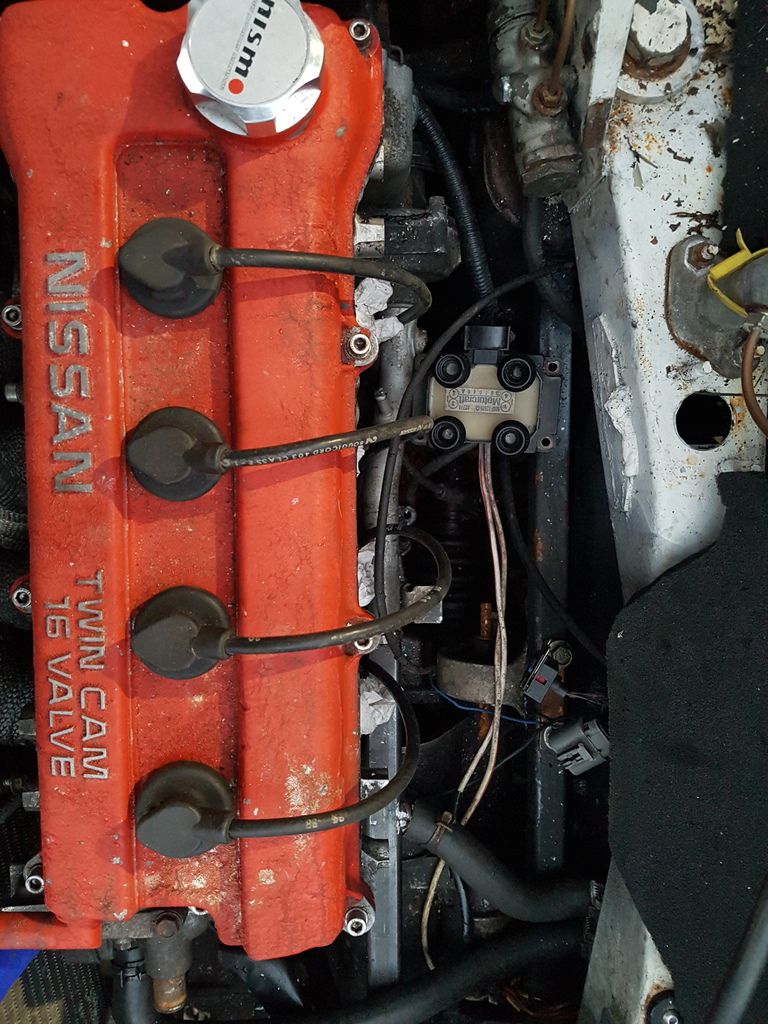

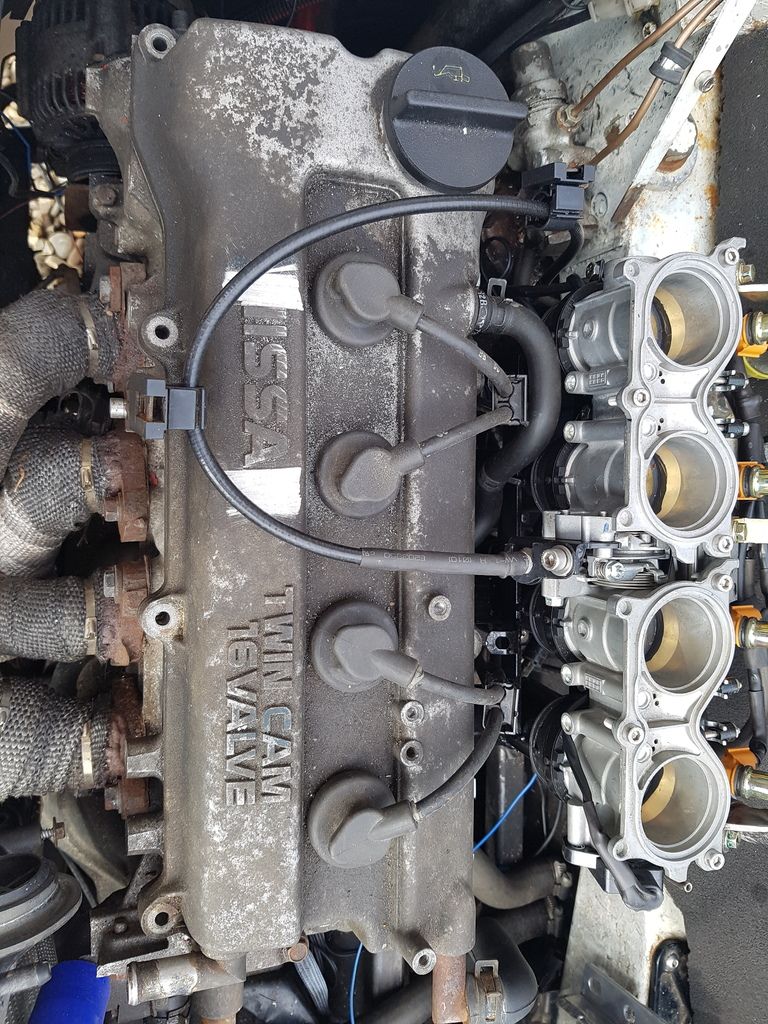

Time to play with the inlet manifold

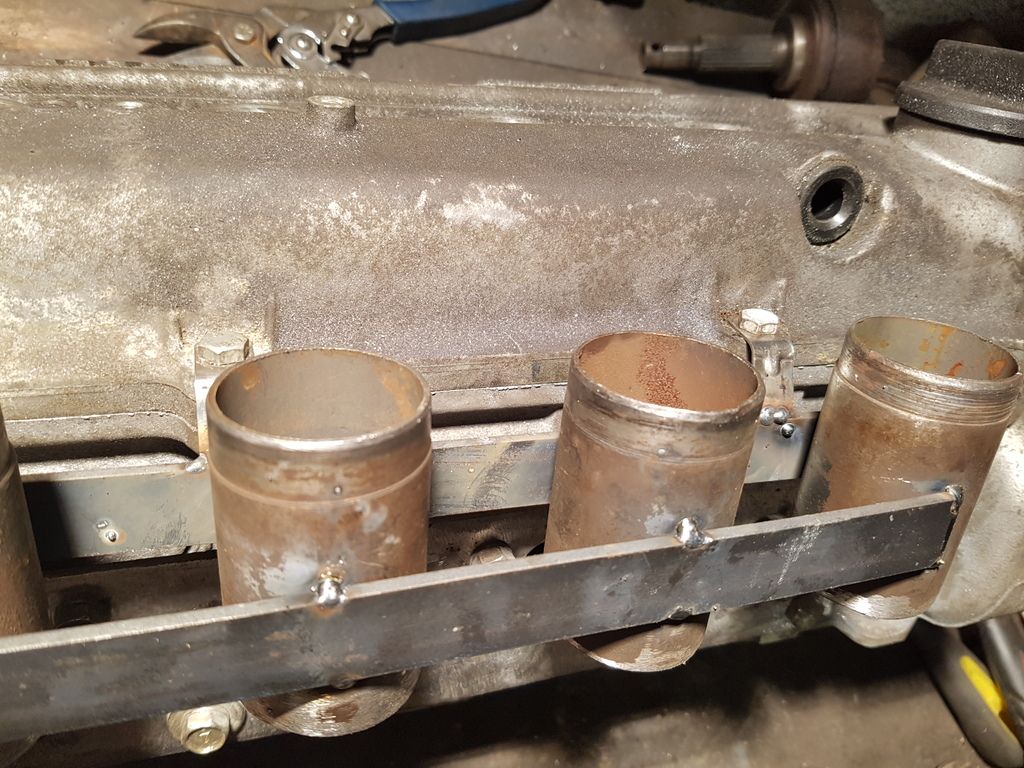

Last time I talked about it I had given up with making a new backplate and had ground off the old one.

as you can see.

So bolted that up to my spare head.

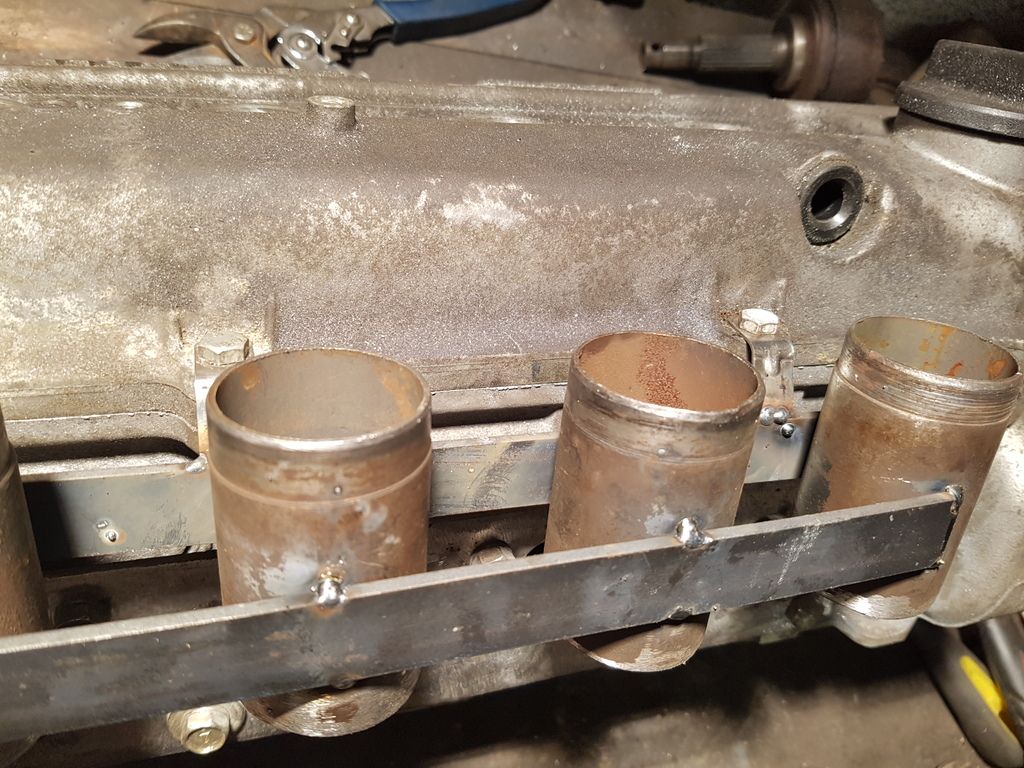

I wasn’t having the runner going off all wonky on me this time so tacked some reinforcing bits to them to keep them aligned

bracket welded to them and then attached to head.

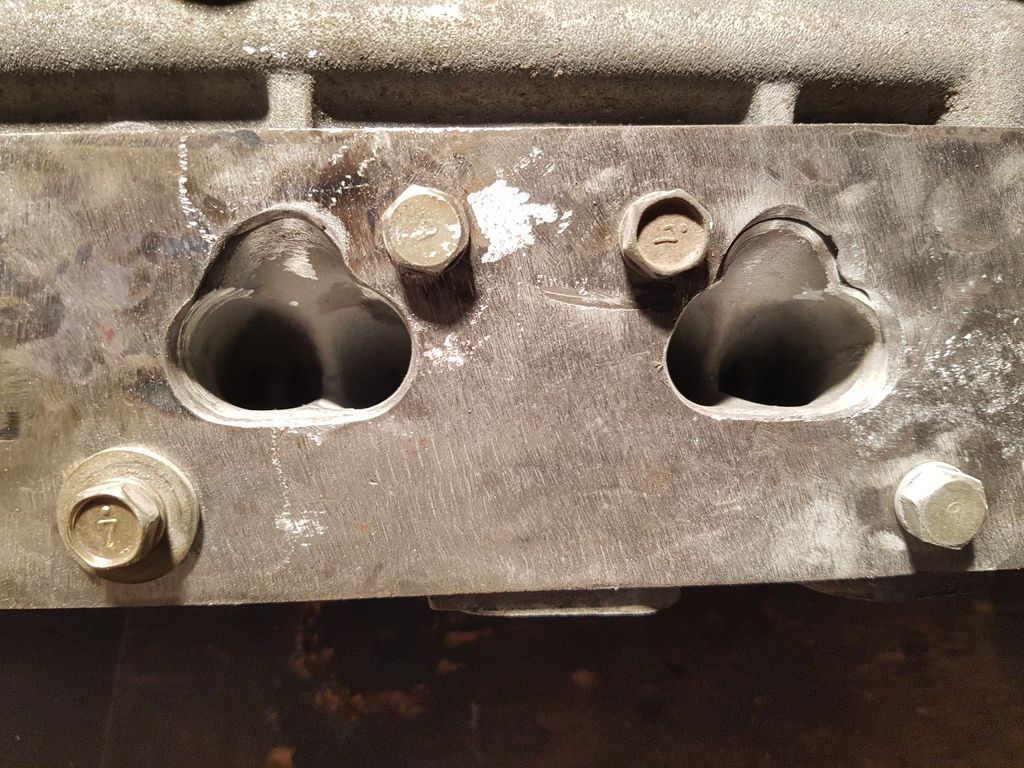

you can see in this one that the holes were drilled a little off and that the mounting plate is slightly wonky!

ive matched the plate to the ports, not that itll make a huge difference as im welding round pipes on!

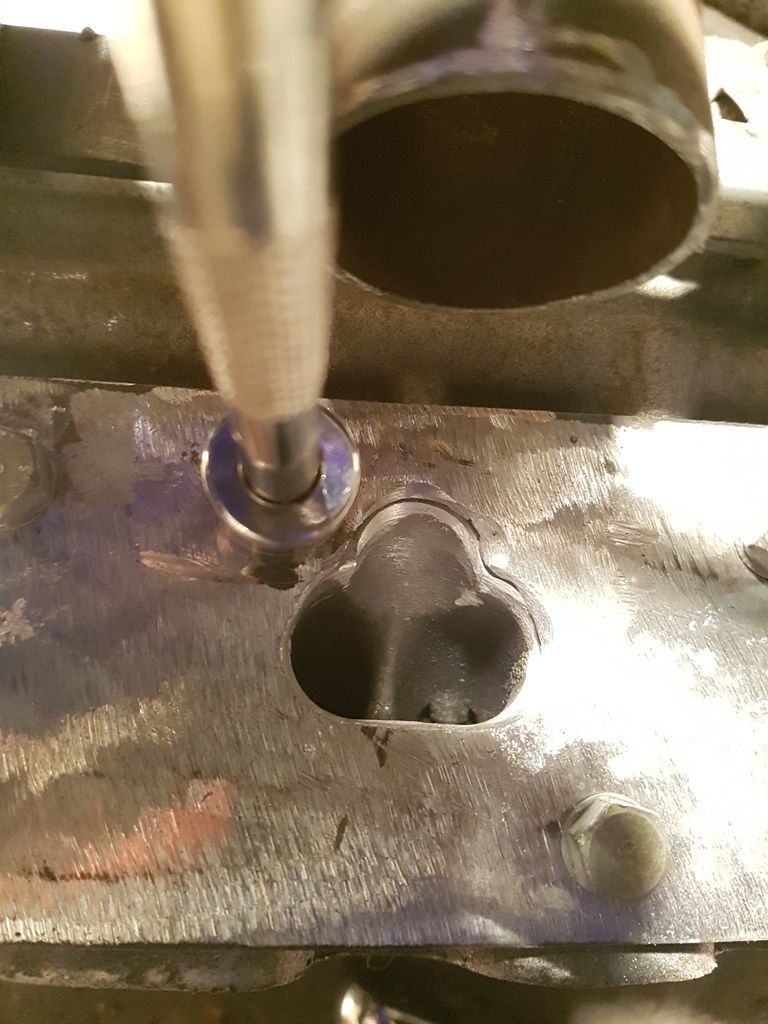

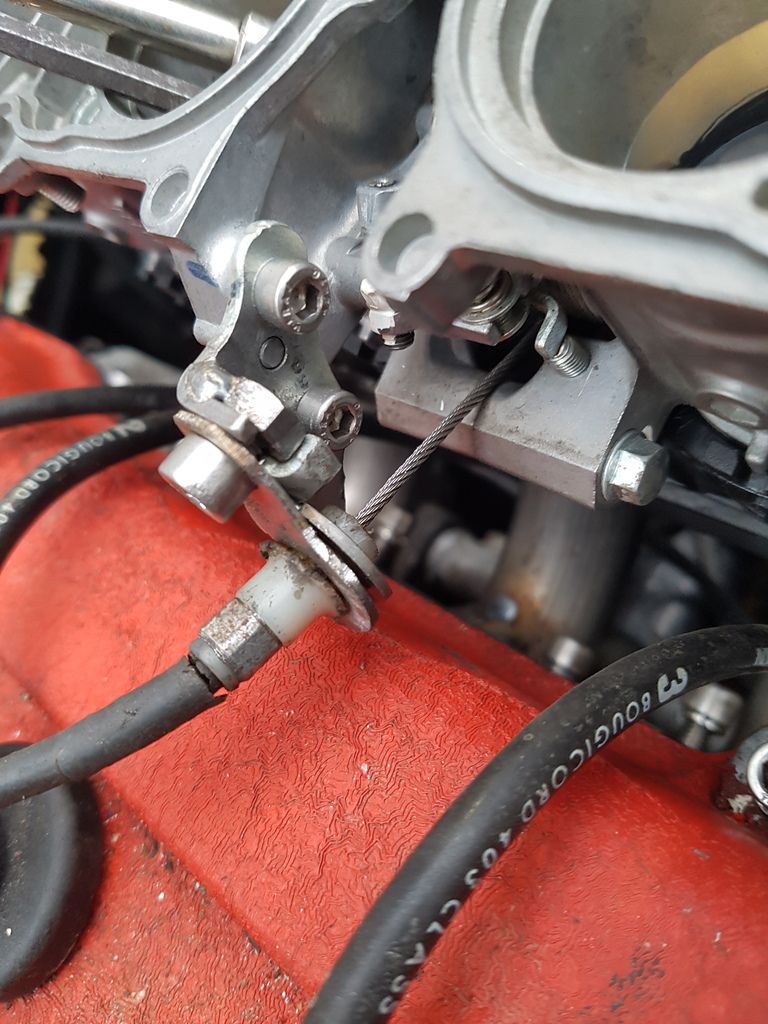

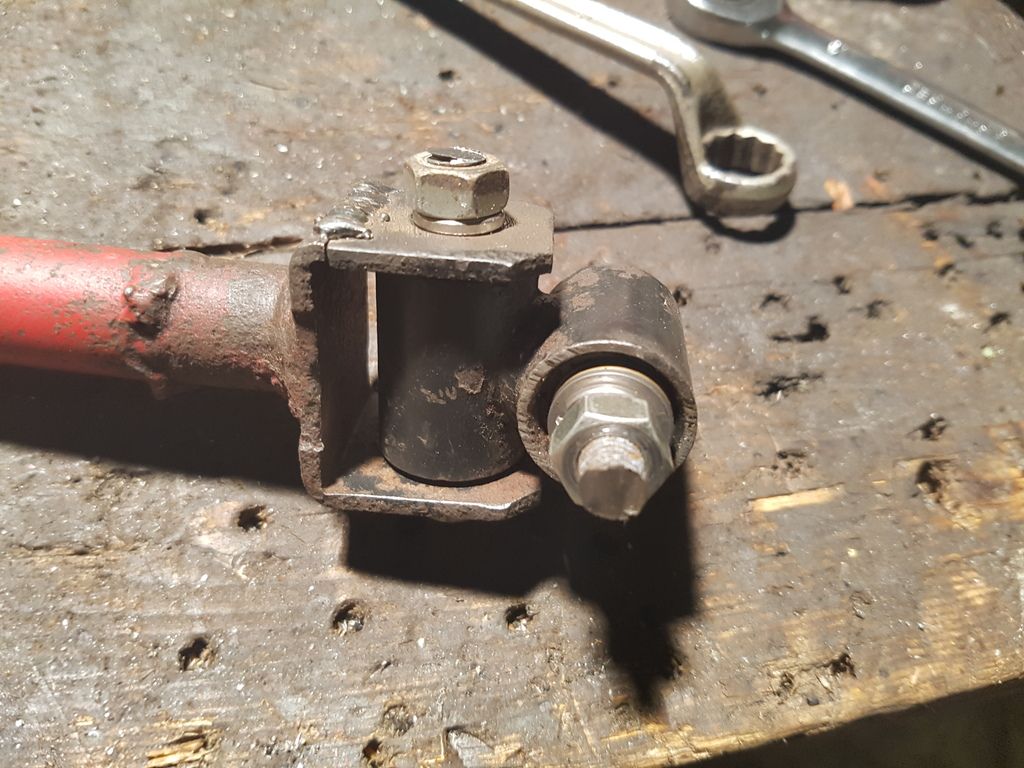

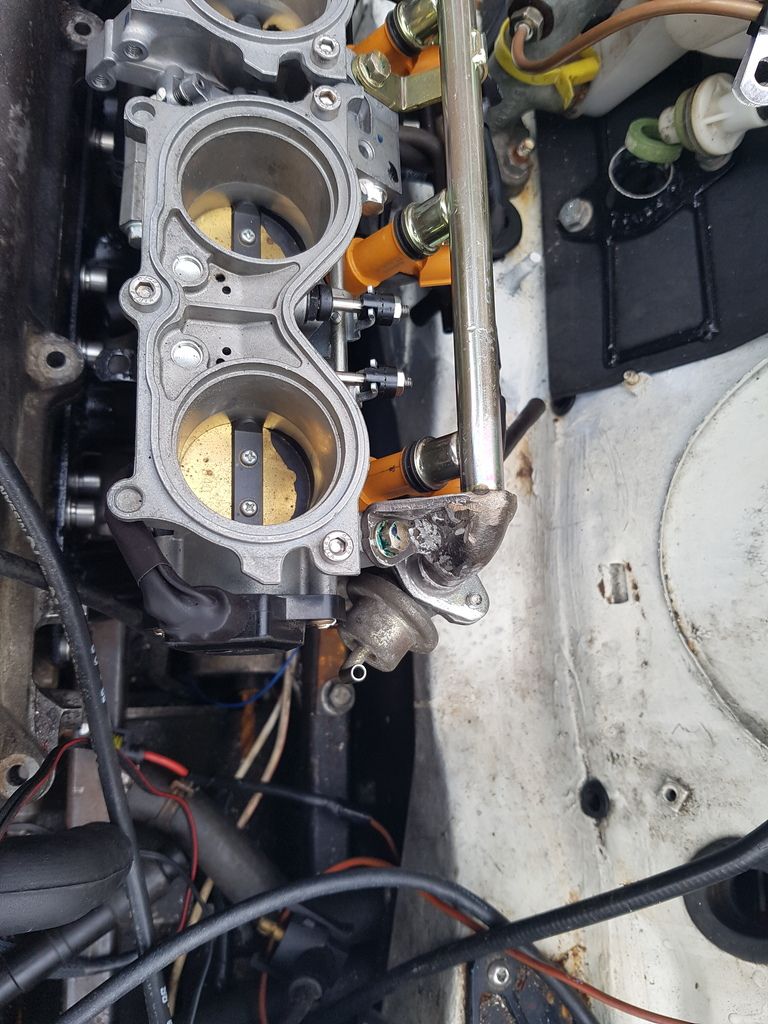

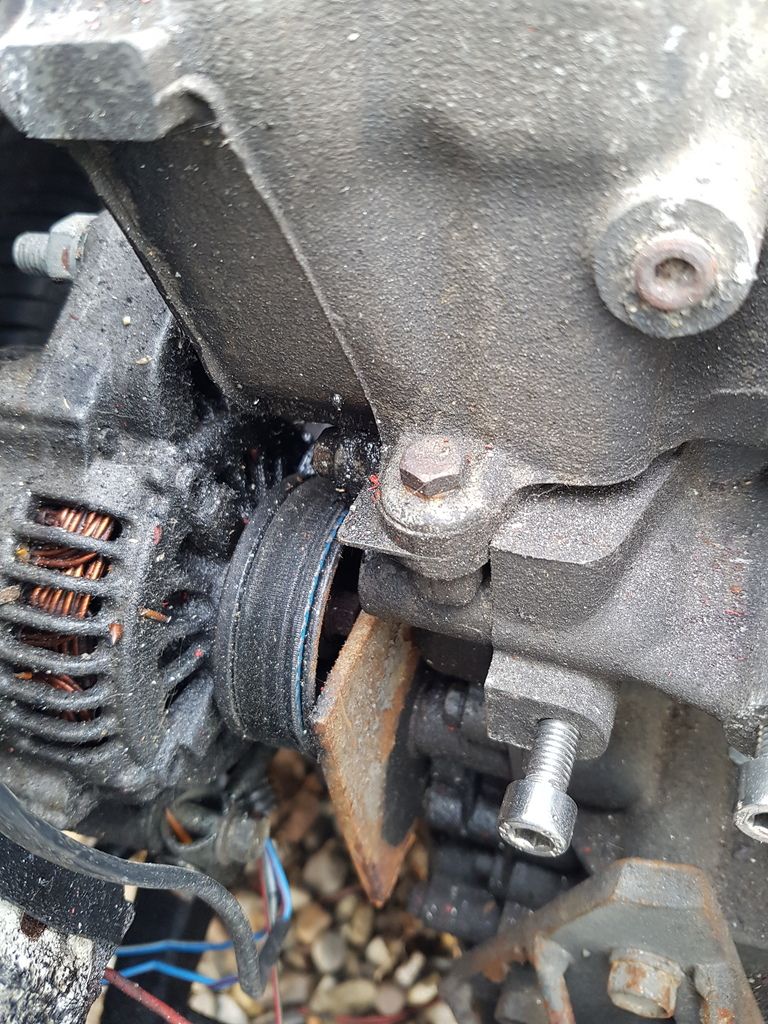

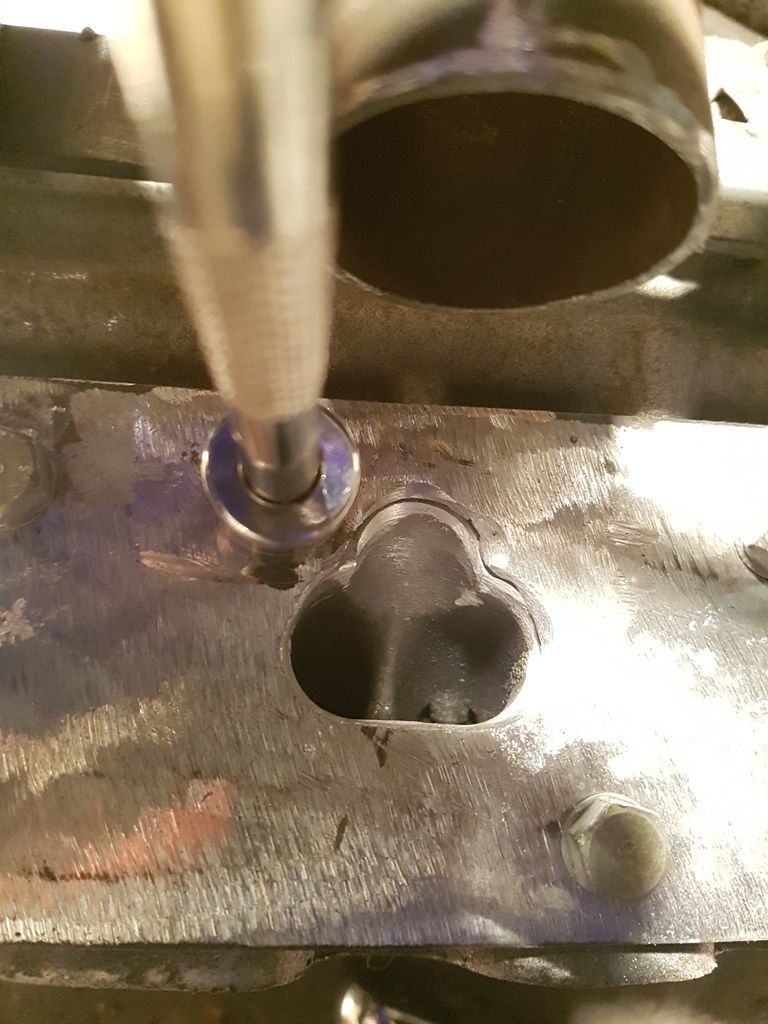

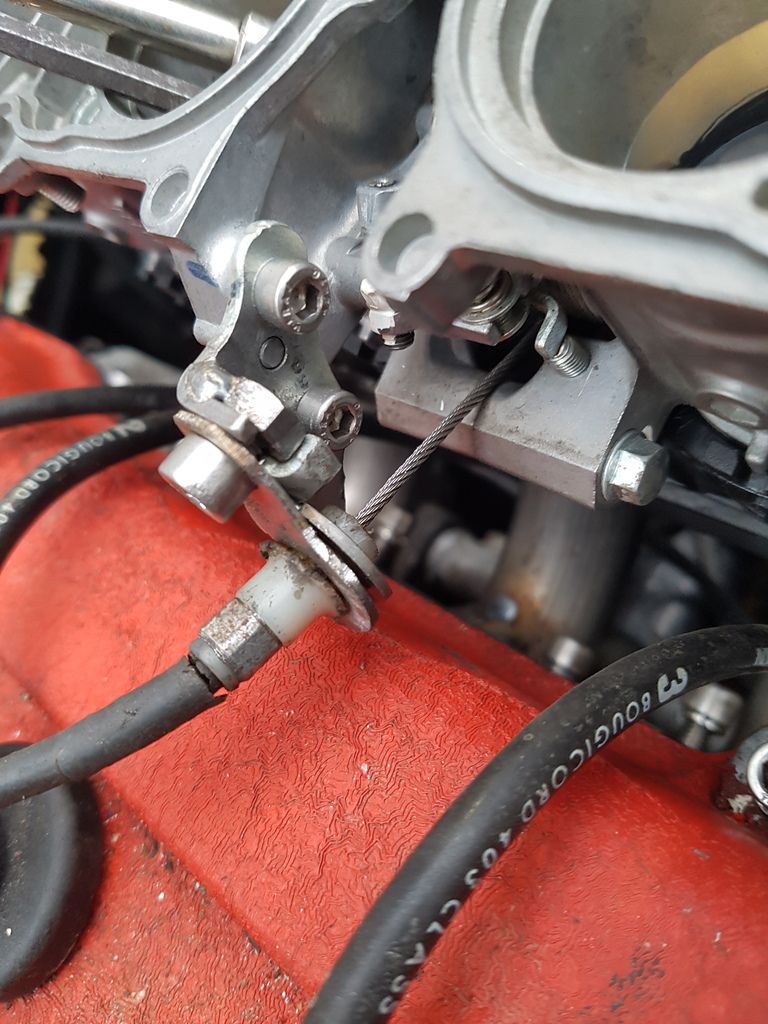

So this is where I paused the other week. As you can see in the photo its tight to the bolt which makes it difficult to get weld and the socket to undo the bolt in the same place!

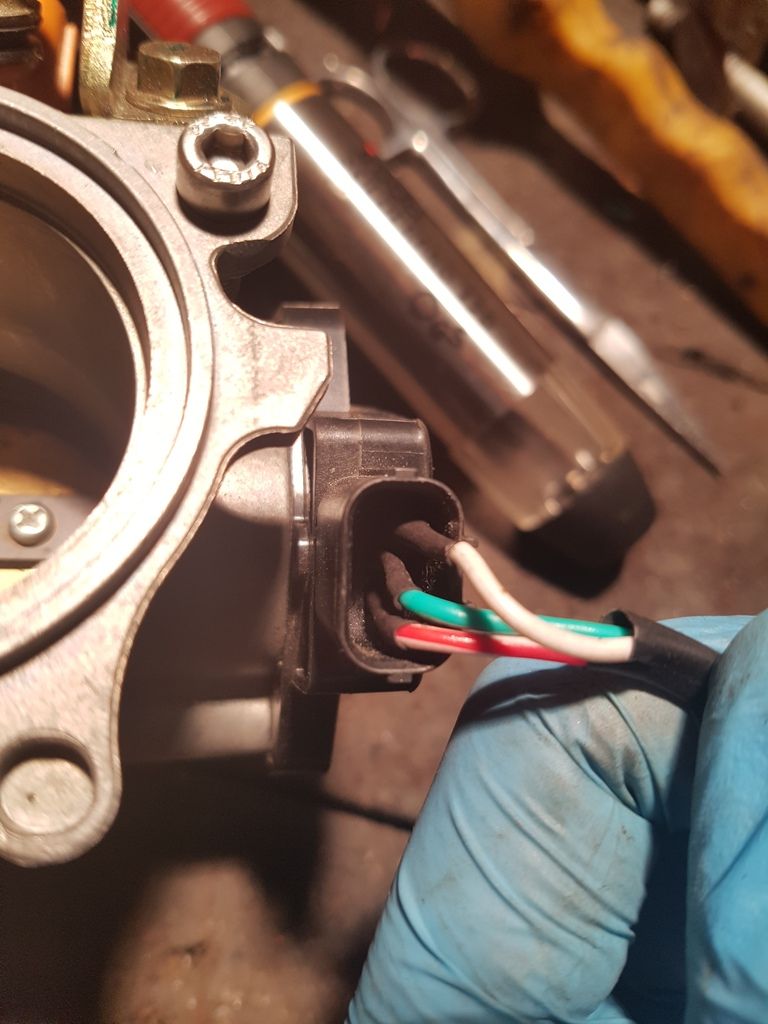

Also the little brackets I welded on wouldn’t work. When I did a mock fit the throttle body hit the rocker cover and the bends on the pipe were too small.

see what I mean?

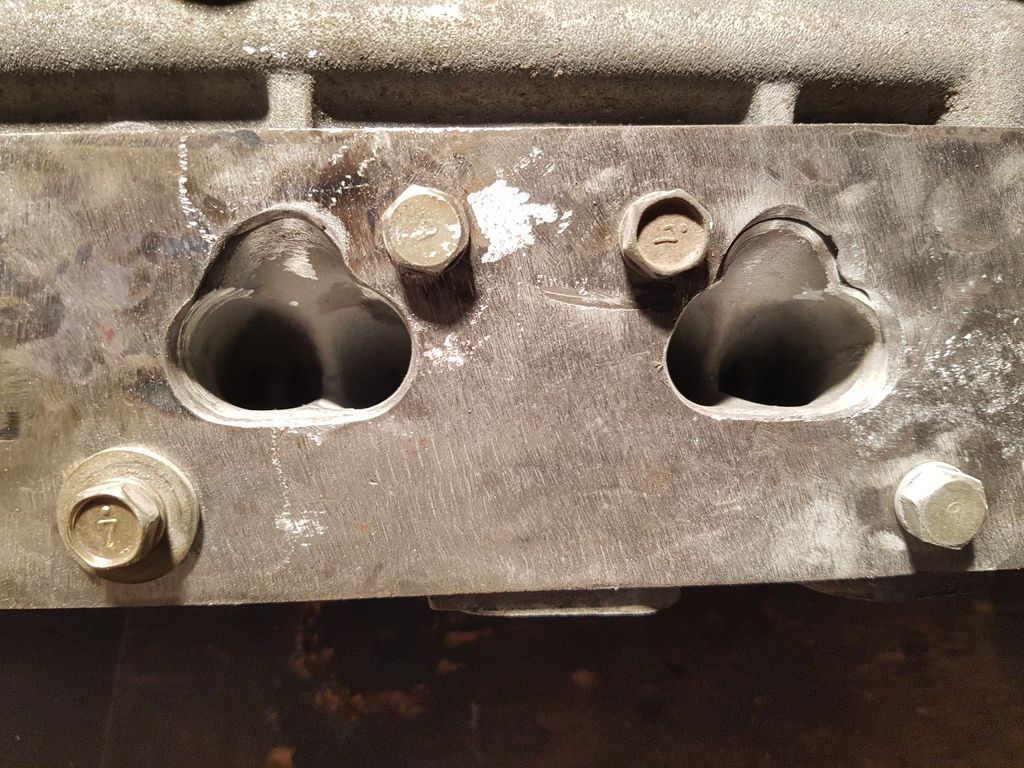

So I had a pause and a think.

This was the issue. Too tight

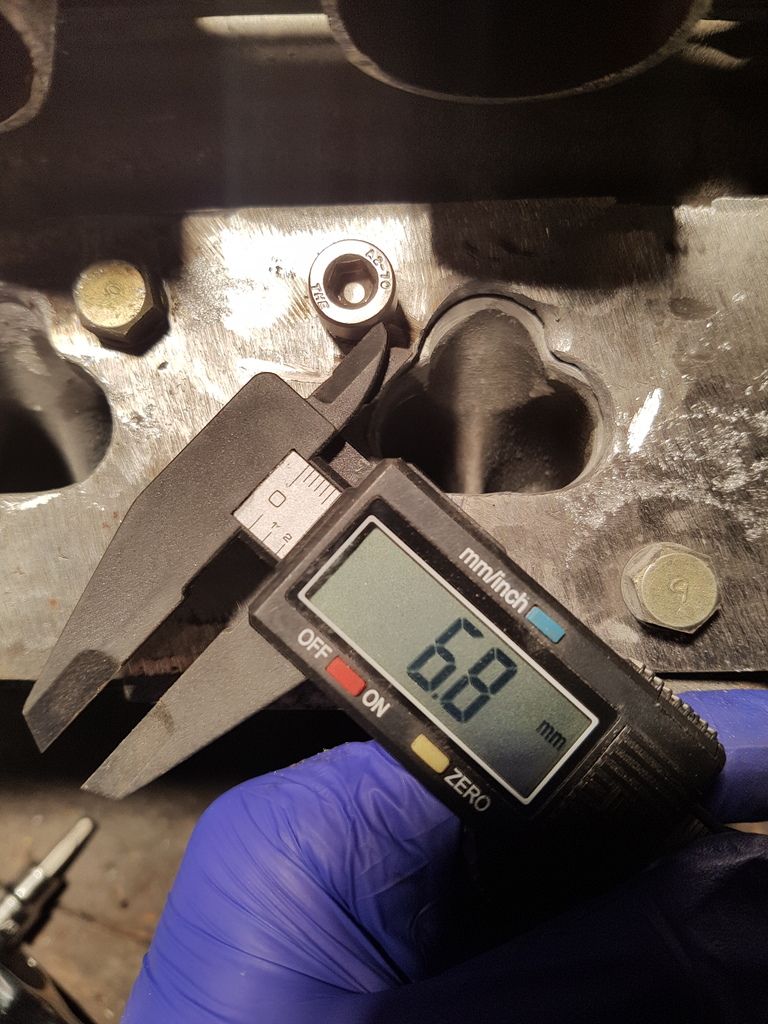

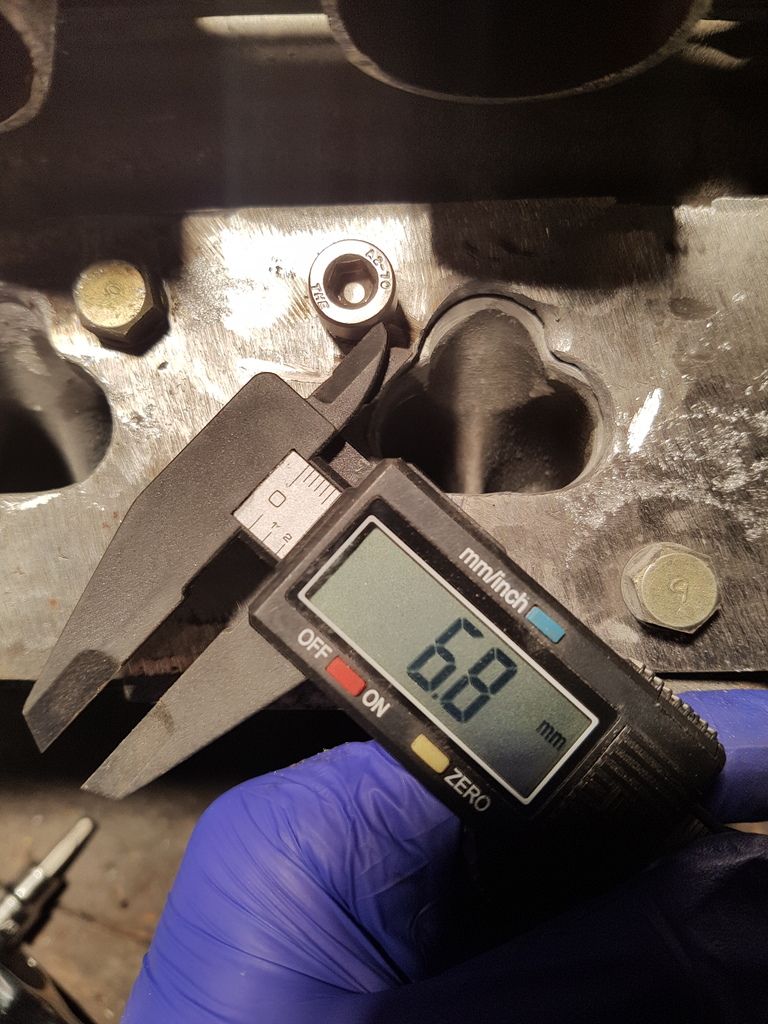

clearance using studs and nuts or bolts

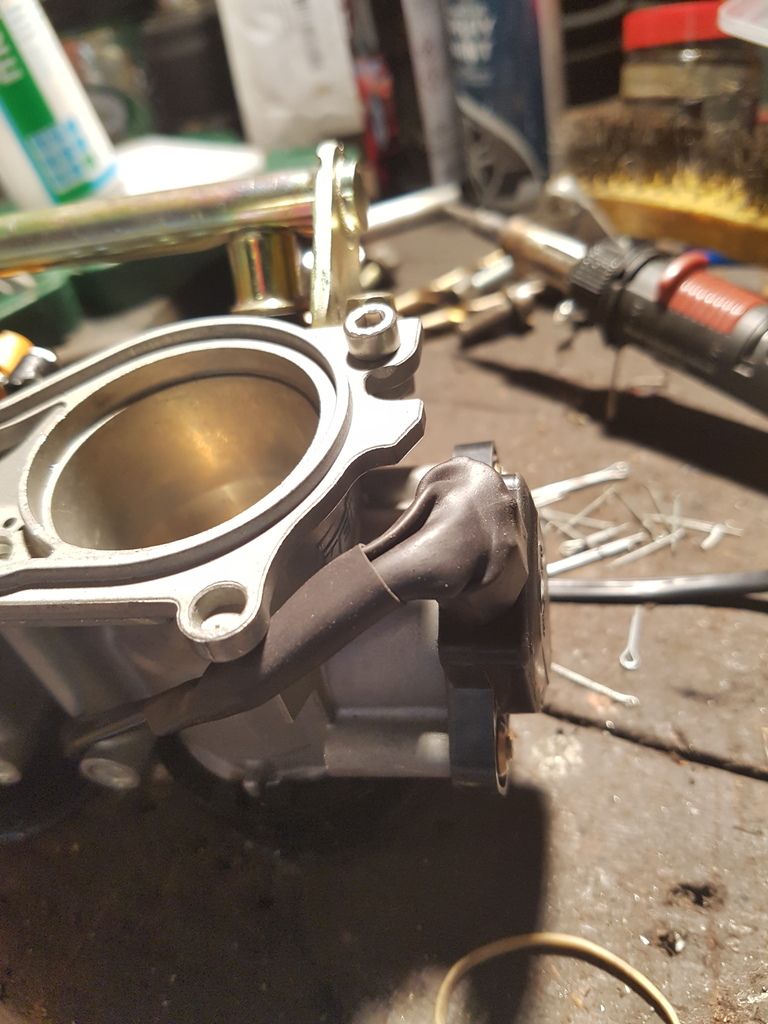

so I had a think and came up with the solution of getting some stainless cap head bolts.

now got a lot more clearance for the welds

All bolts replaced on the plate

Its not a bad solution to the problem however I need to be extra carefull not to thread any of the bolt holes in the head as obviously ali is weaker than stainless and I don’t fancy retapping a head on the car! The mockup head im using this has already happened to on two of the holes therefore im keen to avoid this issue!

So today. Was planning to weld up the manifold.

Got attacked by the welding wire first

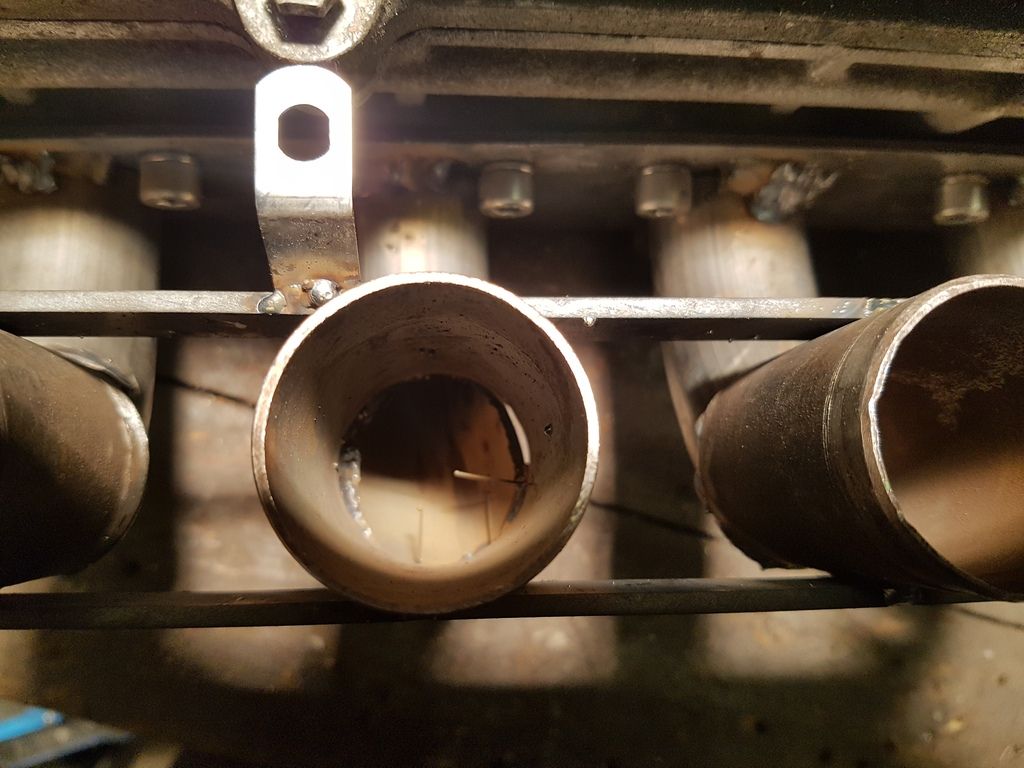

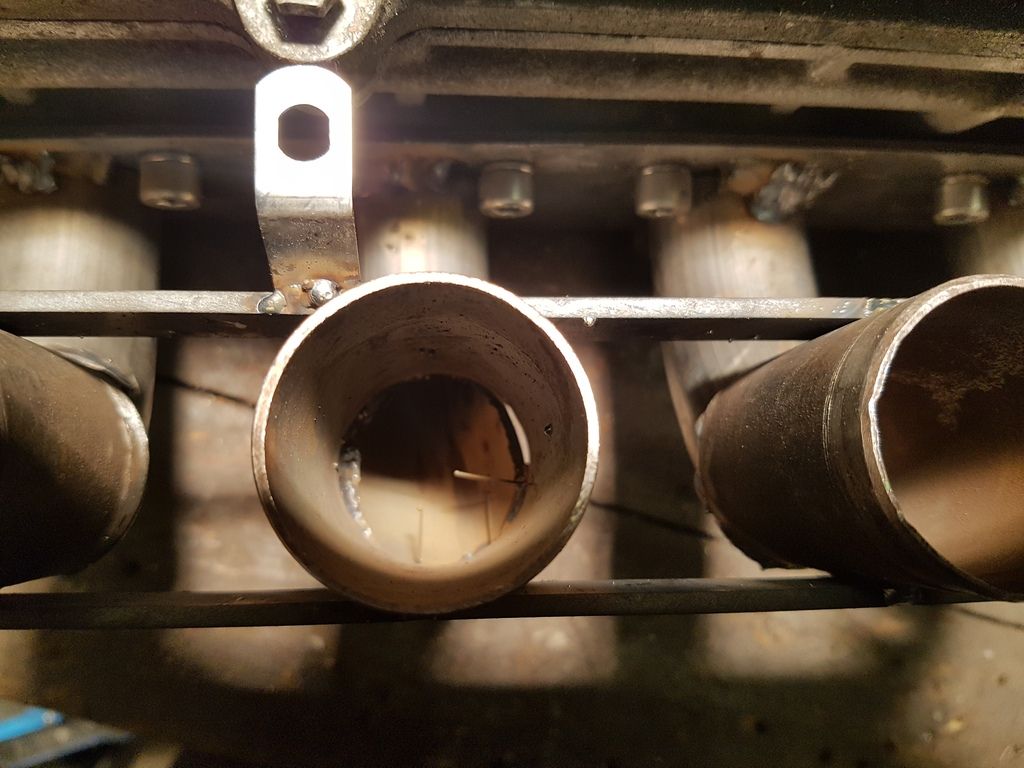

partly welded

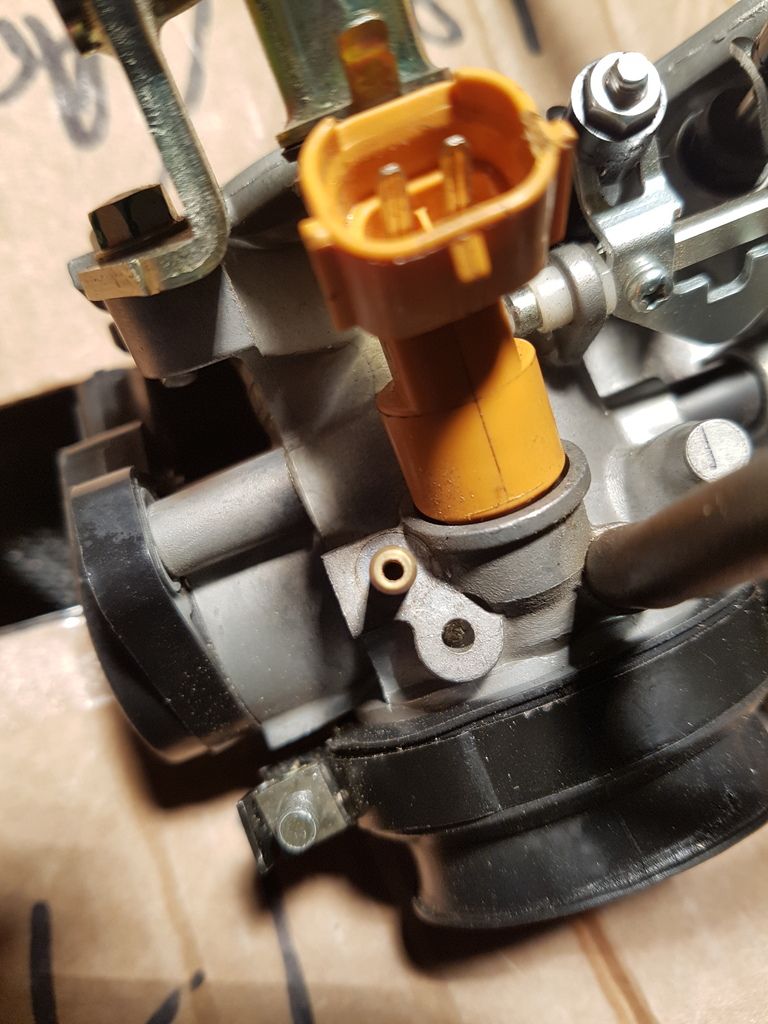

close up

nice and smooth flow

you can see I cut the two outer ones a bit too much also

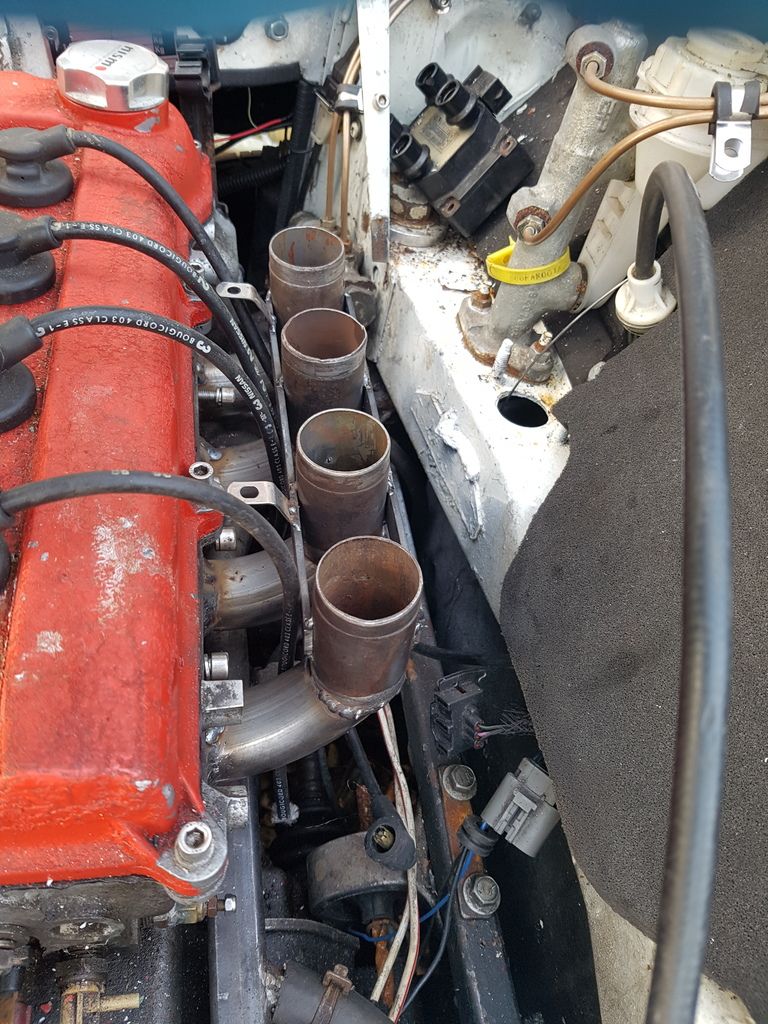

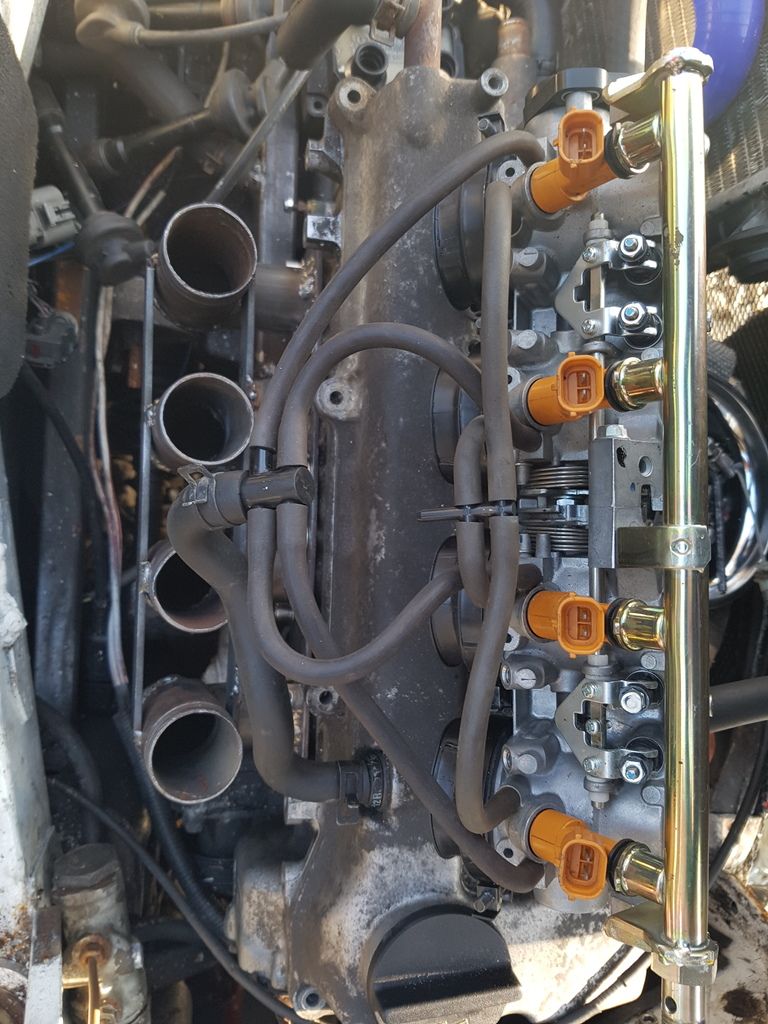

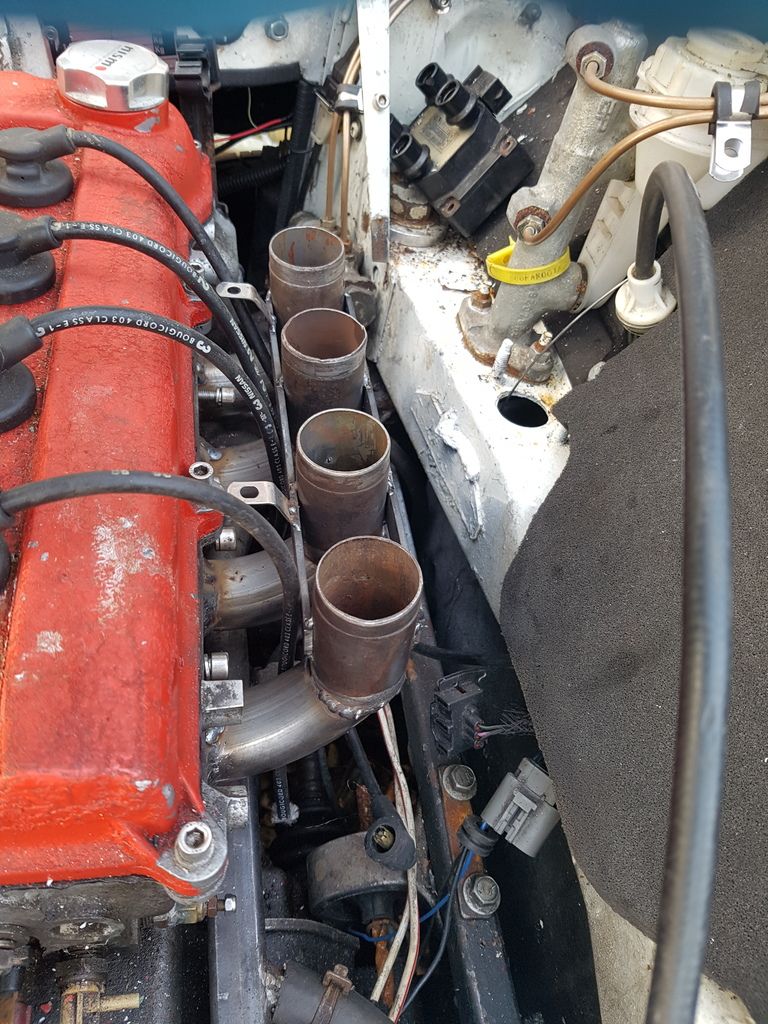

mockup,

nothing hits the rocker cover anymore and I know there loads of space on the car at the back so not worrying about the brake master cylinder either

and mostly welded. Have to do a few bits but I wanted it to cool completely before I took it off the spare head

the flow is fine where I had to add metal back, just needs some cleaning up on the inside

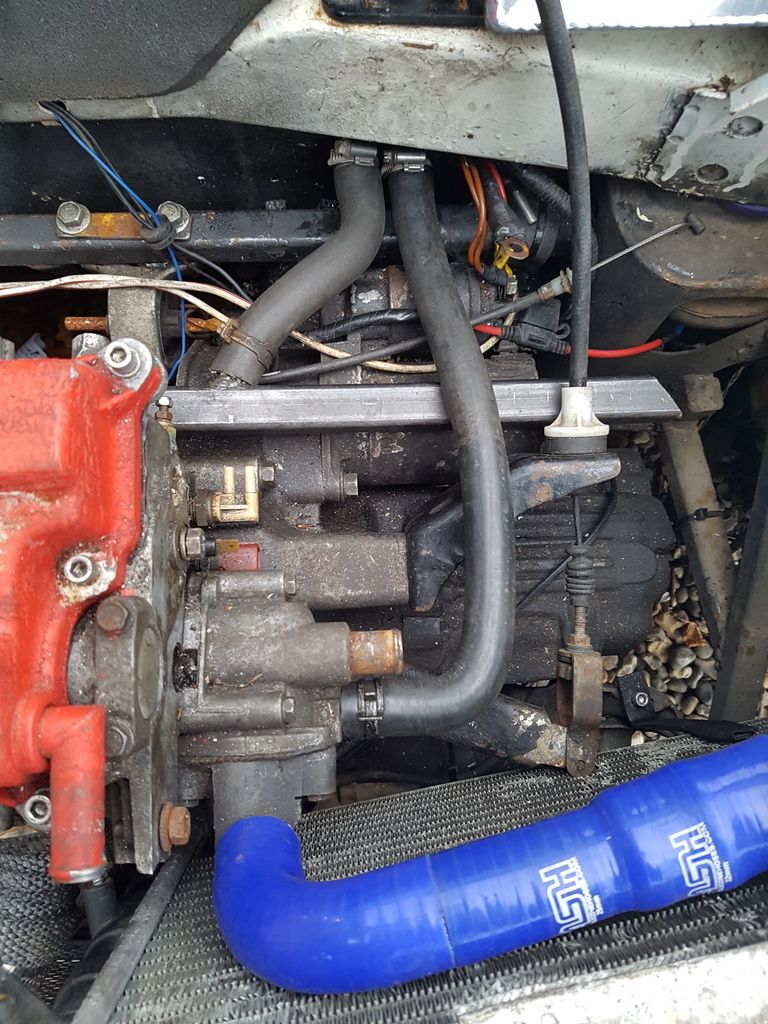

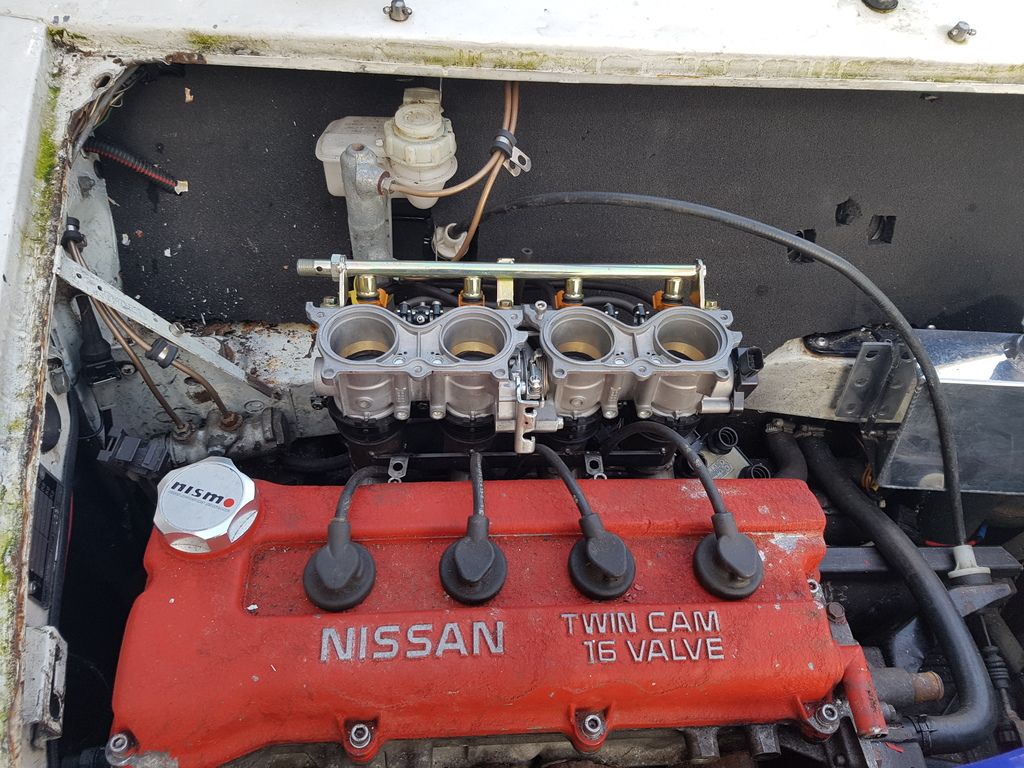

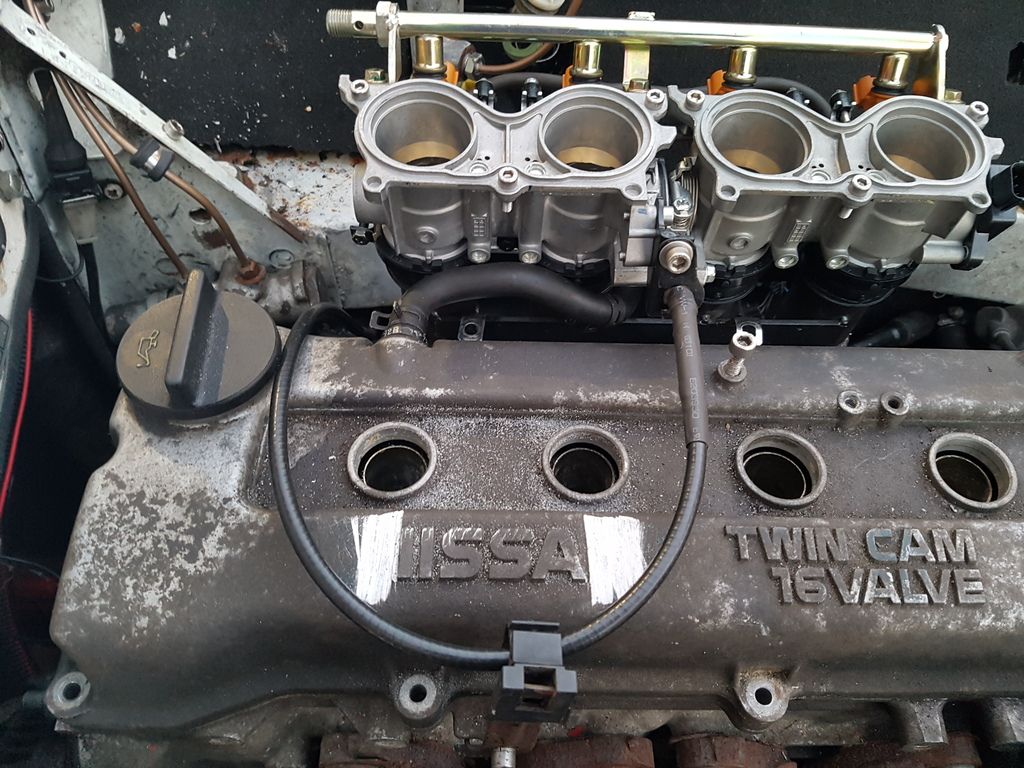

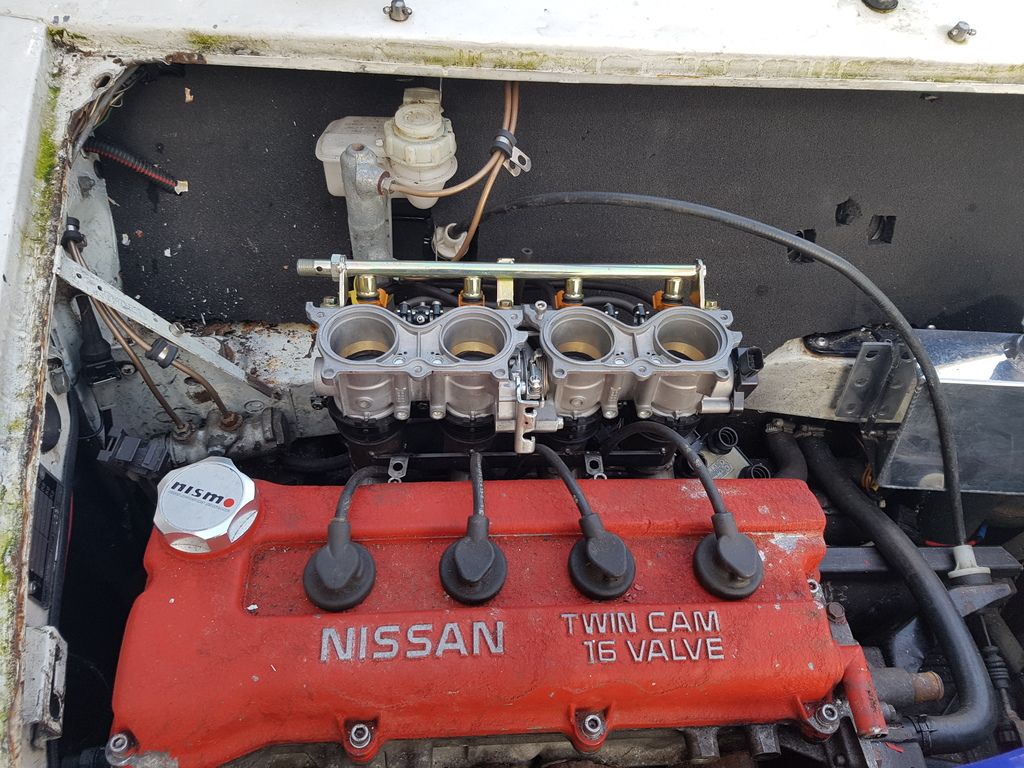

and fitted to the car

still got some welding left to do but I was getting a bit bored of it to be honest

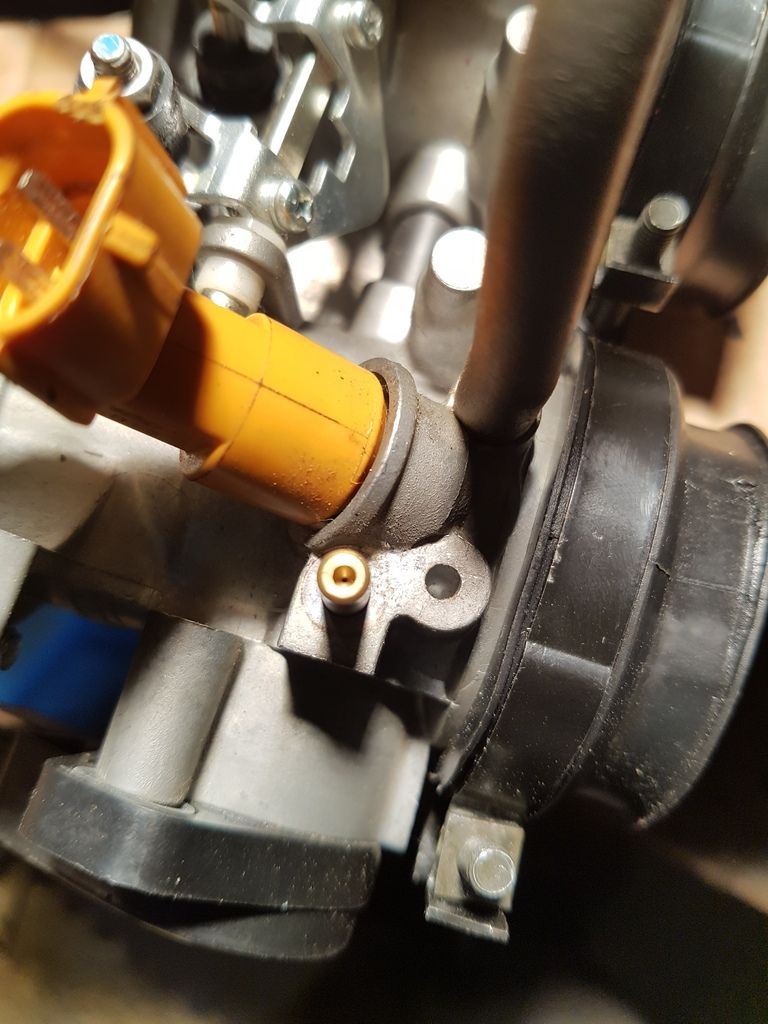

and throttle bodies fitted to the manifold

airfilters placed on top. Will be snug with the bonnet! But hopefully the long inlet manifold runner will be torquey

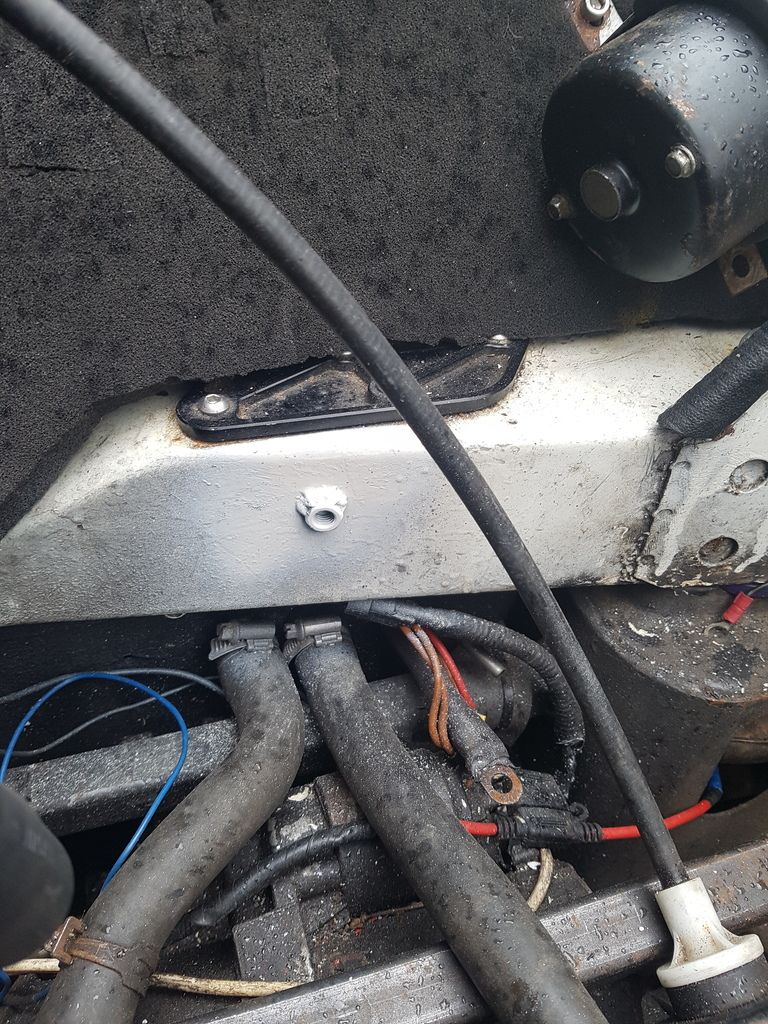

On a side not this is almost as busy as the engine bay will be,

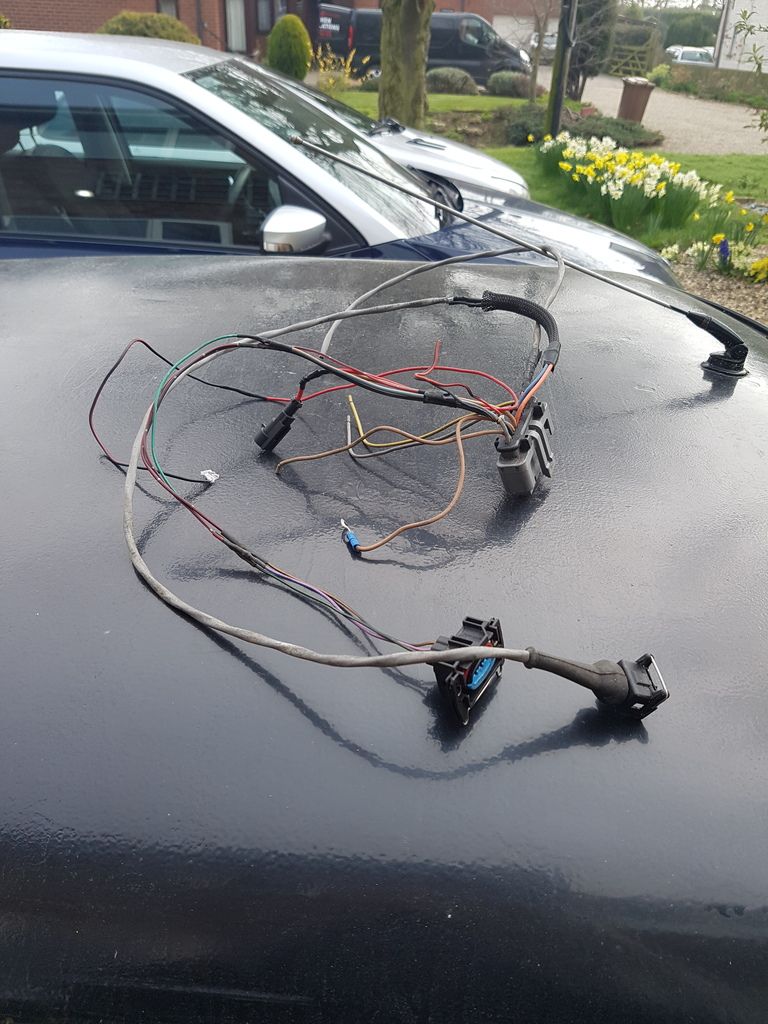

Im planning to replace the sound deadening with one new piece that runs the length of the bulkhead. I also need to refit the wiper motor in the usual position and have asked for the Retrosport cover for my birthday to add some flair. Lastly im going to get some brushed stainless to cover the exhaust manifold up, this I will bend round to protect the radiator from heat also. Its weird seeing the bay so empty!

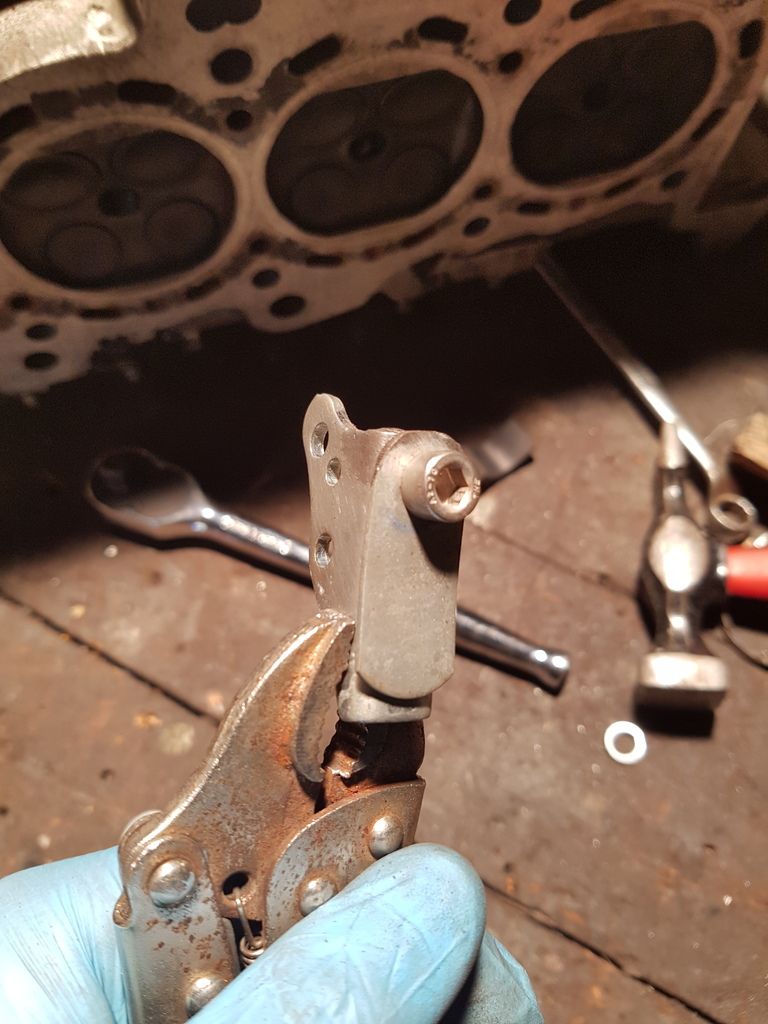

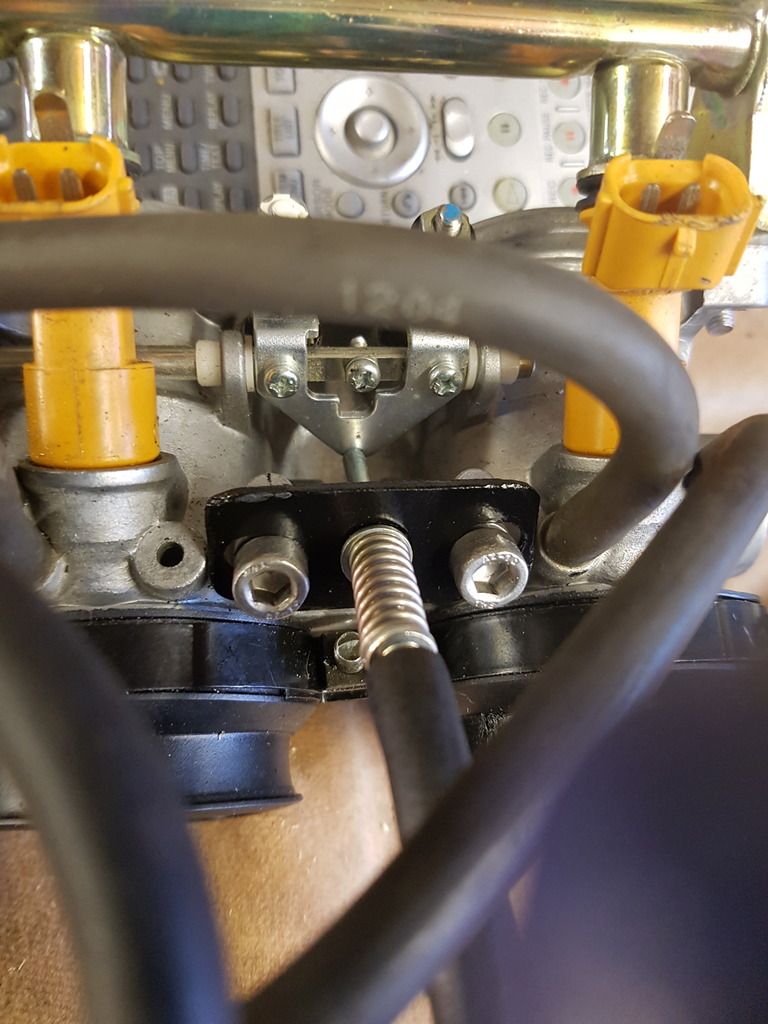

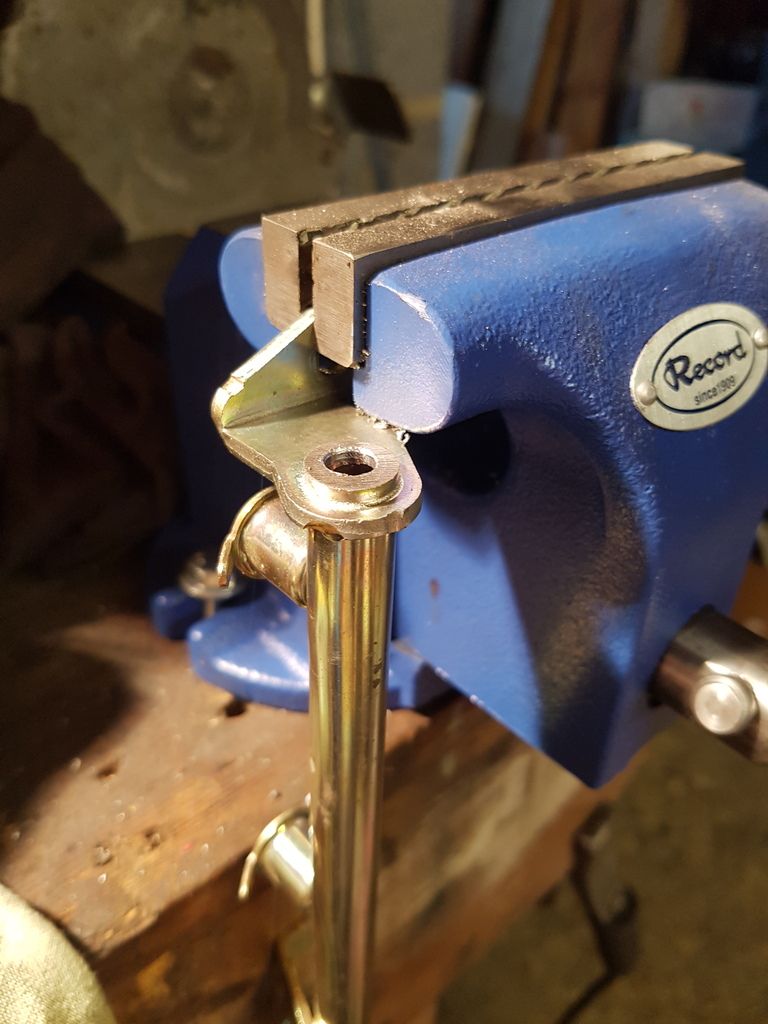

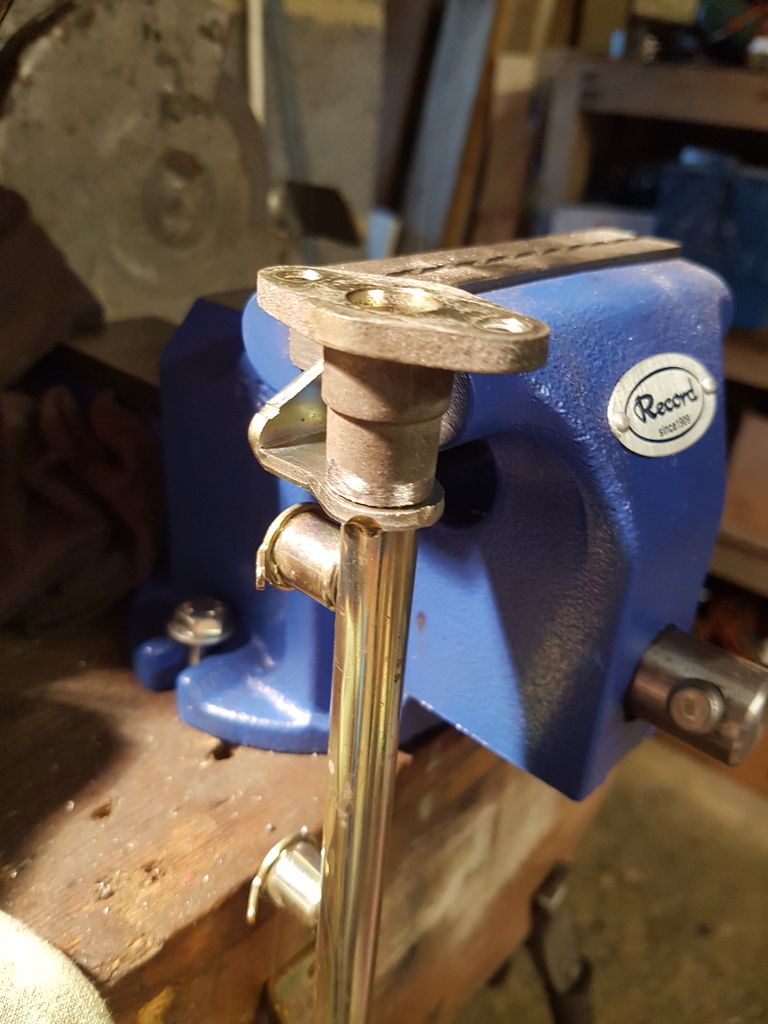

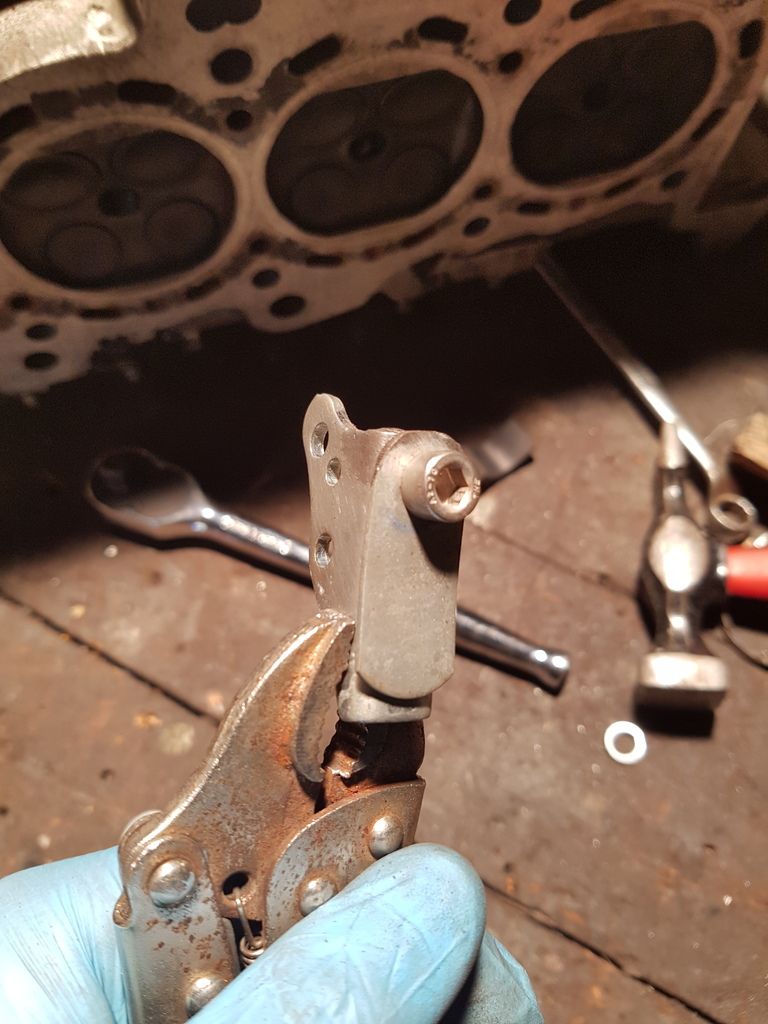

Next up a bit of fabrication

and fitted

It needs a bit of paint but it does the job of holding the throttle cable in place excellently, there is no movement at all and no chance of it falling out due to how ive overengineered it! Just need to adjust it at the pedal end and that’s the throttle sorted!

Oh and got a metal bonnet the other day, still undecided with it tho

So that’s all for now folks.

I start placement at university in hospital theatres next week. That means im working a 37 ½ hour week as well as a 12 ½ hour day at work on Sundays when possible. Ive also got a 3000 word essay to do as well as a 7000 word dissertation.

I cant see myself doing much work on mini as uni work has to take priority. Im Also over mini budget this month by about 50pounds

So keep an eye out for updates people but there may not be many for the next 3 months or so

Lawrence