Good evening

All these updates to add! Had one of those days where you decide to change your plans for stuff, I will try my best to explain.

Driveshaft gaiter

Tacked

Welded and ground back

So I decided not to weld in the next part yet as I want to trial fit it all first. With the spare driveshaft I have I've got loads of suspension movement but I am not going to count my chickens until I have trial fitted it!

I made a metal template to ensure the domed bit was welded centrally as well as making measurements frequently when tacking, for once the cold weather means there's less chance of warping!

So that's ready to trial fit when I fancy rolling around on the ground.

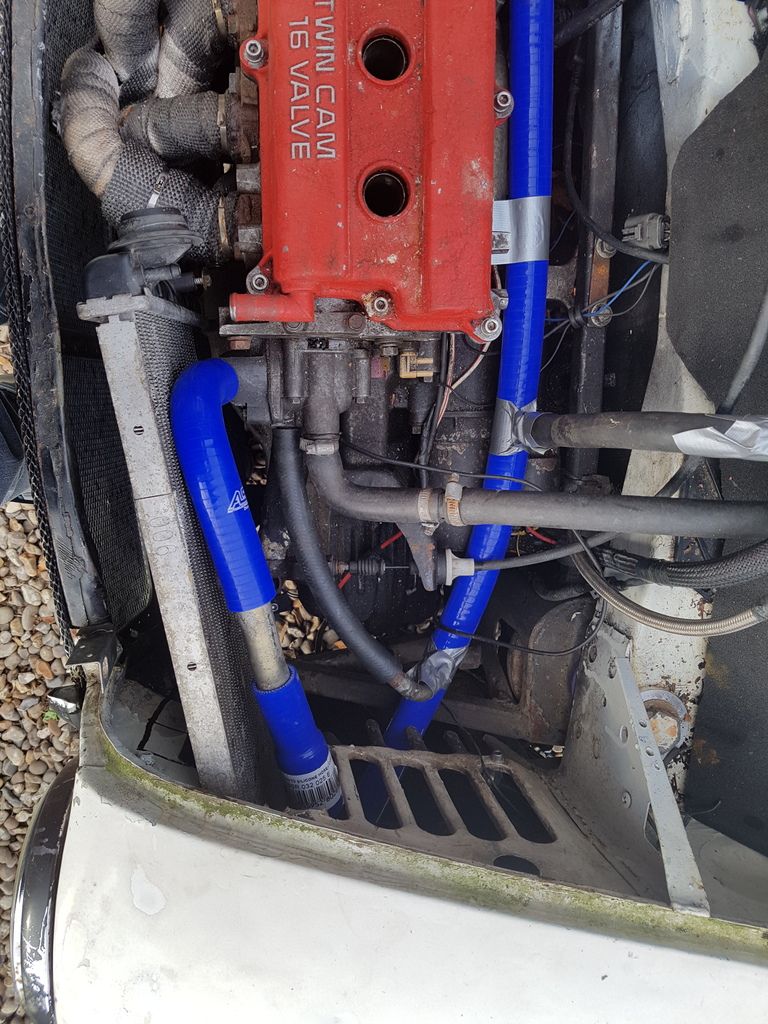

Coolant system

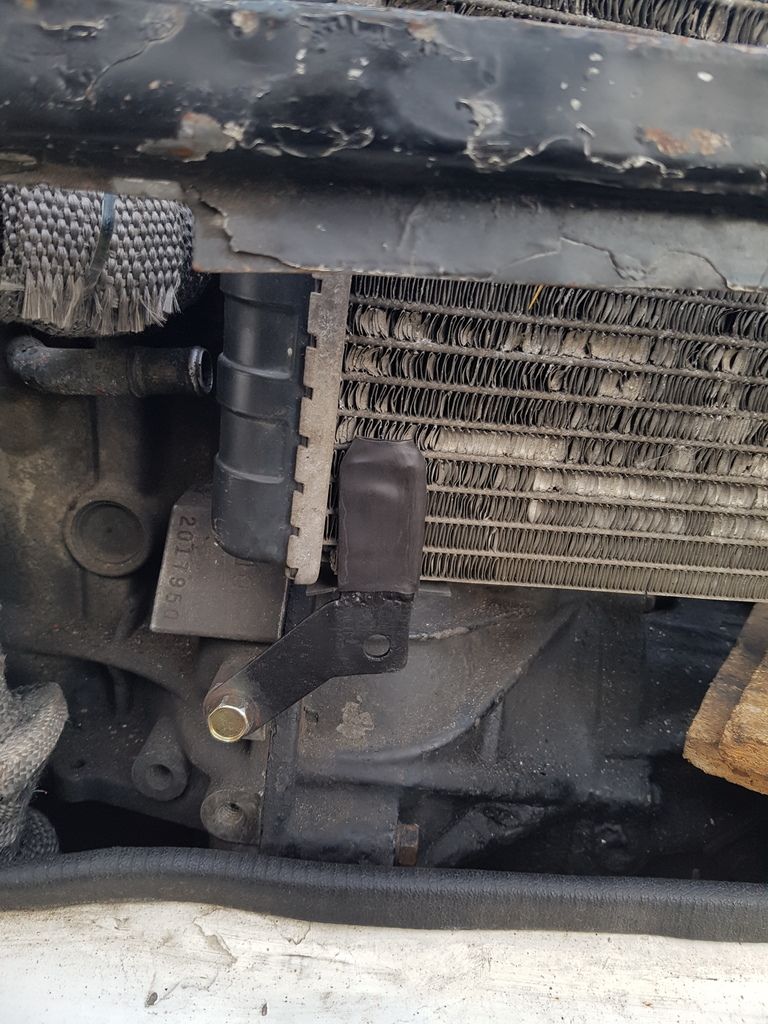

I have made both lower mounts, as I decided previously they are rubber lined and held in place with heatshrink. They look very tidy and hold the rad securely.

Left lower, welded and painted

Fitted

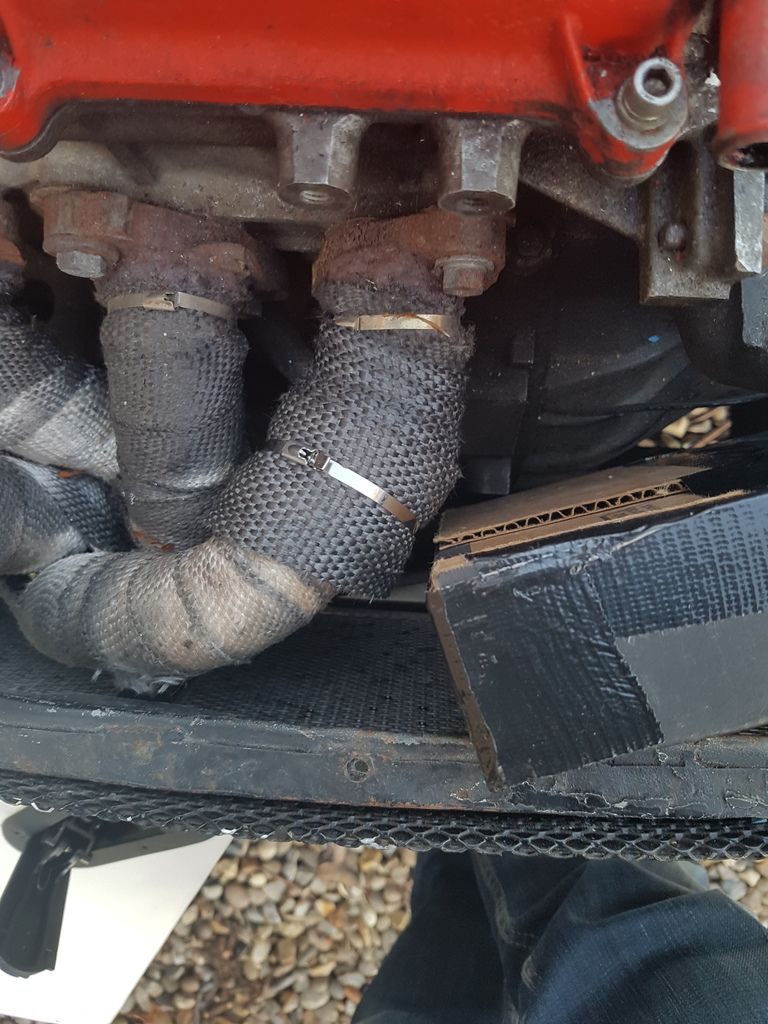

There is plenty of clearance around the exhaust, I still need to cut the bulky rubber mount part you can see in the photo off, that will give more clearance. No clearance issues with the bonnet fitted either.

Right lower mount, welded and painted

Fitted

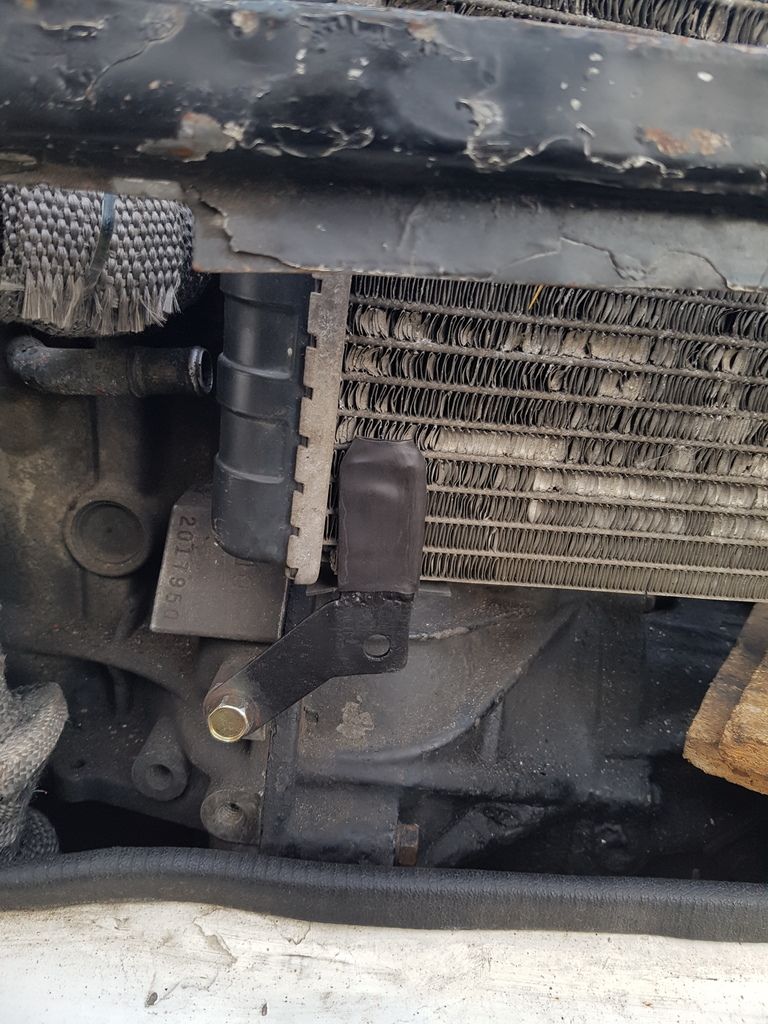

It's hard to show in this image but there is now lots of clearance around the wheel area regarding how close it is to the radiator

Lastly here is an image of all the pipework that has literally just turned up, if I get my uni work sorted tonight I may do some trial fitting of the pipework tomorrow morning, if not it'll be next week when I get out to play again.

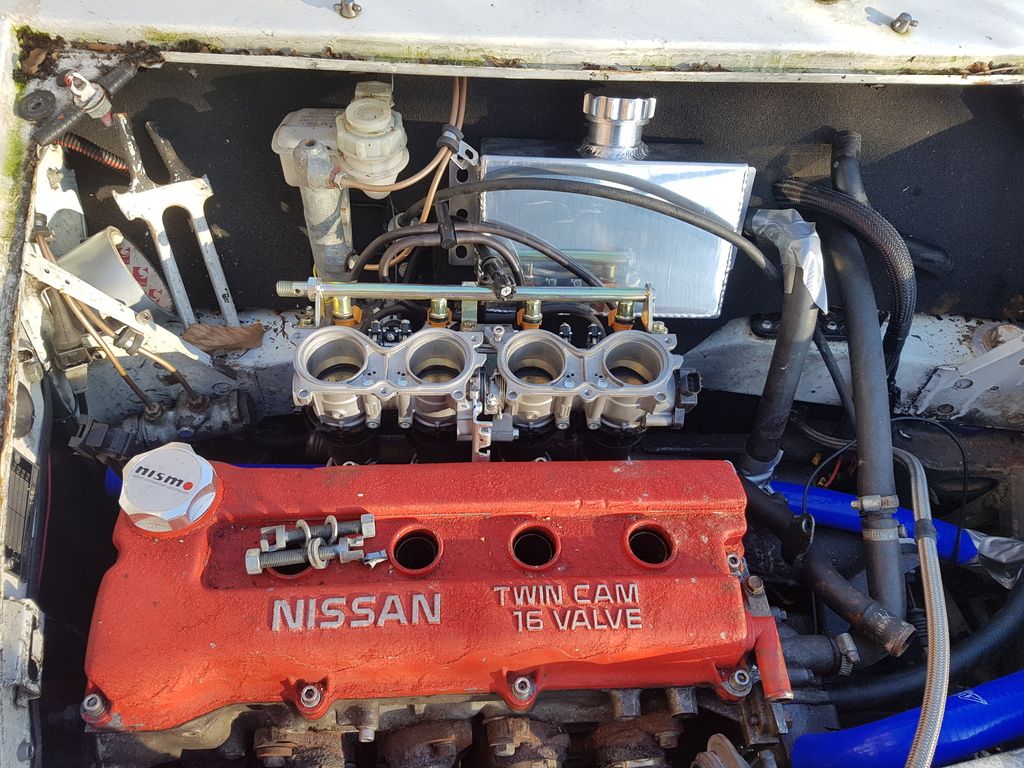

Throttle bodies and manifold

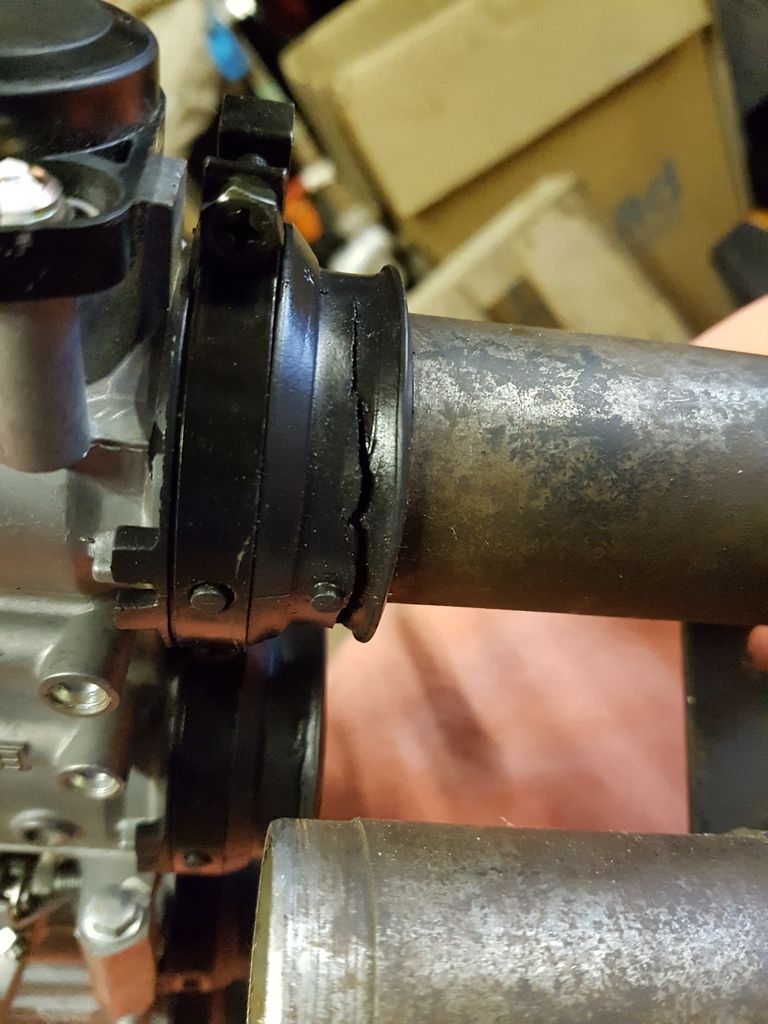

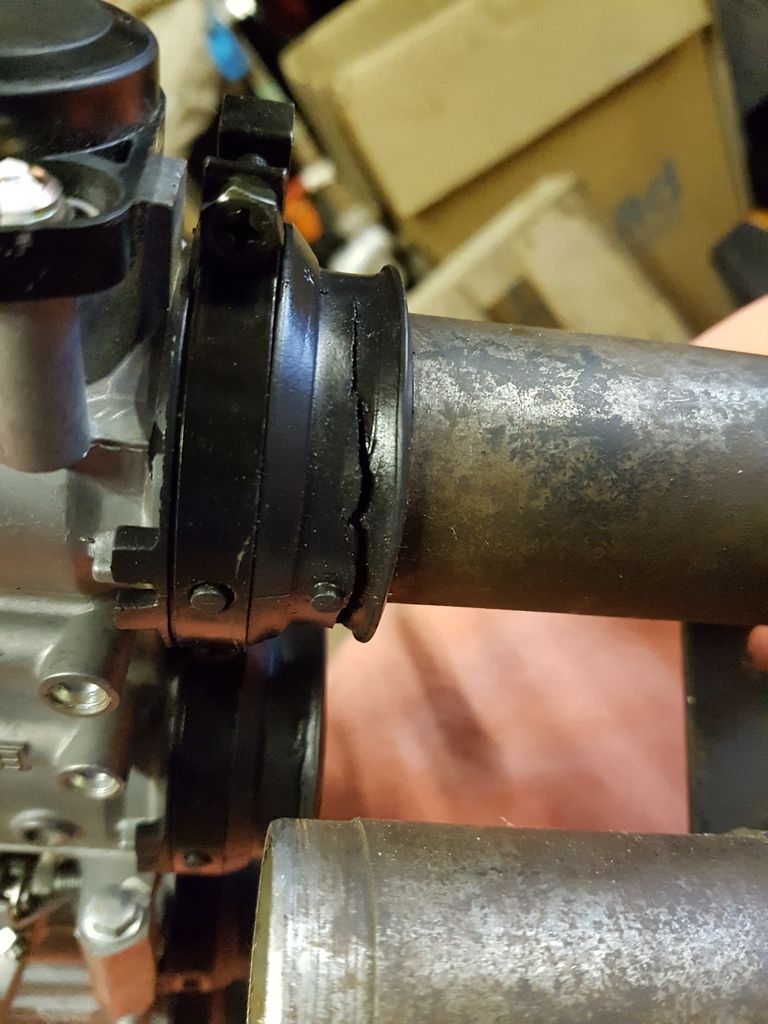

So the manifold rubbers turned up,

they are broken

So that's annoying straight away. Got a refund so that's ok and they will work for mocking up.

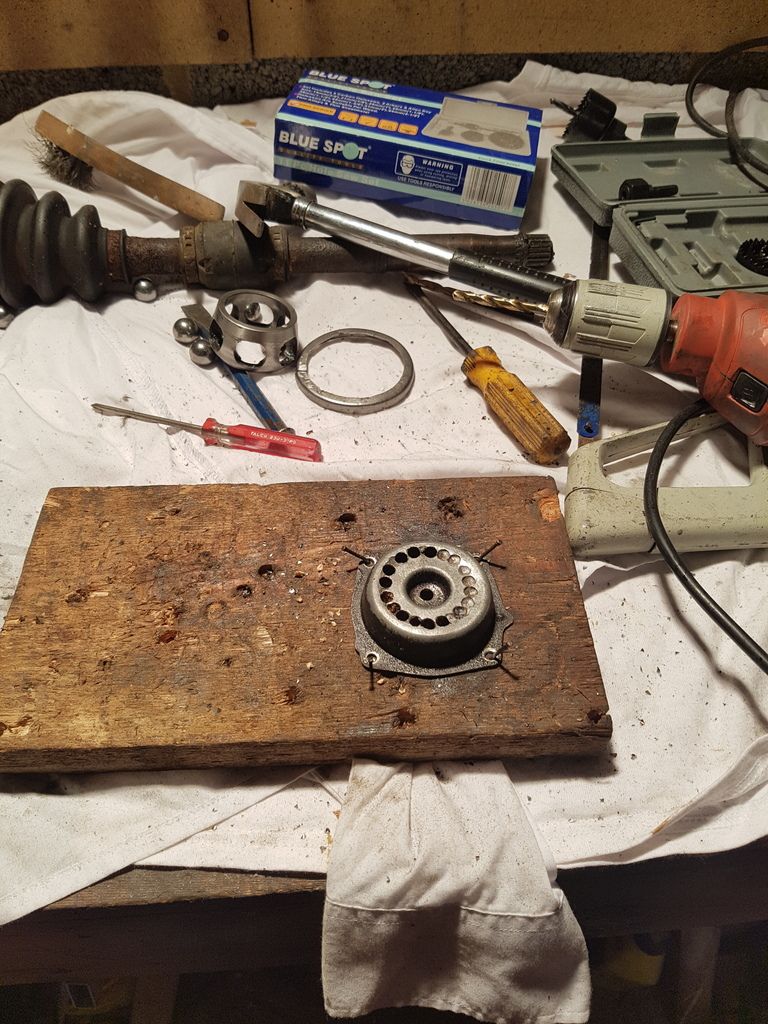

This is where it gets complicated. As you can see in the picture the steel pipes that made up part of the old manifold fit perfectly into the new throttle body rubbers.

Better photo to explain

As you can see someone has taken the time on the old runners to lathe them down for the old carbs.

However the lathing down is an absolutely perfect fit to the throttle bodies too!

(Which sort of makes sense as they are the throttle body upgrade from carbs as the bike was the cbr600)

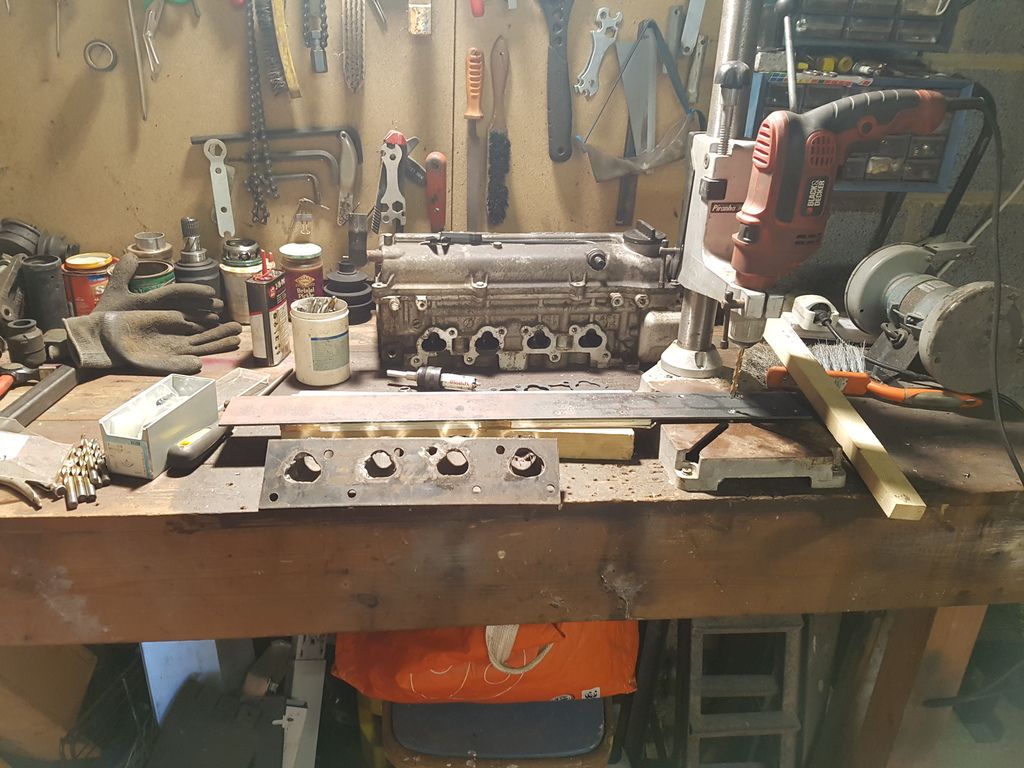

So this is my fun situation,

>If I buy new alloy pipes I can't find them online ones that are the same diameter as the rubbers. The rubber is fairly stiff so I need Ali pipe that is spot on. God knows where I find it. So I need to do this

>I buy Fluorlined silicone connectors which again is not cheap but I can get the pipe sizes suitable easily.

Then

>weld everything together using my new spool gun to weld the Ali

=new manifold in Ali (cost £61.48(fluoro pipe and Ali bends))

Or or

>cut off the old manifold steel pipes (that fit perfectly)

Then

>buy some mild steel 90deg elbows

Then

>Cut the crappy parts off the manifold I had before giving me the flat plate part with the cutouts for the inlets as well as the bolt holes.

>weld the new 90bends to the recycled lathed down part

=

New manifold in steel (£27.78 (2x180 deg steel 38mm bends))

Now the price difference is £30 but I also need to get all the stuff for welding Ali i.e. (Steel brush,grinding disk suitable etc as well as gas (£18) in addition I need to learn to weld It!

Or.

I swop the argon cyclinder I have for co2 (free) buy two steel bends and bosh a steel mani together in a day!

So I am apologising to anyone who wanted to see some entertainment with my Ali welding but I haven't got the time or money to go that way currently. I'm sure others would make the same choice tho.

That's all for now folks

Lawrence

(Ps: I have got one bottle of argon still that I can't take back so I will be making a fool of myself sometime in the future.