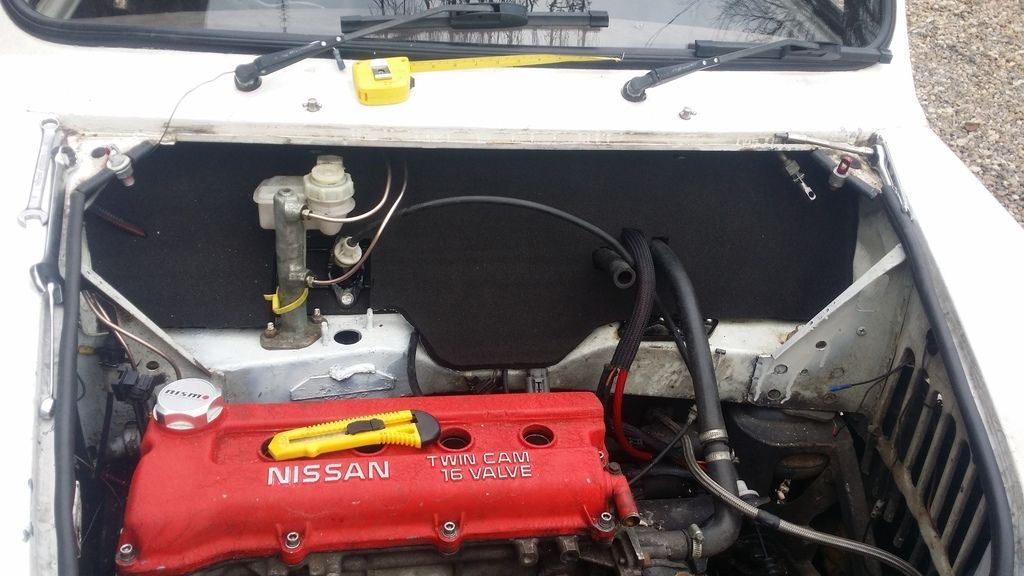

Ken -The 1275 High Compression Engine Micra Mini (Running Project)

#451

Posted 22 February 2016 - 02:11 PM

Lastly I've made a start on the rear engine mount so can begin to make that up come pay day when I get some more gas for welding

#452

Posted 26 February 2016 - 05:40 PM

I'm now on placement from uni. That means I'm working a 37 ½ hour working week but also have to do learning logs and have a big essay to do. But what that means is I now have 3 days off a week so at least one of them can be working on mini! :)

My brake lines arrived the other day from dsn classics. I ordered 1m long lines so have plenty to work with

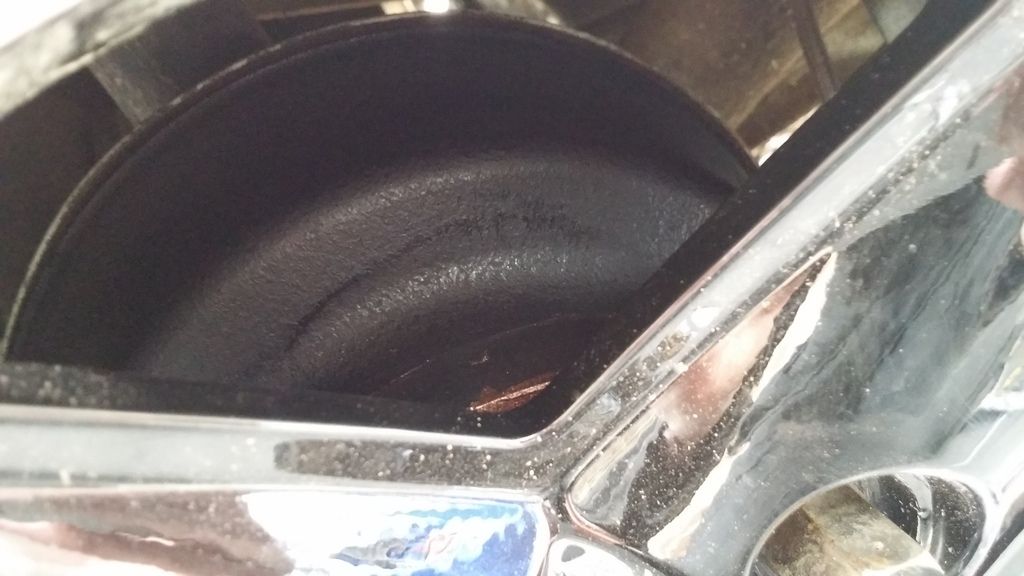

Now waiting on the p clips to secure them. Also measured and fitted sound deadening foam to the bulkhead

Tidied up some wiring on the bulkhead and relocated a few pieces

Made a cardboard template of the sound deadening for the other side

Cut and fitted the foam

Bulkhead looks so much smarter now

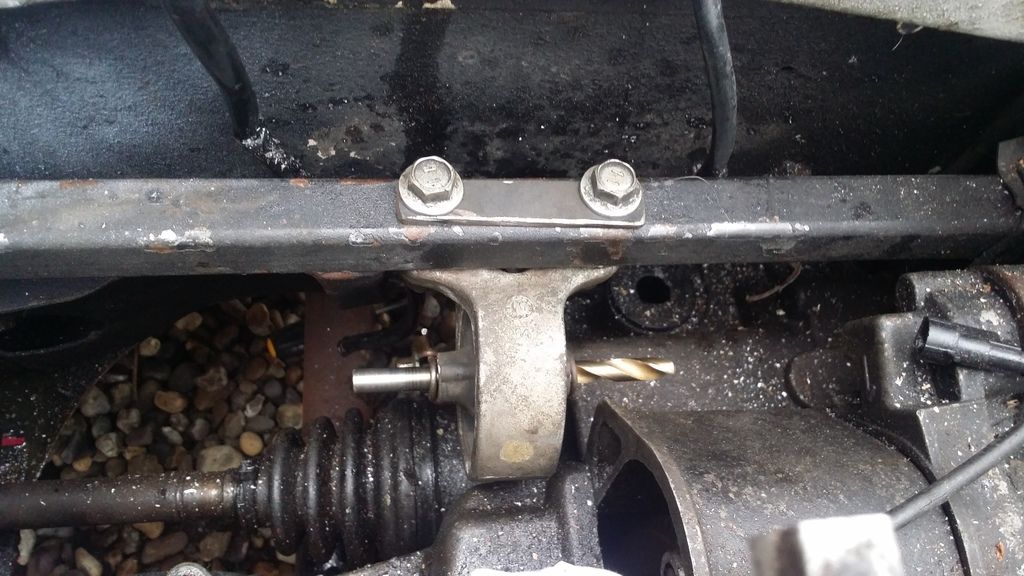

Drilled the holes for the engine mount and fitted it

Mocking up the mount with simple wire twists

Just the one bolt into the gearbox casting holds the engine nicely, however there is a lower threaded area I'll use also and triangulate the mount so it's more secure.

So brakes done

Engine mount done (well the hard part just need to drill some bar but that's the hard bit ok)

Carbs now then :)

Trial fit

Float levels much better compared to before

But as always there's problems :) in all honestly I was expecting some bad luck earlier with my track record!

I have clearance issues

However there is a bright side here. The wire twists that are the rear mock engine mount are there basically to see how much the nissan mount settles.

I need to whip the nsf wheel off to see what clearance there is round the driveshaft gaiter (the whole point I'm redoing the rear mount). Maybe when I take the wheel off I'll find I can lift the rear of the engine more and that will give me more clearance.

But if I have to stick with this clearance what are my options? It's about 3mm so a tight gap

Reckon I can simply notch the bulkhead a little or gently thump it with a hammer?

Hmm

Well feel free to comment. I've been paid but it wasn't a lot so good I'm using my bike as if you cough into the fuel tank after a night out it'll probable get you to work!

I need some argon gas for aluminium welding too then I'll get playing in that department

Lawrence

#453

Posted 26 February 2016 - 06:34 PM

#454

Posted 26 February 2016 - 07:44 PM

The sound deadening is acoustic foam that's designed for recording studios. It's open cell so should absorb noise but I deliberatly got the fireproof type so it's ok in the engine bay. It does burn if you hold a flame to it but as soon as you take the flame away it goes out so hopefully safer. One drawback is that being open cell it absorbs water to some degree so the paint on the bulkhead has to be solid and every month or so I pat it down with a paper towel to remove the moisture

#455

Posted 27 February 2016 - 09:26 AM

#456

Posted 27 February 2016 - 05:47 PM

Right so today I've been sorting the wiring out, trying to get where it goes inside the wings a bit tidyer and better protected. Also moved various wires where they are added into the origional mini loom.

Lastly I fitted my other front side light/Drl. You can see that was a test fit of the indicators also. Slightly dim as it's behind the grill but it was also a bright day so I think they will be fairly easy to see and I'm happy.

Also honed the clutch a little and that's now working great with no rubbing on the bulkhead. The feel is also better, it's less springy which I put down to the bracing bracket on the bulkhead spreading the load.

I'm putting in an order on minispares tonight. Thinking of buying all the annoying bits that have been nagging me for a while but it's total is £85! So I'll look into cutting some bits out

That's all for this week now. I'm busy tommorow and working the next 3 days after that. So next update will be the 3rd March :)

Feel free to comment

Lawrence

#457

Posted 27 February 2016 - 07:19 PM

#458

Posted 27 February 2016 - 09:00 PM

#459

Posted 03 March 2016 - 01:17 PM

Also got lots of niggly pieces like tie bar bolts spring washer etc.

Those of you with good I spy skills will have noticed that my subframe top mounts are shot so I've also bought a new semi solid mounting kit which may improve the handling slightly who knows!

Also bought some new spacers for the rear wheels to make them lovely and flush with the arches :)

It's my birthday on Saturday so I'm off to Colchester zoo with the girlfriend so my next updates will be in the middle of next week I should think!

Lawrence

#460

Posted 03 March 2016 - 02:28 PM

Lawrence,

You are going Colchester Zoo haha, whats your location Pal?

My Girlfriend lives in Colchester and I in Hadleigh (Ipswich way)

Haha

#461

Posted 09 March 2016 - 08:31 AM

Smudger I live near Norwich so we stayed over in Colchester at the uni hotel. Was a nice bday present from the gf :)

So while I was away my shopping arrived

Lots of nice shiny things but not much left now it's mostly fitted!

So I started at the back. Have all new brake parts and some wheel spacers to fit

Current over arch gaps

No poke at all

Extended studs fitted

Trial fit old drums with spacers, nice bit of poke now

Tread under the arch so legal :)

All new shiny brake parts fitted

Warming the drums on the heater for painting

Bit of heatproof black

Fitted

And same the other side

Drums and spacer fitted with lots of lovely copper grease on the faces

All back together

Nice rear view now

Replacing front subby top mounts

As you can see they are shagged

Fitted the new ones

Shiny shiny

That's all for yesterday folks. Now the top mounts are new ive got trouble getting the heelboard ones holes to line up. Oh and the front braket broke off for one of the teardrop mounts which is nice of it

Feel free to comment

Lawrence

#462

Posted 09 March 2016 - 08:41 AM

#463

Posted 09 March 2016 - 10:00 AM

The brake shoes are the wrong way round, I'm not exactly sure what difference it makes.

Mixing those solid and flexible subframe mounts is a no no too.

Edited by Artstu, 09 March 2016 - 10:05 AM.

#464

Posted 09 March 2016 - 02:02 PM

Cheers for the photo of the brakes artstu, I can't find a clear photo in my Haynes so just popped them on using the tiny photo I had to help. I'll make them correct when I bleed the brakes. Will also print your picture off so I can pop it in the Haynes for the future

Thanks for the helpfull comments chaps

Lawrence

#465

Posted 09 March 2016 - 07:05 PM

5 user(s) are reading this topic

0 members, 3 guests, 0 anonymous users

-

Bing (2)