Ken -The 1275 High Compression Engine Micra Mini (Running Project)

#421

Posted 13 January 2016 - 05:45 PM

#422

Posted 14 January 2016 - 06:55 PM

Considering you started with a fairly rusty shell and didn't know how to weld!

Brave of you to weld your own subframe and go through a whole engine conversion!

I think you've been really unlucky with all the issues you've had.

#423

Posted 15 January 2016 - 12:03 AM

I think the luck is down to a lot of trial and error. I've no certificated knowledge of cars, only what I've learnt and taught myself. Then I decided to do an engine conversion, as you do haha :) I'm glad it didn't go to big on it and think vtec and stuck with the micra. It's never going to be a track racer that's for sure but the whole point of the conversion is I didn't have the heart to get a new car for uni and needed something that was reliable (ish)

So time for a little update.

Cable ties have arrived so weather permitting I shall fix my gaitor problems for good hopefully!

I've also tested out the headlights That I fitted for the mot and omg the beam pattern on them is shocking, absolutely awful even with standard h4s fitted and bench tested. There's zero beam cutoff at all!

So plan for my headlights are.

>Pickup some Cheapo sealed beams- so long as they match so they will pass the mot.

>design some new projector headlights for the long run :)

Also have got my rear brake cylinders so they will both be changed and the current nsr one will go into my spares box. I know it seems silly changing it but as I can't remember how old it is why risk potentially ruining new pads for the sake of £8 as it seems a false economy.

I have fixed something tho that wasn't even on the mot!

One think that has been bugging me has been my sloppy clear change, at the top of the stick there was 7.5cm of play once it's in gear (yeah I measured it, sad I know)

Now this isn't a mini slushbox this is a micraminiraccar (all one word)gearbox so I don't like that play and it's got to go.

I checked the linkage bolt and it's slightly loose well there's should be a locknut there and there's not so that won't help. Nipped it up and tested the play. Better but not great.

So I looked through the part draws and through my boxes of misc and found the bolt of perfection

Here's the old on measured by my calipers

7mm shaft is making the linkage sloppy

Replacement

7.8mm.

That's more like it. Test fitted it and it was ever so slightly too snug. Gave it a stroke with some sandpaper and a smear or copper slip and it slipped into the joint all perfect like!

Plain washer, spring washer and then a nylock nut on the bottom and nipped it all up to quite tight torque.

Tested the play in the stick.

1.5cm and my gosh is it slick. Goes into gear oh so slick.

The 1.5cm play is in the micras plastic joint so I'll look at that some day and I reckon through the cunning use of ballpoint shims can eradicate it :)

May do a few bits tommorow on her but got to fit the new cooker and new shower engine first tho. Plus it's going to be cold so depends on that. Maybe tho

That's all for now, sorry about the lack of photos, I'll try harder next time but rummaging for a bolt for an hour is a fairly rubbish photo!

Lawrence

#424

Posted 15 January 2016 - 12:18 PM

You were only 17 when you started it if I remember correctly you were waiting until your 18 th for some insurance.

I remember you saying you wish you had a lathe, let me know if there is anything I can turn up for you. :)

#425

Posted 15 January 2016 - 04:46 PM

I would love a lathe, only a small bench mounted one for little bits and pieces but I just haven't the room for it currently. When I own my own place one day I'll get one :) cheers for the offer for that, I can't think of anything at the moment as most thinks I've managed to make in the end but if there's something in the future I'll give your message

So tiny update from today.

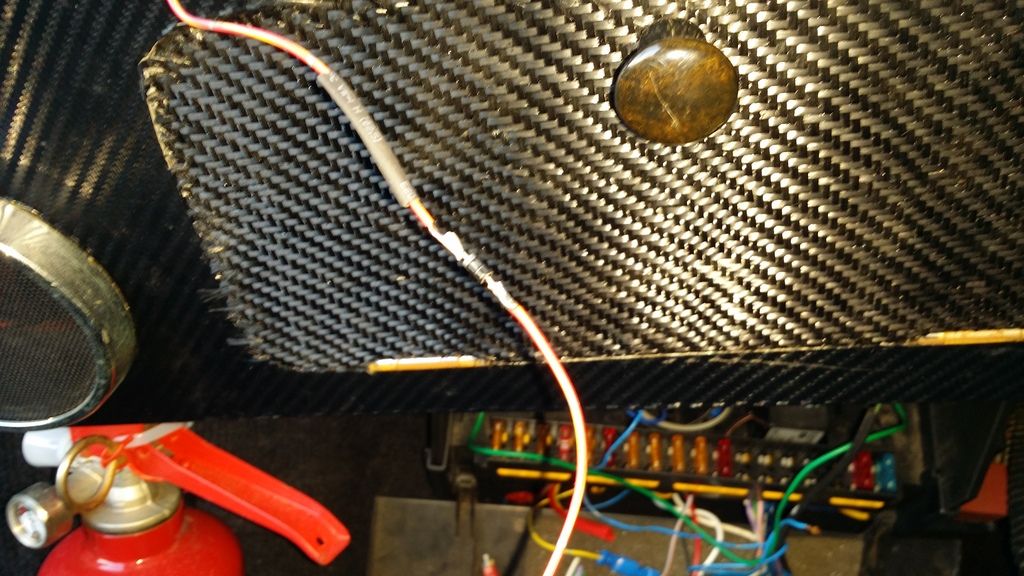

God it's cold outside! I've organised the garage a little and it's ready for a nice day when I can fit parts but today I did a bit of wiring

Fitted a diode into the auto light circuit

I was having a problem when it was on as power was going back through it and into megajolt. This meant when I get home from anywhere and it's dark so the auto lights are on turning the ignition off left the engine running, was initally a bit of a laugh but now it needs sorting. So diode fitted and it should be all good

Secondly I fixed the interior roof light

The two side ones have constant power now so I can use them when the engine is off and the Middle one comes on when the door opens :) just like a modern car.

The roof light has been there for ages but I had it wired via the auto dipping mirror/fuel pump switch so it meant you could only use it when the fuel pump was on. Pretty useless so never used it. Should be better now :)

Lastly for today I've ordered a few bits on eBay

>1mm welding tips

>0.8mm aluminium wire

>plastic liner for the welder

Just need to pick up some argon and then I can mig weld aluminium. I know it's not going to be as tidy as tig and only works for thick aluminium but should be perfect for making a new inlet manifold

And lastly I've ordered an innovate lc1 Wideband to get the fueling spot on. Chose the innovate product as it offers data logging and will be very handy when it come to fueling eradicating trial and error :) (it was a suggestion from L-jonez a long long time ago but as they aren't cheap ive been putting it off)

So that's it for today!

Can't wait for my welding stuff to turn up to give mig welding aluminium a go and that wideband should hopefully be awesome!

Lawrence

#426

Posted 23 January 2016 - 05:40 PM

Basically I've been so snowed under with uni work that I haven't really managed to do anything to mini

Last week I made a new front wiring loom as the old one was looking suspect and when I investigated it the insulation was going very brittle. So new h4 connectors and wire ordered. All soldered and heat shrink on the joint then covered in protective tubing

So that should do when I get the headlights fitted.

Next to arrive was my aluminium welding bits. Went to fit them to the welder but remembered I had to weld the o2 sensor bung on so put those bits to one side.

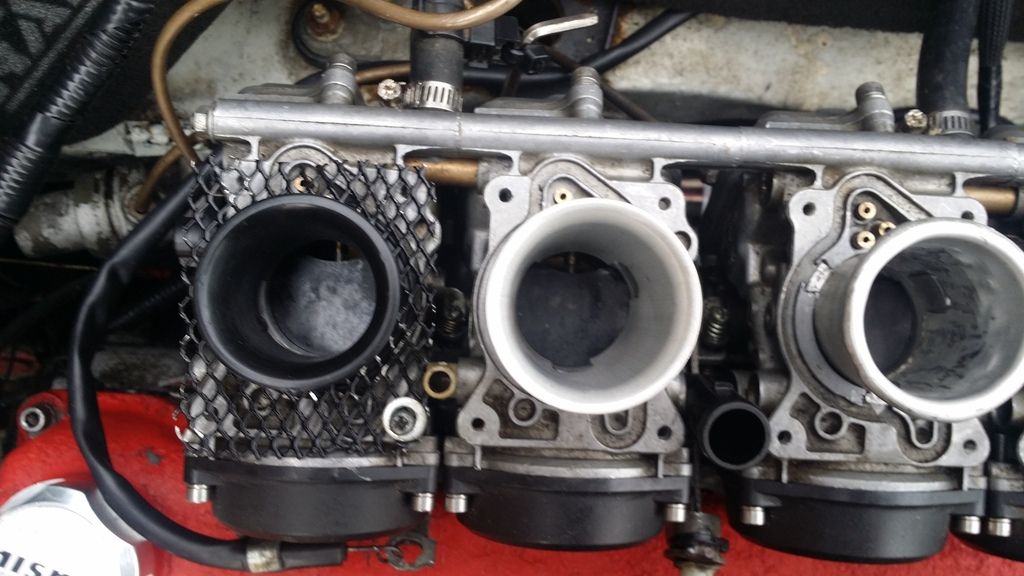

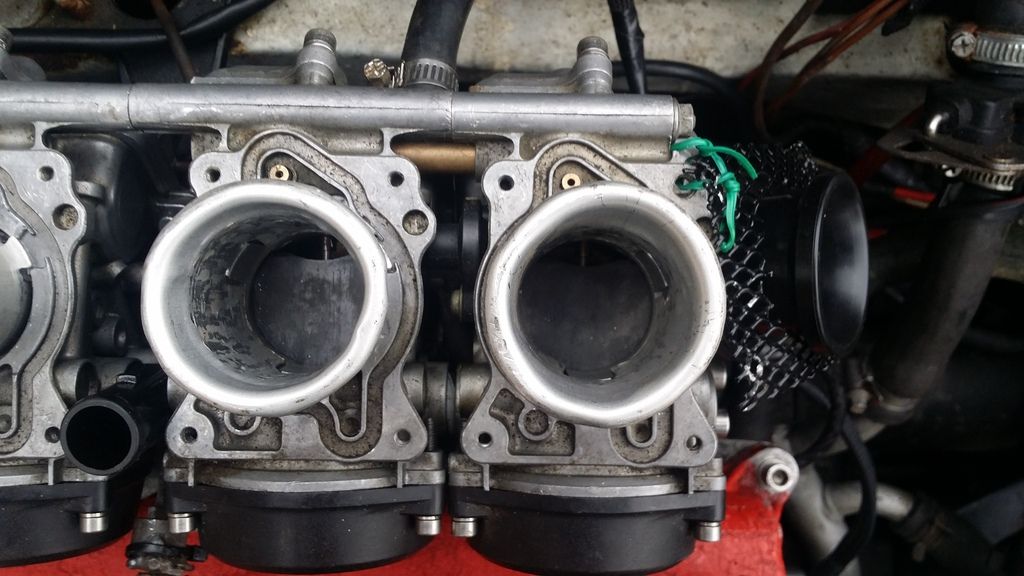

Then these arrived. Advertised as cbr600carbs with dynojet kit so should have adjustable needles!:)

And as you can see they do! That's £15 well spent.

Sadly they are not identical to my current carbs. The needles will fit which is the important part and they share some parts. Only problem is they are a smaller bore. They will do for mocking up a new manifold all the same tho

My wideband lambda also came. Great piece of kit for the price and has data login functions that I need to look into. Gauge wired in

Exhaust taken apart to weld in the bung, as luck has it I have a perfect sized hole saw!

Tacked

Welded and painted

Also added my restrictor to the inside of the exhaust, hopefully will stop the booming noise but let's wait and see!

And this is where the bung is down the back of the engine. I checked a few times to make sure it's not going to clash with the driveshaft

Also got my door light switches to replace the old ones so now I have a reliable interior light!

That's all the pictures I've got today folks. Now for some story telling!

When I fitted the O2 sensor it said 22.4 at idle which is major lean. Reving the car saw 16 so still very lean. Now I found this very strange as she is driving lovely and pulling away nicely most of the time. Research into afr says 16ish is best for economy which would explain why I'm getting alright mpg.

Then I had a think.

>when she's cold with the choke out she drives better and doesn't overrev changing gear UNTILL she warms up so the choke is in

>when she's hot she drive fine but overrevs changing gear

So I thought she was running rich which is why she was over revving

Wideband says nay she be lean

Wind out the mixture screws 6 times and I see afr of 18 at idle and 16again when reving to about 3500 (not what)

Take all the needles out and fit the dynojet ones a notch higher than the old ones (measured with calipers) so that will make afr richer

So now I'm seeing afr at idle of 14 which is the recommended number and 14again revving it

Now the throttle response is loads better. Much snappier compared to before. Carbs need balancing again but it's Definitely better than before

So I'm fairly happy now :) one thing I did notice tho is that when she's cold/warming up she's puffing some blue smoke so I suspect the valve seals may be dying (I've not changed these) still ok when she's warm but it's something to think for the future never the less

So that's all for today folks :)

I'll be looking at the brakes tomorrow. Was supposed to be working but didn't realise the time so never booked a shift, that's me being a muppet!

Feel free to comment :)

Lawrence

#427

Posted 23 January 2016 - 07:26 PM

#428

Posted 23 January 2016 - 07:43 PM

#429

Posted 23 January 2016 - 08:04 PM

Edited by l_jonez, 23 January 2016 - 08:08 PM.

#430

Posted 28 January 2016 - 08:47 PM

First of all I had a look at the carbs. I really wanted the new trumpets to fit as mine look cheap and it annoys me. I worked out if I hammer the new ones over a socket the aluminium stretches and become a perfect fit!

Much less restrictive compared to the old ones and a tidyer look too

I've also finally sorted out my 13s!

Got some revolutions 13x7 from a local chap and I'm happy with my purchase.

Fitted, no spacer

Other side fitted. 1 ¼ inch spacer. Too much poke

Front view

Nsf with spacer

And with 1.5cm spaced out

Rears tried on. Me likey

Rears need spacing about a 1cm also

Clearance for A panels

Clearance at the front. No trimming required yet but suspension is high, I shall reassess when the car gets lowered

Painting the front arches

Primer

Painted and Also added a nice p seal in the gap between the arches and wing which is a nice finishing touch

So next up, rear arches, osr needed a lot of adjustment but now fits a lot better :)

Had to re drill four of the holes

Sealed up the old holes with sealent for the time being to keep the old girl waterproofish

Primered

Painted

Took apart the bad side for the brakes and there's no sign of leaks! Maybe they just needed adjustment!

Arch fitted again

Monster truck mot clearance

And took a photo of the other side. It really does look stupid now one side looks good!

So that's up to date for now until tomorrow when I do a few more bits. Still got the nsr arch to sort out and then that needs painting, fitting along with a seal.

Mot wise.

Rear brakes and handbrake needs adjusting and Ns driveshaft gaitors need restraining

Also need to put the dash back together and properly wire in the afr gauge

Fingers crossed I can book her in for a mot Saturday but I need to see the gf soon as she's feeling a bit neglected lately poor thing

That's all folks

Lawrence

#431

Posted 29 January 2016 - 02:13 PM

#432

Posted 30 January 2016 - 12:47 AM

#433

Posted 30 January 2016 - 02:17 AM

are you using washers as spacers?

#434

Posted 30 January 2016 - 08:50 AM

Well I'm now single haha

Oh don't start rubbing that in. I would have been done ages ago if I lived the ideal life 😭

#435

Posted 30 January 2016 - 09:00 AM

Well I'm now single haha

Oh don't start rubbing that in. I would have been done ages ago if I lived the ideal life

At least I've got plenty of money to spend on my mini now haha

5 user(s) are reading this topic

0 members, 3 guests, 0 anonymous users

-

Bing (2)