So people. Time for another update :)

That's the plan coopdog. The decision is do I go all out and stick with the 998 for a little while, go all out beast or go a bit less all out! I'm making a post to add to the general chat section later

So since the new engine has been fitted everything has been going fine more or less. She's completed a few 70mile round trips for uni the other week and behaved herself well. Heater has been reinstalled in the car so I'll be nice and toasty this winter. Everything is working as it should.

On my to do list is the nearside inner pot joint that needs changing and I need to check the wheel bearing also as it may be suspect too.

I planned to redo the undersealed floor of the car this weekend but when I had a look it seemed that when she had her big oil leak the entire underside has been liberally coated with a castrol layer so not going to bother this year! Bonus there I suppose.

So this week I sorted the front end filler I put on a few weeks ago

Sanded down

Primed

Painted

Also touched up the bonnet

And back together, finished painting the bonnet chrome piece also

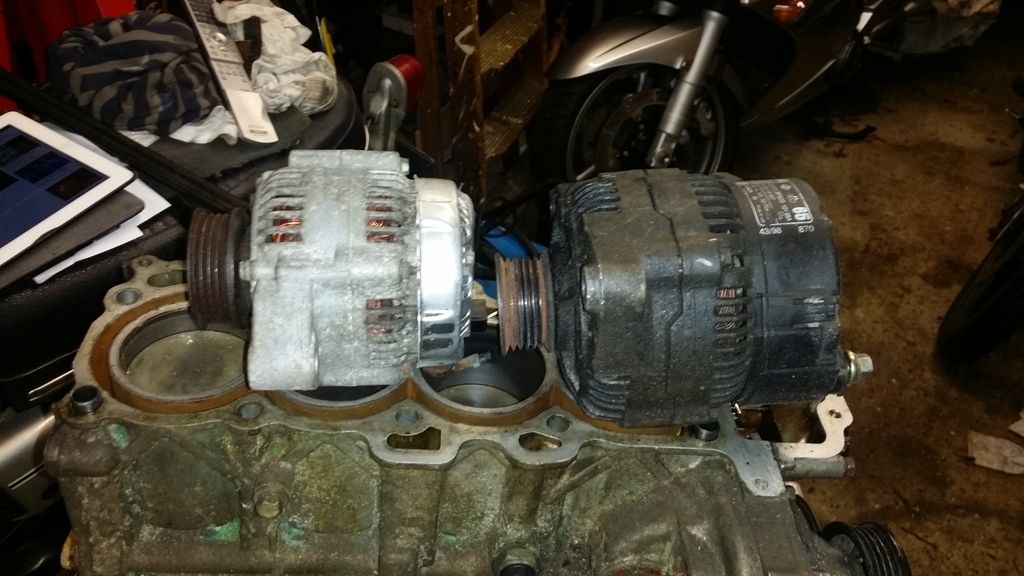

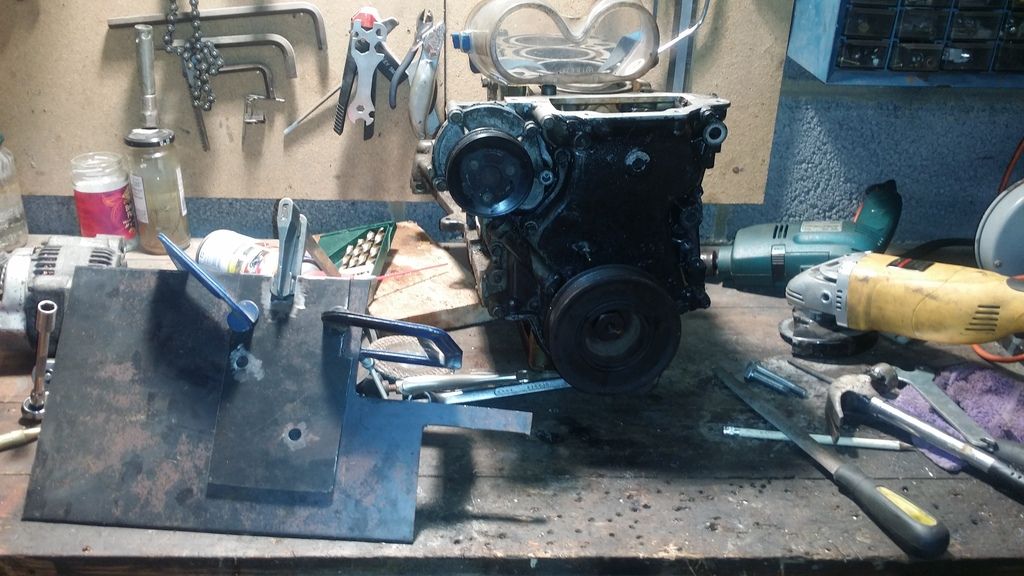

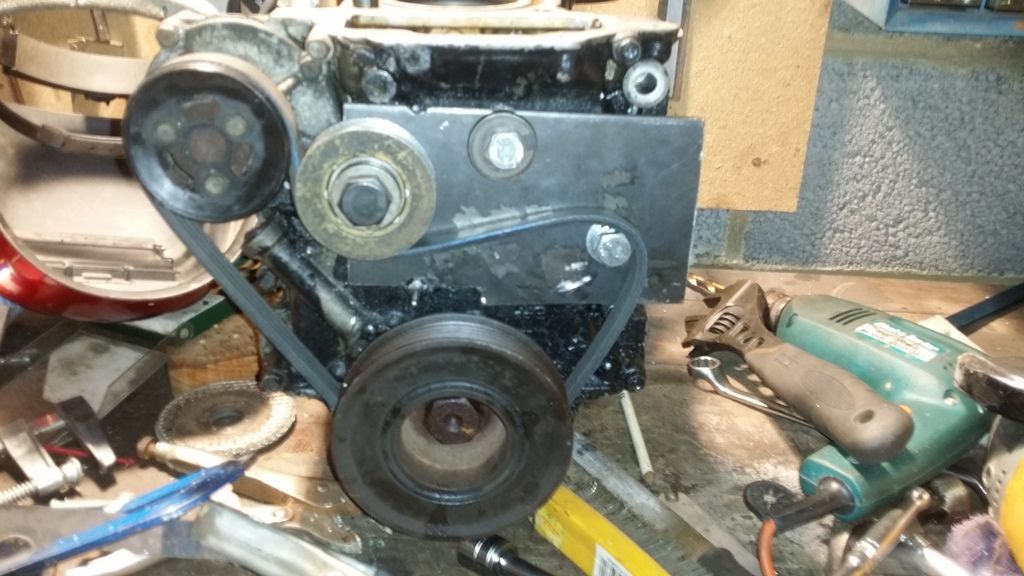

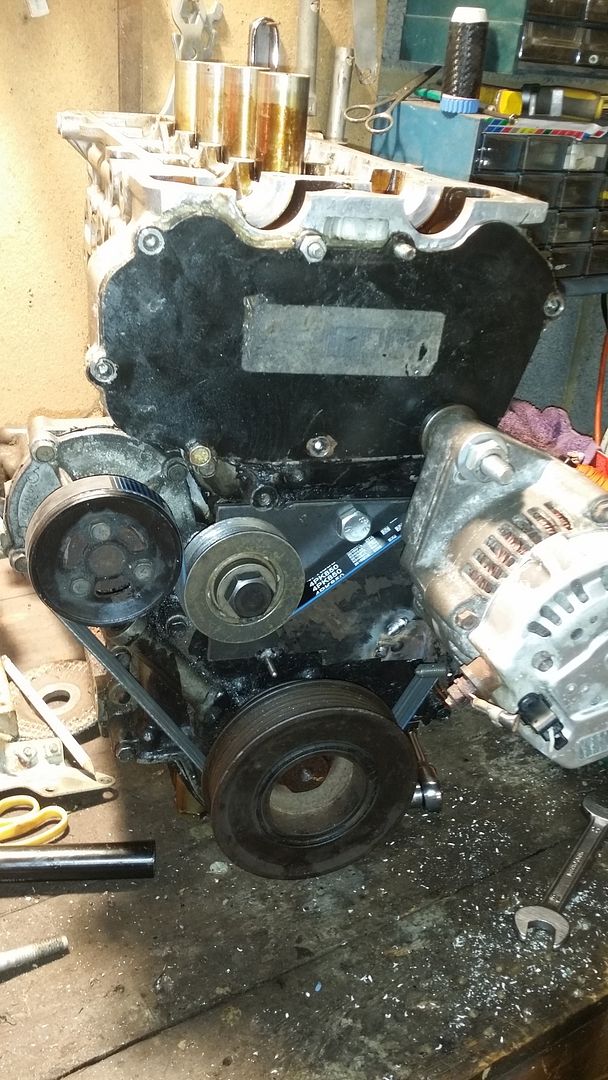

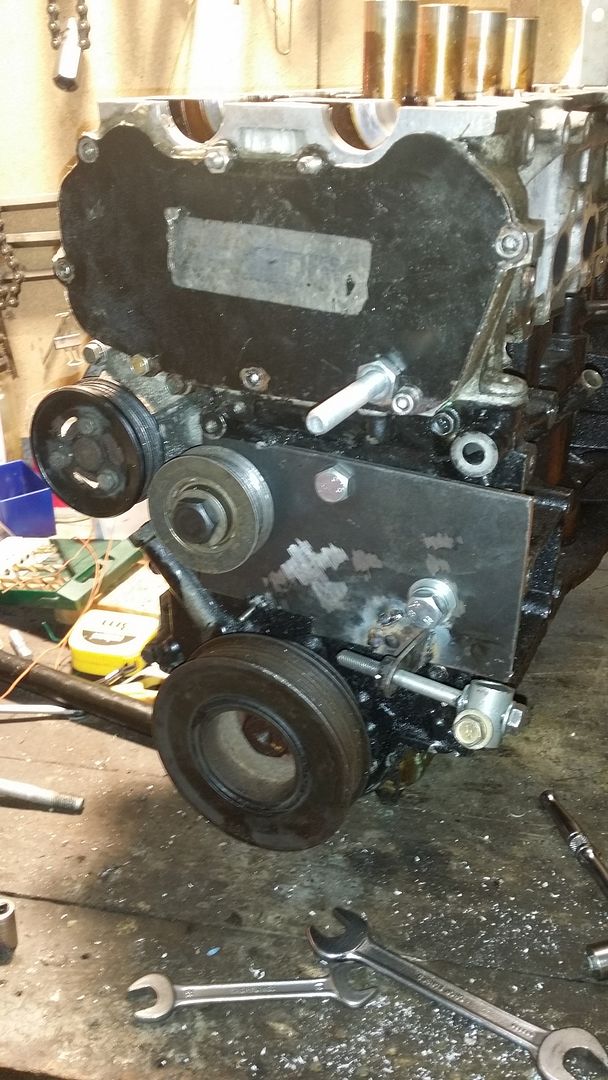

And lastly took the knackered 1.3 engine apart.

Does anyone know why the side of the Pistons are so clean?

That's all for now. I've been researching the engine choices that I have bun can't make my mind up unfortunatly

Just going to continue to drive her now and will keep updating if anything important comes up.

Feel free to comment

Lawrence