Mini is progressing lots now down to my dad.Hopefully by the end of next week the front of the car should be done next which would be great as all that would be left would be the left hand sills,door step and door skin along with two floor pans and the right hand outer sill.That might sound alot to some but in the scale of this project there just small touches

.Just have a few tiny repairs on the bulkhead above the rear arches and the rear window frame edges.

Anyway today was more prep done by my dad to get it all ready for the inner wing to go on.

New section to replace old crusty section as it was in bad shape as shown in yesterdays photos.

Window frame edge section fitted too as before hand the last person left it bare with no paint so it was quite bad which most of it missing.

All the edges which join to the inner wing cleaned and prepped ready for welding .Also inside around the back of the dash was done as its hard to get too once inner wing is in

Bulk inside just had welds ground down and then sprayed to protect it for time being until it gets done at body shop.Still needs alot of the old paint stripping back around the large repair section but think i might be doing that on sunday.

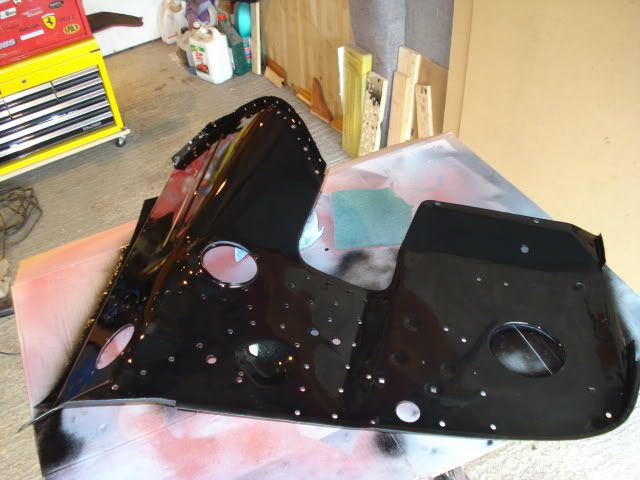

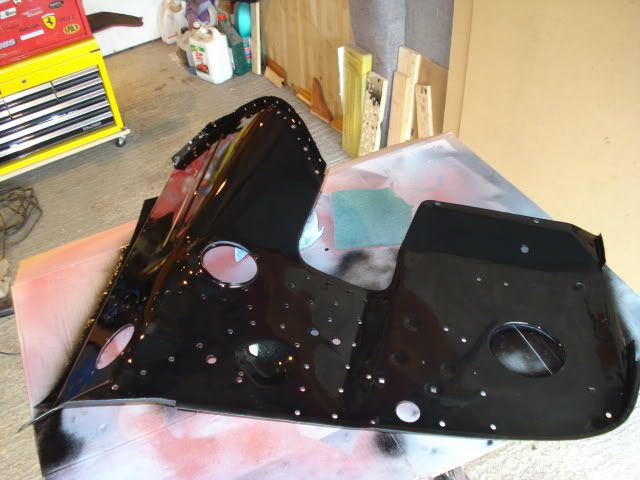

Inner wing preped with etch primer,primer and gloss black just to stop it rusting for time being,will be red in the end but this is just a temporay measure.Lots of holes in it as it will be spot welded on with a mig as we don't have a spot welder yet.

And some shiny bits,got all the bits to build up rear brakes and arms now so thats a fun job to do,just need to buy surspension kit and can get rear subframe built up.

That all for now folks,

Edited by scsracing, 03 March 2010 - 07:46 PM.