Project Erm

#406

Posted 12 December 2010 - 10:04 PM

#407

Posted 13 December 2010 - 01:32 PM

and then sealed

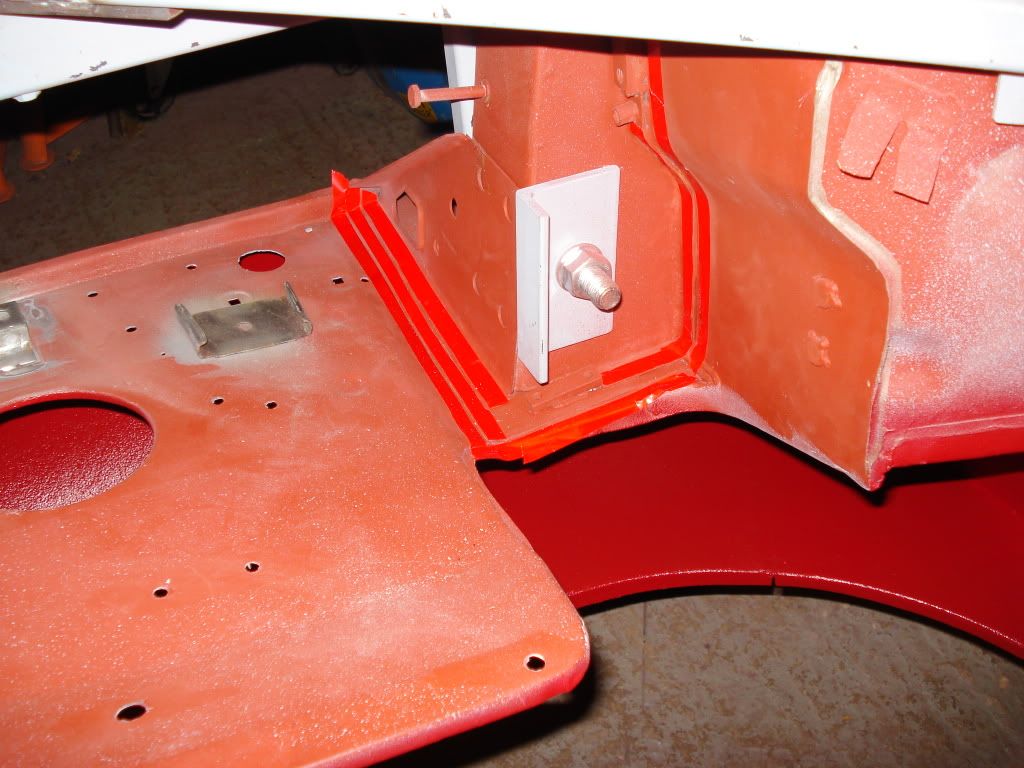

Then managed to put the final top coat layer on the r/h inner wing

Now its back out to the garage to sort out the stupid roof ariel and the rust around it

#408

Posted 13 December 2010 - 01:40 PM

Again. your work looks super. Thanks again for your advice.

All the best

Hugh

#409

Posted 13 December 2010 - 01:55 PM

NB to self: Must stop being diverted by irrelevant details,

eg must find ladder feet which fell off last week

#410

Posted 13 December 2010 - 04:47 PM

Great project!

#411

Posted 13 December 2010 - 07:12 PM

Neil, I see your online right now - lunch breaks are great. As usual you are meticulous. I thought it would be too cold to paint! We are frosty here. Is the seam sealer painted on or is it something that comes from a mastic gun?

Again. your work looks super. Thanks again for your advice.

All the best

Hugh

Hi Hugh i have to admit i have had my thermals on and the heater to take the edge off enough to comfortably work. The seam sealer is applied with a mastic gun but the Semkits that i use (Aviation sealant) has a tube diameter somewhat smaller than a standard so its a fiddle with the pneumatic gun that i have. Unfortunately the correct type of tool is chuffing expensive but where there's a will there's a way.

Had to go online just to check on something and load the first batch of pictures, i have now got more to add so will be doing that shortly. The paint is only in the inner wings so not to worried if it looks a tad funny not that you could tell anyway with it being on top of stone chip

#412

Posted 13 December 2010 - 07:14 PM

How do you make it look so easy?

Great project!

Blimey i wish it was easy, it took over an hour just to mask up let alone getting the sealant to look somewhat decent, still once its got a nice shiny coat of paint on it it will have been worth it

#413

Posted 13 December 2010 - 07:36 PM

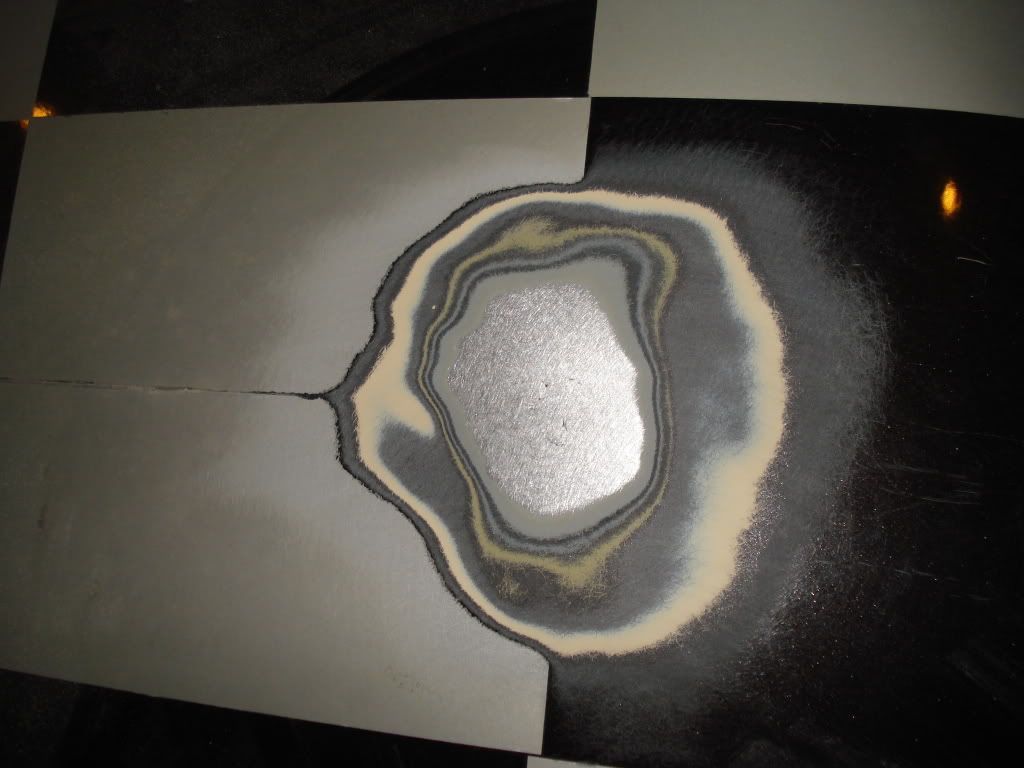

and the rust under it

now no more

Noughts and crosses anybody

now gone as well, sorry for the poor photo camera had a moment i think

did suffer some minor skin ripple with the welding but a skim of filler will sort that out.

Had to stone chip the fresh vent closure plates i had made

then all nicely painted to match the paint in the inner wing

All sorted now quite a bit done today so very happy with the progress after the slow previous week.

#414

Posted 13 December 2010 - 11:31 PM

#415

Posted 14 December 2010 - 12:16 AM

any chance of making a couple more that i can buy

looking good

#416

Posted 14 December 2010 - 08:33 AM

#417

Posted 14 December 2010 - 02:20 PM

any chance of making a couple more that i can buylol

looking good

If i could get a supply of the sealed anchor nuts then i could but they are not cheap, mine i had laying around the garage and the rivets so cost me nothing

#418

Posted 18 December 2010 - 05:14 PM

#419

Posted 21 December 2010 - 01:58 PM

Anyway enough griping, once i sorted the airline fittings, got the compressor going (Clarke compressors suck big time in the cold) and the heater on i managed to remove all of the old vinyl adhesive with lashings of Acetone.

then it was time to sand. Now before anybody says what about the sunroof well that's Scott's job to remove it but as he is slaving away in Halfords today i will forgive him for not removing it so sanded around it but will finish it all off once the sunroof is out. Also i will have to go around the roof gutter with some other sanding implements as the DA will only go so far.

Anyway i decided 3 1/2 hrs in the garage is enough for today so time to hit Sky+ and watch all my recorded programs. Happy days.

#420

Posted 13 January 2011 - 07:27 PM

Scott has removed the sunroof and it looks like Stevie Wonder has cut the aperture still at least its hidden by the sunroof,

The filling has now been done and sanded down. I did make a sanding board to get a better finish due to the compound curve of the roof,

Sanding block

Roof sanded down including the guttering which was a right pain

The new bonnet needed modifying as Scott wanted the old style look so off with the lip

Before

and after

The old bonnet looked good from the outside but once the lip was off and the front sanded down it was a right tea bag so its off to the skip with it. Too much effort needed to repair it.

Once the car is off the spit the bonnet will be installed ready for gapping and shaping the front to make sure it follows the contour of the front panel.

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users