Spent the best part of an hour carefully grinding out the old/new welds on the heelboard where i had attached the replacement sill section. Finally got the sill out and realised what a mess i had made of the floor repair i did in the rear corner the beginning of the rebuild. BUGGER!!! The metal was too thick and just looks wrong so its got to go.

Managed to cut the new sill section to size but had to refold part of it to match the heelboard contour, bit of a difference compared to the front of the inner sill.

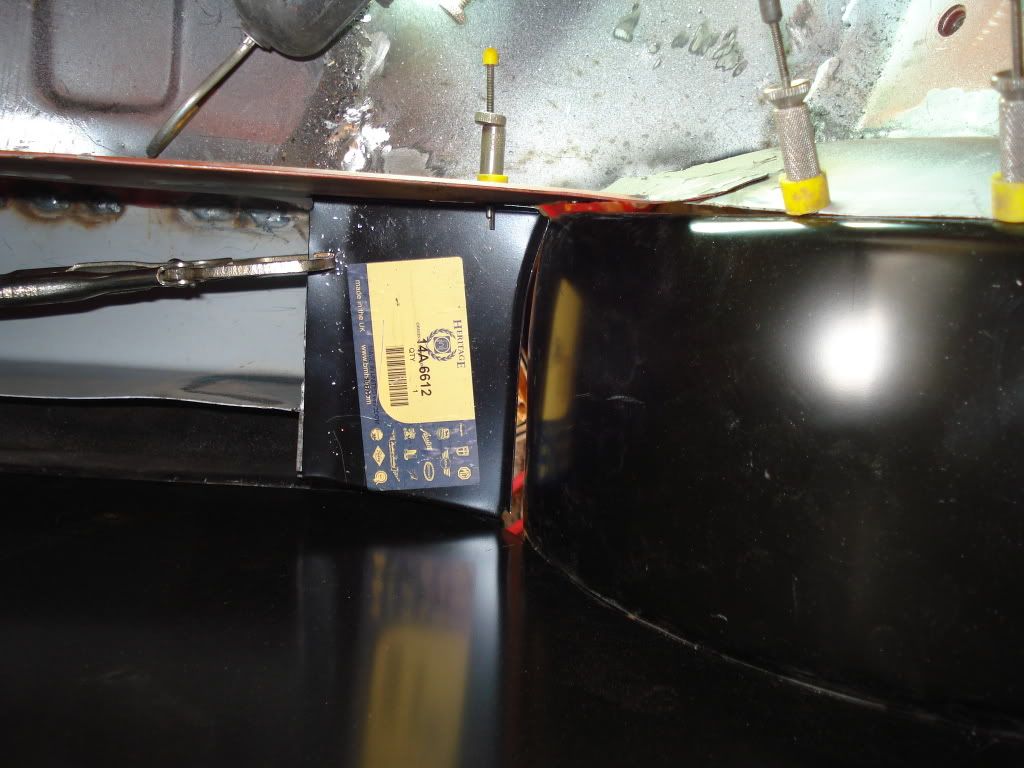

Clamped in place but still need final fettling

Companion box needs to be removed and moved down slightly as it is sitting high.