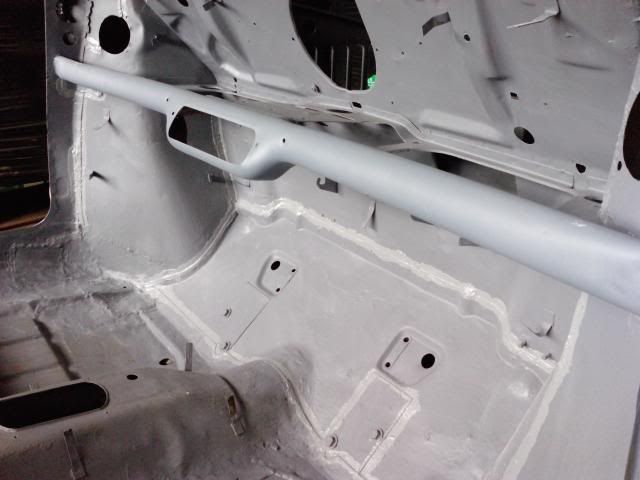

so, the most recent progress, cut out the old inner wing, grey oxide primed the front end and seam sealed it. then fitted the front subframe.

Posted 23 January 2010 - 05:39 PM

Posted 31 January 2010 - 10:43 PM

Posted 01 February 2010 - 02:41 AM

Posted 01 February 2010 - 06:22 PM

Posted 18 March 2010 - 06:26 PM

Posted 18 March 2010 - 06:34 PM

Posted 18 March 2010 - 06:44 PM

Posted 18 March 2010 - 10:24 PM

I really would not rely on one bolt in each rear subframe mounting - the trunions will rotate around that bold and the subframe will move about, probably snapping the front mounting bolts. I also doubt any MoT tester worth his job would pass the car with missing mounting bolts in such a key area.

Posted 19 March 2010 - 08:53 AM

Posted 19 March 2010 - 08:59 PM

Posted 19 March 2010 - 10:19 PM

what the f were them lights good build though

Posted 22 March 2010 - 07:28 PM

Posted 12 February 2011 - 07:31 PM

Posted 29 May 2011 - 09:04 PM

Posted 29 May 2011 - 09:16 PM

0 members, 3 guests, 0 anonymous users