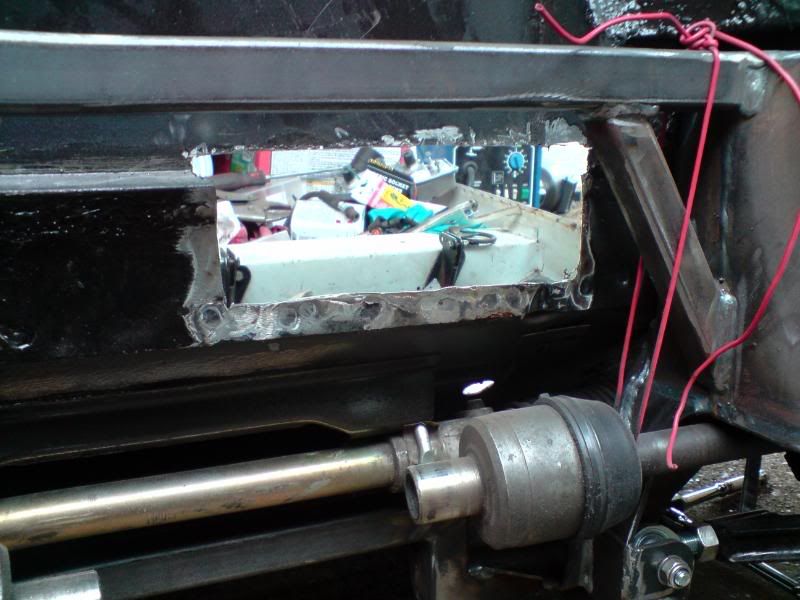

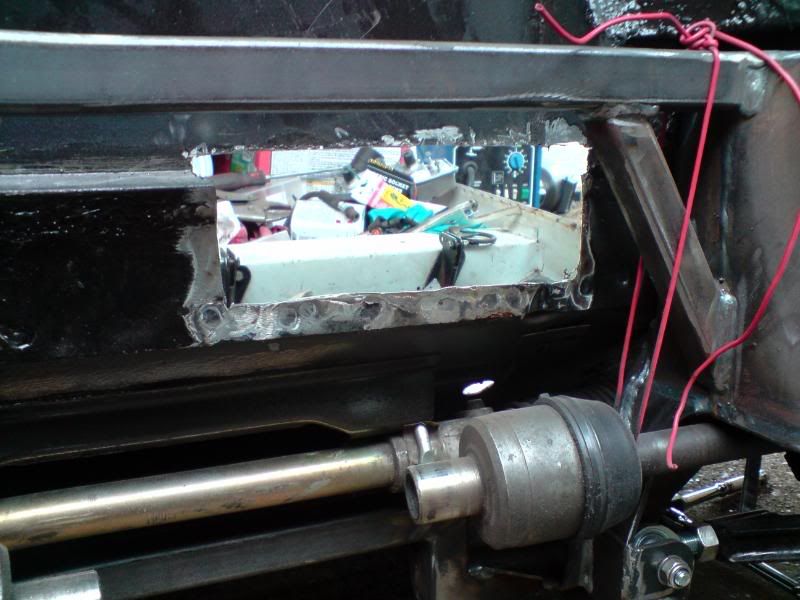

started modifying the turbo box to make room for the k series gear selector linkage. didnt get much done though as run out of gas

cut out

new shape tacked in

Posted 19 June 2009 - 07:26 PM

Posted 20 June 2009 - 09:41 PM

Posted 22 June 2009 - 11:46 PM

Posted 23 June 2009 - 09:31 PM

looking good man! i need to start on my welding... got the mk2 to weld up!

Posted 23 June 2009 - 09:38 PM

Posted 23 June 2009 - 10:13 PM

Posted 29 June 2009 - 09:04 PM

Posted 30 June 2009 - 07:30 AM

Posted 30 June 2009 - 04:03 PM

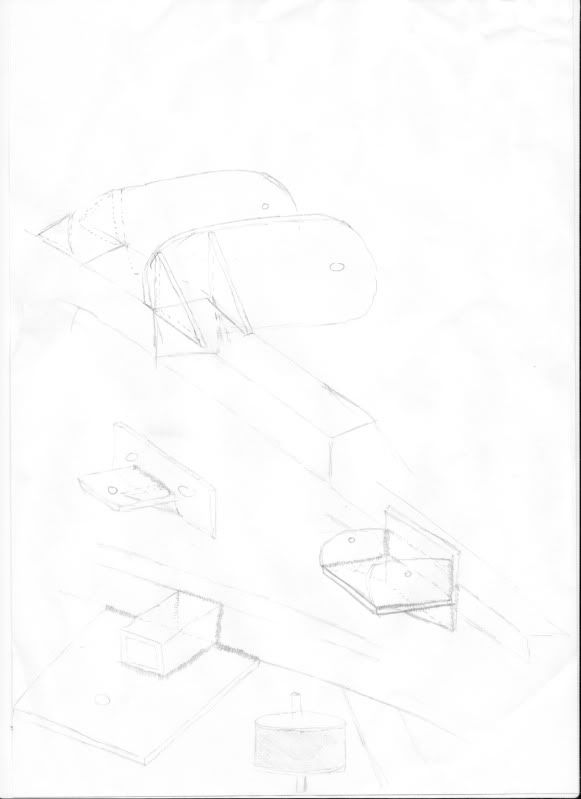

are you sure the petrol tank is going to fit with that new boot hinge?

Posted 01 July 2009 - 09:36 PM

Posted 01 July 2009 - 11:12 PM

Posted 09 July 2009 - 05:16 PM

you'll need pads in those calipers

lol

i found my FG front was slightly shorter than a standard one... but i had a standard subframe too... hmm....

Posted 10 July 2009 - 10:09 PM

Posted 12 July 2009 - 10:37 PM

Posted 13 July 2009 - 09:45 AM

0 members, 1 guests, 0 anonymous users