Project 'lesbian Rose'

#91

Posted 20 May 2009 - 11:57 AM

#92

Posted 20 May 2009 - 10:20 PM

fg battery box

fg roof skin

TDK rear beam axle (to replace the bent huddersfield minis one)

havent really done much on the project lately as been trying to get the clubby through an MOT. it failed last week so replaced parts/sorted all problems plus extras...then it failed its retest today on the same things!!

i think the garage are tampering with my car to make it fail though as the metal cv gaitor tie i fitted monday has mysteriously dissappeared (which would of had to of been cut off) and the gaitor has come off so failed the MOT. the first gaitor they failed had a hole in which was just the right size for a screwdriver.

Also they said there is excessive play in the track rod end...which is brand new, the one which failed first time i only fitted at easter!

something seems a little fishy to me >

#93

Posted 20 May 2009 - 10:42 PM

Nice new bits I'll be checking them out fitted later on =p

#94

Posted 21 May 2009 - 10:32 AM

Man that's pretty lame on the MOT! If they're going to charge you for a full test next time round I'd go somewhere else. My gaitor tie came off on the way back from my MOT

Nice new bits I'll be checking them out fitted later on =p

its booked in at another garage for tomorrow, only thing is it needs to be there for 7.30am! he didnt have any spaces so will fit it in when he can.

work at a school and its half term next week so have time off to get some more of the project done

#95

Posted 24 May 2009 - 08:42 AM

Tried making some internal boot hinges yesterday but they are a lot harder then i thought lol could not get the right shape and as you shut the boot they tried sliding up the back of it. so i gave up on them and moved onto something more fun.....chopping my roof out

before:

after:

the remains:

fg skin resting on back in the garage

#96

Posted 27 May 2009 - 06:14 PM

fianlly finished fitting the zcars fg dash and pod

also fitted my tdk rear beam today. its great having one that doesn't bend when you adjust it

#97

Posted 27 May 2009 - 08:59 PM

#98

Posted 28 May 2009 - 08:50 AM

nice progress! like the beam especially, jealous

cheers mate. the beam is alot better than the old one, it is more rigid and also slightly lighter.

next major part is to get the engine in....but i dont have any engine mounts

is there any welders/fabricators on here that live around hertfordshire area that would be able to help me out? pretty please?

once the engines in i can get it started and out sort gear linkage. once thats positions i can get the interior sprayed and seats, pipes etc in which would be a major step forward

cheers

#99

Posted 28 May 2009 - 03:45 PM

if i can strike my welds/joints with a 2.5lb mallet without it moving or cracking the weld at all, would they be sufficient enough to take the weight of my k series if i gusset them aswell?

cheers

#100

Posted 28 May 2009 - 10:11 PM

decided i no longer needed the big hole in the bulkhead, that sat behind the carb, so plated over it

plate welded in on the outside....

and seamed on the inside just to make sure

then ground back as much as i dare

now i've decided to build my own engine mounts, i just need to find an engine crane to buy so i can position the engine whilst i make the mounts.

#101

Posted 30 May 2009 - 05:04 PM

#102

Posted 01 June 2009 - 08:22 PM

havnt checked this thread since the start, but its brilliant

. i may just do that roof skin thing

cheers mate, still not where i wanted to be by now though lol the roof will take a lot of fidling and adjustments to get a good fit but not going to fit it until i have a roll cage in for easy access

looking at front coil overs and was just wondering would the standard 350lb springs that come with them be ok with the k series conversion? if i remember rightly i think the k series is about 30kg lighter.

Also my allspeed subframe is hitting the inside of the fg front valance and stoppingit from going on fully. has anyone else had this problem is it just a bad mould of my front?

cheers

#103

Posted 06 June 2009 - 07:06 PM

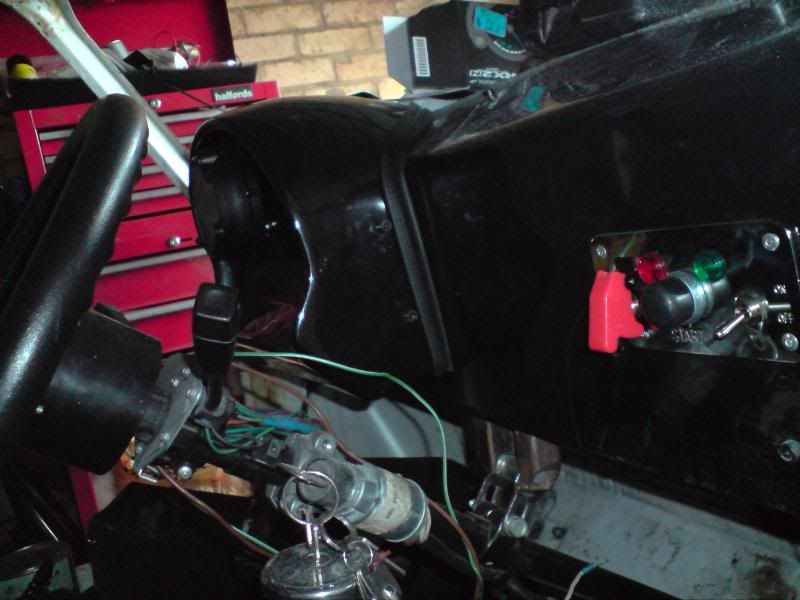

finally mounted my digidash into the pod, but havent wired it up yet, will do so when i do the rest of the loom. also fitted my push button start panel

started tubbing arches today, was not as bad as i thought it would be. just time consuming with small adjustments. didnt finishh though as run out of gas and halfords dont have any until mondays deliver

i'll let the pics do the rest.

before:

fitst bit cut out:

rest of quarter panel removed:

started tacking new metal in place:

as far as i got when gas run out:

#104

Posted 10 June 2009 - 09:04 PM

do i need to turret the arches for running coilovers or would it be strong enough if i was to brace between the current ones with 1" box section or 2"x1"?

also having a problem finding a flywheel sensor for my k series, the only one halfords have listed is for 2 bolts and the sensor does not fit through the hole in the gearbox case.

my engine only has a single bolt (sorry for the bad pic, was dark at the back of the garage)

can anyone help/point me in the direction of the right sensor?

cheers

#105

Posted 15 June 2009 - 10:48 PM

still waiting on my front coilovers to show up after almost 2 week so might have to give mini speed a call. cant get the engine in place and make mounts until i have them.

also just read that you need the immobiliser from the donor car for the ecu/engine to work, is this true? if so i'm stuffed as i dont have the 5as immobiliser and fobs, they didnt come with the engine, r can i bypass this by connectingthe ignition straight to the engine?

cheers

3 user(s) are reading this topic

0 members, 3 guests, 0 anonymous users