been a while since my last update. unfortunately not made any major progress on the car but been making a few bits at work. anyway here's a few little bits.

had a tidy up of welds on the bulkhead and inner wing areas. once finished of the seams should blend in fairly well hopefully

as you can see i also quickly knocked up a foot rest. not entirely happy with it so replacing it with a Ti one when weather allows.

also been seaming and stitch welding hte front subframe for strength.

dropped my gear linkage to gearbox connecting sleeve thingy down the drain a while a go so had a new one made up at work from nimonic steel

been modifying the gear linkage rods

uj's have been drilled and tapped as well but no pics

started rubbing down chrome parts for painting when i couldn't do much else because of bad weather

been lightening the subframe, only half way through this though

here's most of the internal linkage in place

finished making the rods yesterday, fitted it this evening and..... it doesn't work properly

where there's movement of the rod in the connecting sleeve to the gearbox followed by the movement of a uj it allows the linkage to 'wobble' too much. going to modify it at work next week by removing the connecting sleeve and shorter piece of the original linkage. will then bore out the thread from one end of the uj and drill a hole in it for the roll pin to connect directly to the 'box, then make a new longer piece of rod for the centre section. hopefully will cure my problems.

finished a pair of these today at work

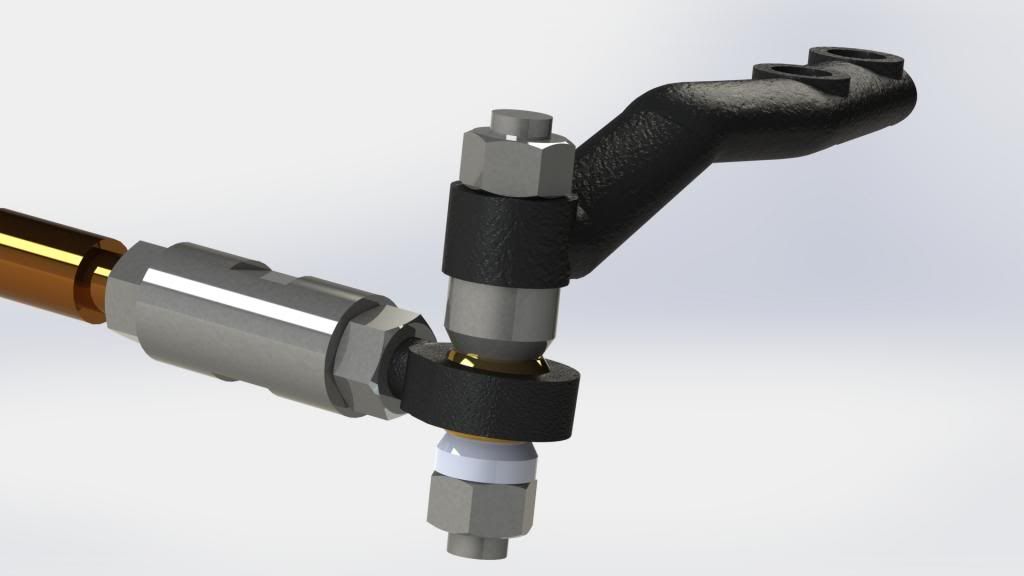

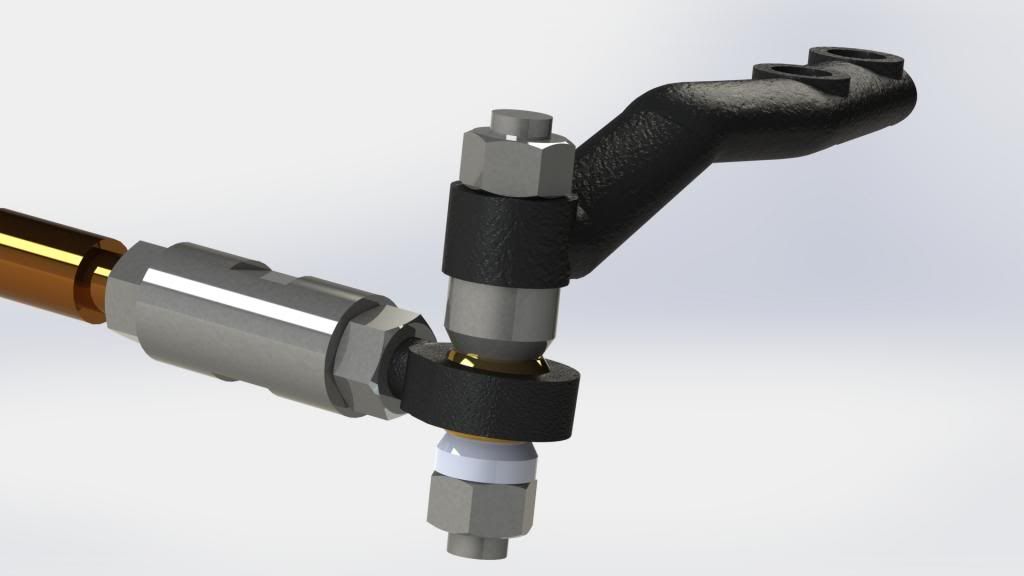

EN24T turnbuckles for steering rack. 1/2" unf LH and RH threads with high strength/misalignment spherical rod ends. Also have a pair of upgraded cooper s steering arms that have had their tapered bores drilled and reamed to 1/2". once i have set the ride height i can work out how much steering arms need to be lowered to help remove bump steer and make some spacer 'axles' to go between the rod ends and steering arms.

will look something like this (quick drawing/rendering i made in solidworks):

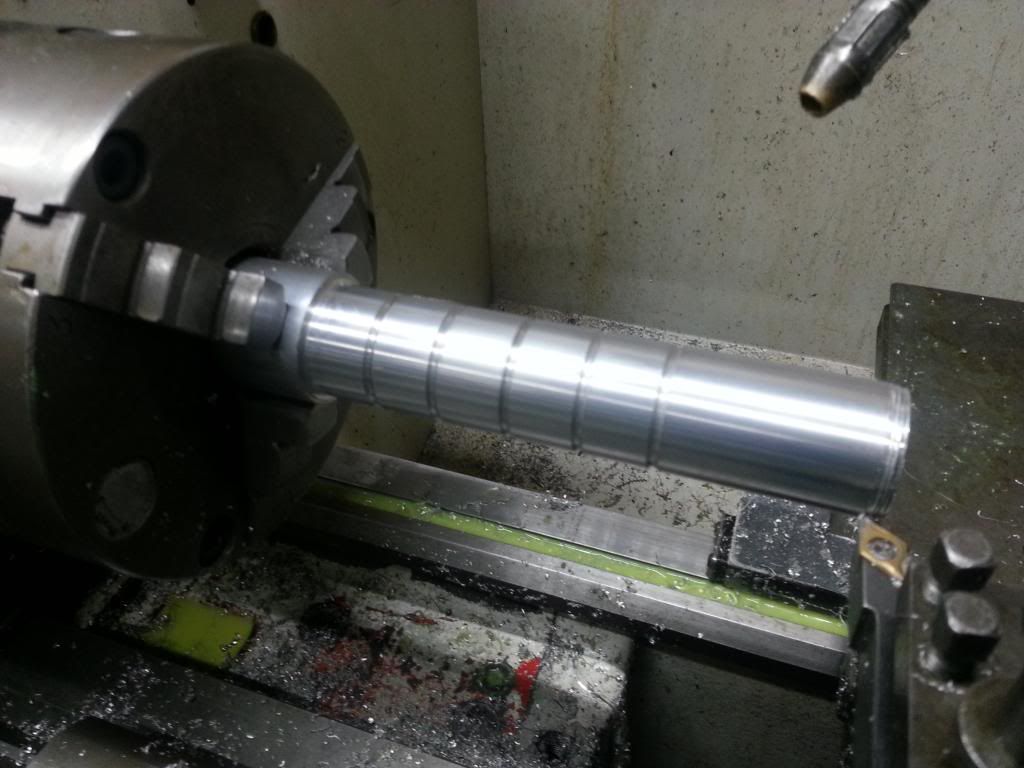

this is what the axle piece should look like roughly (rubbish threads i know)

!!