Project 'lesbian Rose'

#136

Posted 17 October 2009 - 02:56 PM

#137

Posted 19 October 2009 - 02:56 AM

well i havent really done much on the project lately, sort of lacking the will and drive to do it at the mo. still havent managed to sort out the wiring, i just dont understand it at all lol.

thinking about maybe buying one of these if it makes things easier

http://www.cbsonline...rmod-1185-p.asp

i know its quite expensive but if it makes things easier i might just bite the bullet. what do people think of them?

anyways heres the few small bits.

started spraying my roll cage

got the back box mounted

need to sort the link pipe now, may get a 'floating' flange fitted to the manifold end to make lining up and fitting easier

these arrived from Mighty_Mini today

a mate gave me these today as well.

he bought them for his kit car but with the new IVA regulations they wont pass. unfortunately they are not real carbon fibre lol

also would it be ok to mount fuel cut off switch here?

dude, the fuel cut off switch has to be somewhere on top and make sure its top (not upside down) i've been workin on metro gti while ago because it wouldn't spark so its all fix now, thats how i found out the the fuel cut off switch has been upside down..

good luck with the project n keep us post

#138

Posted 19 October 2009 - 07:13 AM

Jordan.

#139

Posted 30 October 2009 - 12:59 PM

not really much to report, going home for the weekend next week so hopefully will get some bits done then but....

had a good day at uni today. was talking to the automotive technician about my project and he turns around and says 'i've got some spare CBR 600 throttle bodies if you want them?'. obviously i said yes, heres what i got:

they virtually brand new! now i'll need to get a inlet manifold made for them as cant space them onto a cut down k series inlet like my GSXR TB's as they are pairs like webbers

#140

Posted 26 December 2009 - 05:16 PM

heres a few pictures of some recent bits.

driveshafts from aband

oil filter adaptor plate. the top outlet fitting hits the alternator so need to fabricate a new alternator bracket to move it out more

outer sills are on. still need to get the a panels replaced though.

ordered my master cylinders for brake and clutch but screwed up the order. have the wrong one for brakes so need to send it back and exchange for the right one.then will be getting an internal m/c pedal box made by OWEN

also been working on splicing the looms. got the engine so it cranks but need to sort a few other bits then i can see if it runs. also working on getting all the mini controls and lights working again. once everythings working i'll start fitting the new switches and push button start.

cheers

#141

Posted 13 February 2010 - 06:34 PM

so happy with

unexpectedly went home last weekend (big potholes = 3 wheeled mini

still no luck starting the engine, think the ECU plug is knackered as the connectors all move in and out when you move the loom

also bought these from someone on 16v mini club

should fill the miglia arches nicely without spacers

#142

Posted 16 June 2010 - 01:40 PM

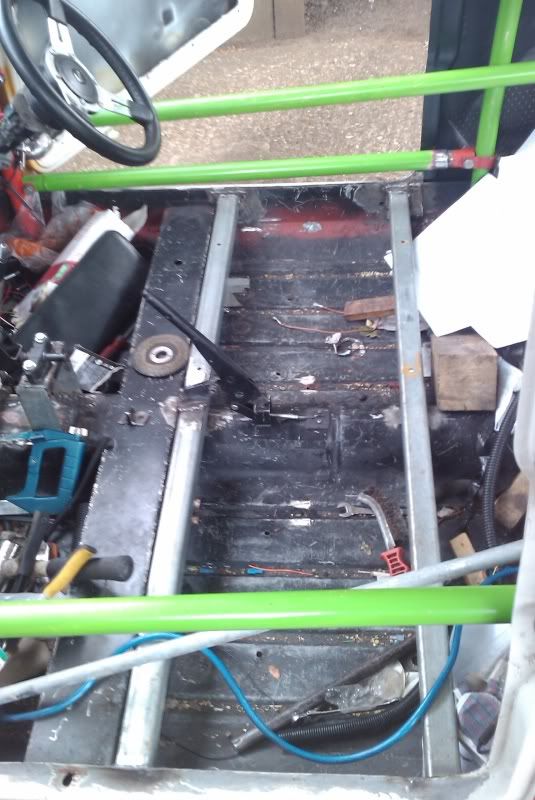

anyway heres an update to the point where i am now.

so the wheels are now fitted and fill the arches nicely

have a fiesta collapsible steering column to fit incase i do end up needing an IVA.

bought a rebult garrett T25 turbo for a later phase of the project. couldn't resist. picked it up for £50

oil filter adaptor plate drilled and taped, with oil pressure and temp sensors fitted

got all of the roll cage in for the first time

was bored one day and found half a can of kawasaki green left over. think this may be final colour

new A panels fitted, these ones are properly aligned. found out the previous n/s panel i had fitted for me before was almost 5mm to far back!

lifted the front enough to fit a manifold under after swapping the 13" wellers for 10" and this is my ground clearance. (lifted it by around 1")

and this is with the ali cam cover

got the exhaust system sorted and all fitted. used an MPI cat to rear box pipe as flange is same as a K series manifold flange, then like pipe just slides onto that. thinking im going to need to lift the car even more as it keeps catching on the little step up into the garage.

welded in some C section for seat mounts and modified the handbrake to be vertical. problem now is im having my seat further back so need to find some tube same size as gear selector rods to extend them or another set of rods to shorten.

been cutting out holes for headlights and rad cooling on the extended fg front.

flower power headlights! lol

(the picture was pre rad hole drilling)

used some smaller C section to make some boot strengtheners/fuel tank supports.

this is the only picture i have that sort of shows them.

whenever i get work on the car it seems to be a magnet to the local kids.

found this whilst working on the boot but not sure of the best way to sort it?

remote oil filter is now mounted onto the front of the head.

(rubbish picture but shows the position)

still can't get a spark from the engine. checked the coil and that's ok. the injectors are firing, which from what i've read means the ECU is getting a signal from the crank sensor.

need to take the engine out to reduce the size of the now un-needed turbo box to give more room for the pedal box but i cant find the engine strop lol

cheers

#143

Posted 31 December 2010 - 02:39 PM

#144

Posted 31 December 2010 - 05:20 PM

its still going, sort of. don't get much time on it due to uni so its come to bit of a stand still. got some stuff done on odd weekends home but nothing big enough to deserve an update each time.

just got some money for xmas and birthday so mixed with student loan should be able to order some parts in the new year

i'll try and get some sort of update together later or tomorrow

#145

Posted 01 January 2011 - 08:19 PM

#146

Posted 01 January 2011 - 08:49 PM

#147

Posted 01 January 2011 - 10:05 PM

the clutch is off the engine!!!! finally managed to get it off, after a few hours of attacking it with an angle grinder. had to almost chop it in half to get it to release from the crank!

its a good job i'm replacing the crank as it got a little damaged lol

the u washer thingy was still in position even though i'd had to turn the crank whilst the flywheel bolt was out.

the clutch housing has been damaged even more so will def.. be needing to replace that too

just a question... did you try turning the flywheel till the closest piston was at its highest point then try to lever it off???... i thought mine was stuck till i found that out as haynes doesnt actually tell you that???

#148

Posted 01 January 2011 - 10:40 PM

Well thats rhubarbed that crank! What were you trying to do?

Edited by charie t, 01 January 2011 - 10:40 PM.

#149

Posted 02 January 2011 - 01:39 AM

#150

Posted 02 January 2011 - 01:42 AM

the clutch is off the engine!!!! finally managed to get it off, after a few hours of attacking it with an angle grinder. had to almost chop it in half to get it to release from the crank!

its a good job i'm replacing the crank as it got a little damaged lol

the u washer thingy was still in position even though i'd had to turn the crank whilst the flywheel bolt was out.

the clutch housing has been damaged even more so will def.. be needing to replace that too

just a question... did you try turning the flywheel till the closest piston was at its highest point then try to lever it off???... i thought mine was stuck till i found that out as haynes doesnt actually tell you that???

started off with the piston at TDC but when it wouldn't come off started to turn it so i could hit it evenly around the flywheel to try and release it, but had no luck either way

2 user(s) are reading this topic

0 members, 2 guests, 0 anonymous users