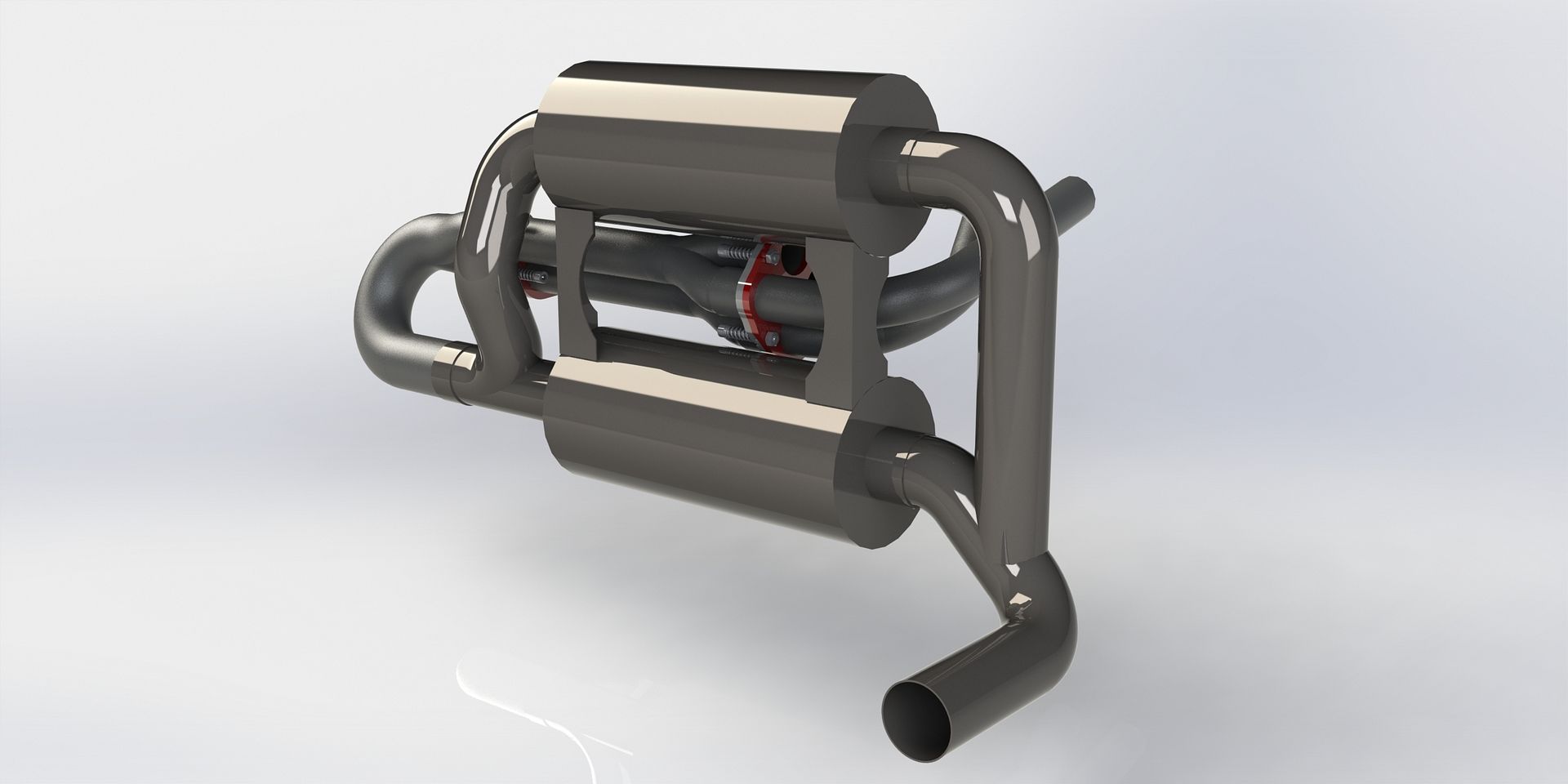

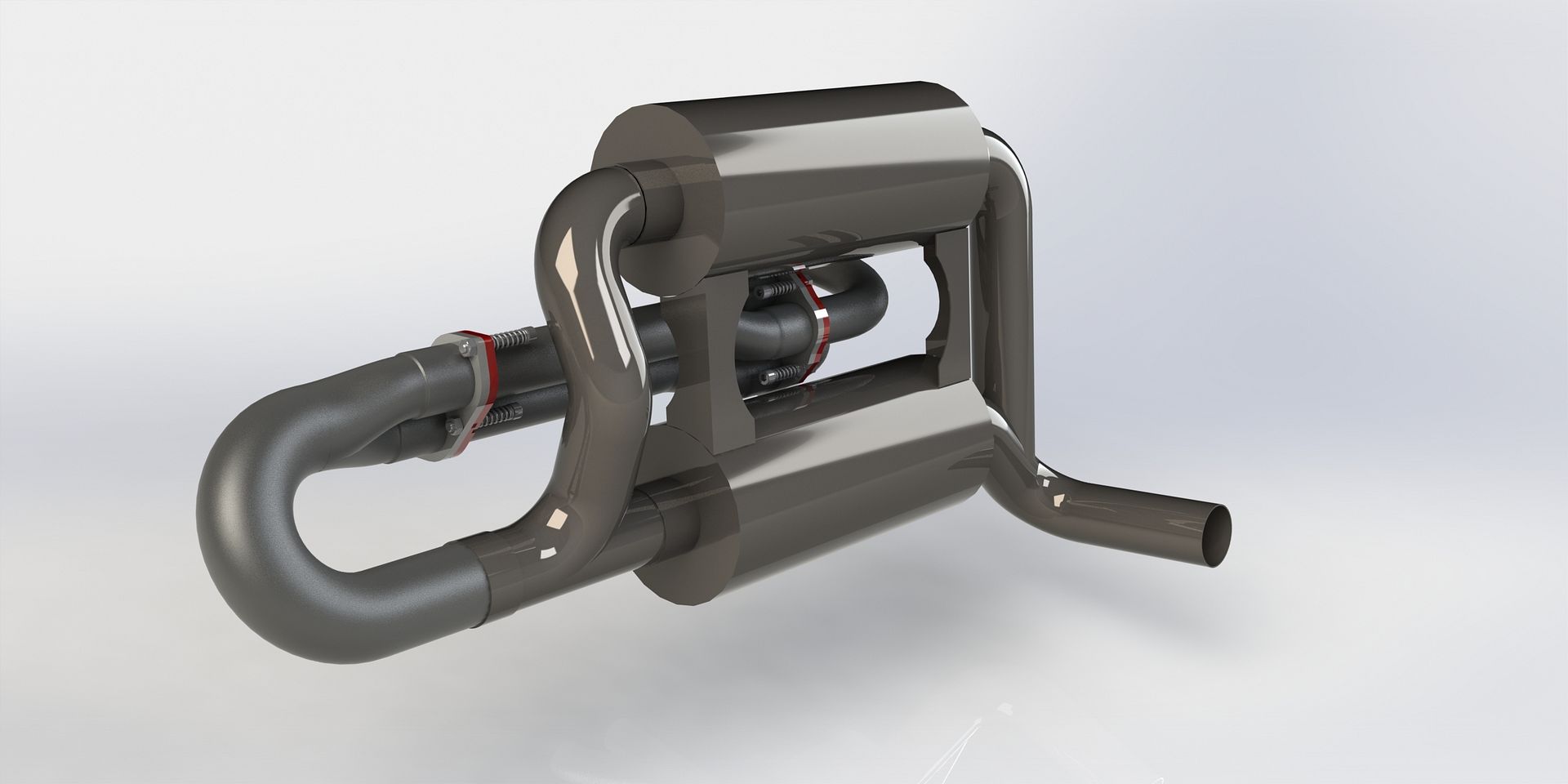

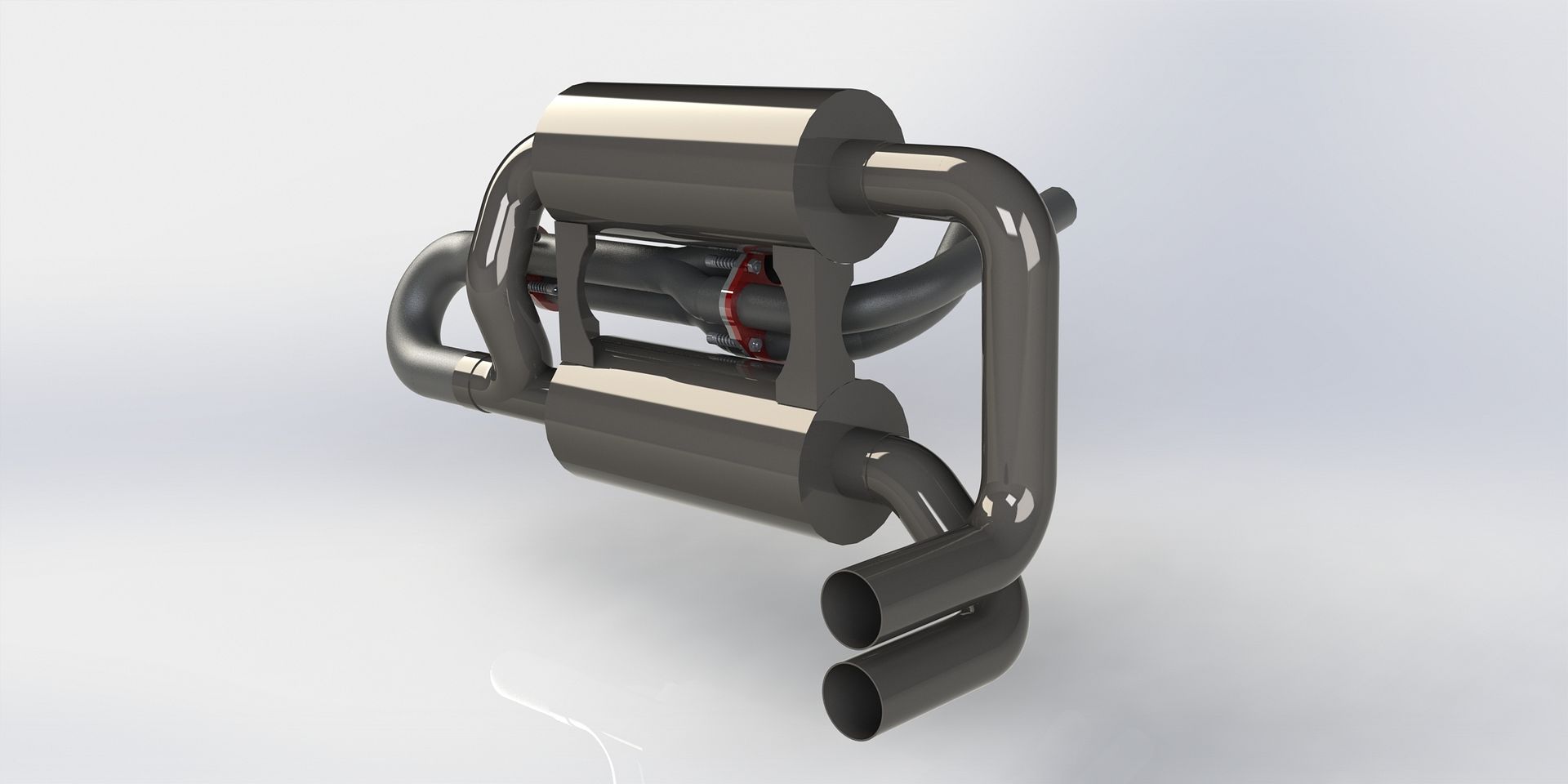

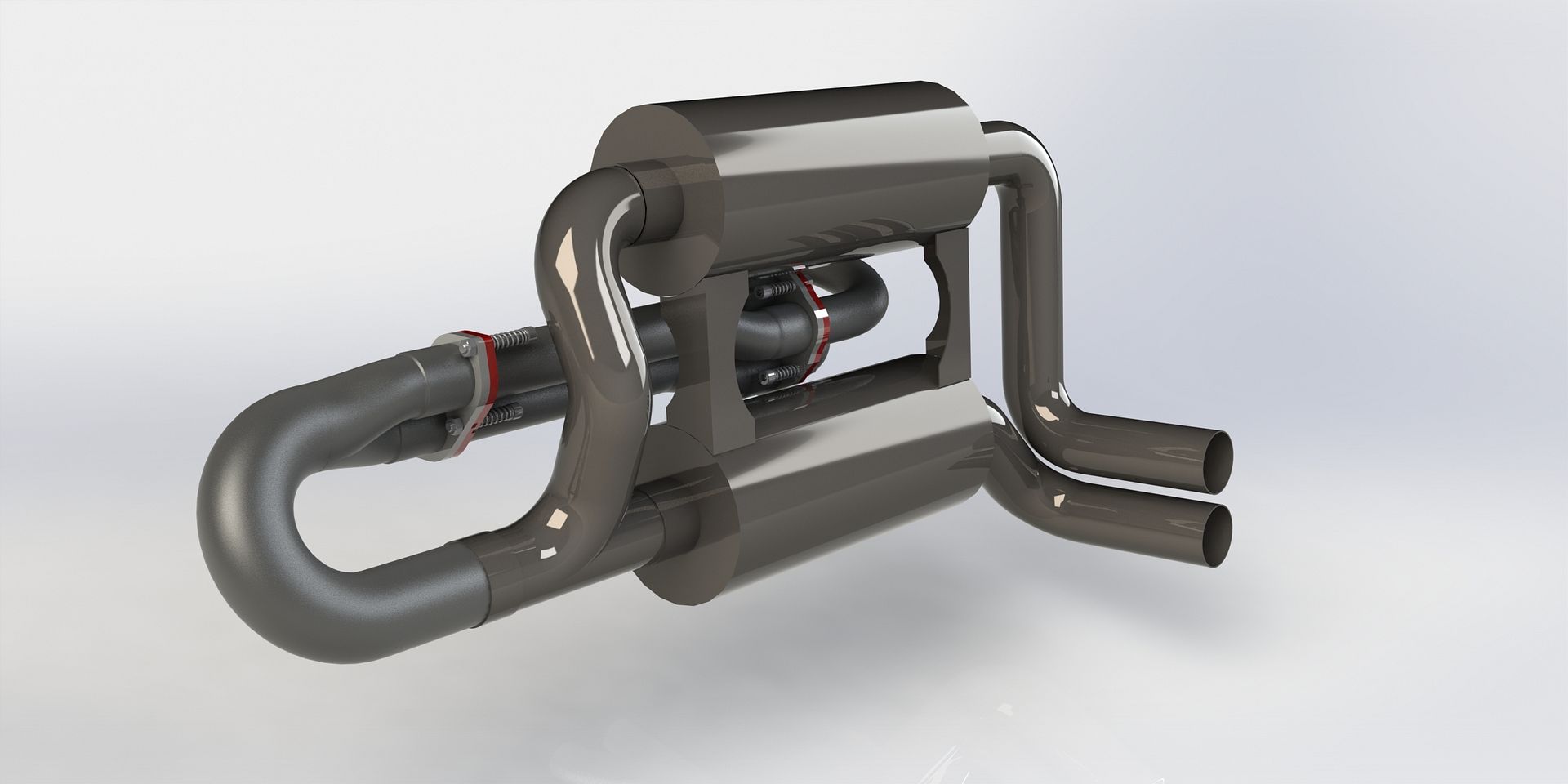

70mm Clockwise Motion Throttle Body

Some of you might recall that I had previously bought an OBX 72mm Throttle Body, well - it was a piece of cr4p - and returning home, after getting it dyno'd last (two years ago) I couldn't get it to idle as air was p!ss!ng past the throttle plate. So I had to replace it with the original 62mm TB, this was robbing the motor of power as the supercharger is quite sensitive to restrictions up stream - approx 20hp missing (based on back to back test guys in the US had done).

Recently I had decided I want that missing power back and tried to get the throttle plate fitting better. However after much fettling and f-ing around it still leaked like a *******. the problem is that I couldn't do anything about the gaps by the spindle which were 5thousandths of an inch both sides, now this might not sound a lot but when there's 2litres of the vacuum every 2 revolutions you be surprised how much air it can suck through those tiny gaps

I had been searching the tinterweb for some time trying to find a suitable 72mm replacement but couldnt. I chanced upon this 70mm Clockwise Motion TB when doing a search, I ordered it from http://r-motion.co.uk/. Great service and very quick to send the part once the order was made. These guys look to only stock top notch parts and Mike, the owner, races, so knows his sh!t...

FYI - anyone trying to Google Clockwise Motion wont find any way website, these are the people that make the baffled sump insert that is used in the VTEC Zcars conversion and are very popular in the Honda scene. Years ago I spoke to Ian @ Clockwise and I got the impression that he was getting lots of calls from people asking stupid questions. I know everyone has to start somewhere but if you're constantly plagued with newbie questions your gonna get cheesed of with it. From what I can gather they are still an operating company but only deal with distributors now.

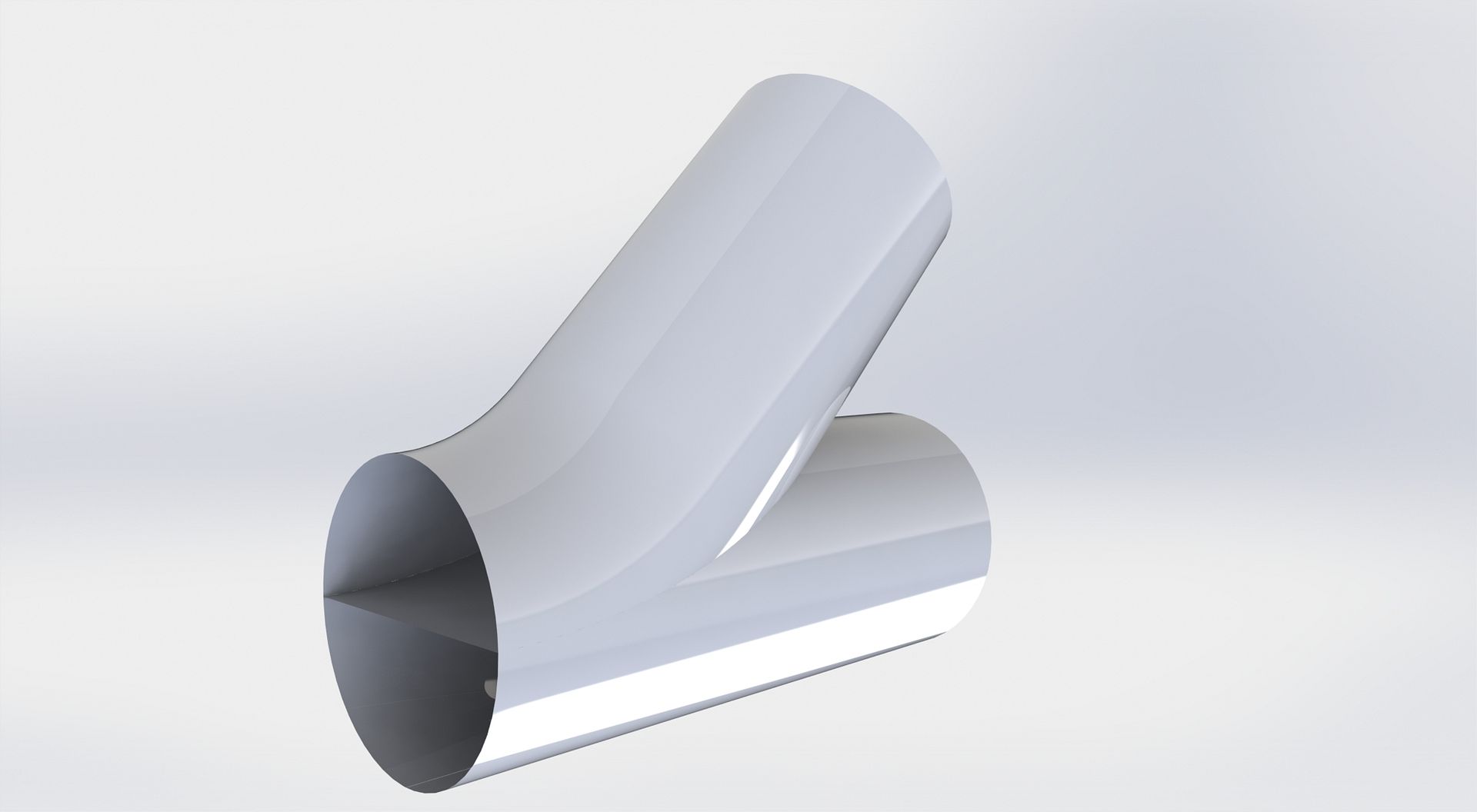

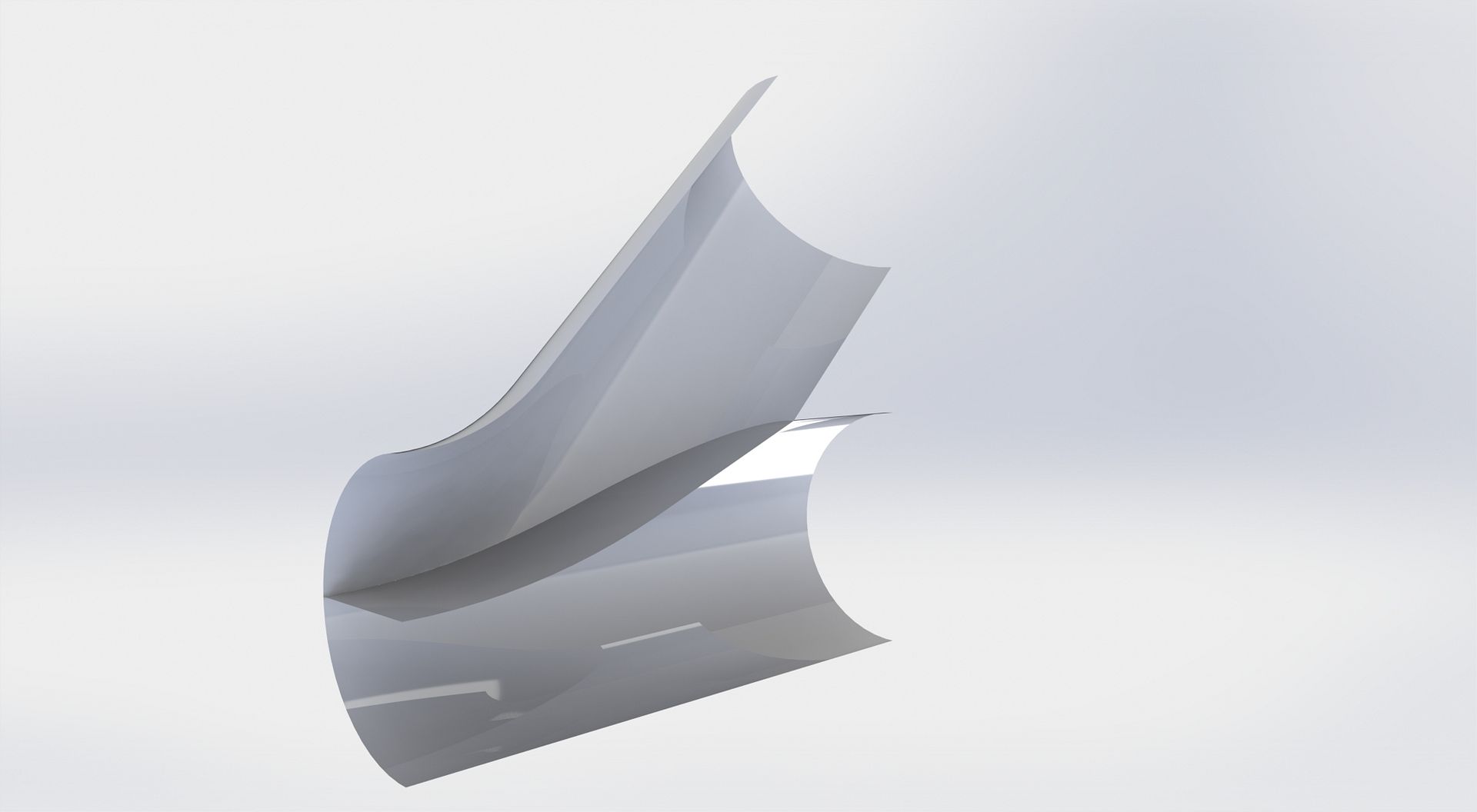

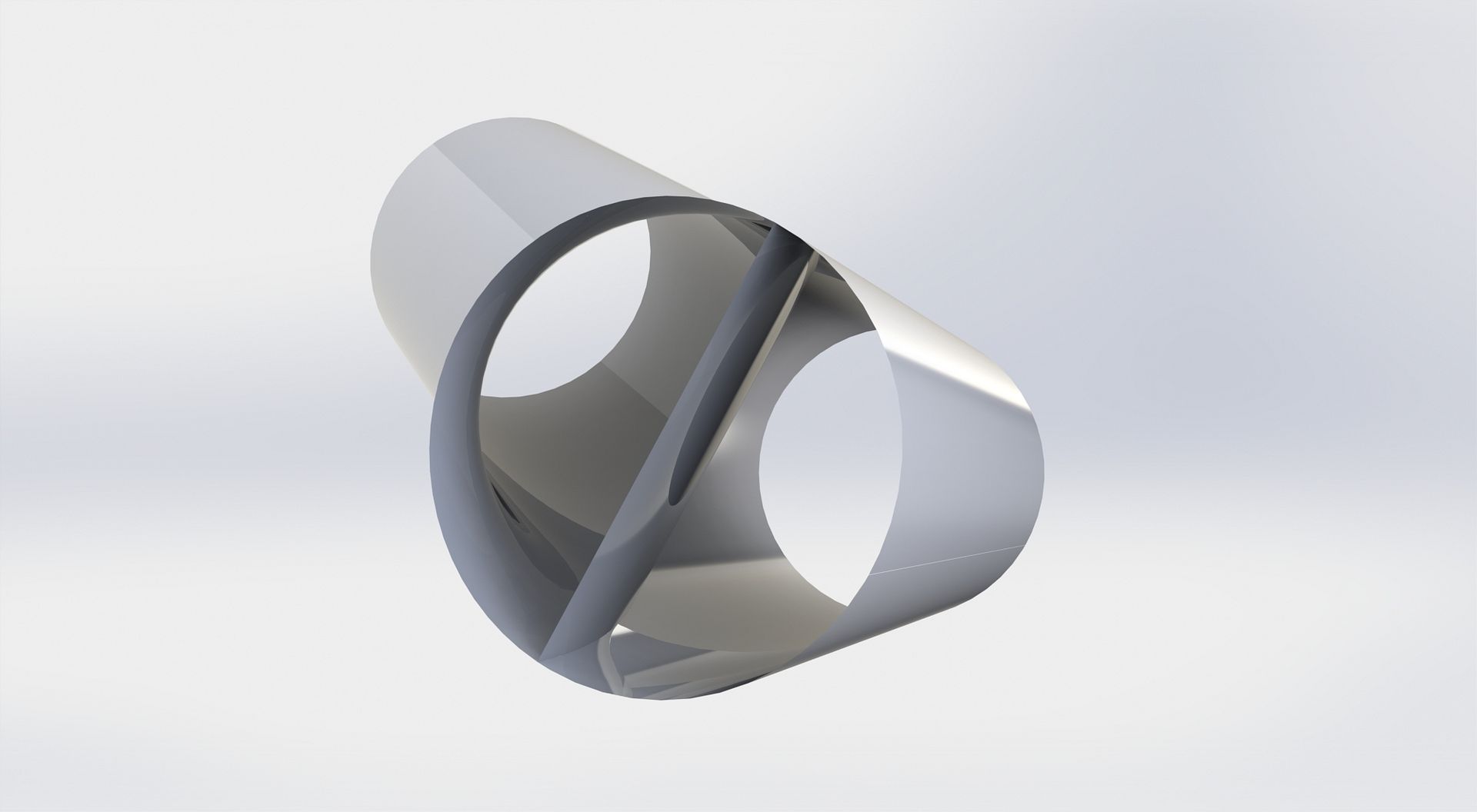

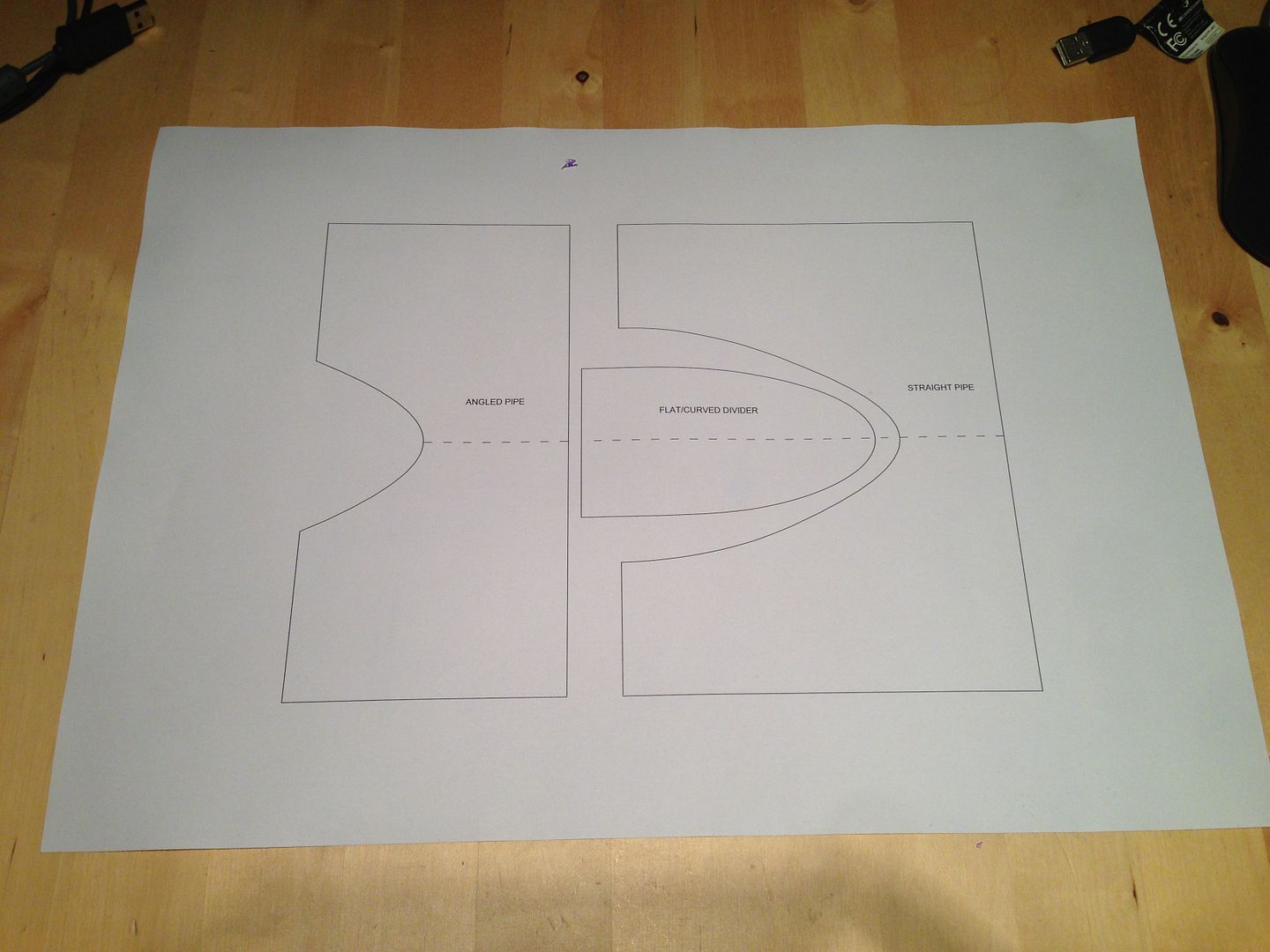

Anyhow, I also decided that in an effort to compensate for using a 70mm instead of 72mm that I was going to improve the cold air intake. I am changing from the old 3" up to a 4" intake right up to the throttle body. This is throwing up its own problems, firstly the old setup I had for the throttle cable cant be used as you physically cant fit it on the TB with the new 4" silicone adapter on there. So the old grey matter got out into use, in an ideal world I would have made a 3D model and got it machined out of a single block, buts that expensive and frankly I couldn't be ar53d to get quotes and wait for it to be done. So I whipped up a new cable holder/adapter/turn around a corner thingy majig....

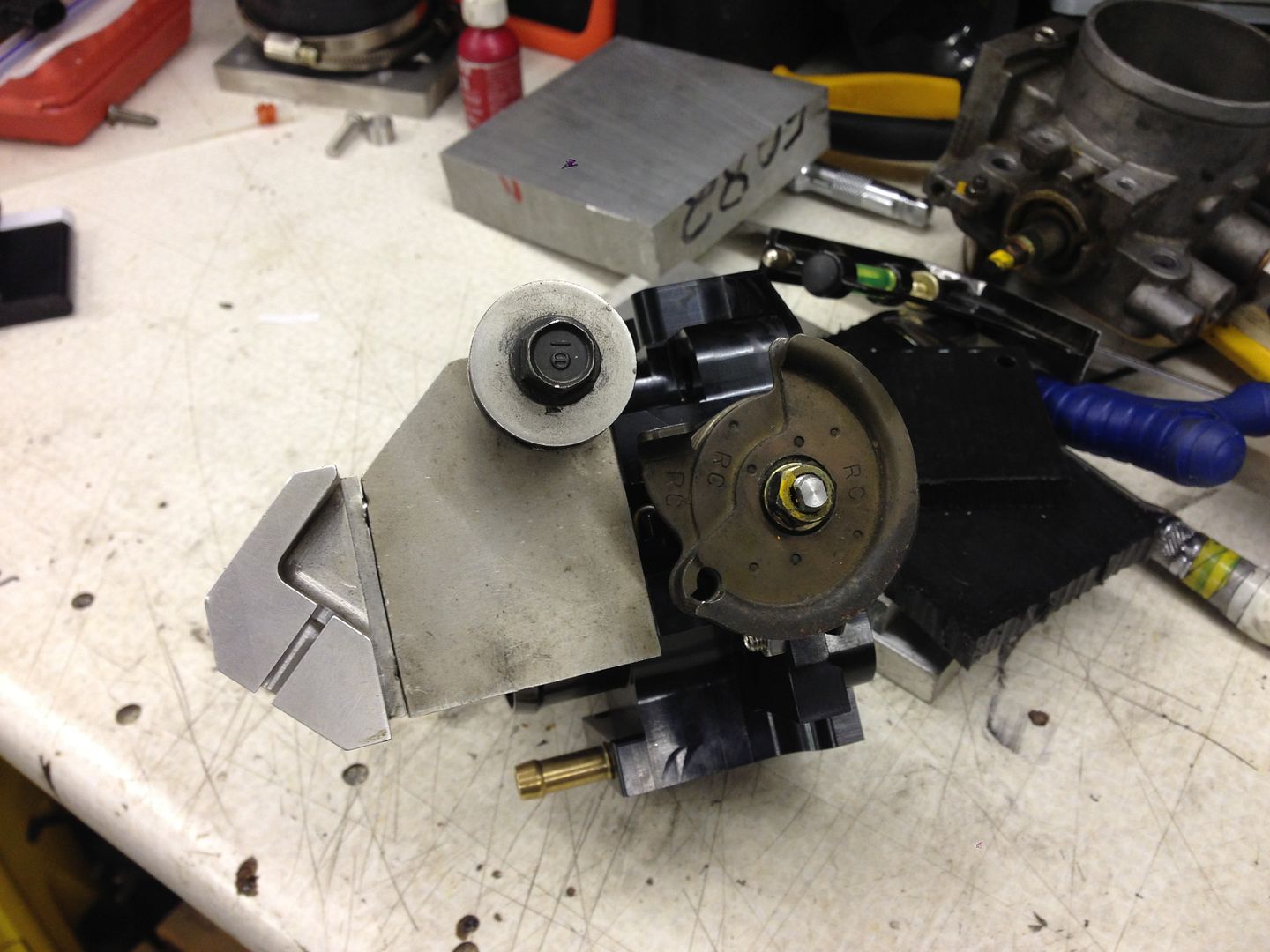

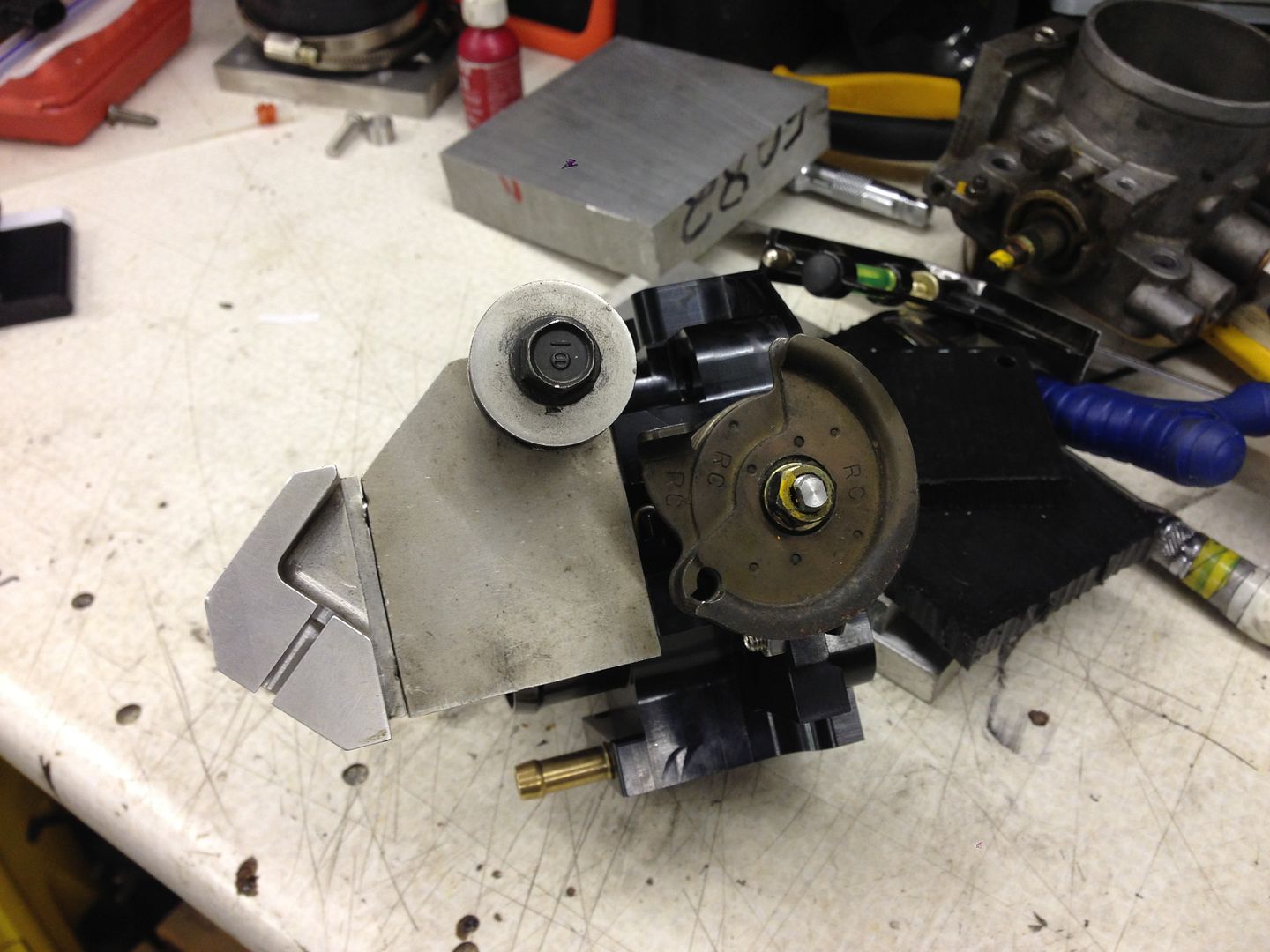

So here's a few photo's of the old TB with the old throttle cable holder (Martin AKA Rust and Oil (Minibusa Van build) made the nicely machined part for me) the rest of the ghetto setup I had made myself - in a rush I might add....However what I ended up with saved me having to order a longer cable.....

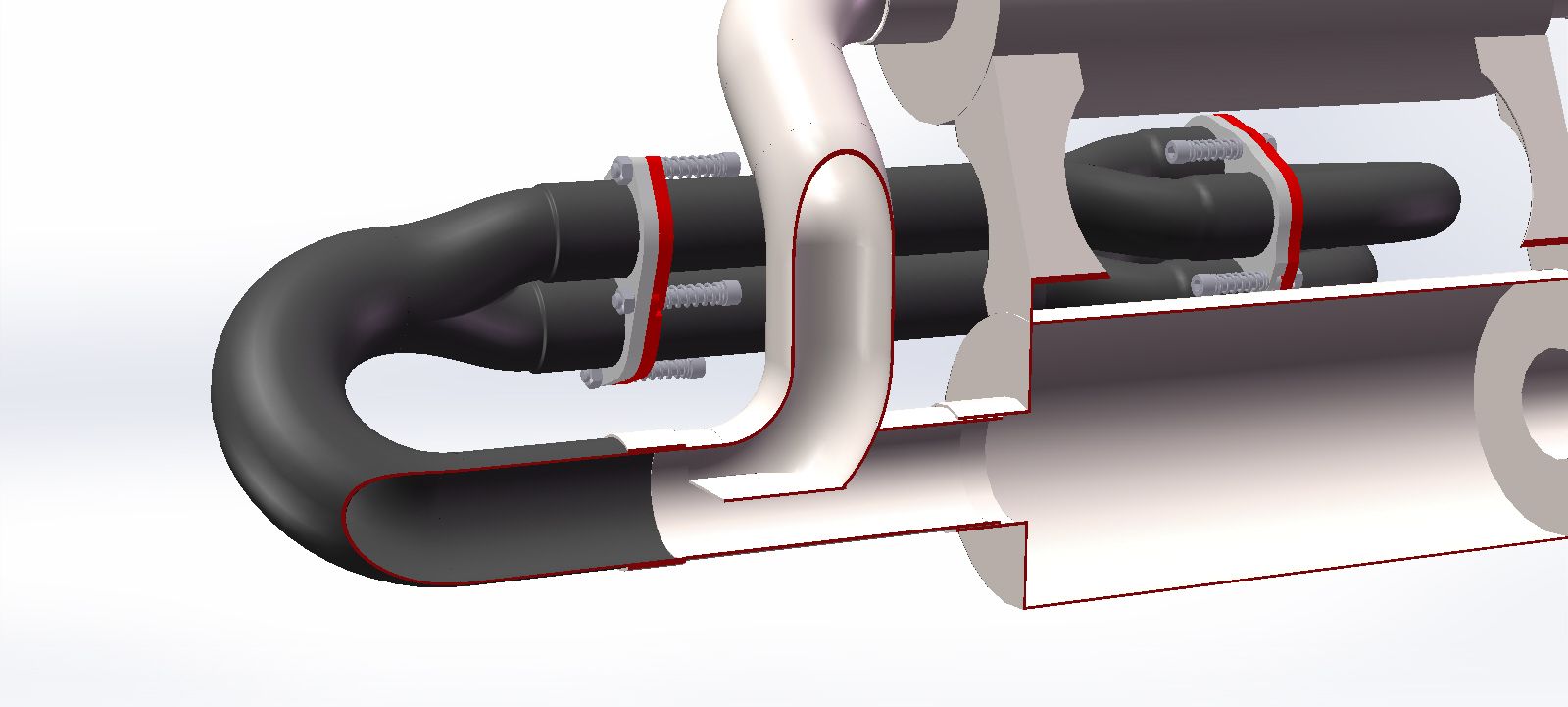

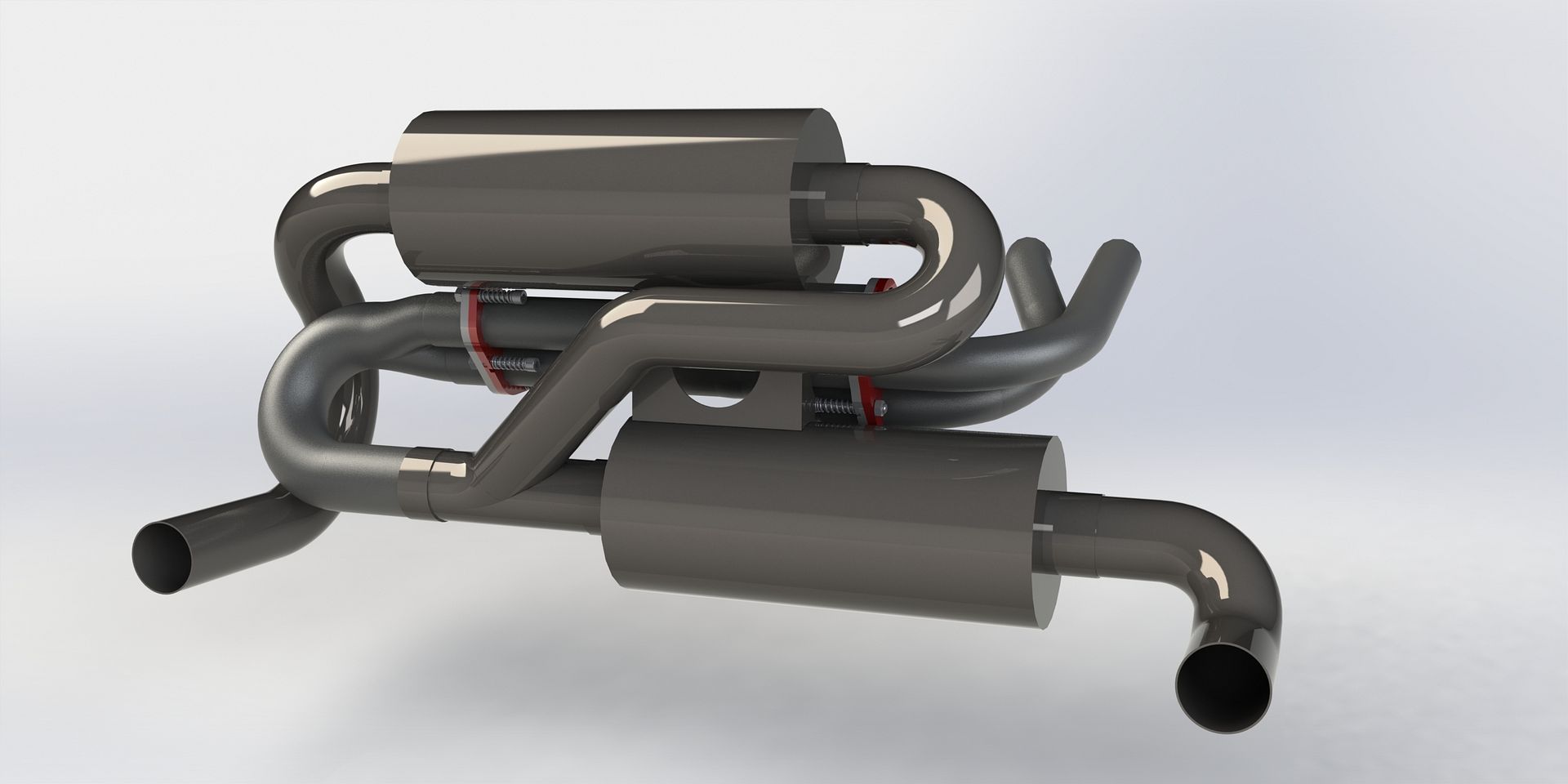

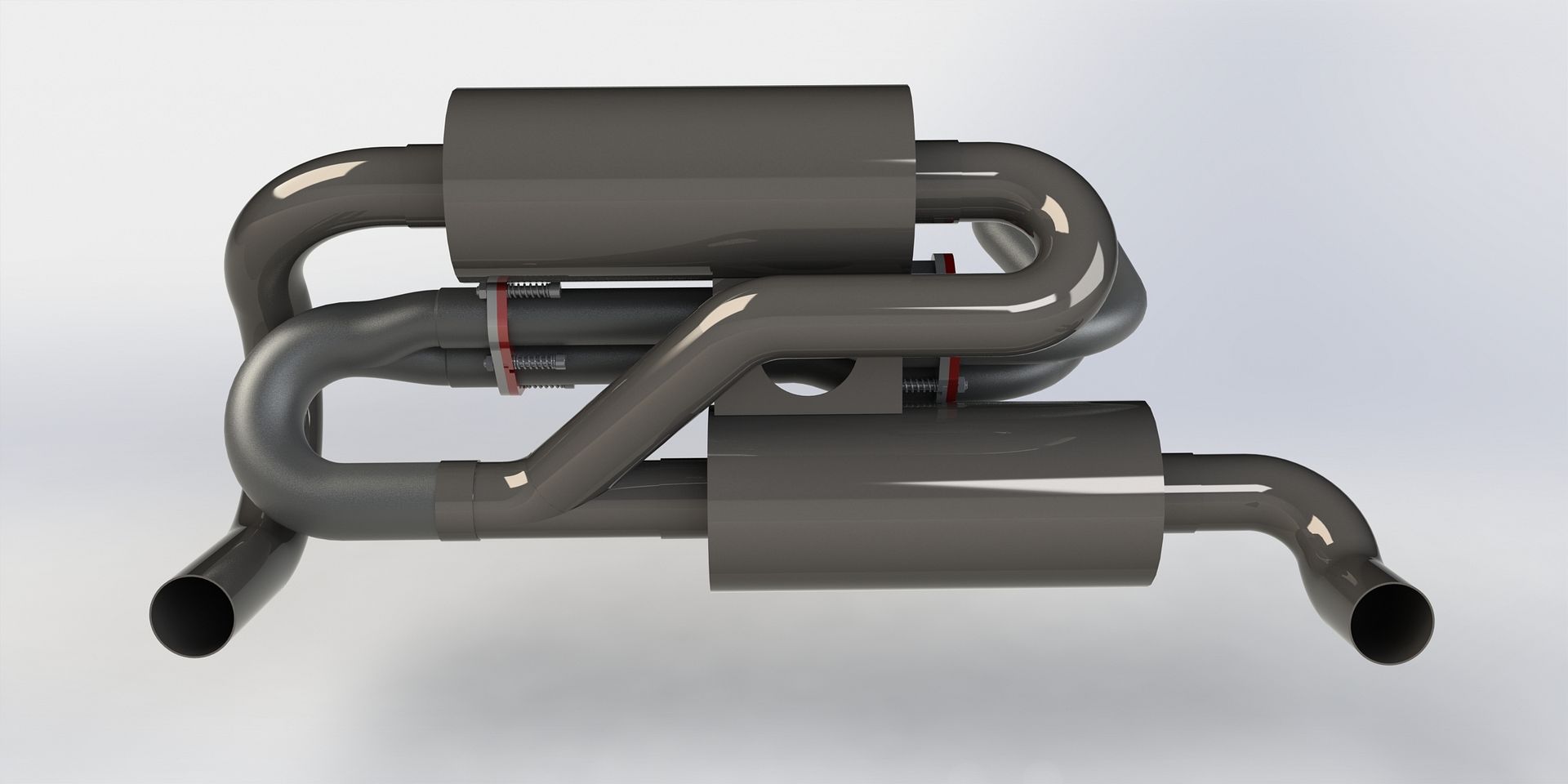

Old Setup - on new TB:

New Setup:

For the eagle eyed among you, you might be wondering how I pass the cable through the acetal part of the mount - if you disassemble that part of the mount you can slide the acetal part over the cable and then reassemble, making the hole where the cable end sits much stronger than with a slot in the side of it for the cable to pass through during assembly.

I also realize that the air flow, pre throttle body, would be much better if the transition from 4" to 3" was more slight, ho hum.....

Now I have to work out how I am going to make a true cold air box and feed it with multiple 3" cold air pipes....

More to come later - waiting on bits now.....

.

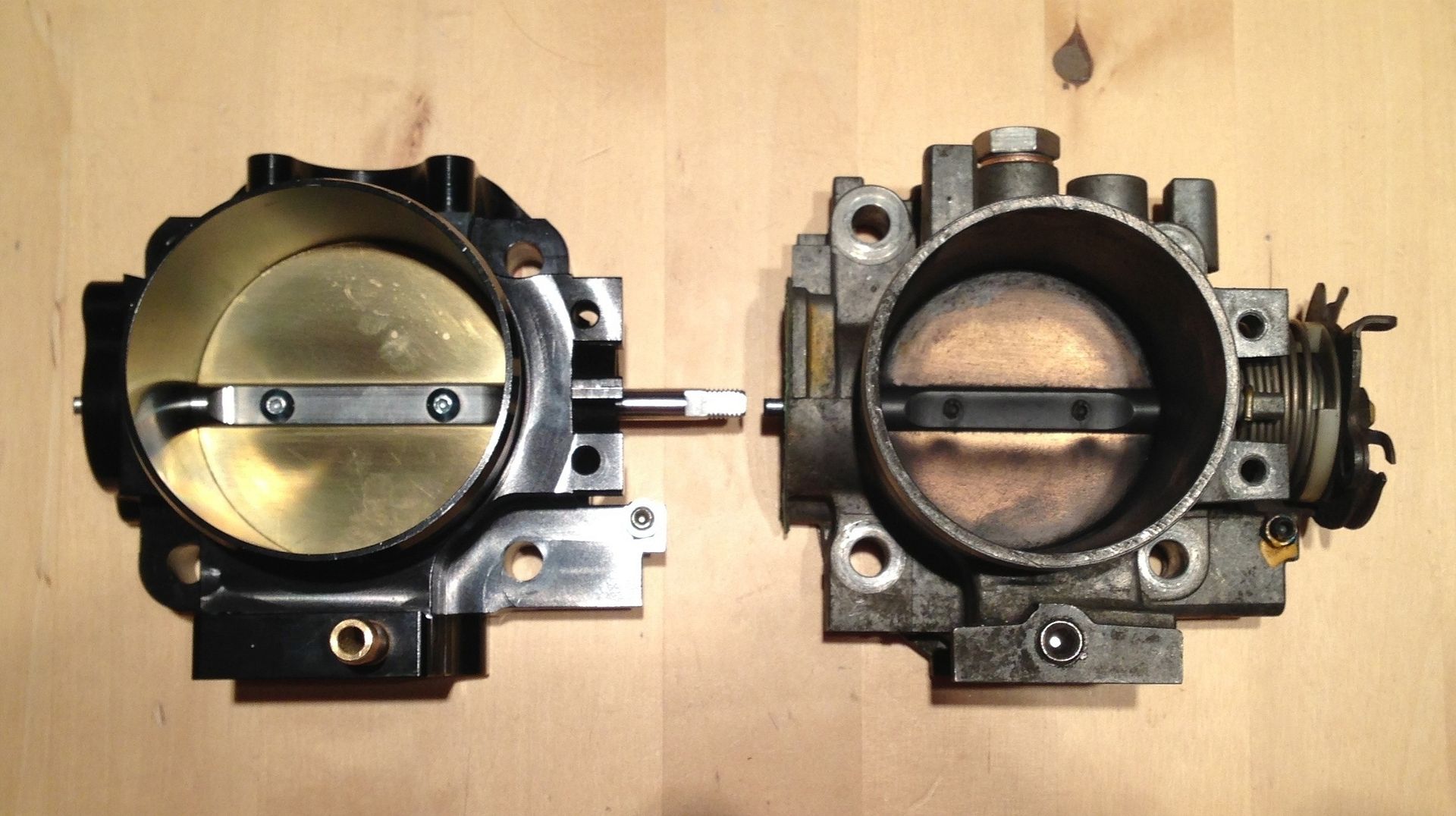

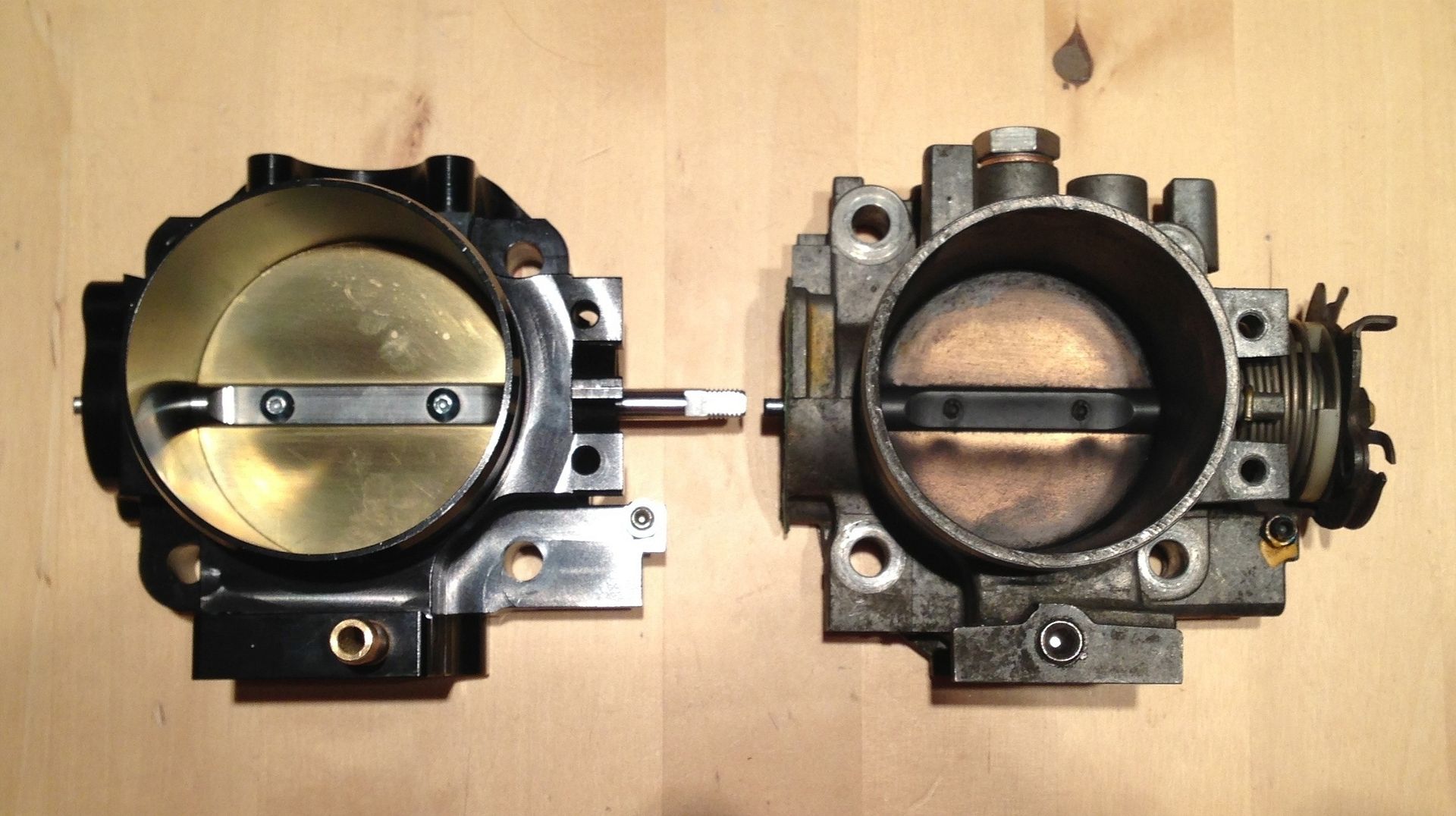

Oh, here's the old TB verses the new: its defo going to be worth swapping them

Edited by cptkirk, 16 February 2015 - 12:30 PM.