Well theres not much been happening actually on the car but theres been some more research and design work going on.

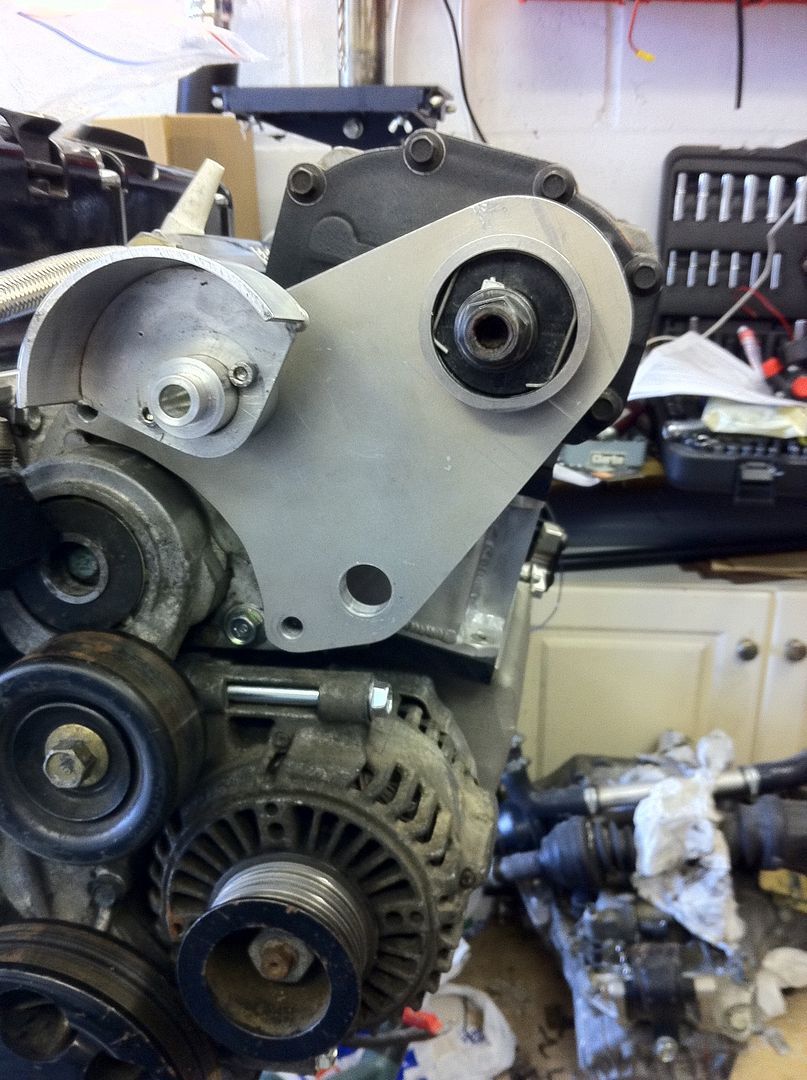

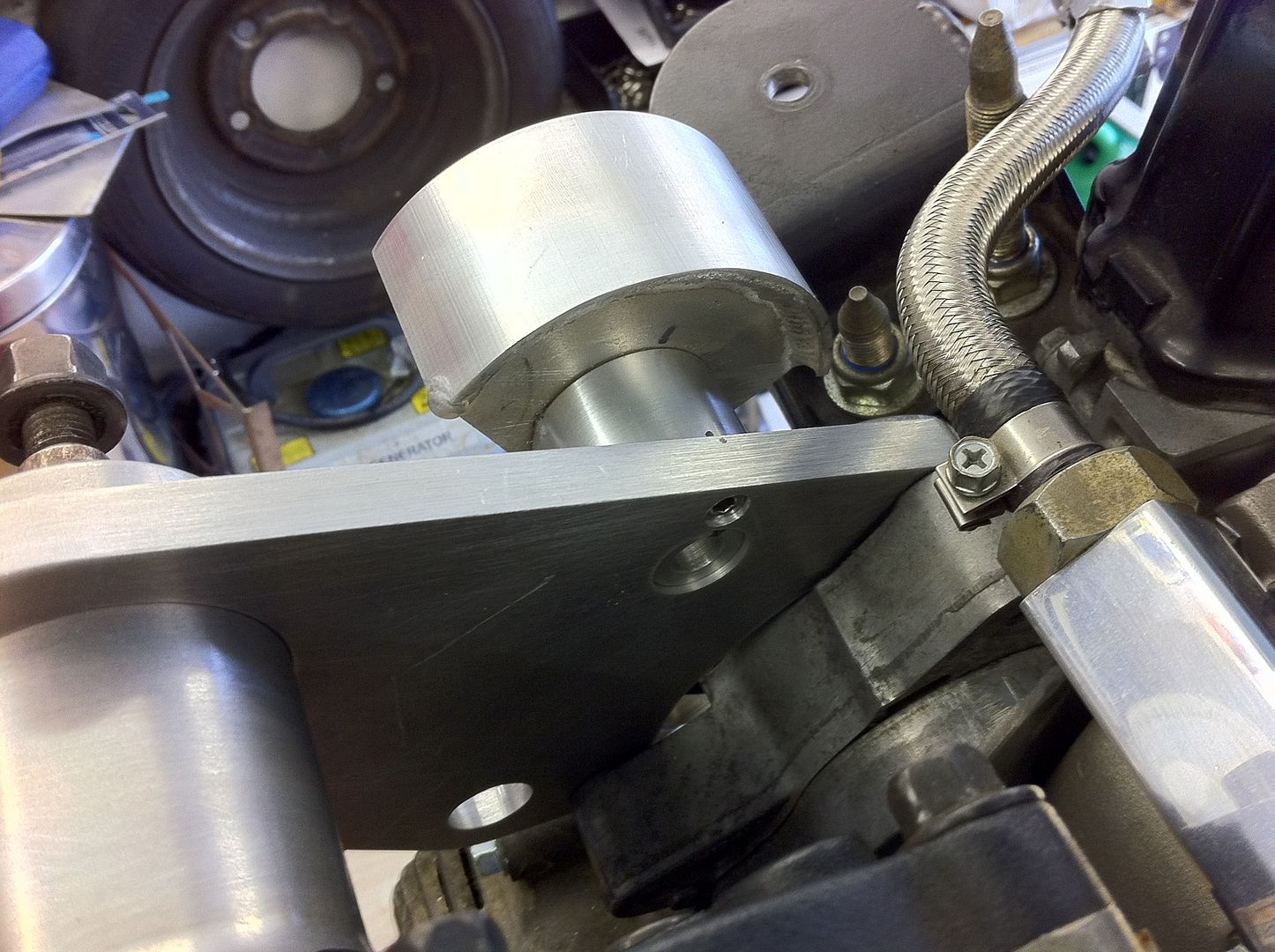

I now have a new design for the belt routing which incorporates the latest revision of the snout clamp (version No.11).

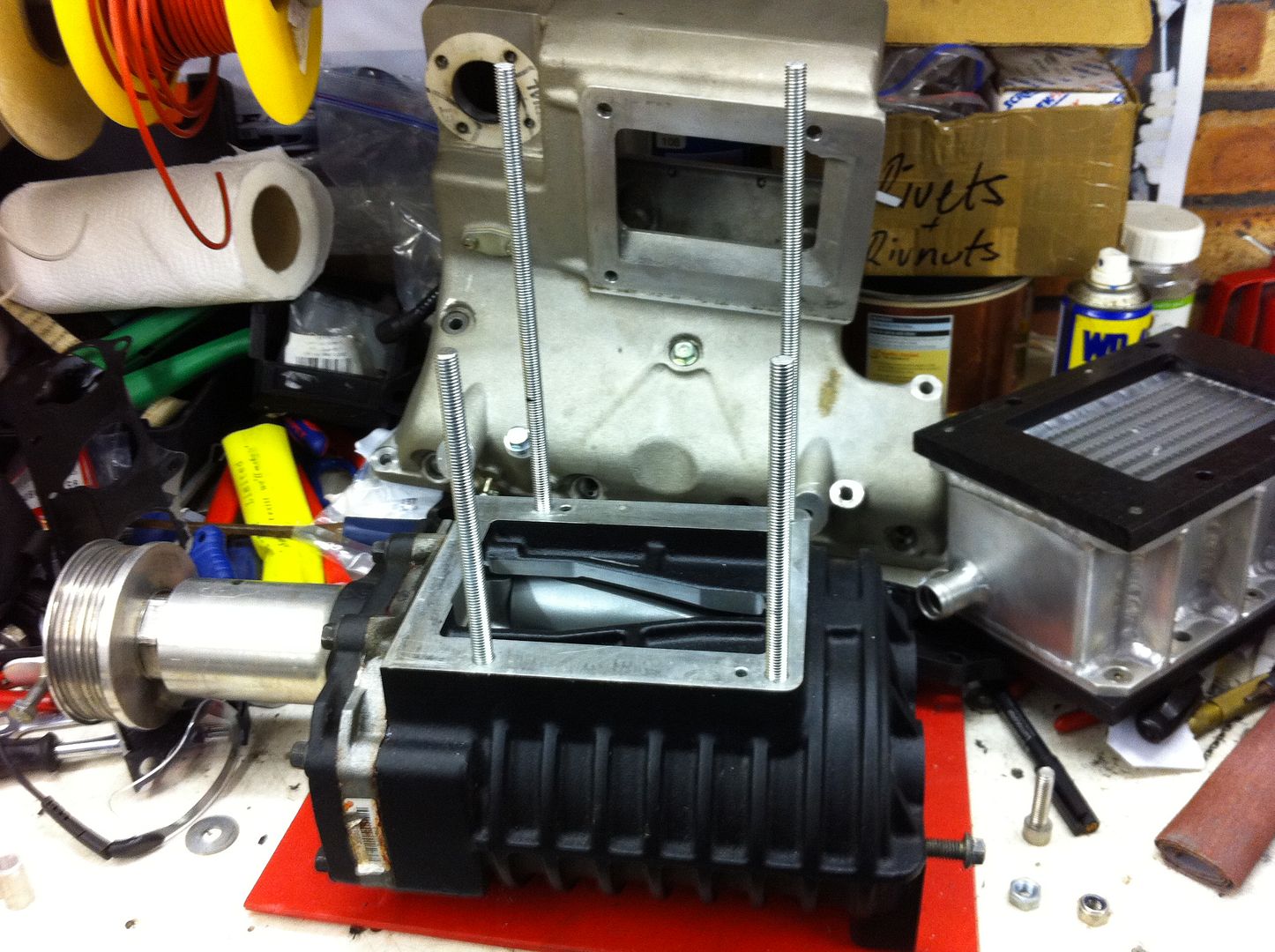

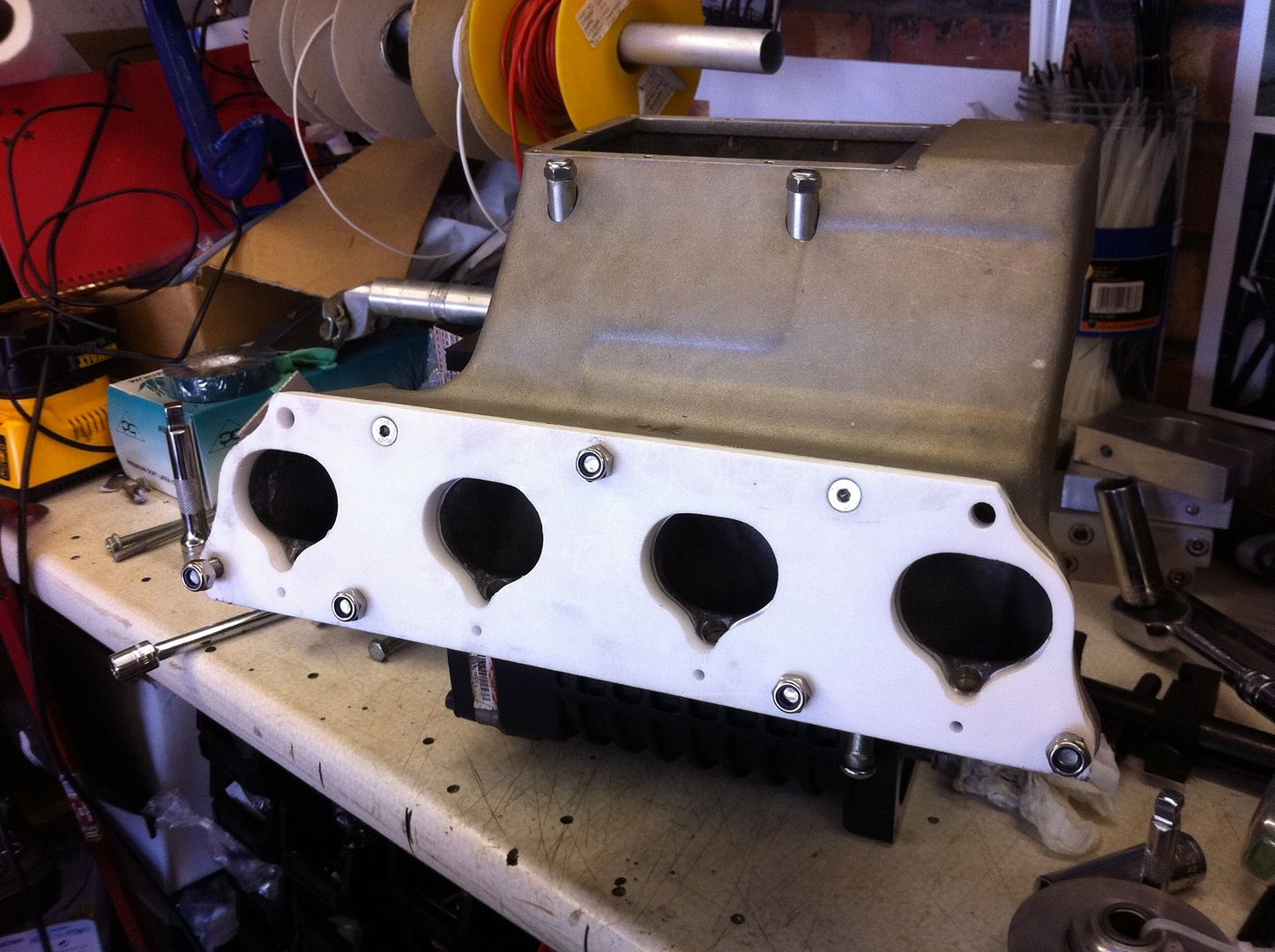

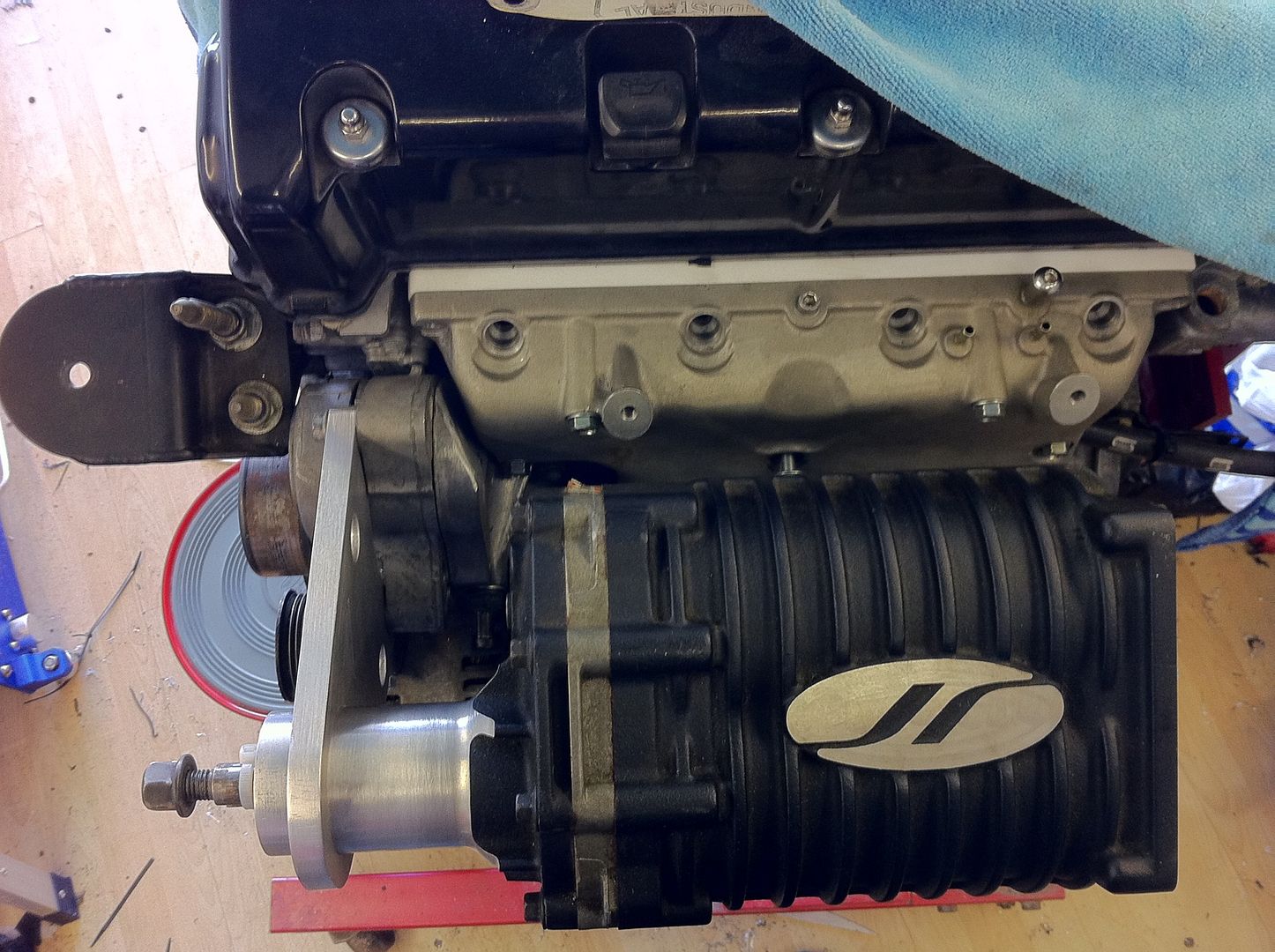

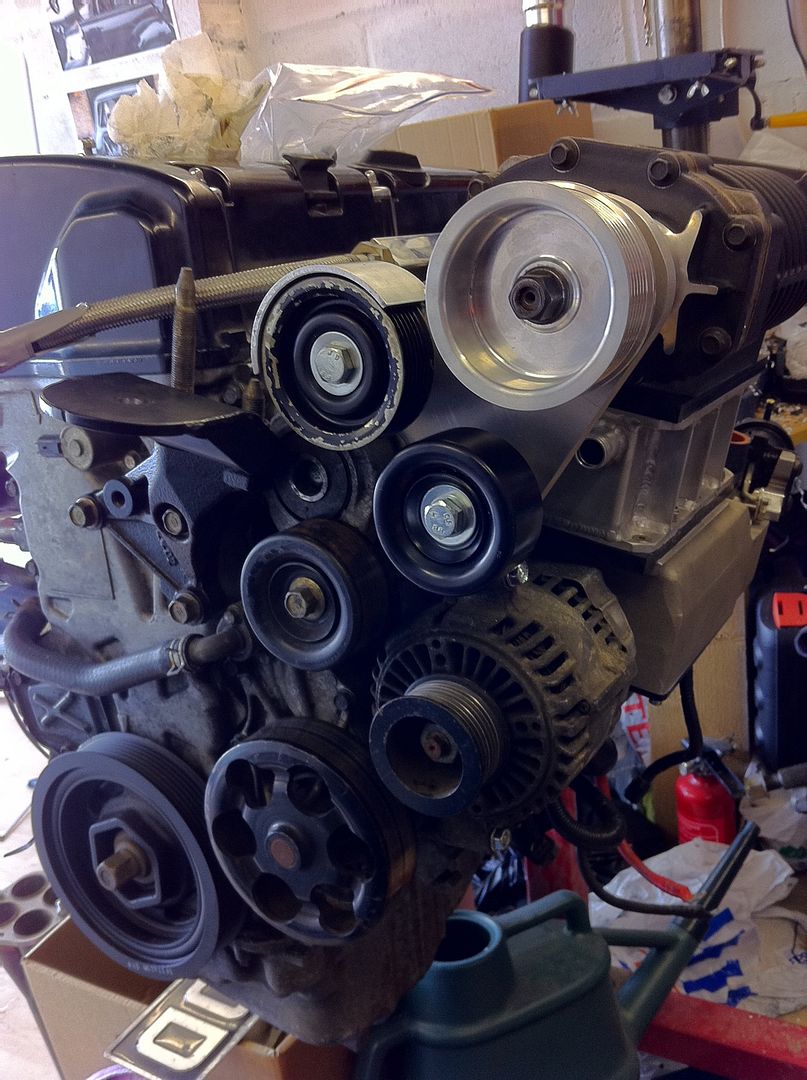

I am going to be using the OEM grooved idler pulley that is used on the EP3 Civic and will be using another smooth tensioner, the same as in use on the auto tensioner. I have drawn up 2D pulley layouts as was suffering with what appeared to be belt stretch and wanted to know how effective the auto tensioner was in its current configuration compared to the OEM setup. I drew two setups, measuring the theoretical belt length, one with the tensioner completely off and one with it as it would be without a belt (fully on). So my current setup on had a difference of 21mm in belt length, hence it being a b1tch to get on and n ot able to keep the tension very well, compared to the OEM setup that had 60mm difference in belt length. As an added bonus it has increased the amount of wrap on the supercharger pulley by a considerable amount, very happy.

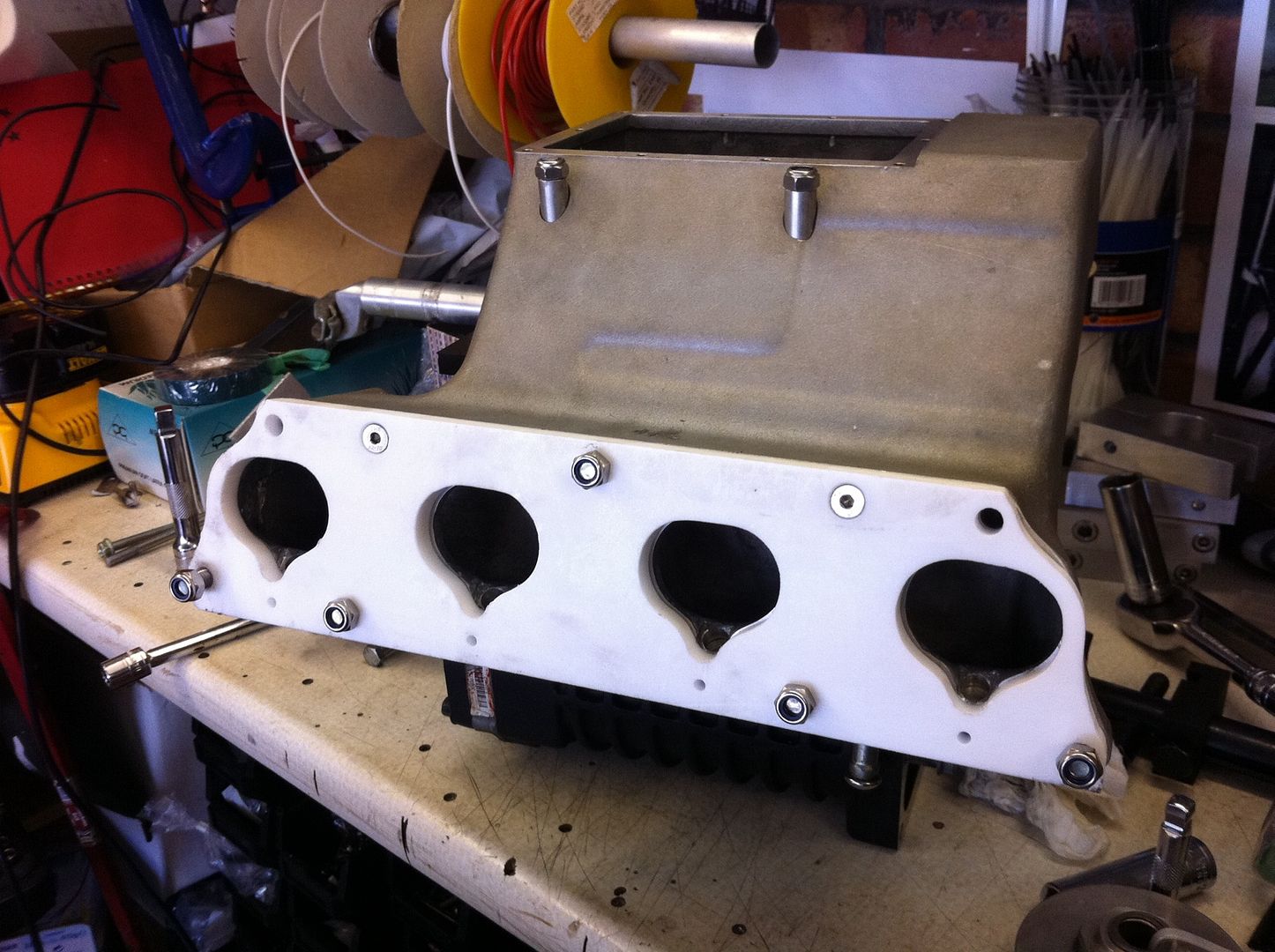

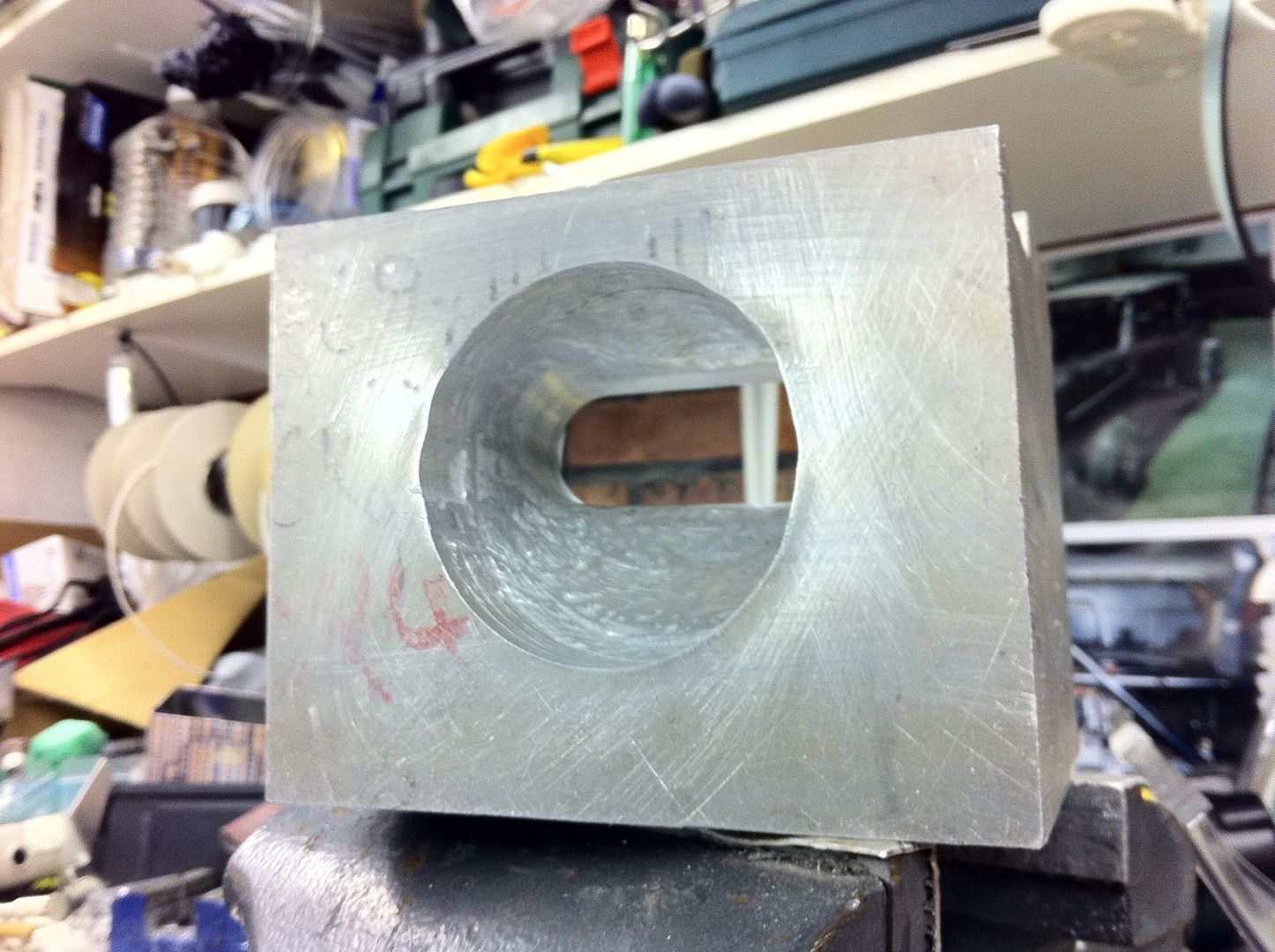

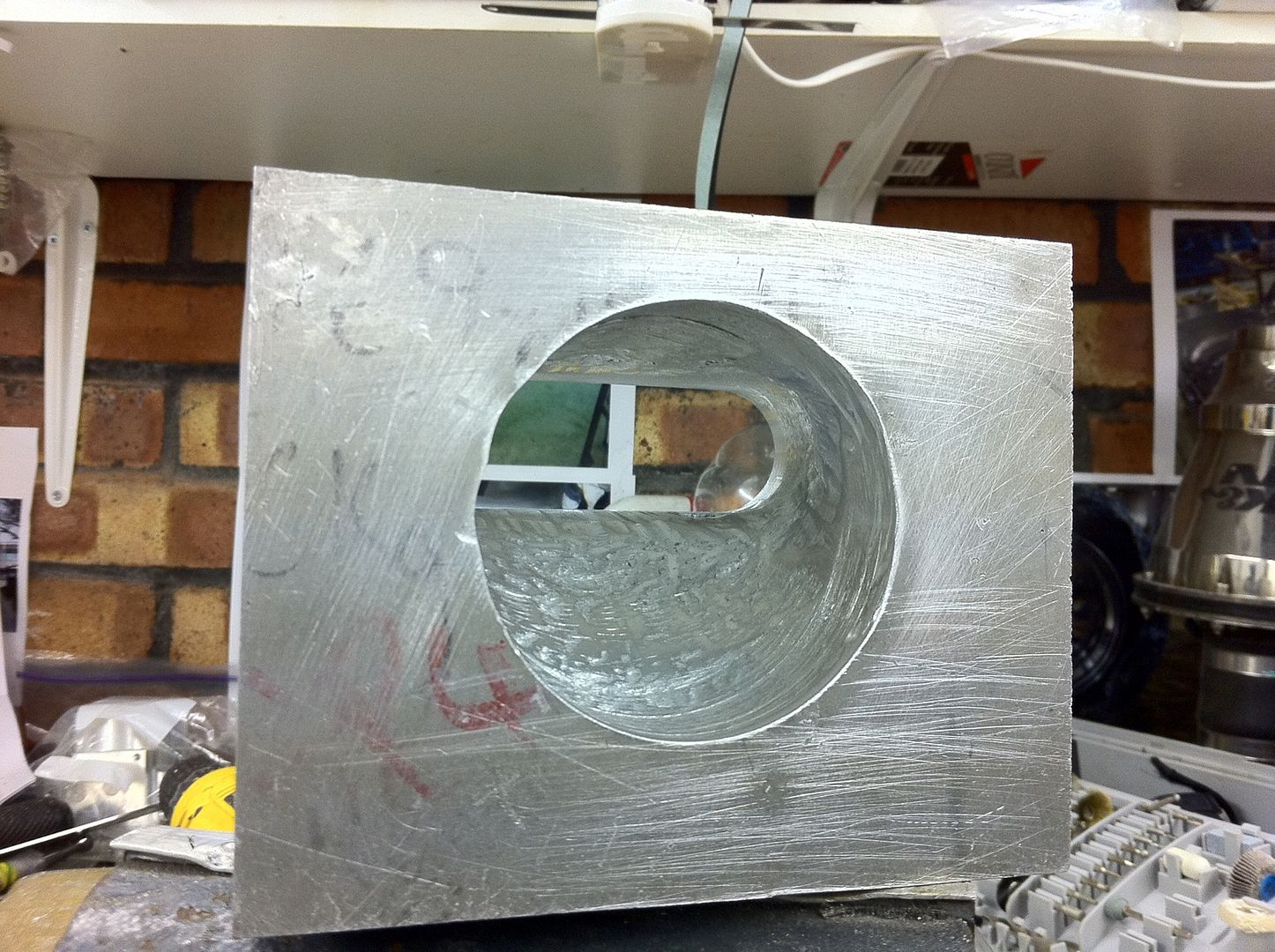

I have the plate and billet rod sat here waiting to be machined and should be able to get the turning done in the week and the mill work next week. Bring on the light nights so I can work on the car.

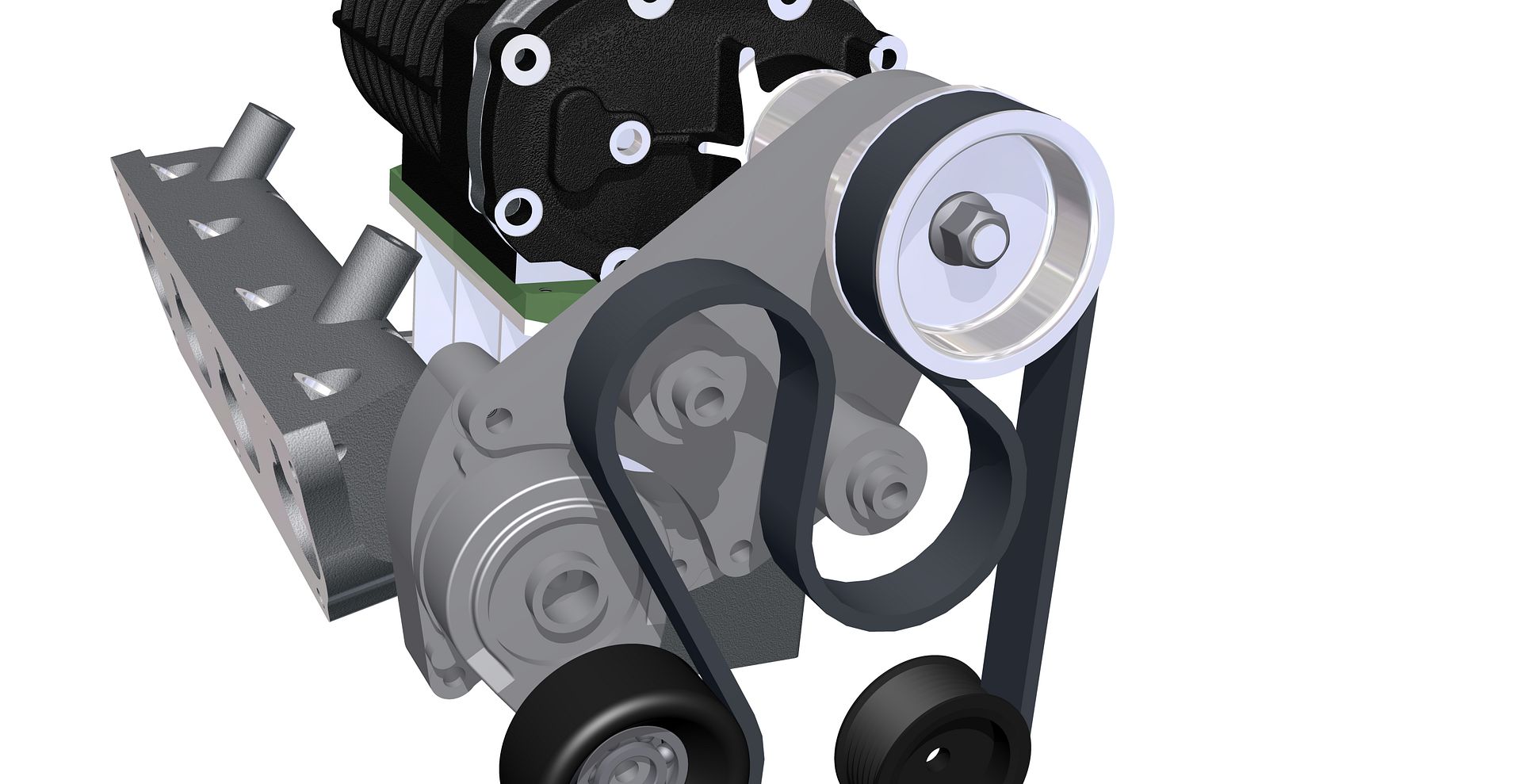

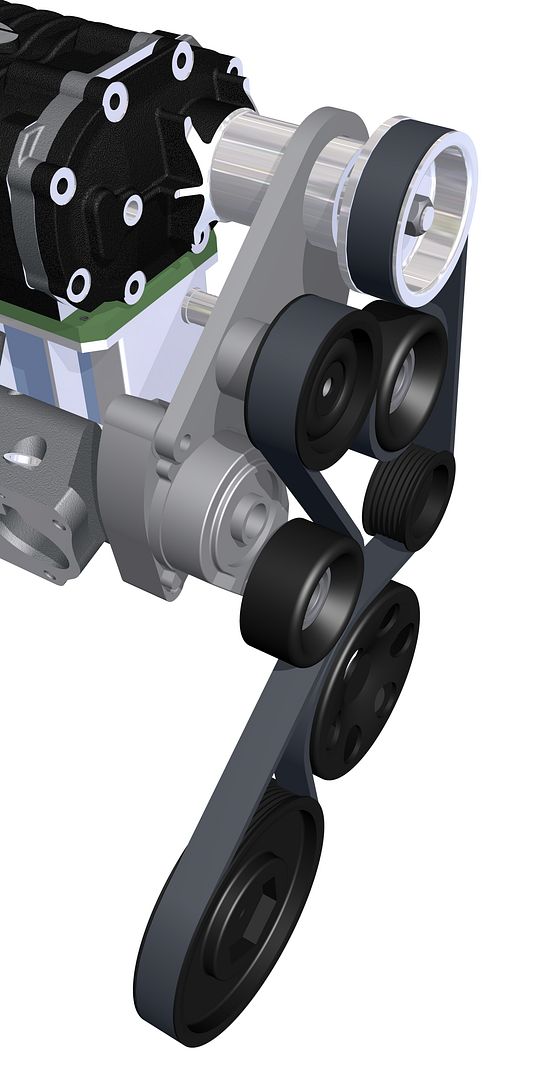

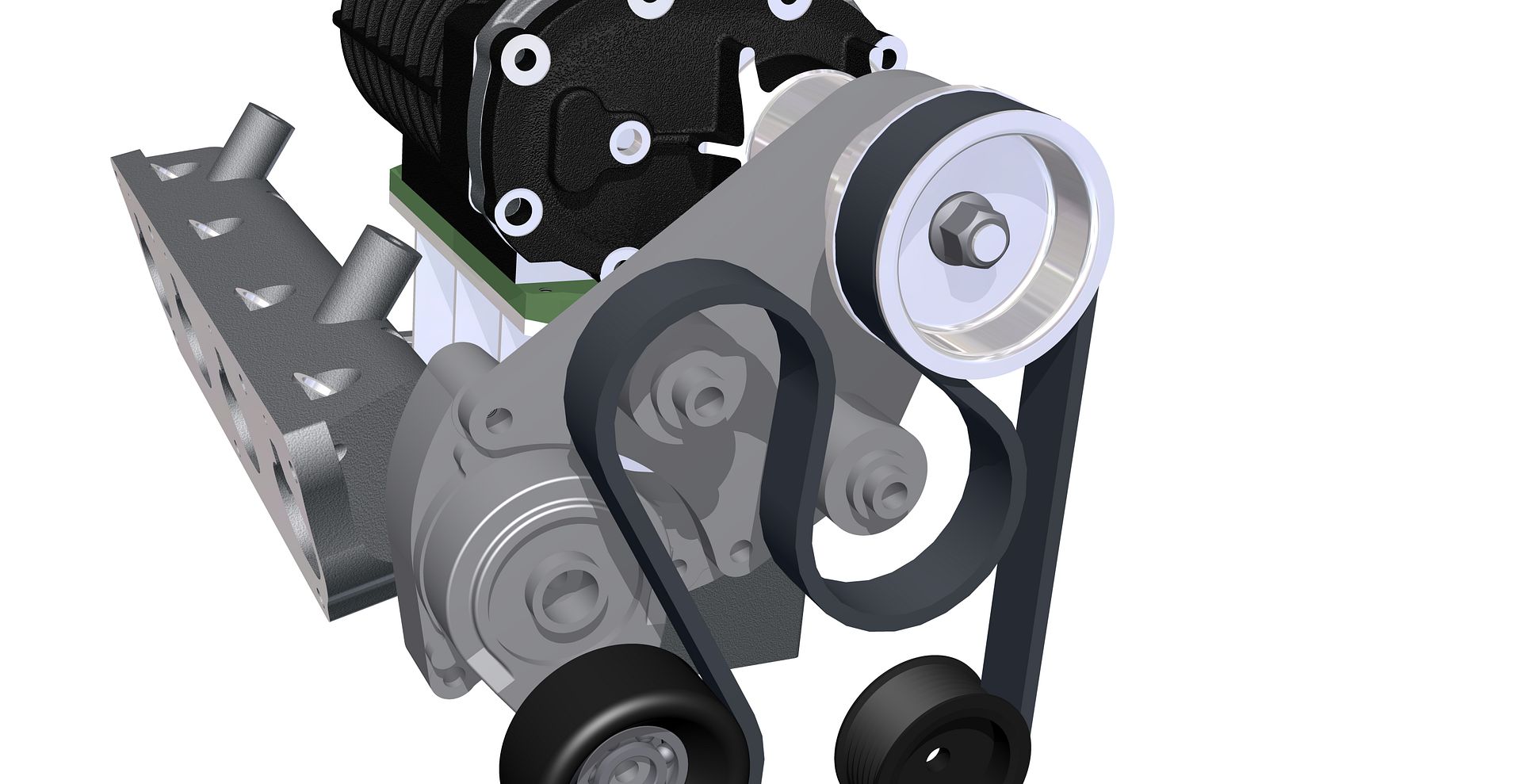

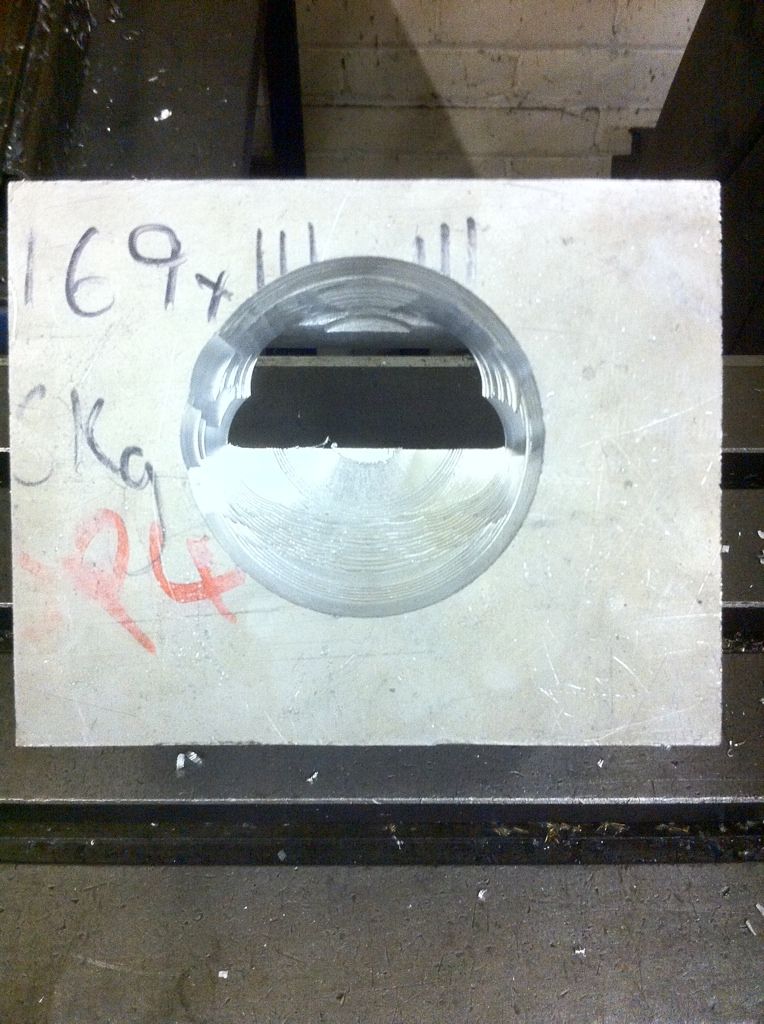

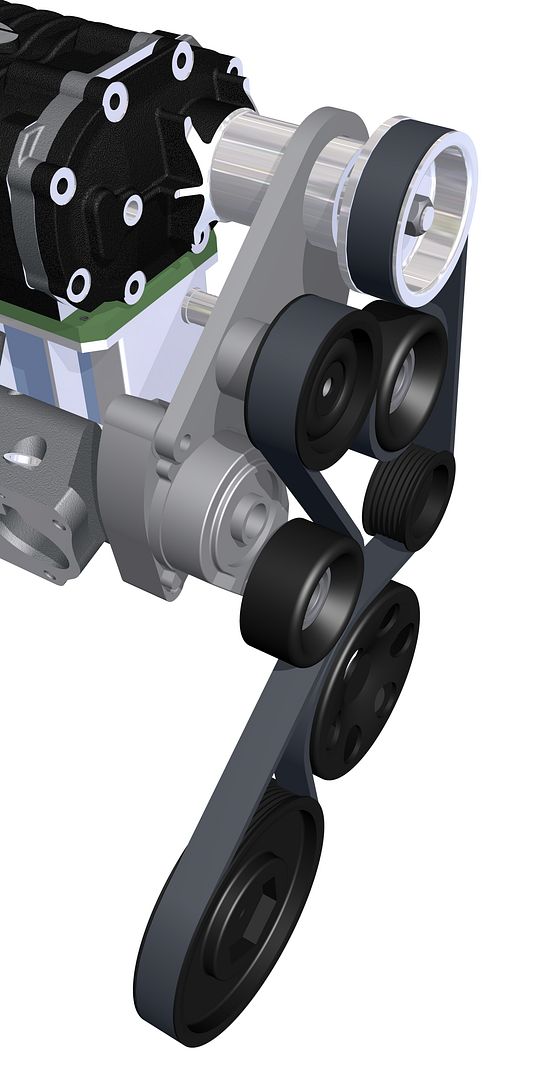

For those that are interested I did a few renders of what the new setup will look like:

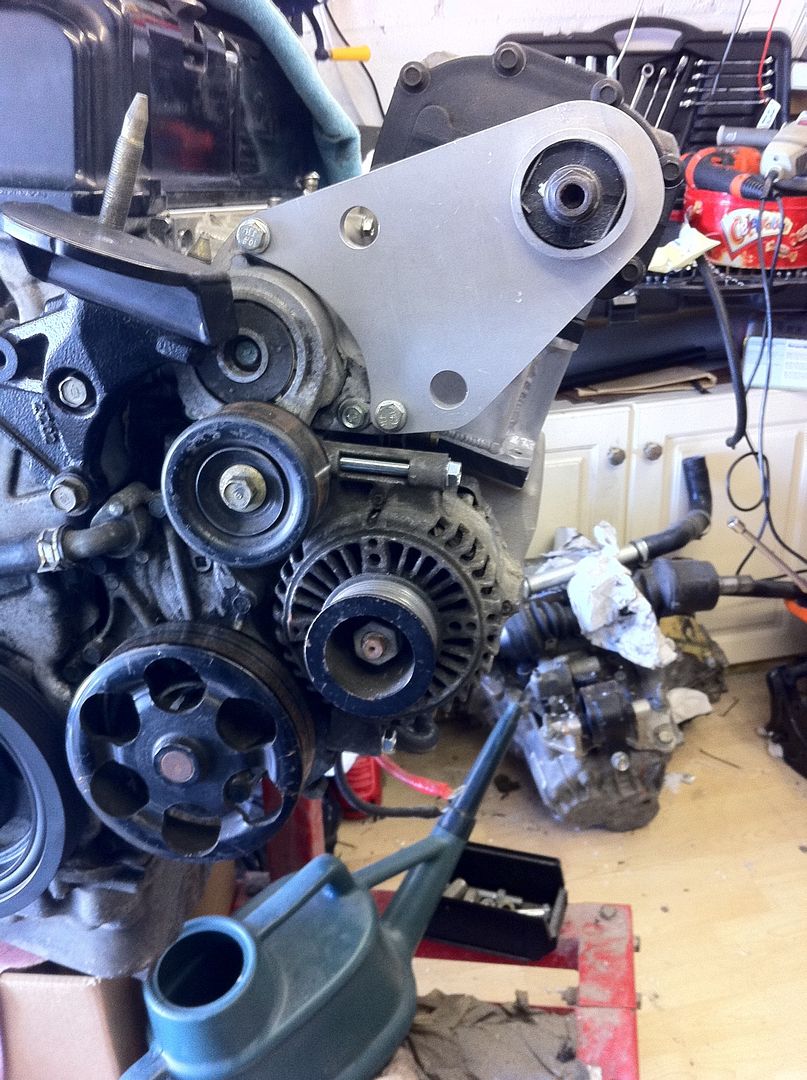

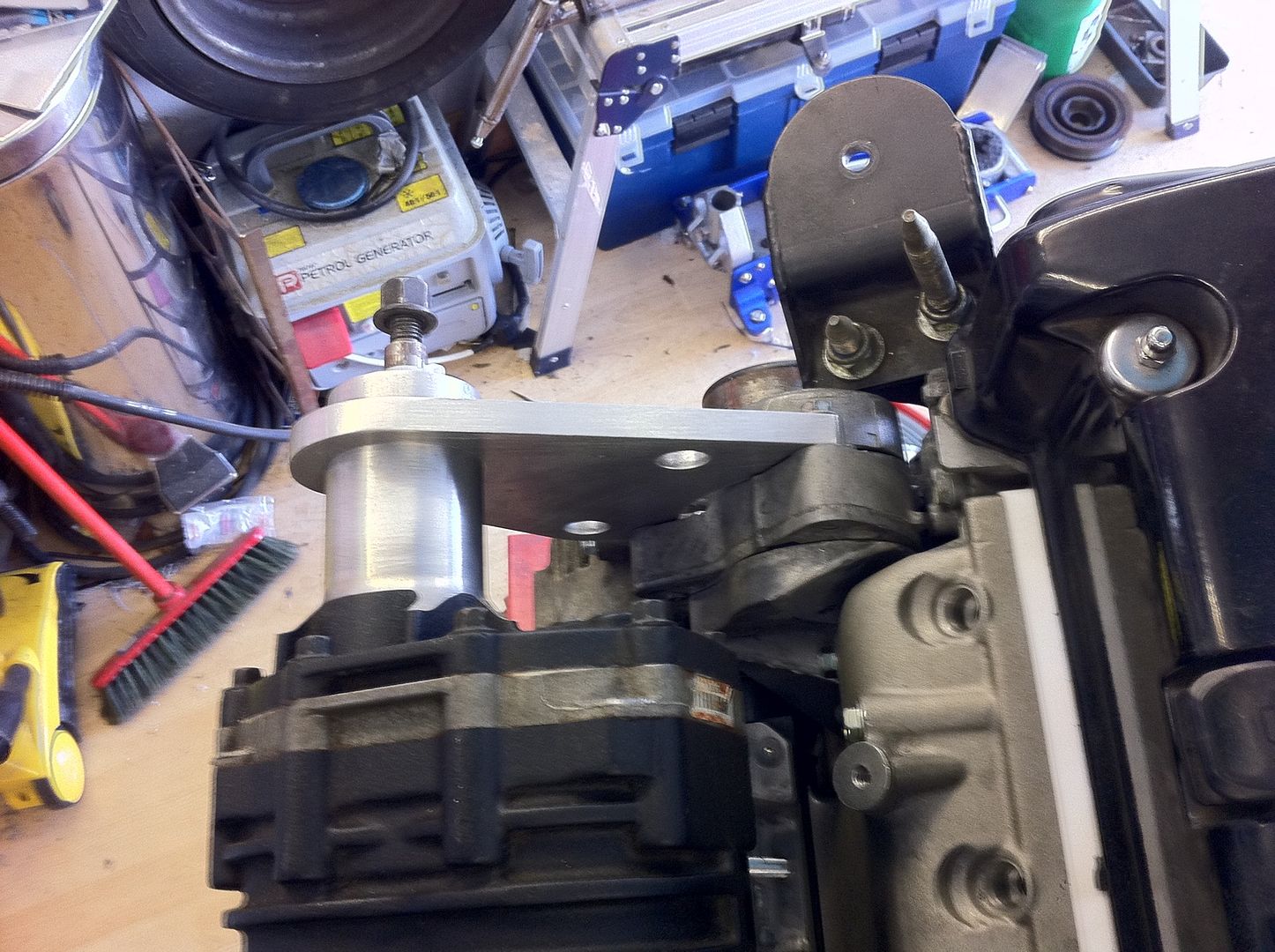

Heres what the current setup route would be, the red arrow shows how the tension goes on to the belt:

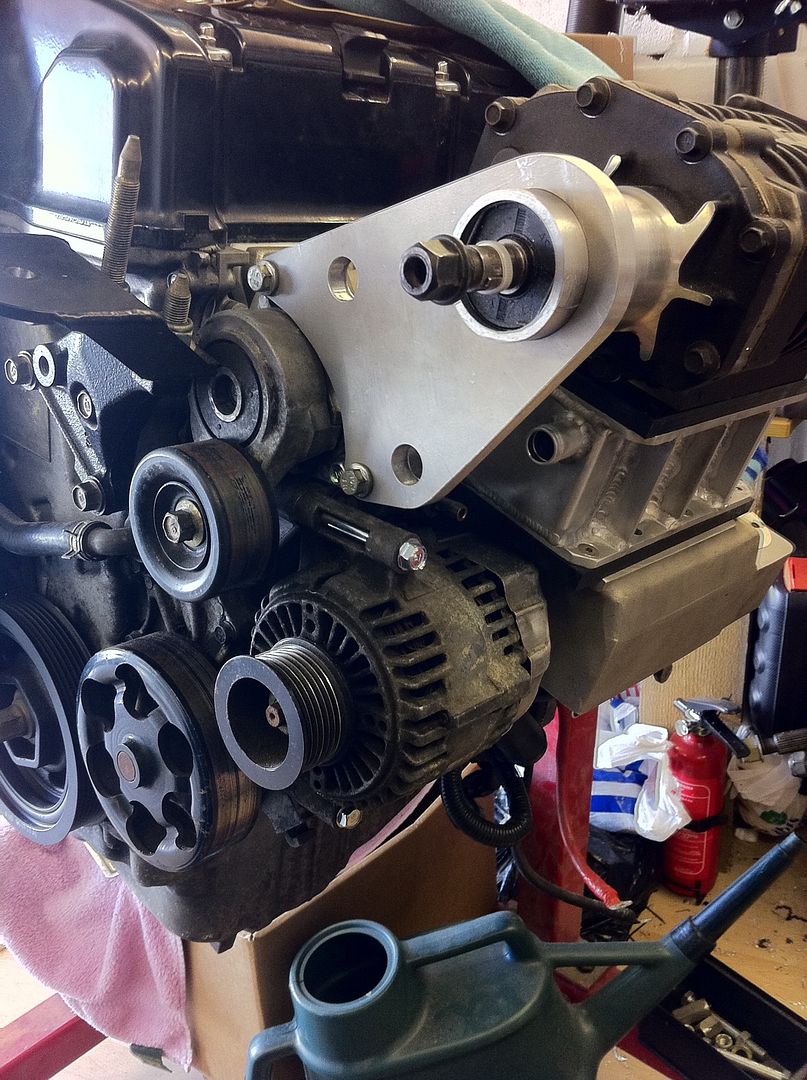

Heres the new setup:

One showing the new snout clamp/pulley mount