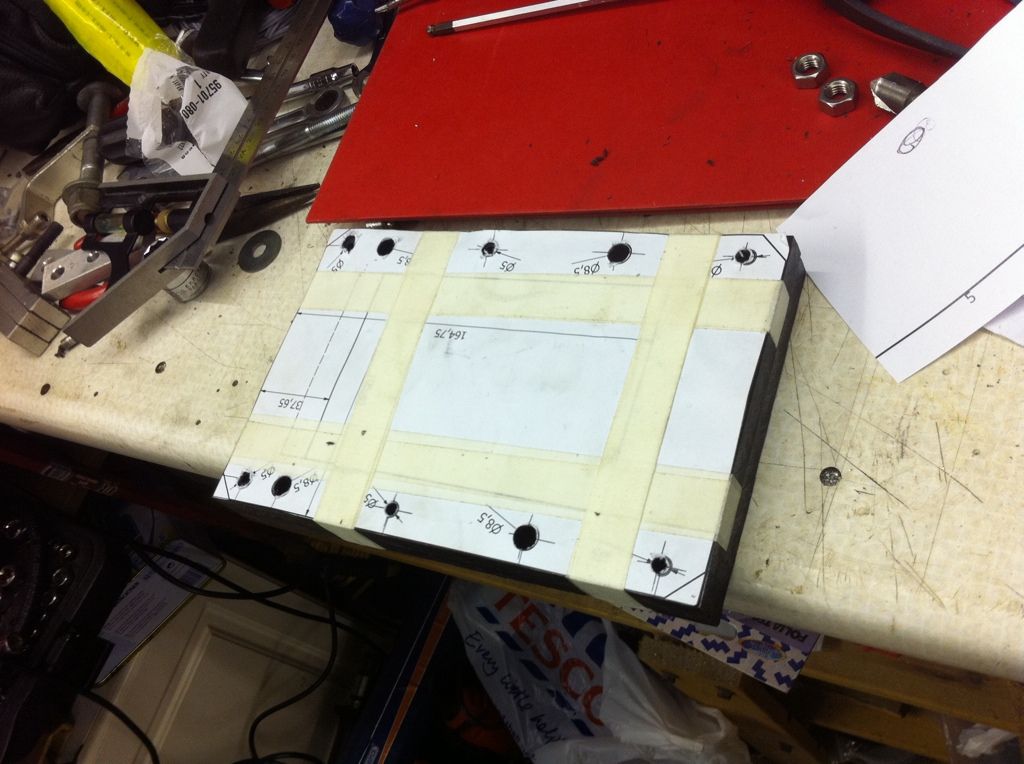

I made a start to the adaptor plates that will sit either side of the intercooler cartridge, as shown in the CAD model this will make all the air flow through the intercooler. I am still undecided as to whether I use acetal on both side or make the top plate from ali, that way transferring heat from the body of the charger into I/C....mmmm....time will tell. I managed to cut out the central hole but didnt get a picture, all that remains now is to get the sloped edges machined in.

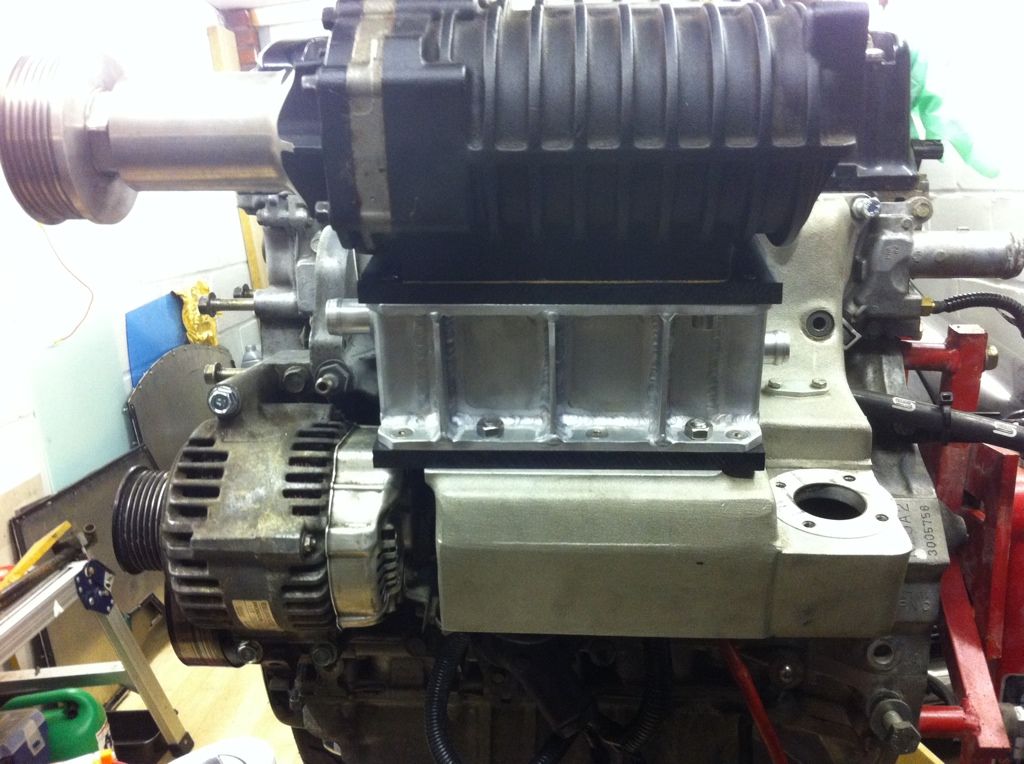

After that I couldnt resist putting the charger on it and then the manifold back on the engine as you see in the photos at the end of the post.

Adaptor plates:

Intercooler Cartridge in place: