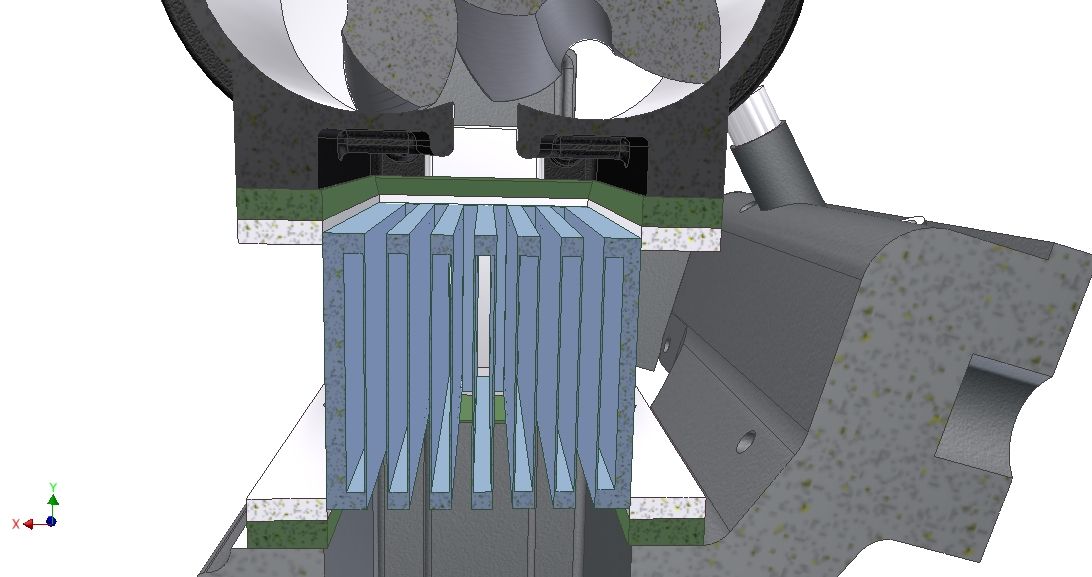

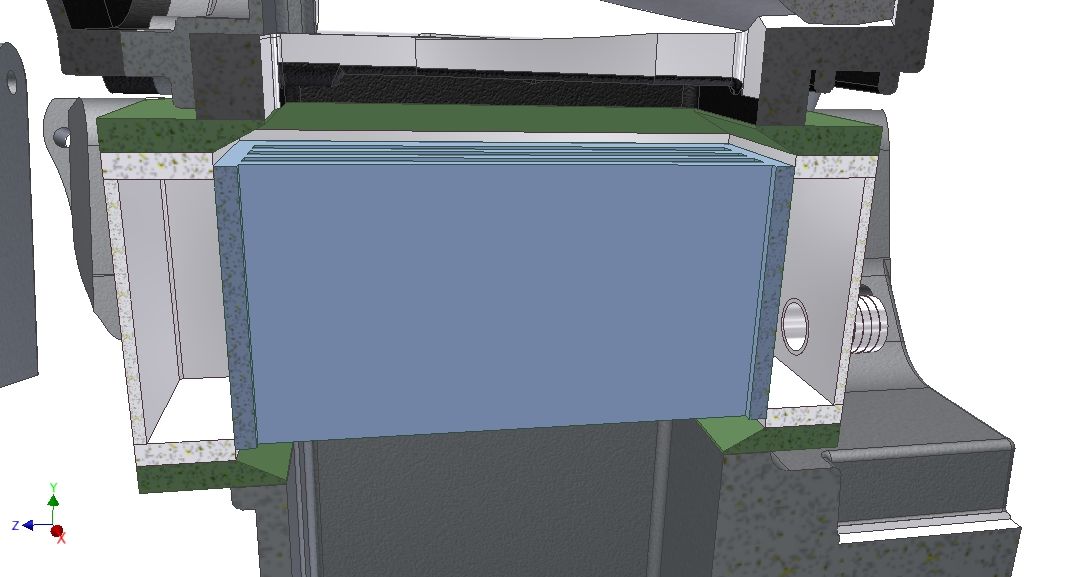

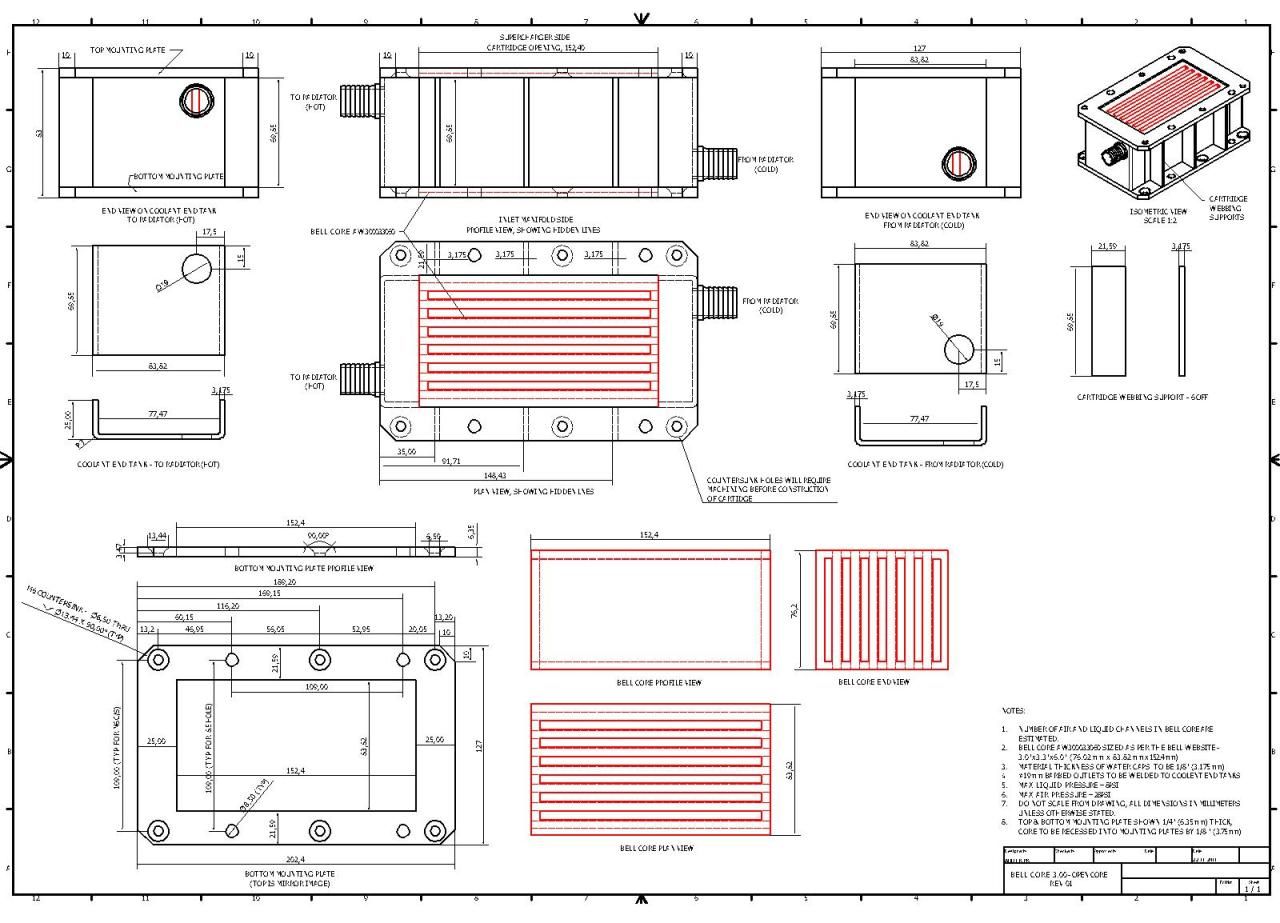

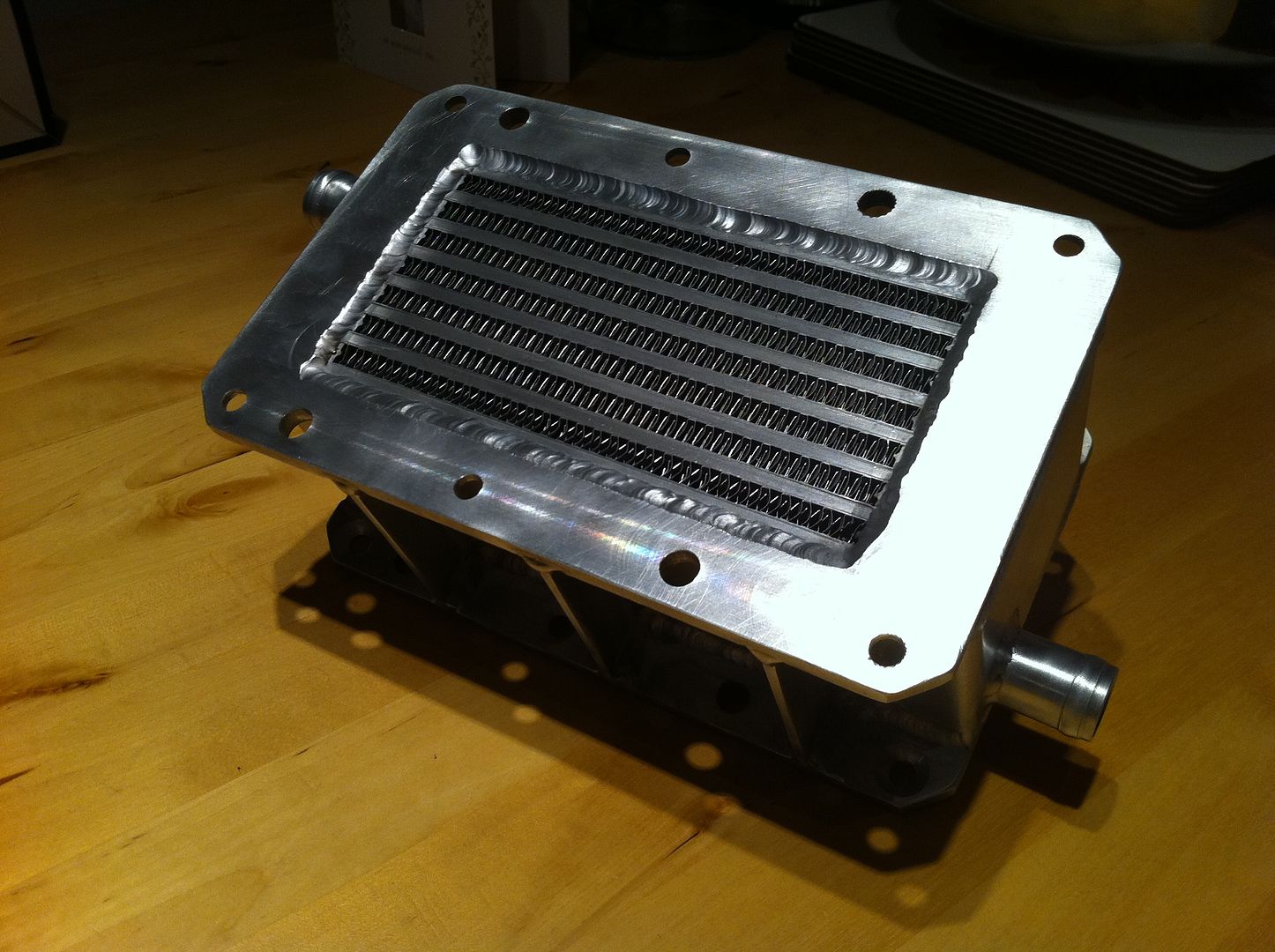

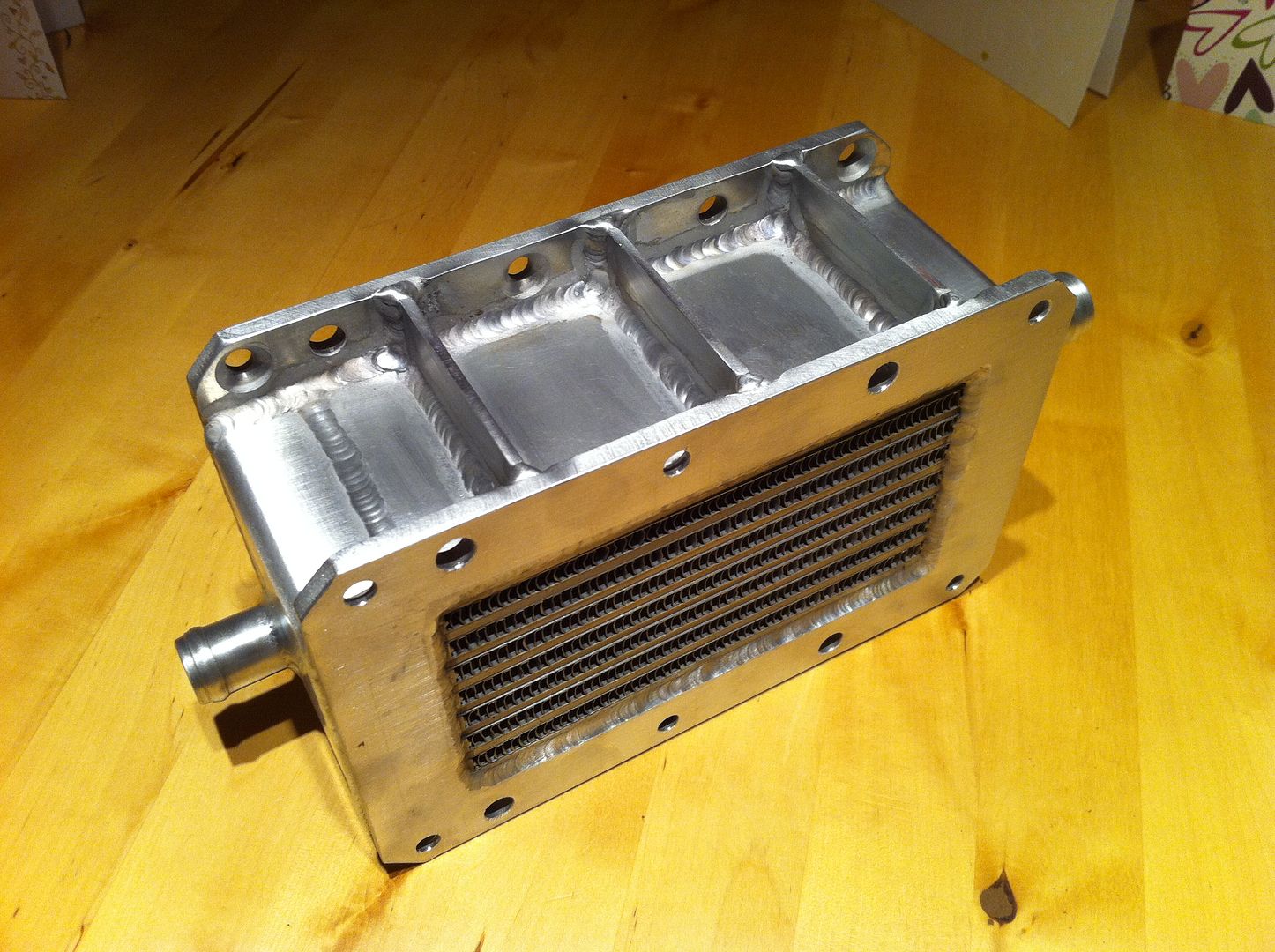

No news on the I/C yet, still doing revisions in response to comments from the guys at Bell.

I downloaded some photos from the camera that I took last weekend, they are just to show what state the car is in at the minute and how tight it has become in the garage. I am having to clear stuff away as when its used to try and keep some free surface to work on.

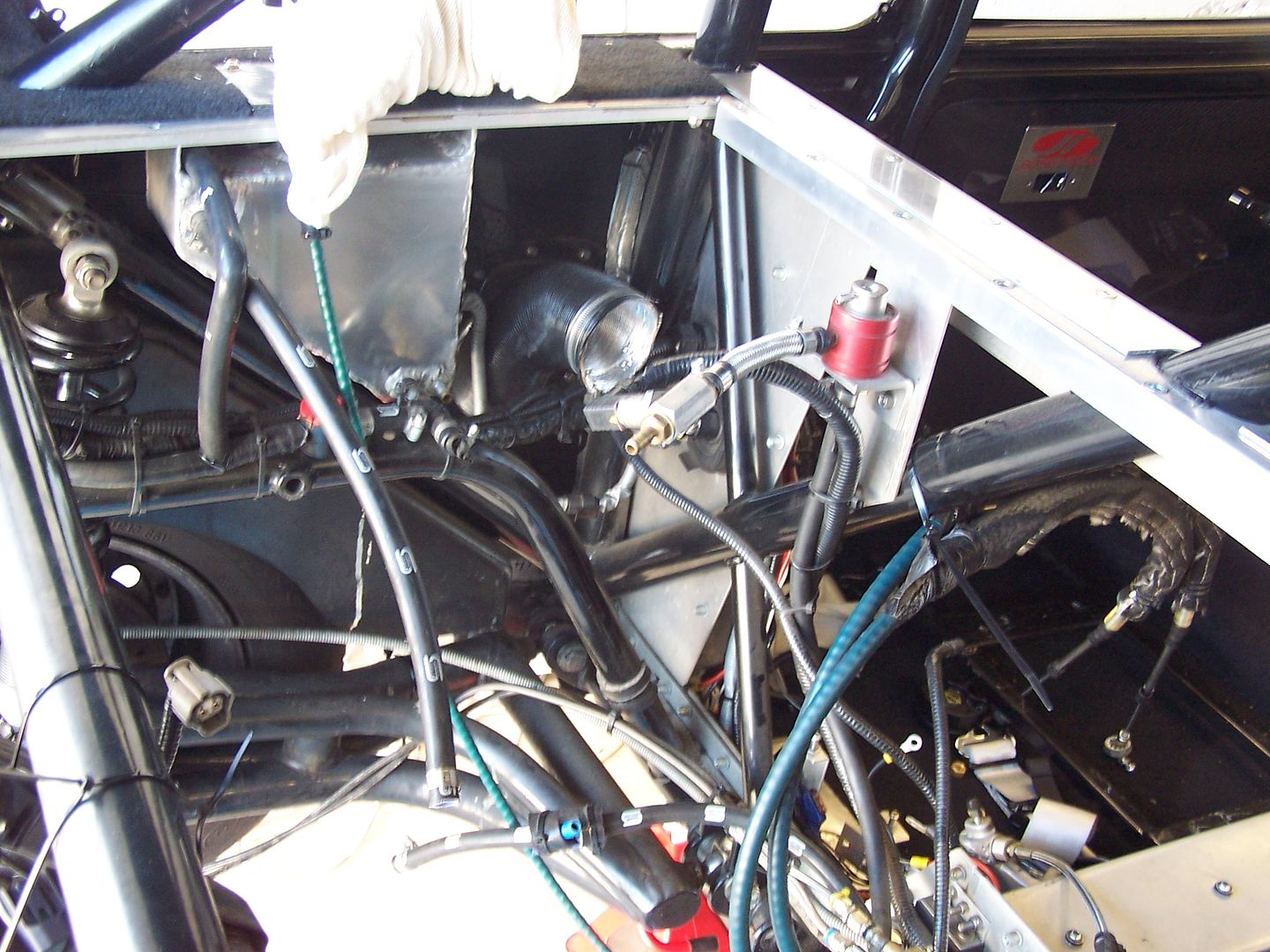

Anyhooo, here's a few photos that might be of interest to anyone wanting to see what the engine bay of a VTEC Zcars mini looks like without an engine in it:

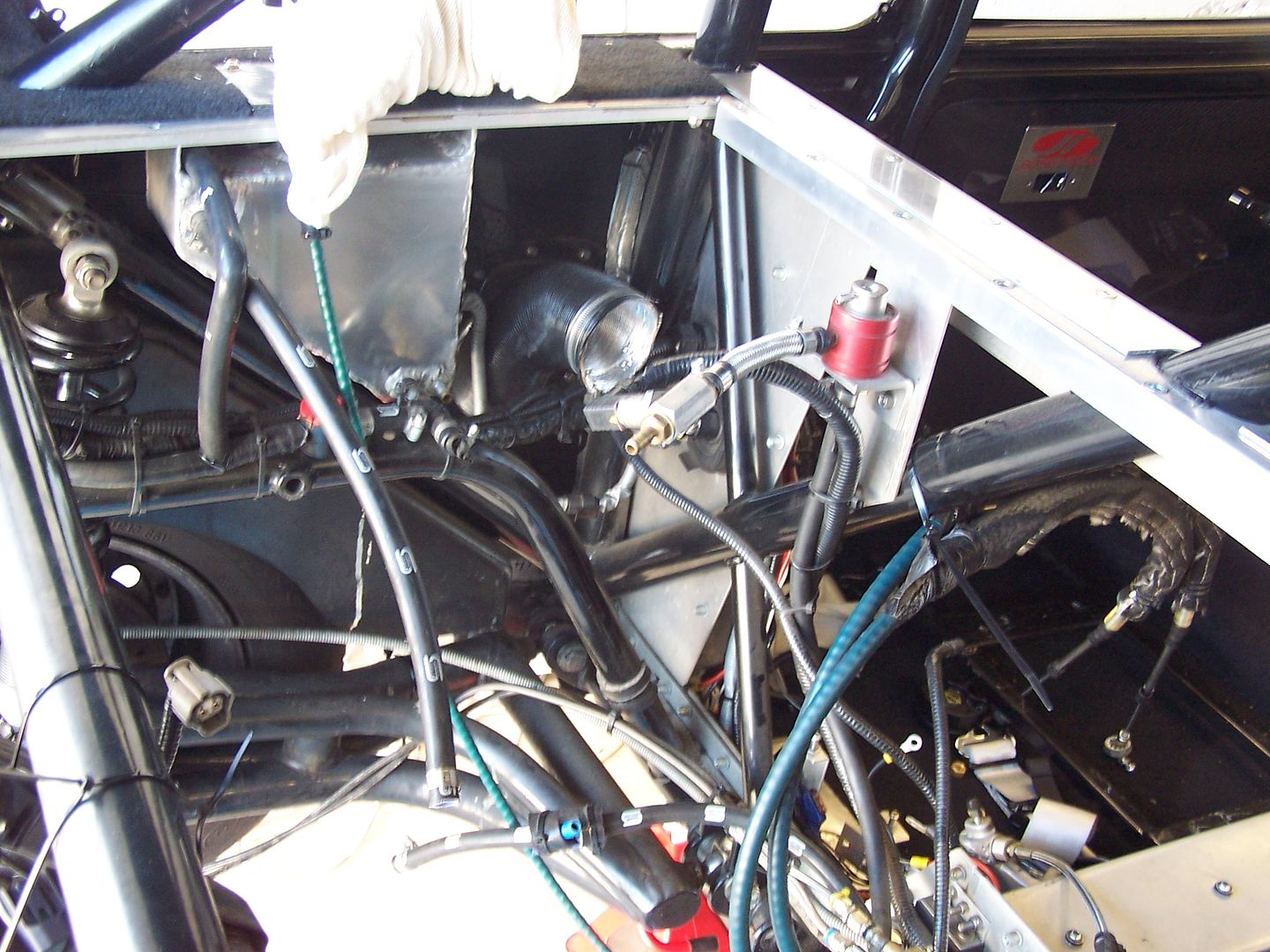

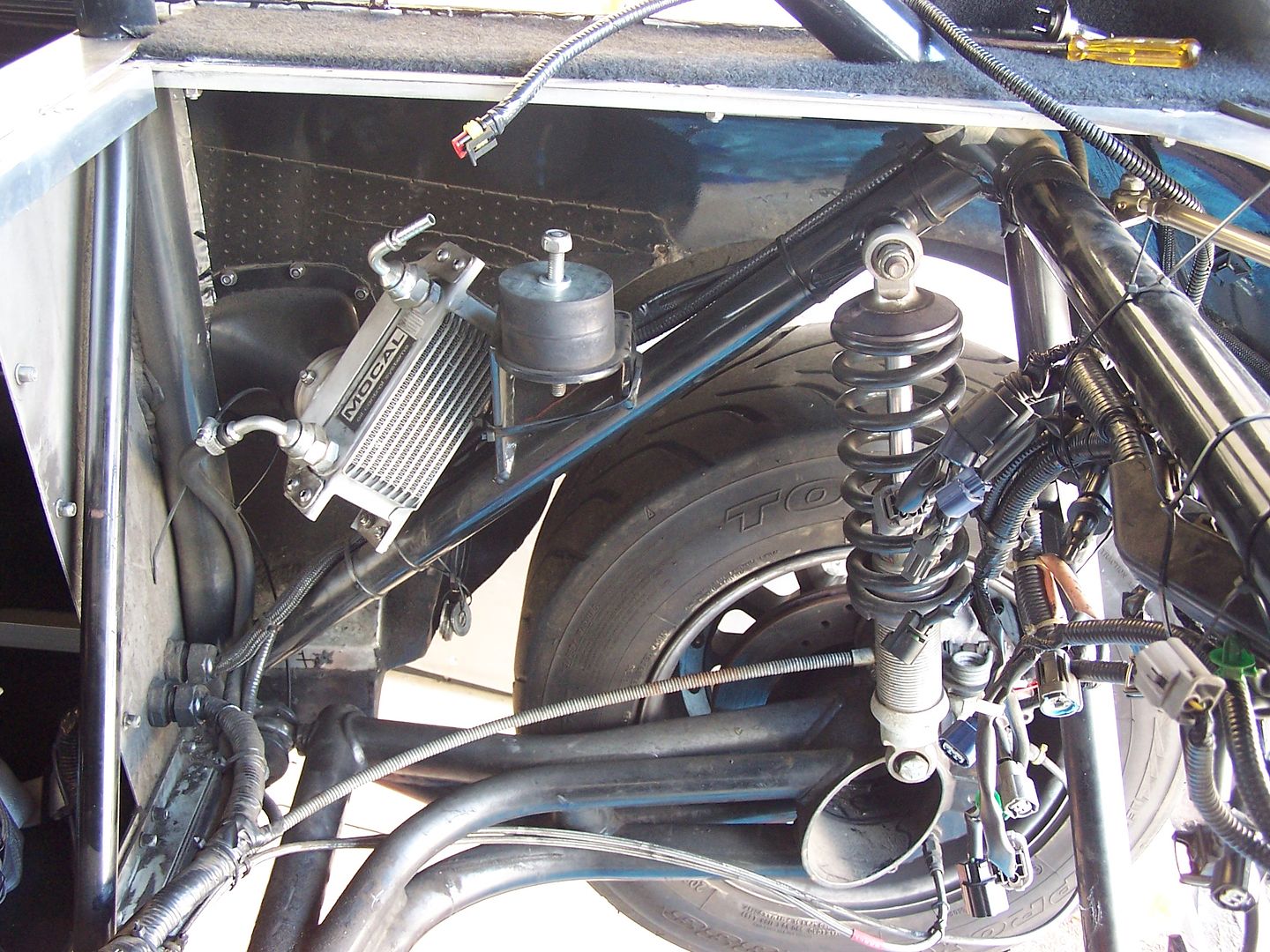

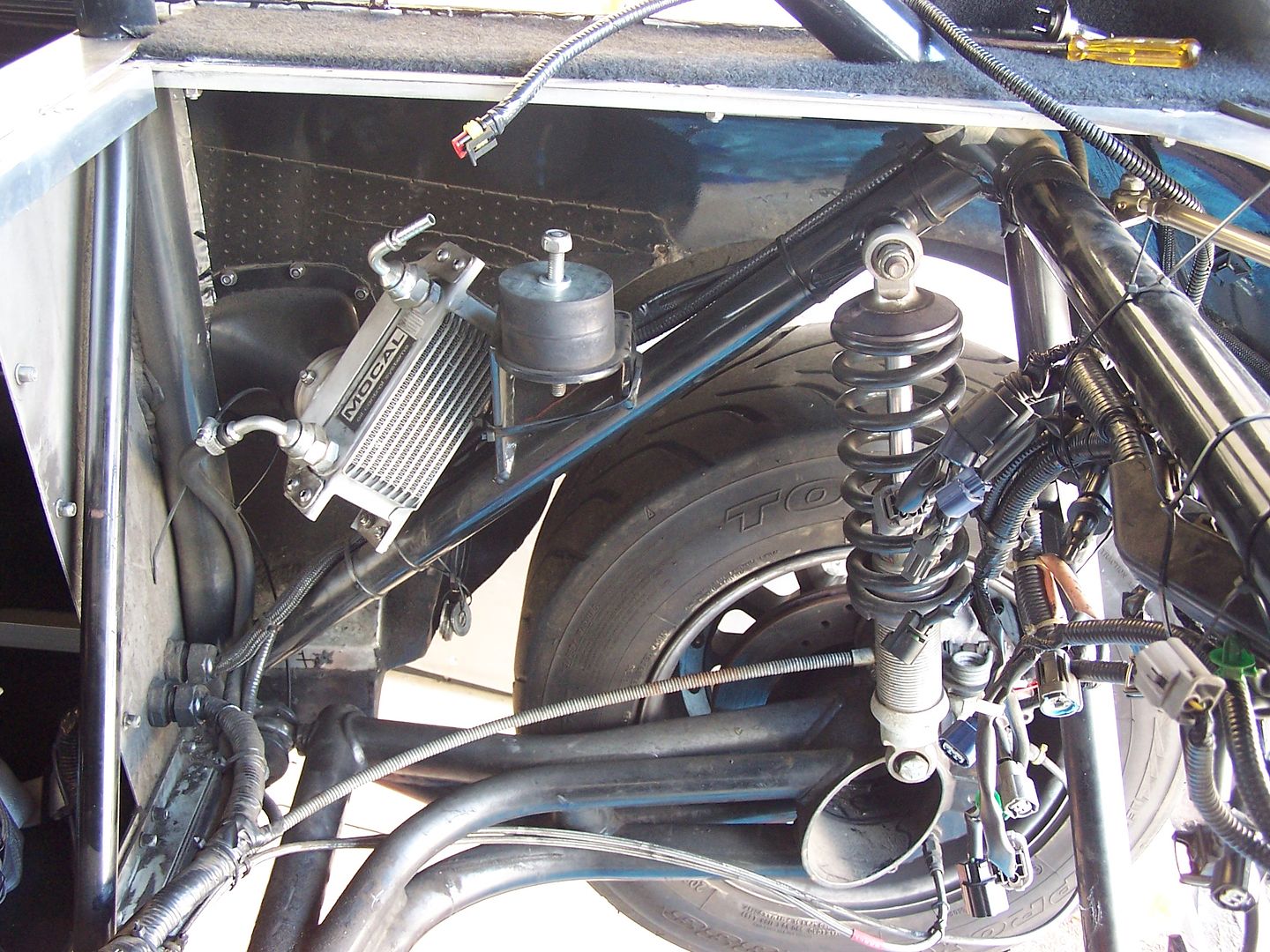

Below is a picture showing the main reason that I took the whole engine out, it wasnt just to change the clutch. The top rear suspension mounts have been bugging me ever since I got the car, as yet they havent failed but I know of some cars that have. So in an effort to eliminate the problem I am going to be making some additional supports to really beef up the mounts and greatly reduce the sheer forces on them. So you can see what I am going on about look at the photo below and you can see that all the force from the suspension unit is trying to make the bolt and its mount sheer from the frame. Since my frame has been made Zcars have beefed up this bit by adding a small rod in the mix to the top diagonal. As I am not intending to strip mine out and have it re-powder coated I am going to fabricate a brace bar that will hold the inner end of the bolt solid, more of that to come:

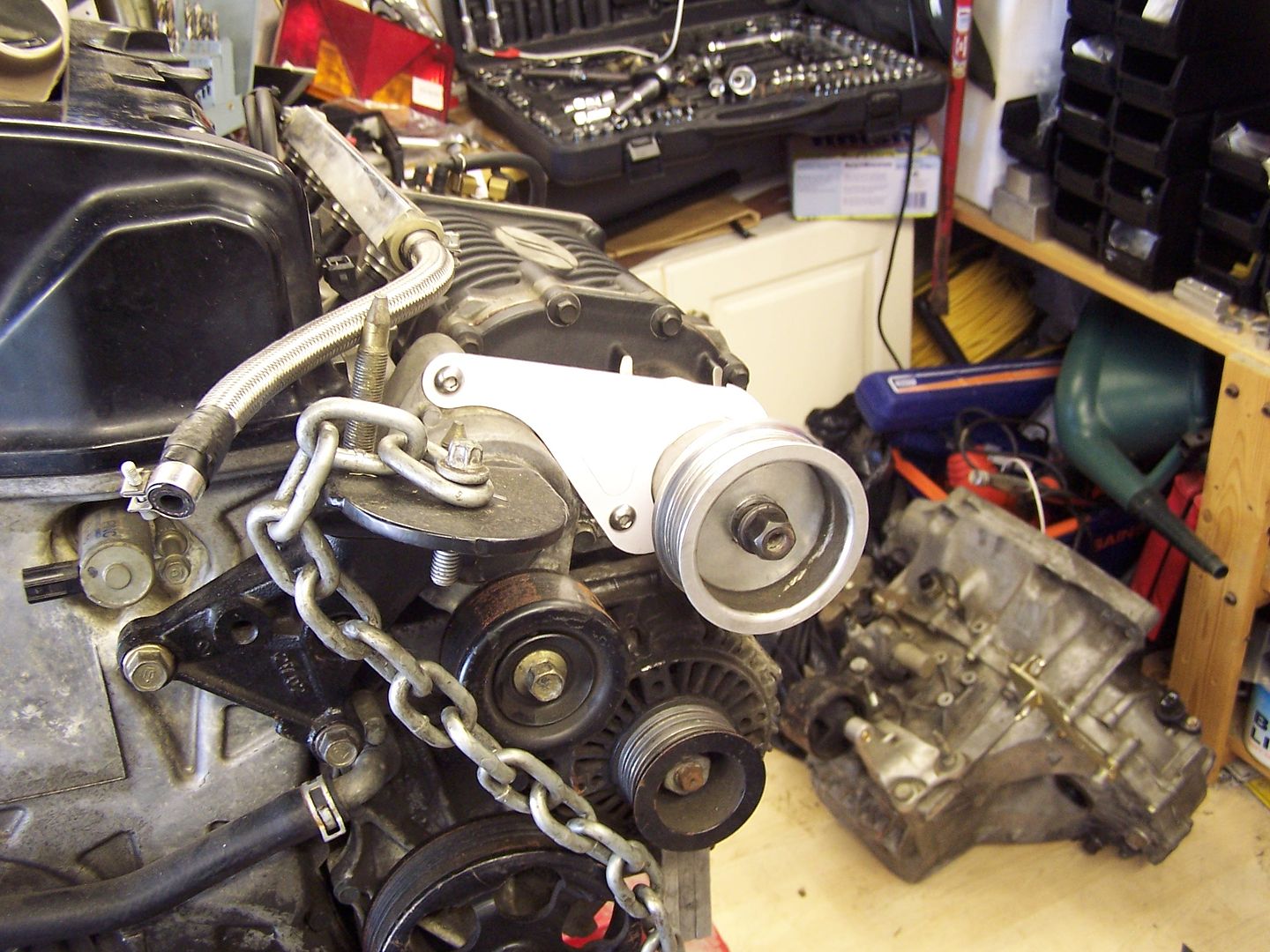

Good old facebook got me the loan of an engine stand to allow me to tinker to my hearts content.

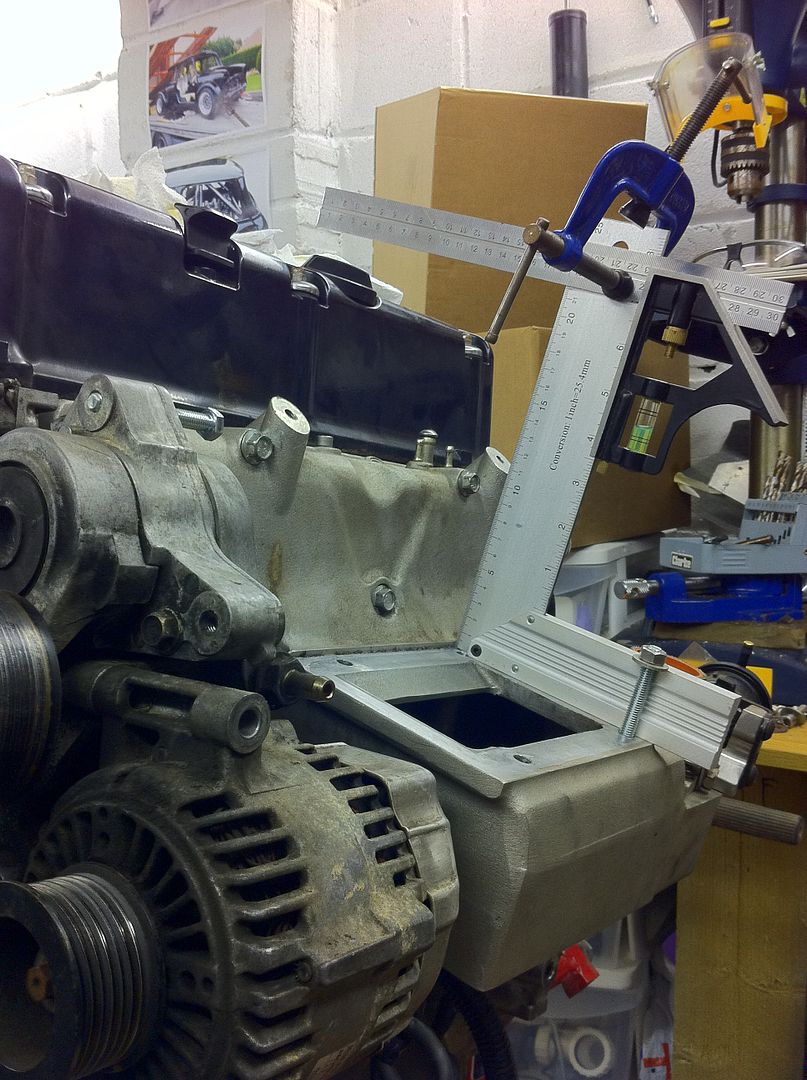

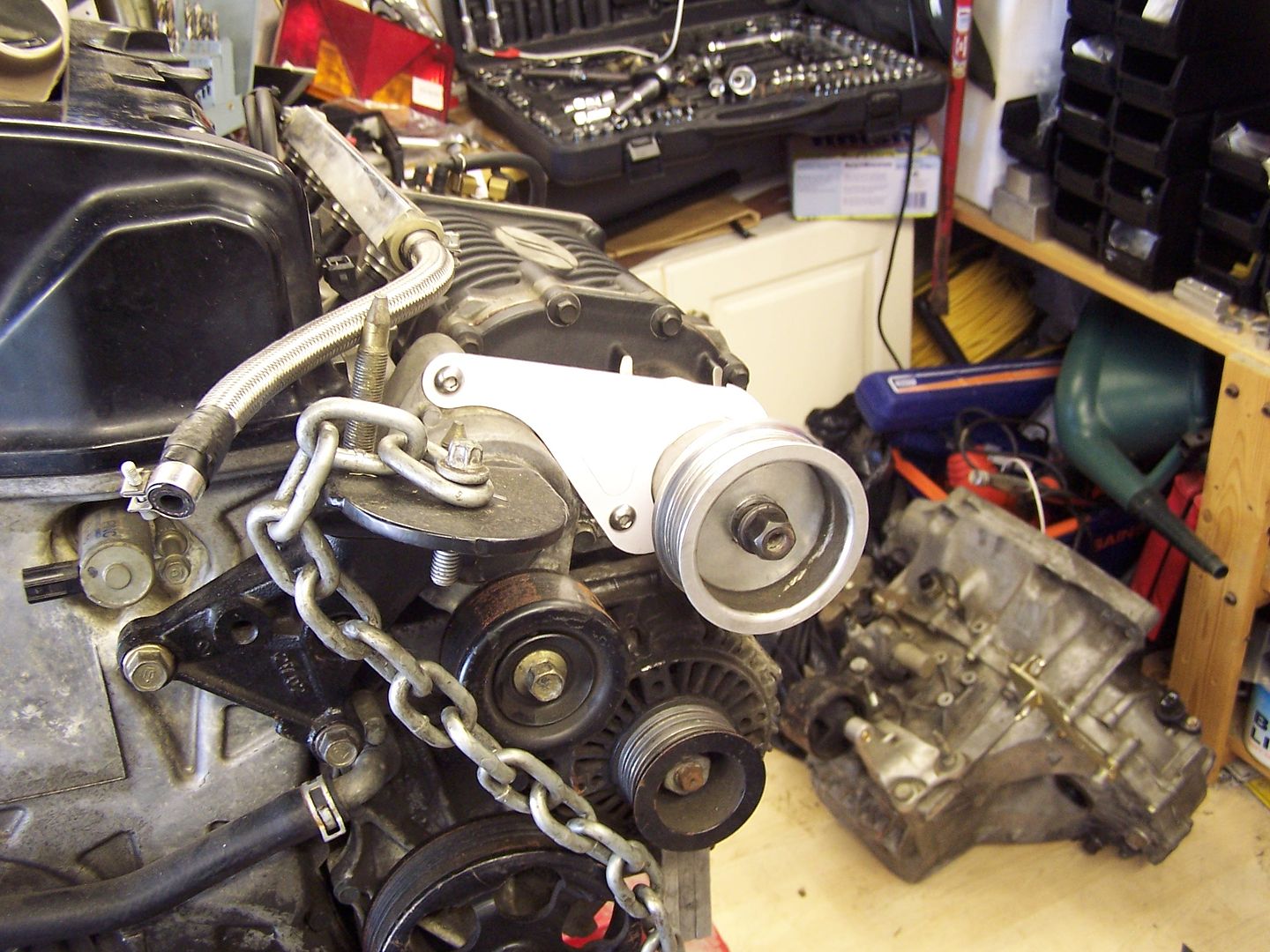

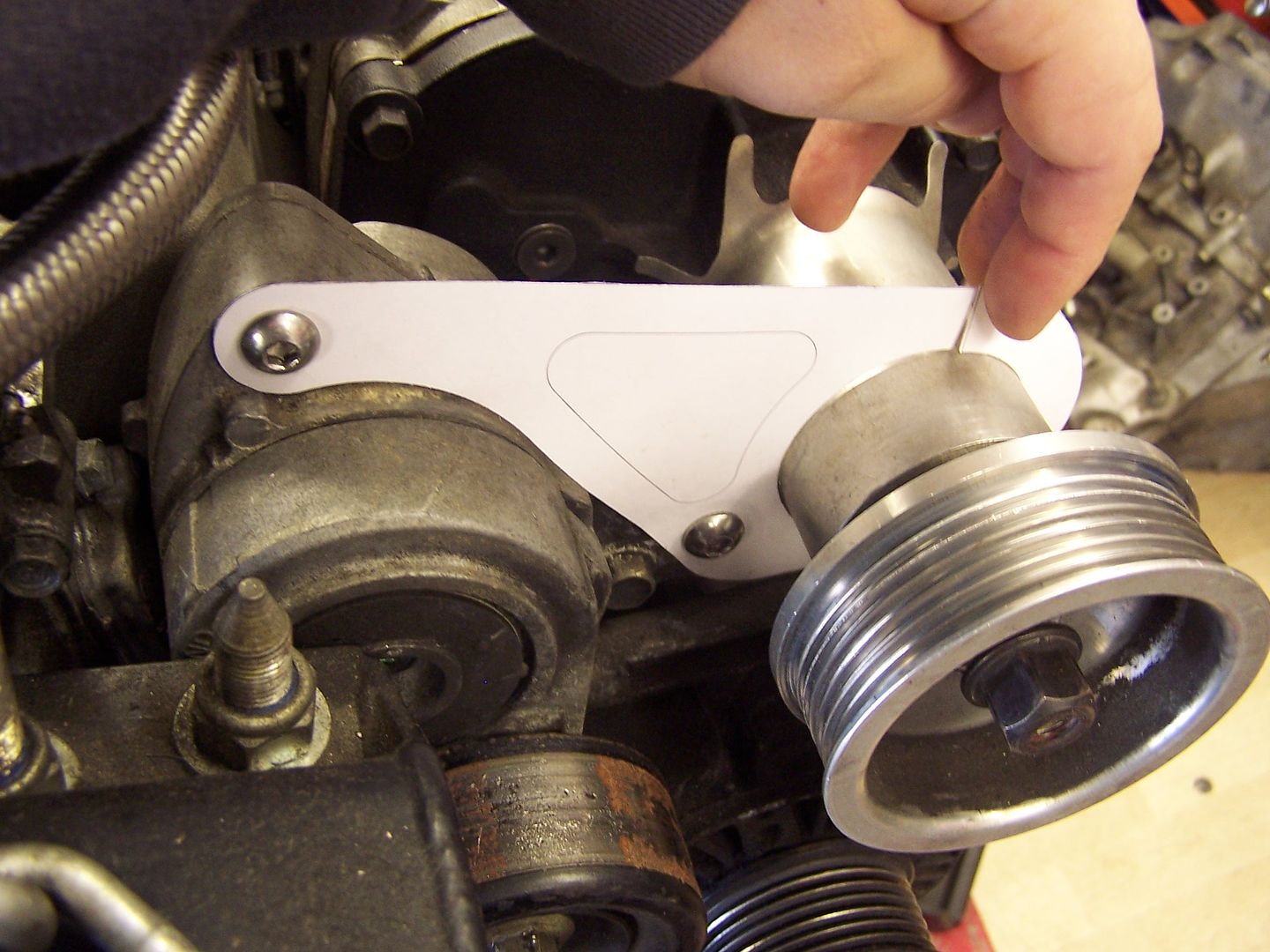

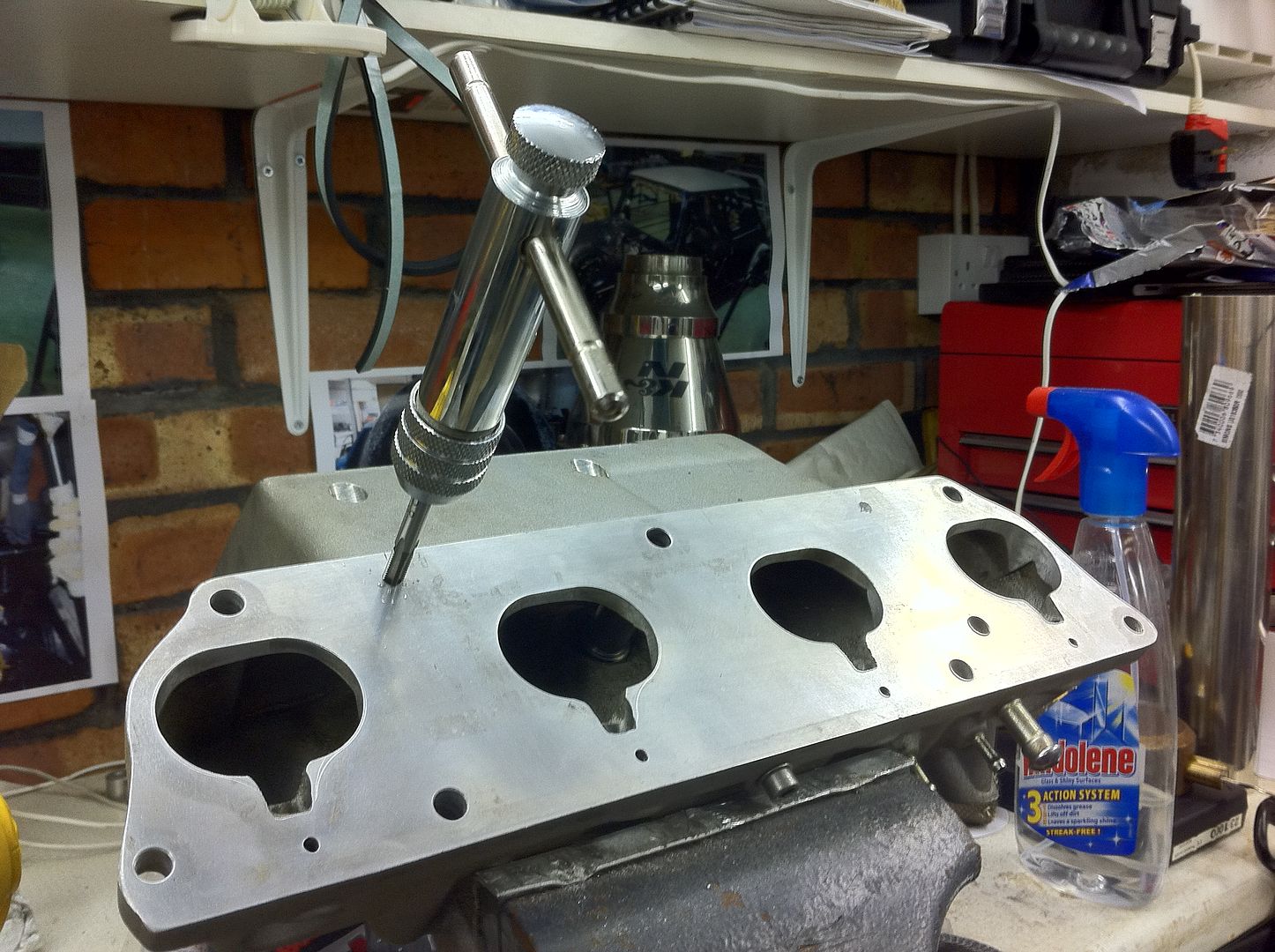

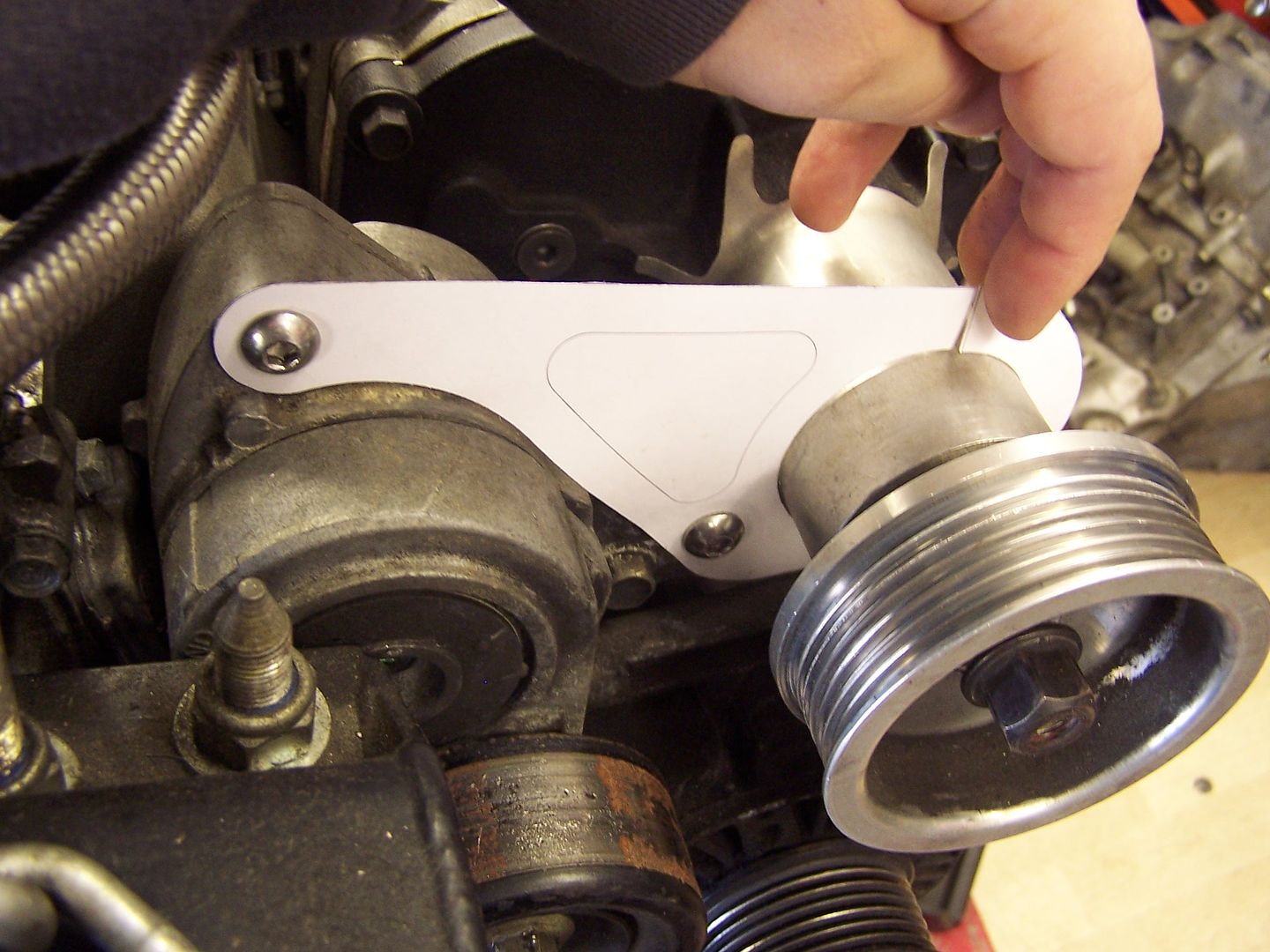

In the picture below is a card version of my first attempt at a snout clamp, before I decided to go chargecooled, the design has definitely come on a long way since this version.

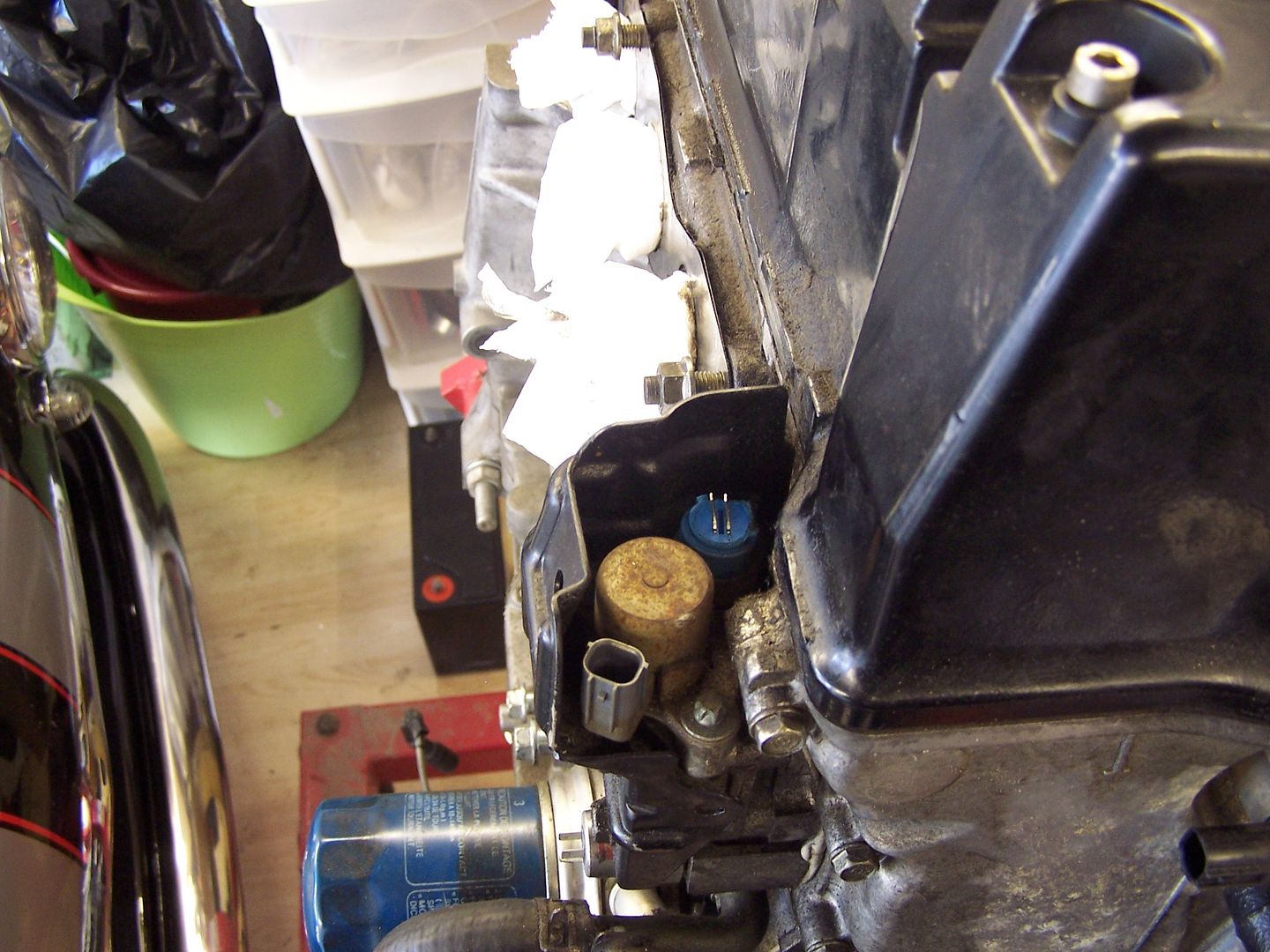

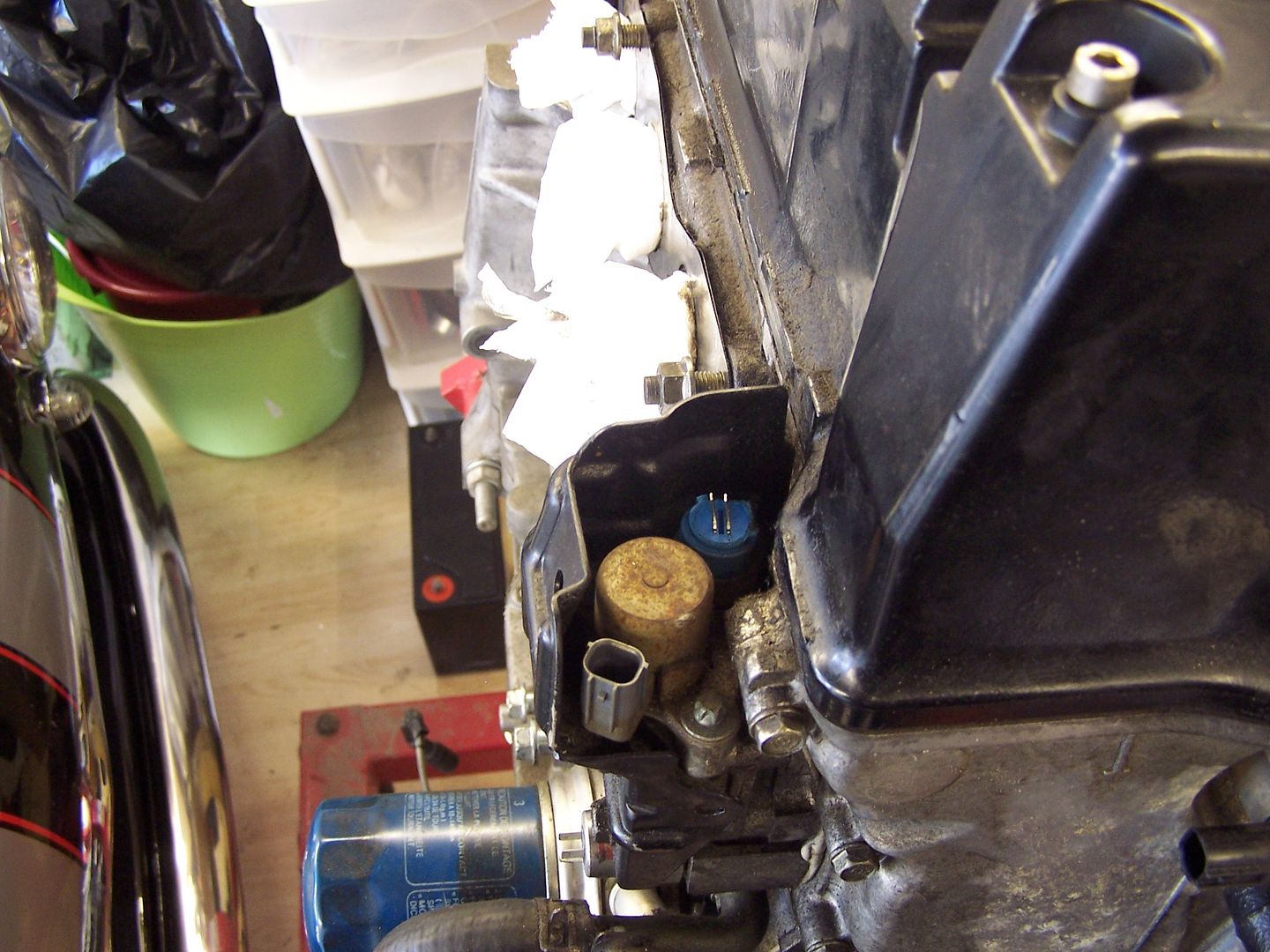

Below shows a broken sensor, its the VTEC oil pressure sensor of which Honda UK want approx £96 for one, I have managed to get one from the USA for £42 inc P&P, genuine Honda part..... Feck knows how long its been like that, the clip just came off in my hand with the top of the sensor still inside it - ooops...

That's all for now folks.........

That's all for now folks......... .