Supercharged K20a2 Vtec - Race Spec

#601

Posted 10 February 2011 - 04:52 PM

#602

Posted 10 February 2011 - 05:35 PM

nice

After a nice long quote like that, I was expecting a nice big relevent statment. ha ha ha

Car looks amazing, I've been following this for quite a while. Must be a monster on the road.

#603

Posted 11 February 2011 - 08:47 AM

nice

After a nice long quote like that, I was expecting a nice big relevent statment. ha ha ha

Car looks amazing, I've been following this for quite a while. Must be a monster on the road.

Yer I was expecting more as well - classic......

Thanks for the compliment, I have to say its an awesome car to drive, I am gutted its not running at the minute but on the other hand quite glad as the weathers so bad it aint worth taking it out. I dont mind offsetting a couple of wet weather months without it running for another possible 30-40BHP - I want to crack the 3.0secs 0-60 - maybe losing a couple of stone might help as well.........

Roll on April as I am booking up to do the RAF Marham Charity Track Day, with 3/4 of the supersmooth runway being used as the main straight, lets see what the top end is....cant wait.

#604

Posted 11 February 2011 - 11:24 PM

Losing a couple of stone off the Mini or the driver???nice

Car looks amazing, I've been following this for quite a while. Must be a monster on the road.

- I want to crack the 3.0secs 0-60 - maybe losing a couple of stone might help as well.........

3.0sec 0-60?!?!?! awesome!!!, "Go-Big-Or-Go-Home" brother....

keep us posted.

-CC

#605

Posted 15 February 2011 - 04:09 PM

Losing a couple of stone off the Mini or the driver???

3.0sec 0-60?!?!?! awesome!!!, "Go-Big-Or-Go-Home" brother....

keep us posted.

-CC

Ideally both but its cheaper and easier to lose it from me than the car, I weigh in at 125kgs so the poor wee Beastie could go a lot faster with a 75kg person driving...... Time to teach the misses how to do 0-60 runs, that'll get the time down.....

#606

Posted 16 February 2011 - 06:22 PM

Losing a couple of stone off the Mini or the driver???

3.0sec 0-60?!?!?! awesome!!!, "Go-Big-Or-Go-Home" brother....

keep us posted.

-CC

Ideally both but its cheaper and easier to lose it from me than the car, I weigh in at 125kgs so the poor wee Beastie could go a lot faster with a 75kg person driving...... Time to teach the misses how to do 0-60 runs, that'll get the time down.....

125kg???? wowzers thats like 22 stone i struggle to get in at 14 stone !!

#607

Posted 16 February 2011 - 06:27 PM

2.5 is pure excess so it needs to be shifted anyway..

Edited by cptkirk, 16 February 2011 - 06:29 PM.

#608

Posted 16 February 2011 - 06:36 PM

More like 19.5 but whos counting.......

2.5 is pure excess so it needs to be shifted anyway..

ive got plenty of weight that needs shifting... its called the mrs!!

#609

Posted 16 February 2011 - 09:51 PM

I am having issues trying to get the new TB-SC Manifold machined so it looks like I am going to have to do it the old fashioned way, with a hand operated mill, some skill and a lot of patience. by the way thanks to Martin at MRA Minis he would have been able to do it but I already ordered the material and a 1 1/4" slot drill to do the work with.

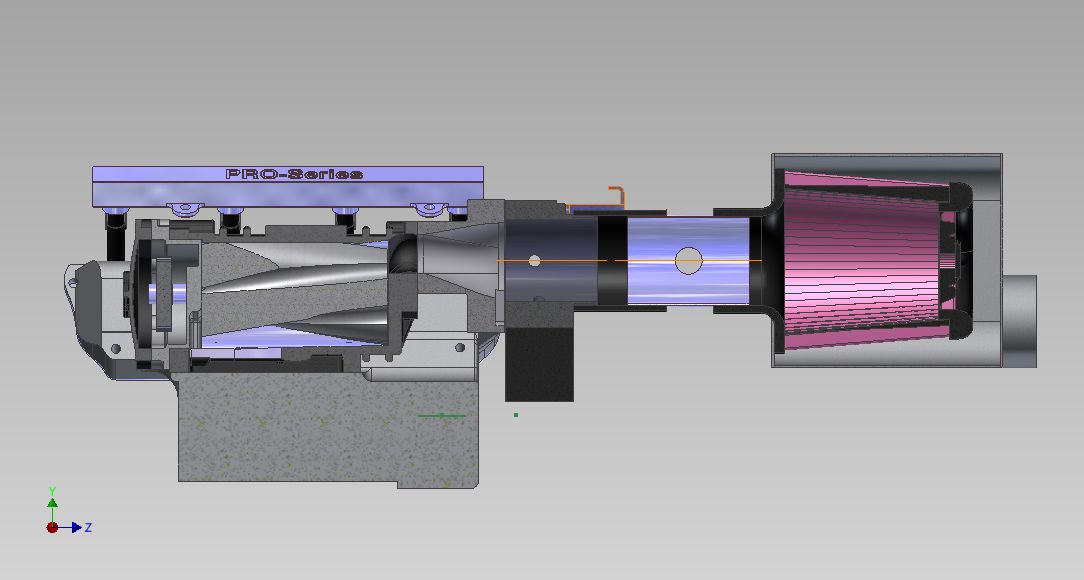

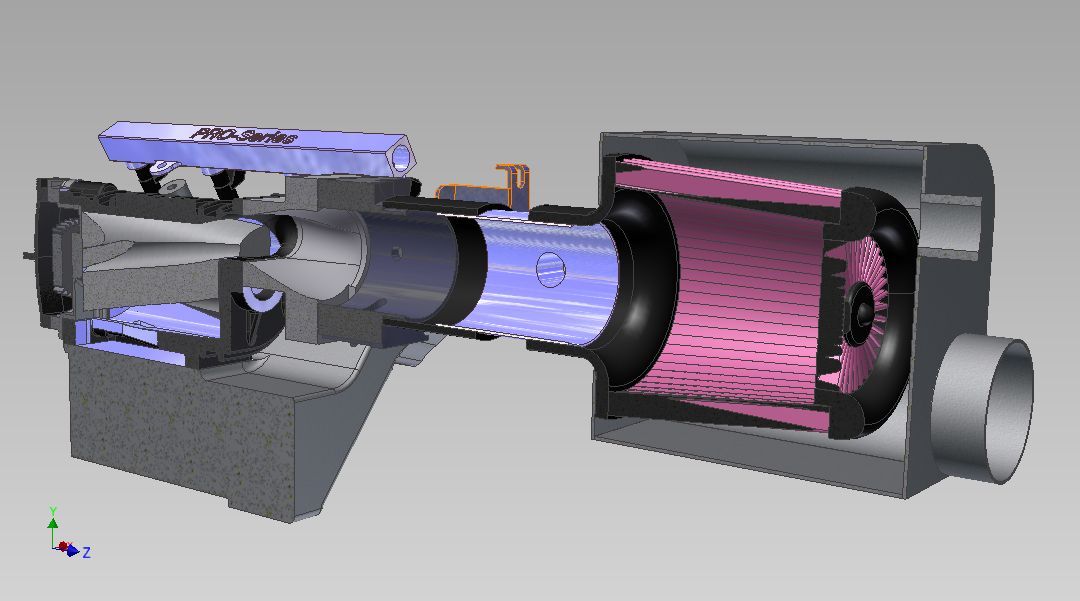

So as for the drawings I have been busy, drawn up the new K&N, nice bit of kit by the way... I have been very busy trying to work out a design that may be useful for others that use the same setup as I in the Acura RSX over the pond. For those that havent been following I am making a new manifold that goes between the Throttle Body and the Supercharger, the old one made the air go round an S bend which isnt great for flow, secondly the OEM TB is 65mm which is restrictive when compared to the opening of the charger body onto the rotors, so a 72mm TB was ordered, received, sent back, another 72mm ordered, recieved and now sits on my table waiting to be sorted into the mix.

The drawings below show how the flow of the new setup pretty much follows a straight line, I am going to have to make another shroud for the filter to keep the intake temps down and feed it from the 76mm NACA duct on the N/S. I am currently toying with two feeds to air filter but yet to decide where I would source more cold air from.

Still waiting for the snout bearings over 28days after ordering....

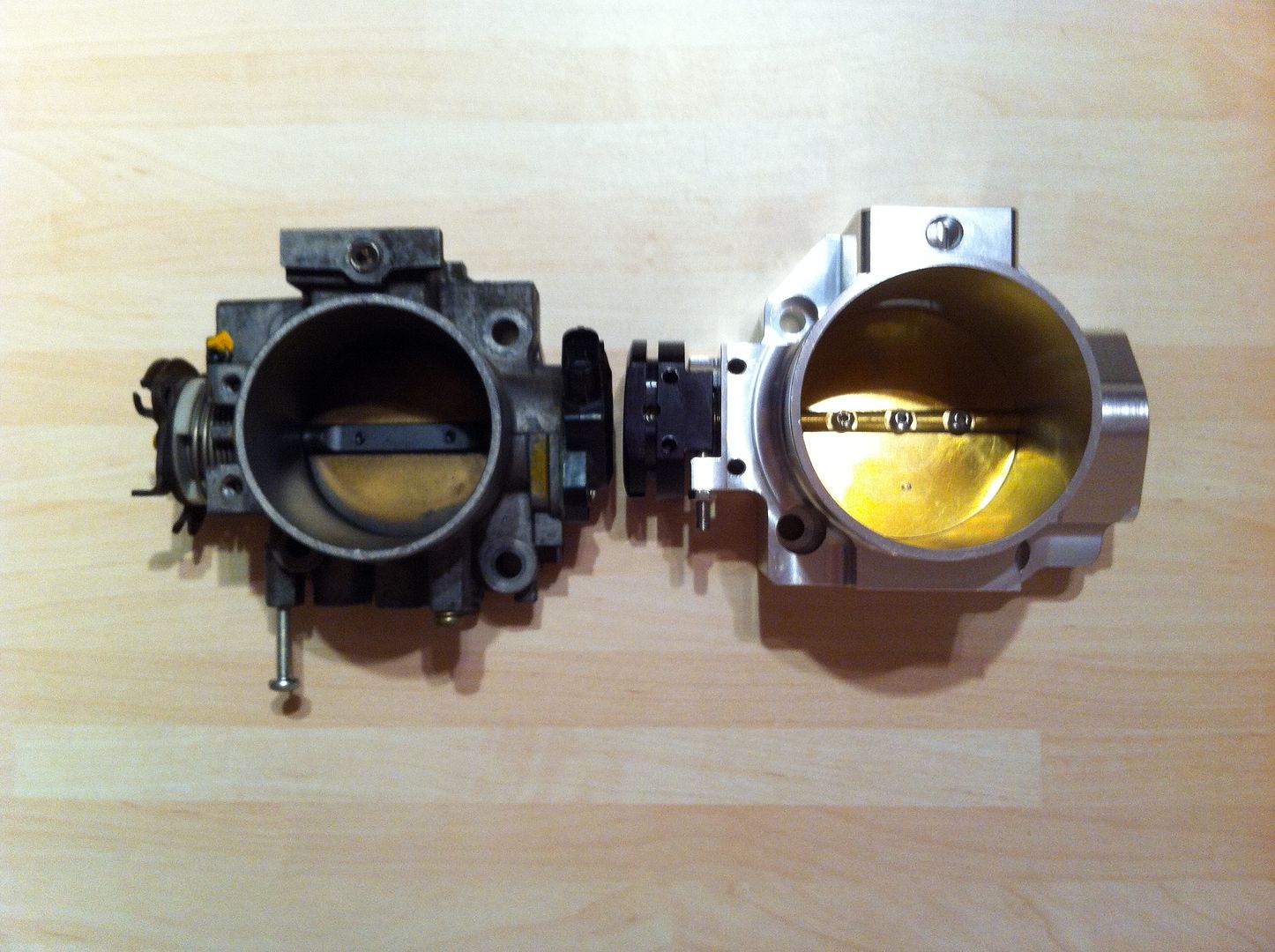

Below is a picture of the new TB verses the OEM, its a bit misleading as the new 72mm actually measures 74mm at the intake and 72 at the outlet, a TB with a built in velocity stack - not bad.....

Edited by cptkirk, 16 February 2011 - 09:52 PM.

#610

Posted 17 February 2011 - 08:19 PM

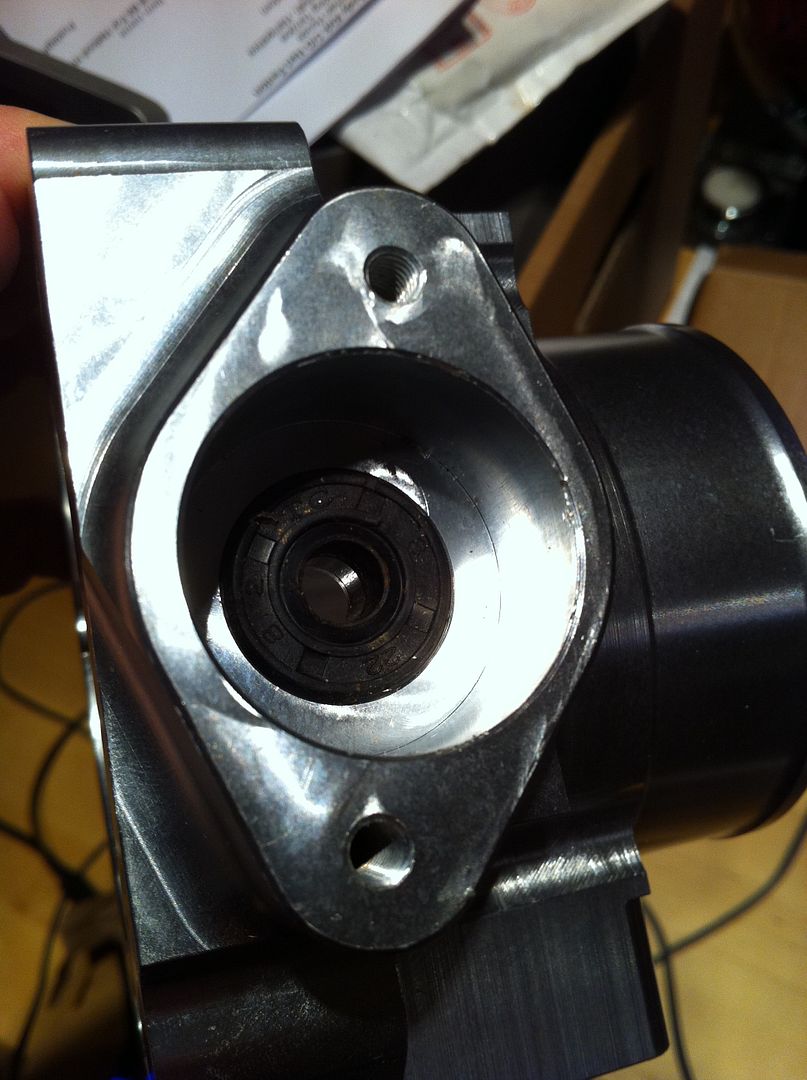

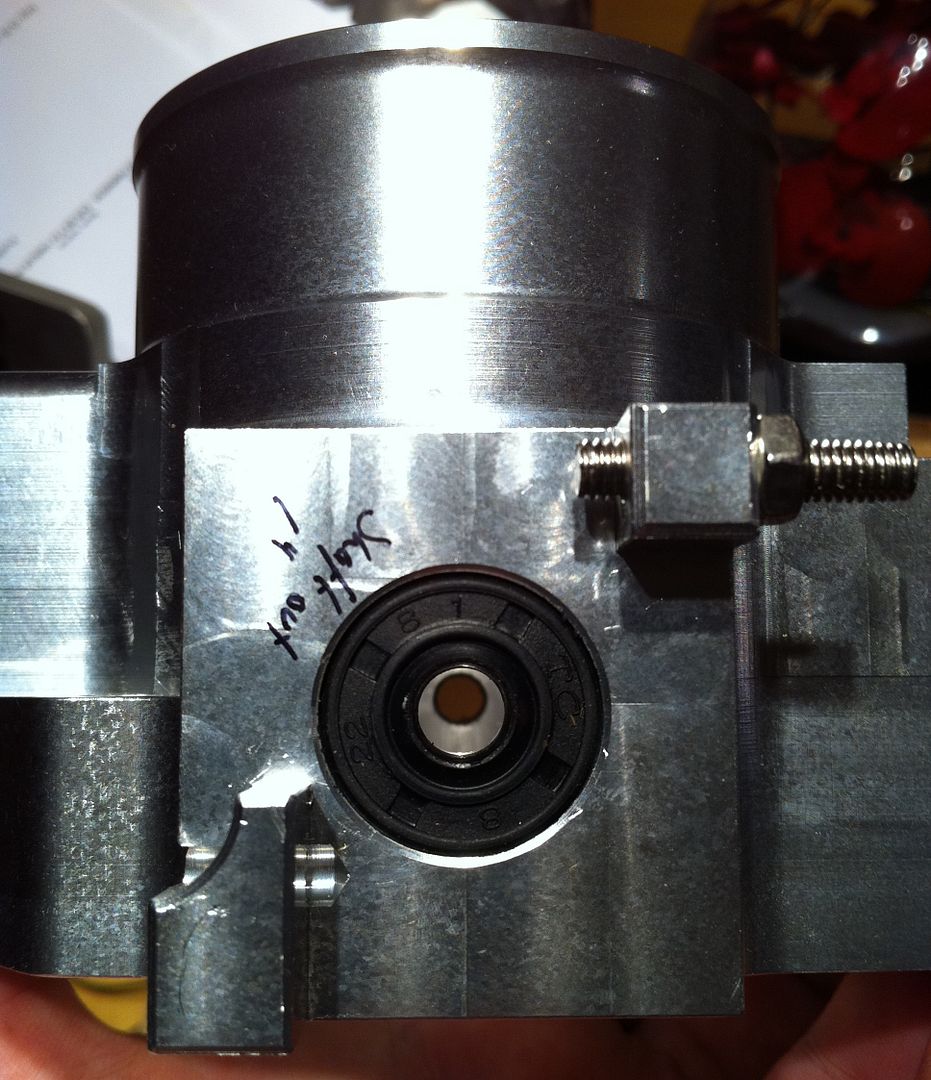

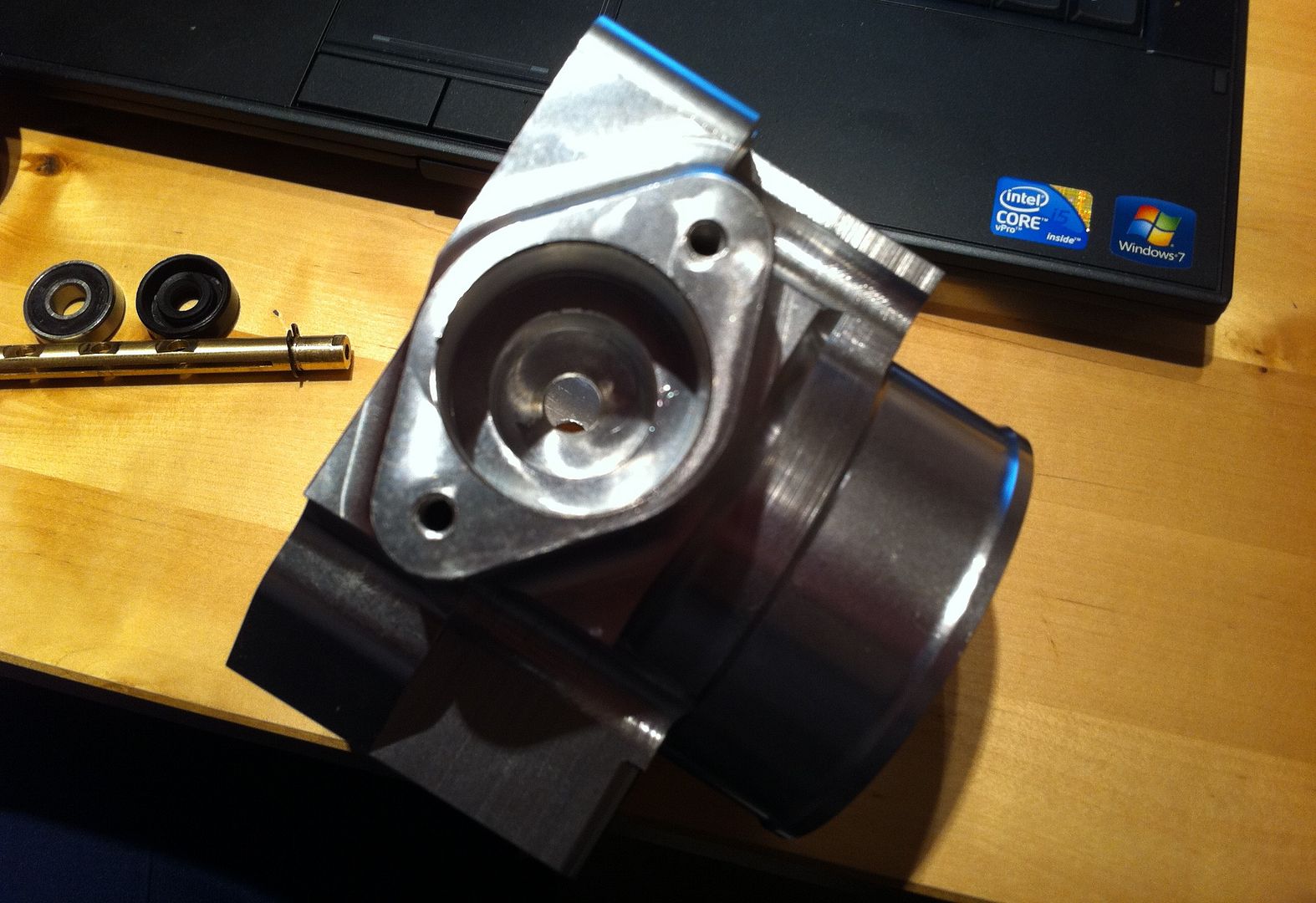

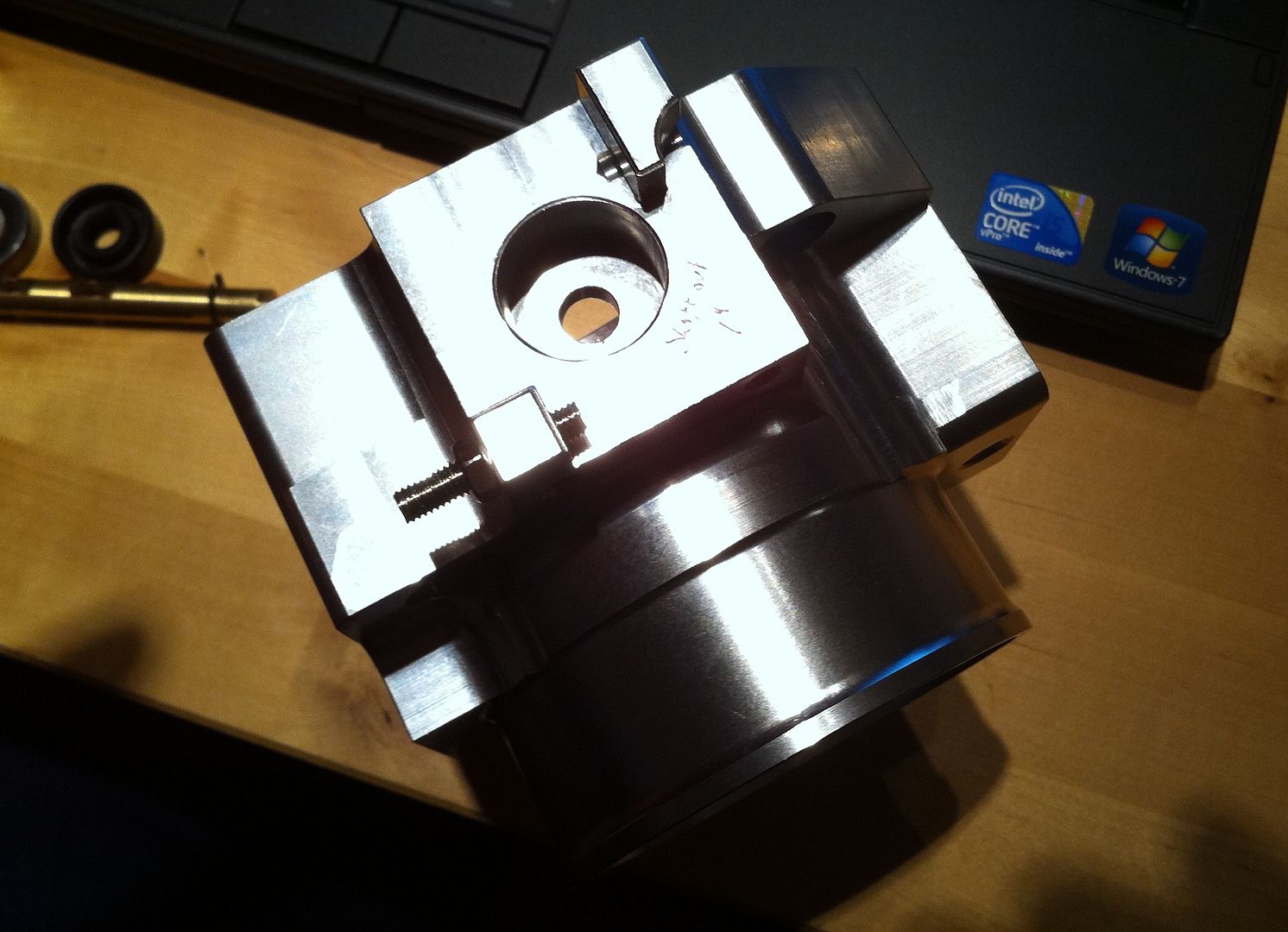

In my plight for more ponies I decided to go to a 72mm TB, I was lured by the cost of the OBX unit, even though I am well aware of 'You get what you pay for'.

So when it arrived I promptly got it out to measure it after being duped by a previous and even more inferior TB that I had previously ordered receiving a 70mm not a 72mm. So I measured the air filter end of the TB throat and that was 73.75mm - initially prompting me to think they had sent the wrong part but before opening my big mouth I measured the outlet and that measures 71.70mm so its fair to say they had sent me the right part. After noticing the big 72 laser etched into the side I was pretty convinced I had the right part.

First appearances aren’t great, some of the machining leaves a lot to be desired, never the less it does look like a hoofing great throttle body.

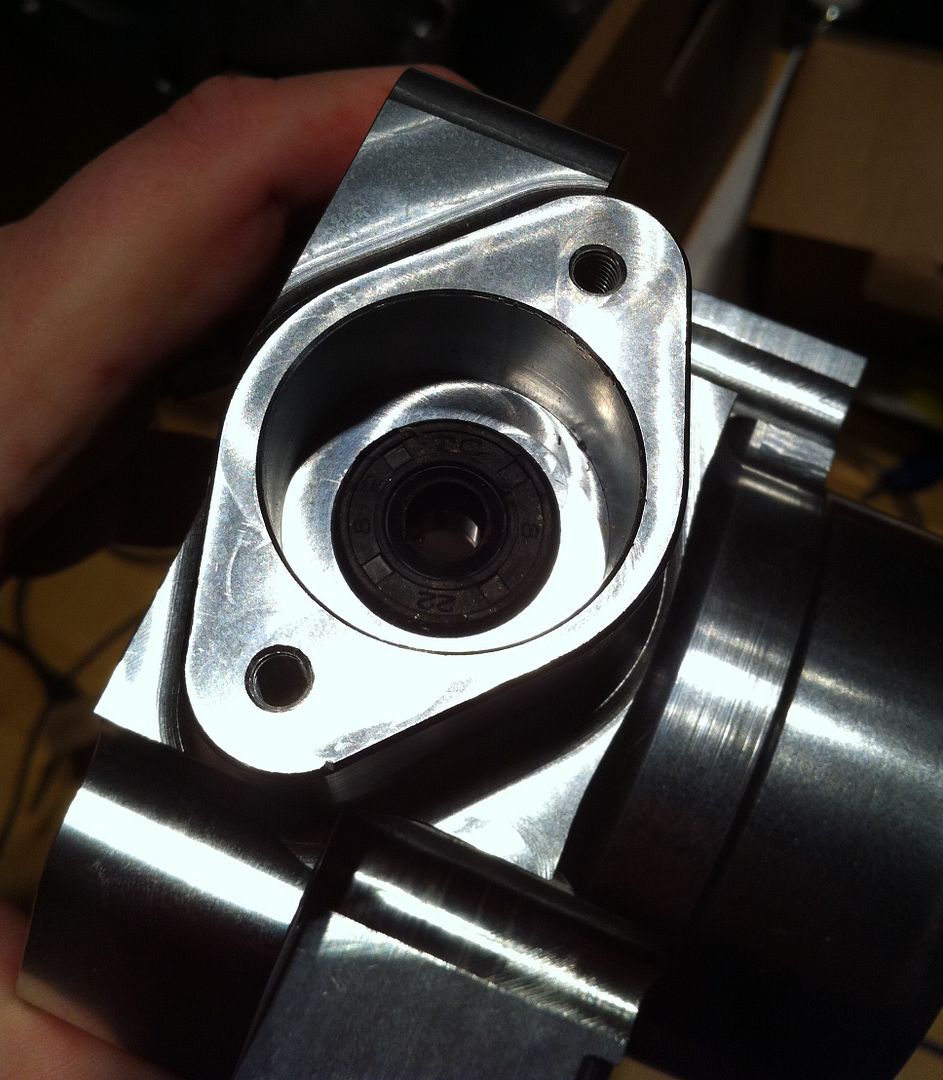

First turn of the shaft via the cable fixing confirmed everything I had read on the web about them being sticky and this was without any heat of the engine bay to make everything expand. So I was intrigued as to what was causing the shaft to labour like it was - out came the tools.......

On turning the first bolt it became apparent that there wasn’t a lot of Loctite or fixant in use, even on the butterfly valve bolts. I got the TPS fixing off to notice a cheap rubber oil seal. Under the cable fixing was another oil seal, below the two outer fixings are two Chinese (ZXZC) made 608RS bearings, rubber seals, they feel average – a bit sloppy.

So once this lot was apart it was really evident that the oil seals are what are causing the sticking with the TB at room temperature. I obviously have yet to see if sticks with added heat.

With all of that in mind I ordered new bearings 608RS-2 C3 SKF and 2x Viton Seals (8x22x7) and await to see how it feels once they arrive....... I will keep you posted.

It is very true - you do get what you pay for and this can be made a whole lot better by spending an hour and about £20 on new bearings and seals - I might even fore-go the seals if the Vitons are any where near as sticky as the rubbers, again got to wait and see, I doubt it knowing other Viton seals but still......

I took a load of photos so people can see what I am going on about:

#611

Posted 18 February 2011 - 12:58 PM

#612

Posted 18 February 2011 - 01:01 PM

I guess it could be waiting at home for me. I fortunately have seen the article before it was released so I know exactly what is in it.

Thanks all the same....

Edited by cptkirk, 18 February 2011 - 01:05 PM.

#613

Posted 18 February 2011 - 04:59 PM

Chris

#614

Posted 18 February 2011 - 06:20 PM

Wait a minute - even I havent got a copy yet.....

I guess it could be waiting at home for me. I fortunately have seen the article before it was released so I know exactly what is in it.

Thanks all the same....

which mag is it in?

#615

Posted 18 February 2011 - 06:30 PM

Wait a minute - even I havent got a copy yet.....

I guess it could be waiting at home for me. I fortunately have seen the article before it was released so I know exactly what is in it.

Thanks all the same....

which mag is it in?

This months Mini World

1 user(s) are reading this topic

0 members, 1 guests, 0 anonymous users